98

fantech fantech

* Ductwork layout may differ depend-

ing on model

DIRECT CONNECTION of the ERV SUPPLY AIR STREAM to the SUPPLY AIR SIDE on the

FURNACE & EXHAUST AIR STREAM to the FURNACE COLD AIR RETURN

SIMPLIFIED INSTALLATION (GOOD)

OPTION 2

1. Furnace blower must operate when ventilation from ERV is required. The

furnace should be set to run continuously or interlocked with ERV. See

furnace electrical connection on page 17.

2. Due to the differences in pressure between the ERV and the equipment it is

being connected to, the ERV‘s airflow must be balanced on site, using the

procedure found section "AIRFLOW BALANCING".

* In the case of a multi-zone system, please contact Fantech customer

service prior to installing any installation type requiring the use of the

furnace interlock"

Installation examples (Cont'd)

In the case of a simplified

installation, Option 1 is

recommended.

Air from inside

* Unit air flow should be balanced while ERV is on "Normal" speed and

furnace blower is running.

Outside

Fresh air to living areas

1 m (3' 3") min. recommended

Cold air

return

ERV/Furnace ducting for Simplified Installation - Option 2

Suggested installation for:

• When bathroom and

kitchen already have local

exhaust system

• May be suitable for

retrotting

Benets: Least expensive

installation type

Fantech energy recovery ventilators (ERV) that use a supply fan shutdown for frost

prevention do not include an outdoor air motorized damper. If you are using a simplied

installation, i.e. connecting the ERV supply air duct to a furnace's return air duct, the ERV

must operate continuously. When the ERV is turned off, no warm exhaust air will ow

through the ERV but the furnace's fan will continue to draw in outdoor air directly into the

furnace. If it's cold outside, cold air will be introduced, without re-heating, directly into

the furnace.

If the ERV is installed such that the homeowner may turn off the ERV during the winter, we

recommend installing a motorized damper between the ERV's supply air and the furnace's

return air duct that closes when the ERV is not operating. See wiring diagram (gure 1).

Damper

Motor

24 VAC Transformer

COM NO

ERV Furnace interlock

See page 17.

24V

120V

Figure 1

*Transformer and Damper motor not included

Motorized

Damper

Motorized

Damper

Stale air to

outside

Fresh air from

outside

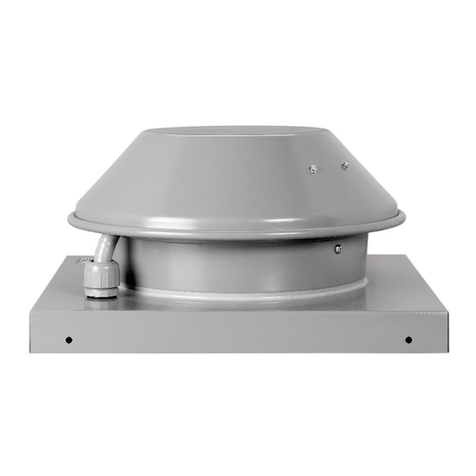

EXTERIOR DUCTING INSTALLATION

WEATHERHOOD LOCATION

• Decide where your intake and exhaust hoods will be located.

Locating the Intake Weatherhood

• Should be located upstream (if there are prevailing winds) from the

exhaust outlet.

• At a minimum distance to 900 mm (3') away from dryer vents and furnace

exhaust (medium or high efficiency furnaces), driveways, oil fill pipes, gas

meters, or garbage containers.

• At a minimum height of 460mm (18’’) above the ground, or above the level

of expected snow accumulation.

• Ideally, keep weatherhoods 1m (3') from corners.

• Do not locate in the garage, attic, crawl space, or underneath deck.

Locating the Exhaust Weatherhood

• At least 460mm (18") above ground or above the depth of expected snow accumulation

• Ideally, keep weatherhoods 1m (3') from corners.

• Not near a gas meter, electric meter or a walkway where fog or ice could create a hazard

• Do not locate in a garage, workshop or other unheated space

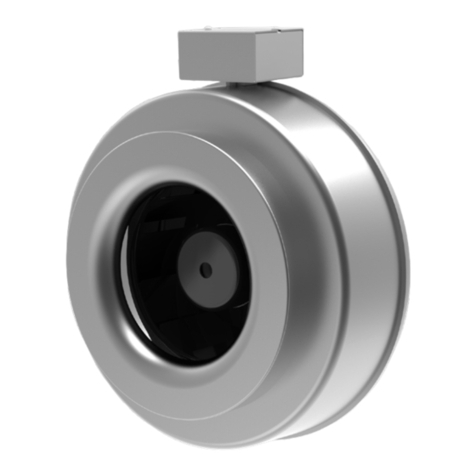

INSTALLING THE DUCTING TO THE WEATHERHOODS

A well designed and installed ducting system will allow the ERV to operate at its

maximum efficiency. The inner liner of the flexible insulated duct must be secured to the

sleeve of the weatherhood (as close to the outside as possible) and to the appropriate duct

connection on the ERV. The insulation should remain full and not crushed. The outer liner,

which acts as a vapor barrier, must be completely sealed to the outer wall and the ERV

using tape and/or caulking. A good bead of high quality caulking (preferably acoustical

sealant) will seal the inner flexible duct to both the ERV duct connection and the

weatherhood prior to securing them.

To minimize airflow restriction, the flexible insulated duct that connects the two outside

weatherhoods to the ERV should be stretched tightly and be as short as possible.

Twisting or folding the duct will severely restrict airflow.

See “Installation Diagram Examples” for installation examples.

1Using the duct connection of

the outside hood, outline the

intake & exhaust holes to be

cut. The holes should be slightly

larger than the duct connection

to allow for the thickness of the

insulated flexible duct. Cut a

hole for both the intake and

exhaust hoods.

3 Push the hood into the opening

and then attach the hood to the

outside wall with mounting

screws.

Repeat the installation

procedure for both the supply

and exhaust hoods.

2Pull the insulated flexible duct

through the opening until it is

well extended and straight.

Slide the duct’s inner vinyl sleeve

over the hood duct connection

and secure. Pull the insulation

over the duct and pull the vapor

barrier over the sleeve. Secure

with appropriate tape or

sealant.

4Using a caulking gun, seal

around both hoods to prevent

any leaks.

STEPS FOR HOOD INSTALLATION:

36" (1m)

min.

INTAKE

OUTSIDE CORNER INSIDE CORNER

EXHAUST

18" (460mm) min. 18" (460mm) min.

6' (2m)

min.

36” (1m)

min.