3

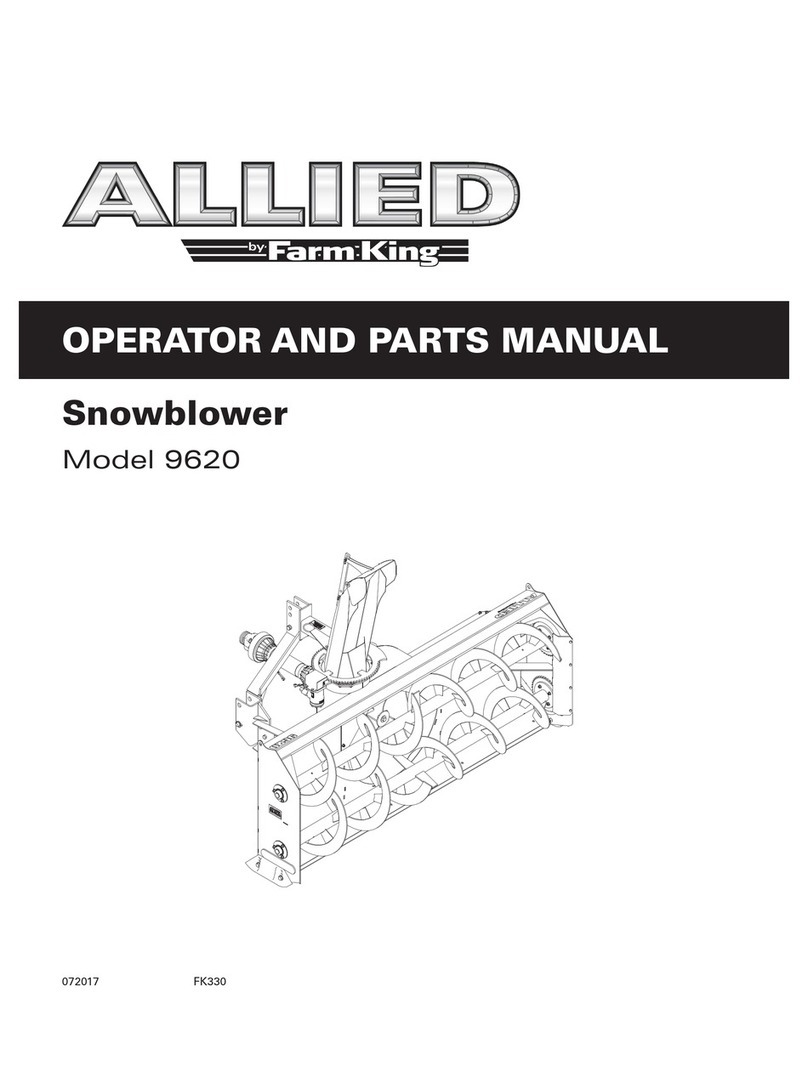

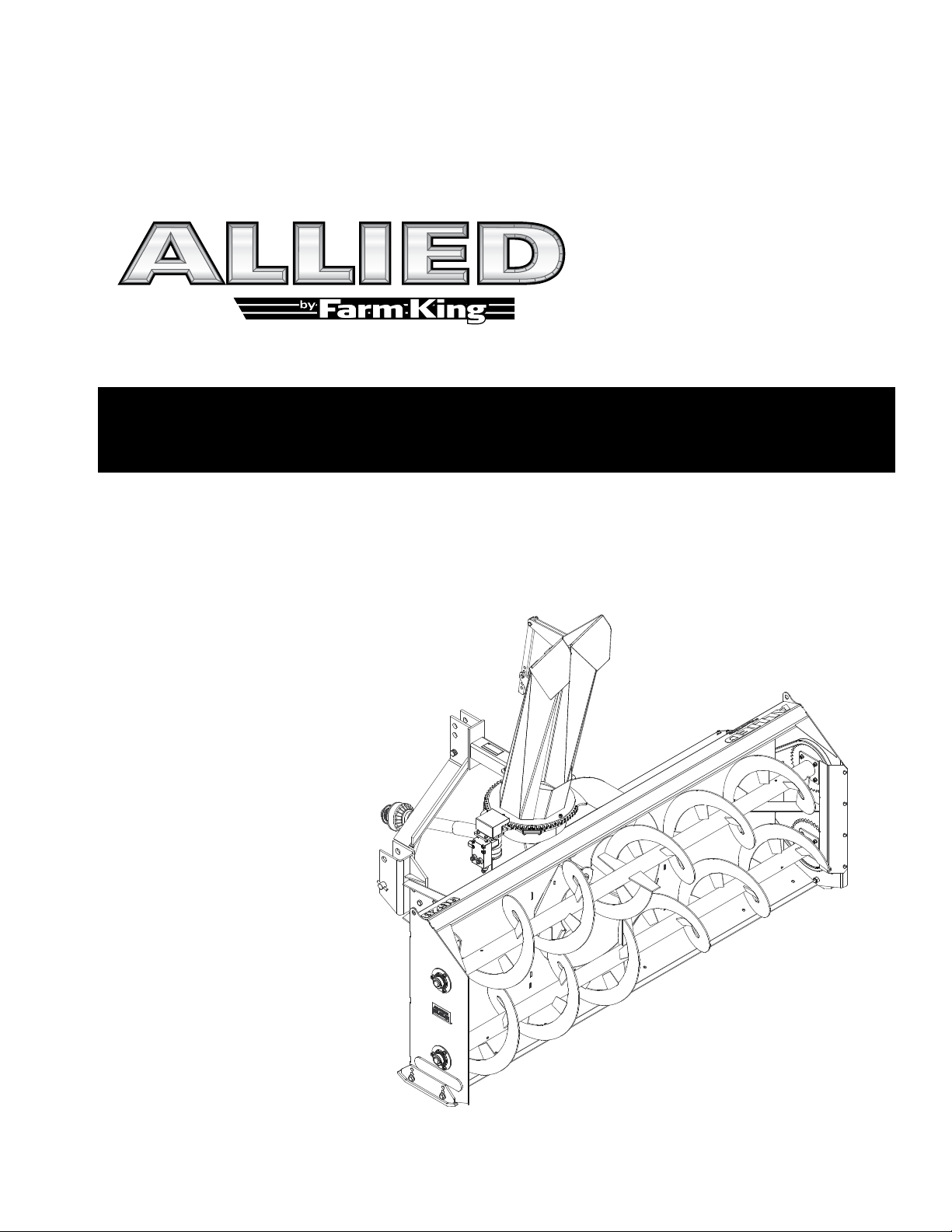

Table of Contents - 9620 Snowblower

Table of Contents

Introduction .................................................................................................................................4

Safety............................................................................................................................................5

• Safety ................................................................................................................................5

• General Safety..................................................................................................................6

• Start-up Safety .................................................................................................................6

• Operation Safety ..............................................................................................................6

• Transport Safety...............................................................................................................7

• Service and Maintenance Safety ....................................................................................7

• Storage Safety..................................................................................................................7

• Safety Signs .....................................................................................................................7

• Safety Sign Installation ...................................................................................................8

Assembly......................................................................................................................................9

• Assembly Instructions.....................................................................................................9

Operation ...................................................................................................................................12

• Operating Instructions...................................................................................................12

• Theory of Operation ......................................................................................................13

Maintenance ..............................................................................................................................14

• BoltTorque......................................................................................................................14

• Hydraulic Fittings ...........................................................................................................15

• PrevailingTorque Lock ...................................................................................................16

Parts Drawings...........................................................................................................................16

• Snowblower Drawings..................................................................................................16

• Snowblower Parts List...................................................................................................18

• PTO Drawing and Parts List...........................................................................................22

• Gearbox Drawing and Parts List ...................................................................................23

Optional Bundles.......................................................................................................................24

• Cylinder Assembly.........................................................................................................24

• Spout Deflector Cylinder & Hose Kit............................................................................24

• Cylinder Assembly.........................................................................................................25

• Long PTO Shaft ..............................................................................................................25

• Hand Crank Kit ...............................................................................................................25

• Bolt-on Cutting Edge .....................................................................................................25

Shipping Kit and Bundle Numbers ..........................................................................................27

Warranty Policy..........................................................................................................................28