Schaeffler Group Industrial BA 20 3

Page

Features Scope of delivery ....................................................................... 5

Design and

safety guidelines

Intended purpose ...................................................................... 6

Qualified personnel................................................................... 6

Protective equipment ................................................................ 6

Hydraulic oil .............................................................................. 7

Maximum pressure.................................................................... 7

Ambient conditions ................................................................... 7

Initial operation Checking the hand pump........................................................... 8

Setting the stroke volume.......................................................... 9

Spacer ring .......................................................................... 9

Mounting the spacer ring ..................................................... 9

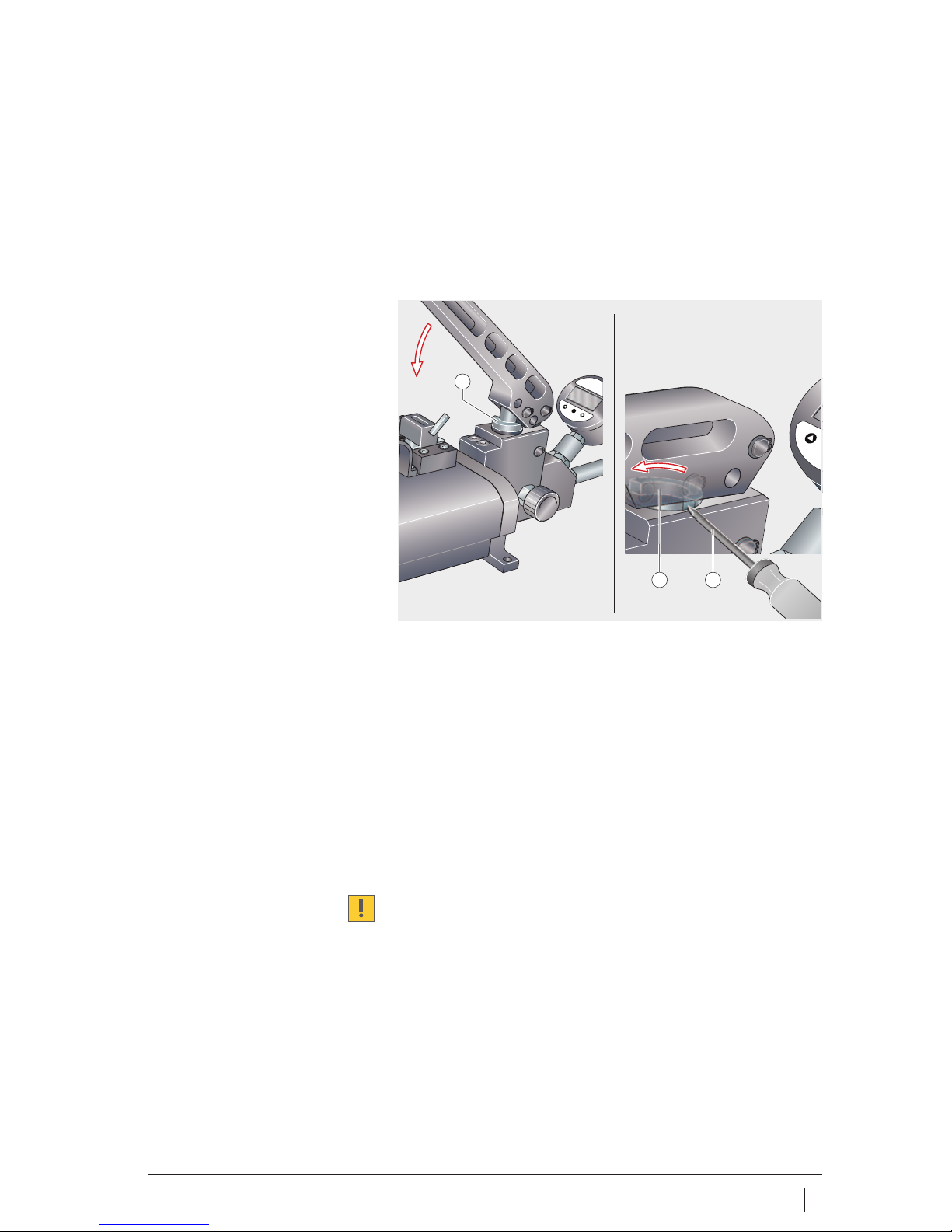

Dismounting the spacer ring ................................................ 9

Operation Mounting the rolling bearing...................................................... 10

Mounting the hydraulic nut........................................................ 10

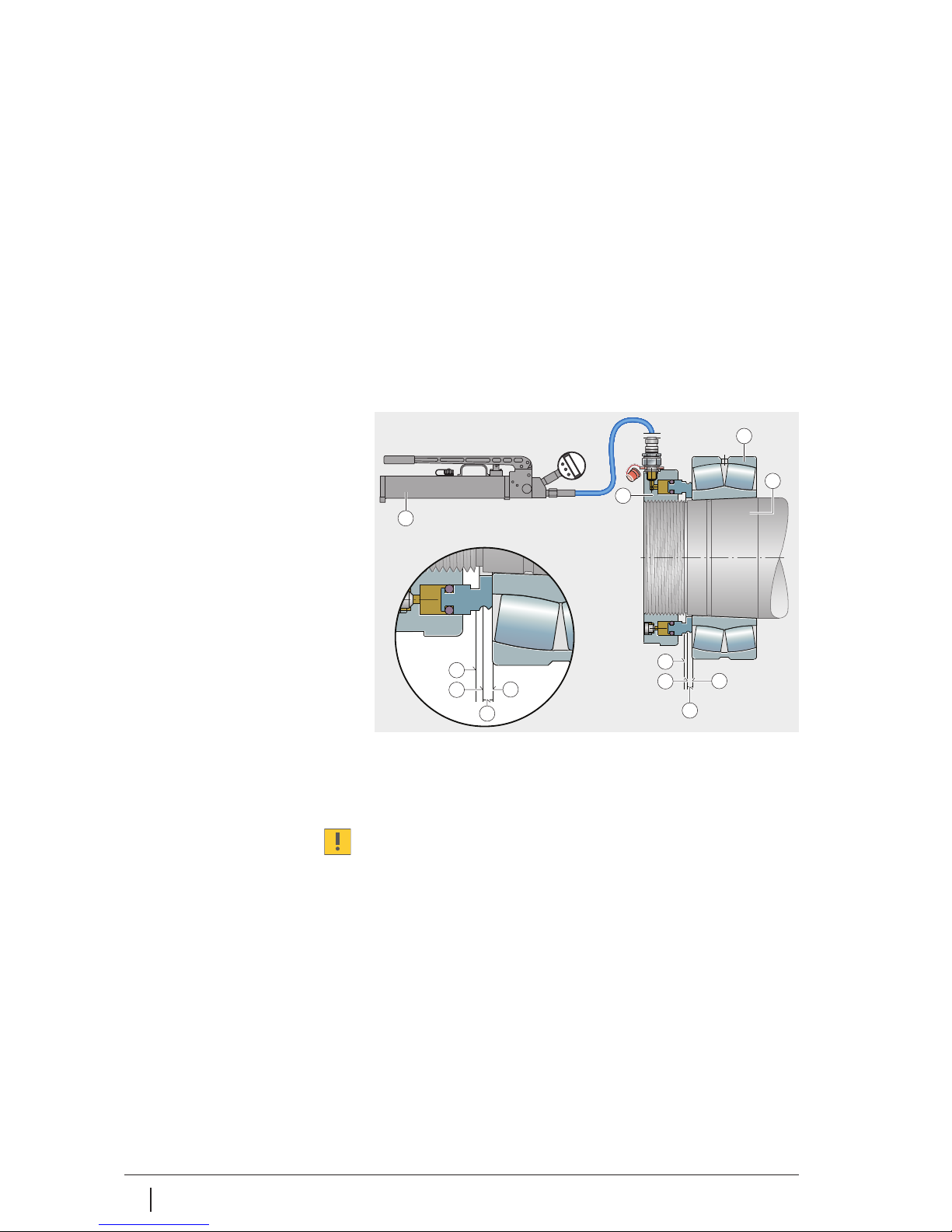

Connecting the hand pump ....................................................... 11

Venting the hand pump ....................................................... 11

Connection .......................................................................... 11

Venting the hydraulic nut........................................................... 11

Setting the start position ........................................................... 12

Determining the start pressure............................................. 12

Building up the start pressure.............................................. 12

Setting the end position ............................................................ 13

Determining the number of strokes ...................................... 13

Moving the rolling bearing to the end position ..................... 14

Dismounting the hand pump ..................................................... 14

Releasing the pressure ........................................................ 14

Removing the hand pump .................................................... 14

Maintenance ............................................................................. 15

Changing the oil................................................................... 15

Cleaning the tank................................................................. 15

Hand pump