FastenMaster PAMFast User manual

PAMFast™AutoFeed System

Owner’s Manual

FastenMaster®and PAMFast™are trademarks of OMG Inc.

Copyright © 2021 OMG Inc. All rights reserved.

OMG Inc., 153 Bowles Road, Agawam, MA 01001

800·518·3569 FastenMaster.com

FMPAM-AFMAN (0322)

TABLE OF CONTENTS

Safety.................................................................................... 1

Precautions............................................................................. 2

In the Box............................................................................3–4

Getting to Know Your PAMFast Tool........................................5–6

Setup and Adjustment.........................................................7–10

Operating Instructions.......................................................11–12

Parts Diagram..................................................................13–14

Tips/Common Wear Parts/Cleaning ..................................15–16

Troubleshooting ............................................................... 17-18

Warranty ........................................................................19–20

I Warning

For your safety, read all instructions before use

1 2

• Never point or press the tool in the direction of yourself or

another person.

Contact FastenMaster at 800-518-3569 with any questions

related to the safe operation of the PAMFast tool prior to use.

a Precautions:

• Only use genuine PAMFast collated fasteners approved for

the PAMFast AutoFeed tool. The use of any other fastener is

not advised and will void the PAMFast limited warranty.

• Only use genuine PAMFast AutoFeed driver bits approved for the

PAMFast AutoFeed tool. The use of any other driver bit will result

in poor performance and will void the PAMFast limited warranty.

• Only use screw guns that are supplied with the PAMFast

AutoFeed tool or recommended by FastenMaster.

The use of any other screw gun may result in poor

performance and will void the PAMFast limited warranty.

• Always disconnect power prior to loading collated screw

strips into the belt guide, replacing driver bits, or performing

any adjustments or maintenance.

• Do not plug into AC outlet or install battery prior to reading.

• Do not operate any PAMFast tool without reading and

understanding all safety warnings and operating instructions.

Failure to abide by the warnings and operating instructions in

this manual may result in personal injury, injury to others, or

property damage.

• Any screw gun that is supplied with any PAMFast tool is not

manufactured or warrantied by FastenMaster. Screw gun

manufacturer warranties, operating instructions, and safety

warnings are provided by the manufacturer and must be read

and understood prior to operating. Failure to abide by the screw

gun manufacturer’s safety warnings and operating instructions

may result in personal injury, injury to others, or property

damage.

• Always disconnect power by unplugging from AC outlet

or removing battery prior to performing any adjustments,

driver bit changes, maintenance, or repairs.

• Always be aware of job site risks. Active job sites present a

number of safety risks, including but not limited to those that

may result in trips, falls, cuts, slips, etc. Some job sites present

greater hazards than others. The use of appropriate personal

protective equipment (PPE) including protective eye-wear, non-

slip protective footwear, and protective head-wear is required

when using any PAMFast AutoFeed tool. Additional PPE may be

required depending on the conditions of the job site. Refer to

the Occupational Safety and Health Administration (OSHA) or

prevailing governing body for a full list of PPE requirements and

safety guidelines.

• Always be aware of what lies below the surface. Electrical, gas,

and plumbing utilities may present a danger. Never install any

fastener prior to assessing potential risks.

• Ensure that all work surfaces are stable, secure, and free

from debris that may lead to trips, falls, or other injury.

Safety

3 4

Reference Guide:

1. PAMFast Owner’s Manual

2. Screw gun manufacturer owner’s manual

3. PAMFast AutoFeed tool (fully assembled)

4. Replacement bits & multi-tool

5. Bit holder for short tool

6. Short Tool Adapter

Screw Gun Options:

• SD-20-P13KUE

• SD-20-MAC13KUE

• SD-20-DWC13KUE

• SD-20-DWC13KIT

(motor not included)

• SD-20-MAC13KIT

(motor not included)

In the Box:

1

2

3

465

5 6

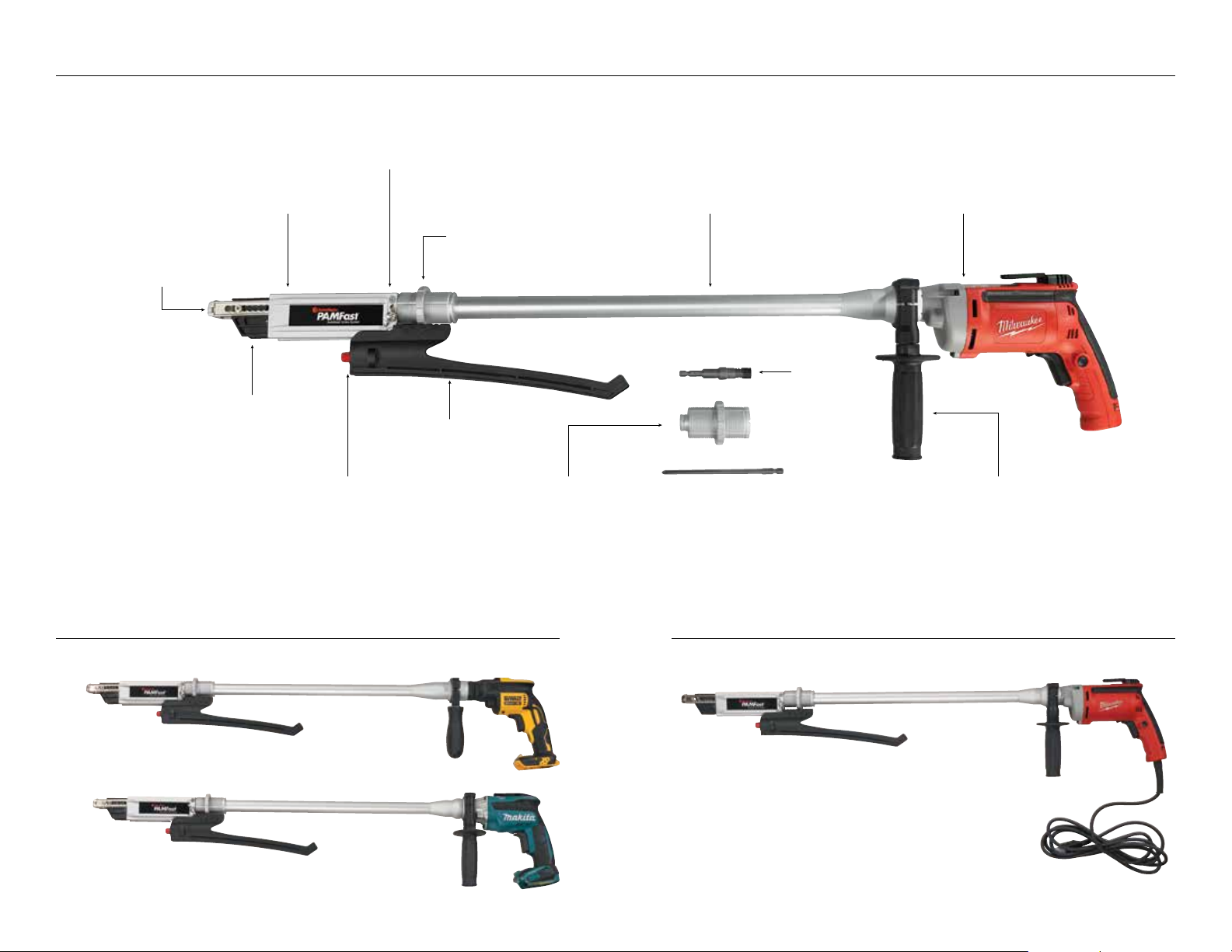

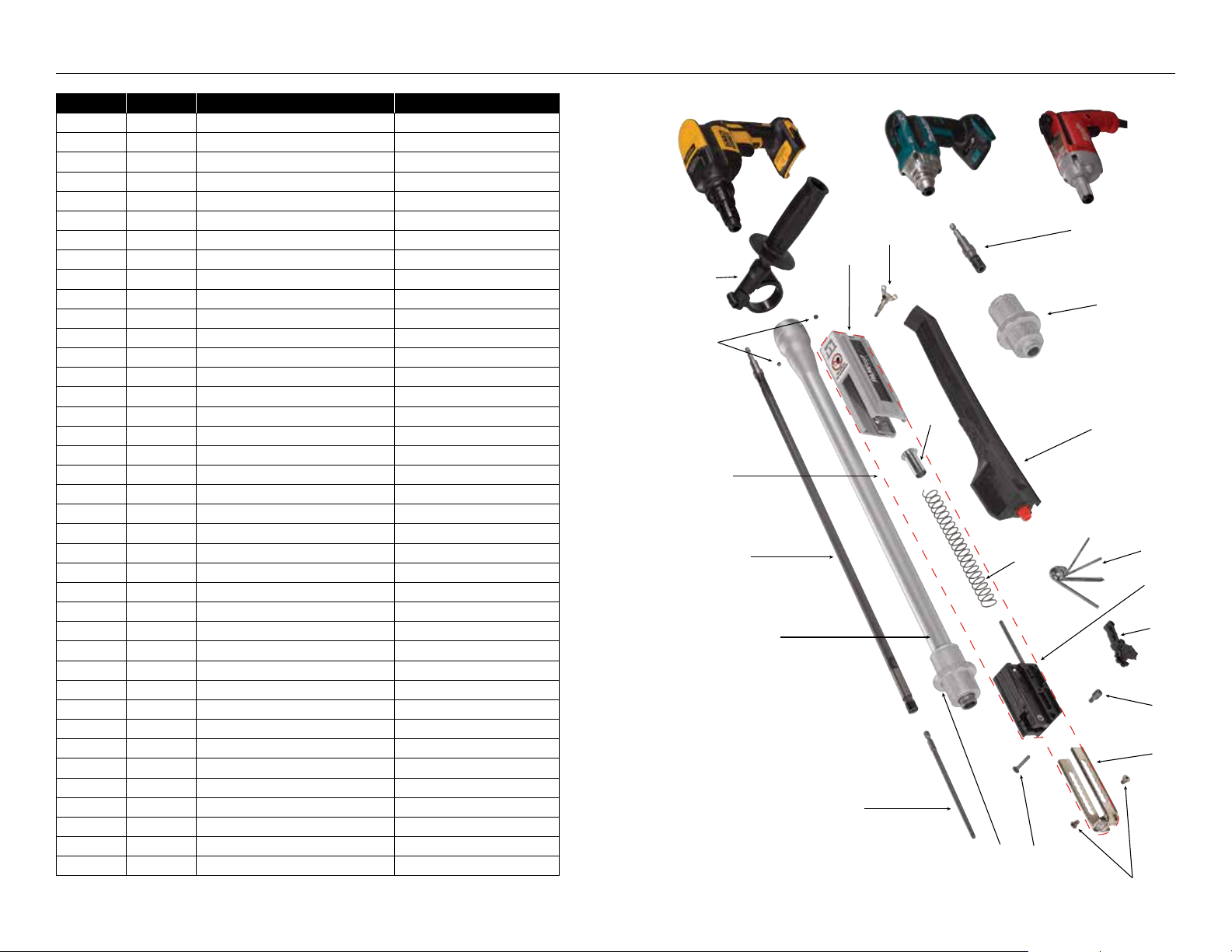

Wing Nut

1"– 3" Attachment Extension Pole

Countersink Ring

Depth Control

Gliding Piece

Belt Guide

Tension Knob/Belt Guide Adapter Bit

Bit

Holder

Extension Pole Handle

Screw Gun

Getting to Know Your PAMFast Tool

DeWALT Screw gun

Milwaukee Screw gun

Makita Screw gun

Cordless Drill Options: Corded Drill Option:

Batteries not included

7 8

Setup and Adjustment Setup and Adjustment (continued)

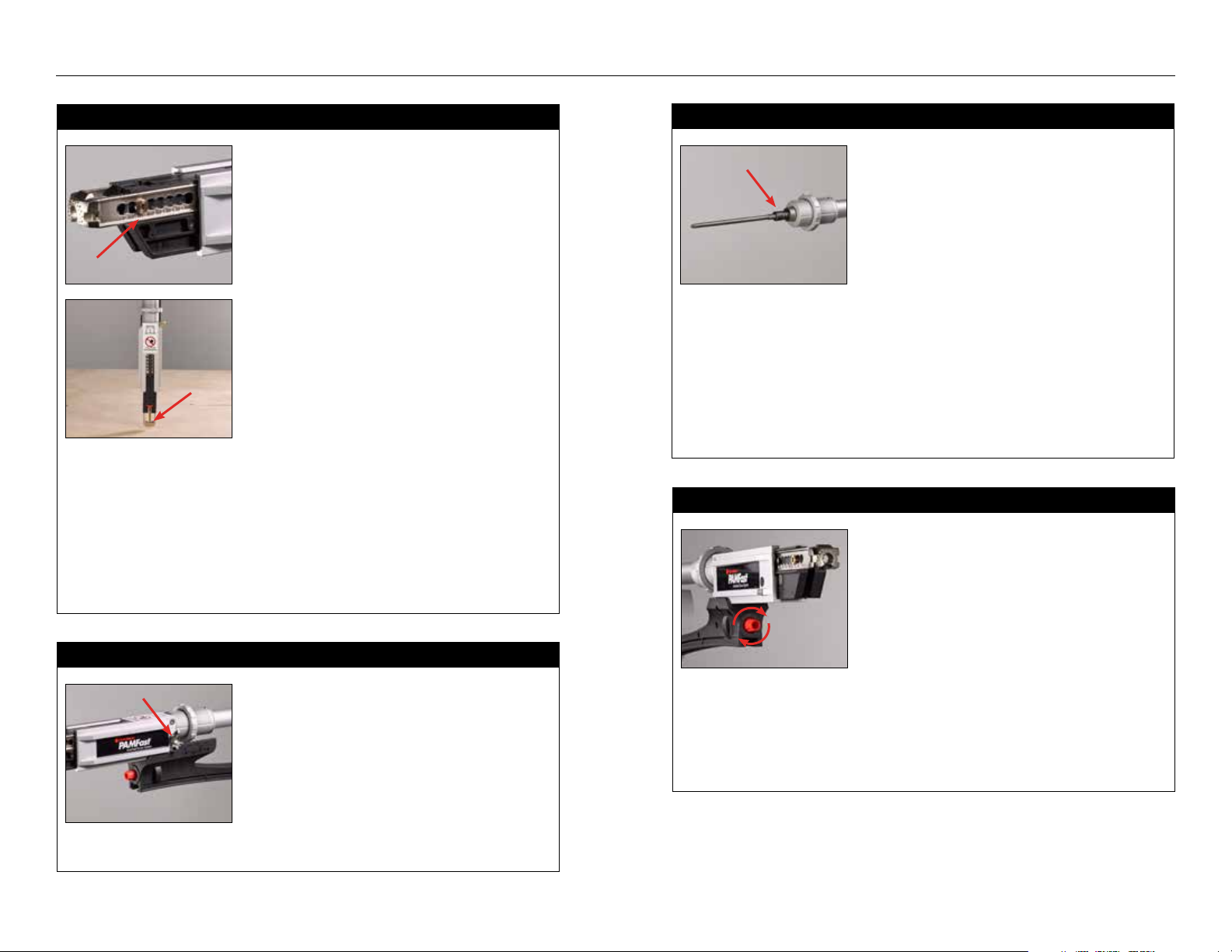

3) Belt Guide Adjustment

Belt tension on the PAMFast AutoFeed

tool is preset for 13⁄4" fasteners. Use

of alternate size fasteners may require

adjustment of the belt tension.

Turn the red Tension Knob clockwise

to increase belt tension, or counter-

clockwise to reduce belt tension.(Fig 3a).

I Do not overtighten This will prevent the collated screw

strip from properly feeding through the belt guide. Proper tension

prevents excessive slack in the collated strip and ensures precise

advancement of the strip between drives.

Fig. 3a

1) Screw Size Adjustment for Depth Control

Start by adjusting the PAMFast AutoFeed

attachment to accommodate the correct

screw length. The screw length is always

displayed on the side of the box of your

genuine PAMFast collated screws.

Loosen the shoulder screws on both sides

of the Depth Control and slide it to the

appropriate setting using the numbers

stamped on the Depth Control (Fig 1a).

When appropriately adjusted, the tip

of the fastener will be approximately

1

⁄

8

"

inside the face of the nose piece (Fig 1b).

I Note that the screws holding the Depth Control/

Nosepiece have collars so be sure that the collars of the

screws sit down in the cutouts of the Depth Control. If they

are not fully recessed, the gliding piece will not go back into

the housing fully and screw will not countersink.

2) Bit Replacement

For smooth operation and to reduce

cam-out, FastenMaster recommends

replacing drive bits after every

1,000 screws.

• Loosen the Wing Nut on the side

of the attachment assembly (Fig 2a).

2) Bit Replacement (continued)

• Remove the attachment assembly

to reveal the bit (Fig. 2b).

• Depress the lock collar and remove

the bit. After inserting the new bit,

release the collar to lock the bit

into place.

I Use only genuine PAMFast bits. Every tool comes

with one PAMDrive bit installed on tool. Additional bits such

as Phillips and Torx may be purchased.

• Bit should be approximately the same length as housing.

• Ensure bit type (Phillips, Torx or PAMDrive) matches

screw recess.

Fig. 1a

Fig. 1b

Fig. 2a

Fig. 2b

9 10

4) Countersink Adjustment

Prior to operating the

PAMFast

AutoFeed

tool, ensure that the countersink ring in

set to the proper screw length.

• Turn the countersink ring clockwise

to increase and counterclockwise to

decrease. Each click represents

1⁄64"

adjustment to the countersink depth.

5) Extension (Changing between stand-up tool & short tool)

The extension pole can be removed for applications that require

a shorter version of the tool. (Fig 5a)

• Remove the 1– 3" attachment from the end of the PAMFast tool

by loosening the wingnut and pulling the attachment. (5.1)

• Twist the extension handle counterclockwise to loosen the

handle assembly. Slide the handle assembly away from the

screw gun motor to expose two hex screws. (5.2)

• Using the 3mm Allen wrench provided with your PAMFast

tool, loosen the two hex screws. Use caution when loosening

these screws as not to drop them. (5.2)

• Pull the extension pole away from the motor by twisting

and pulling simultaneously. The extension pole is designed

to require some force to pull away from the motor.

• Remove the inner rod by pulling it away from the motor.

• Insert the drive bit into the short bit holder. (5.2)

Extension (Continued)

• Remove the drive bit from the end of the extension pole

and insert it into the short bit holder. The short bit holder

and adapter will replace the inner rod and extension pole

respectively. (5.3)

• Slide the 1-3" attachment over the bit until it sets

securely in place and then tighten the wing nut. (5.4)

Fig. 4a

Fig. 5a

Setup and Adjustment (continued) Setup and Adjustment (continued)

I Warning Improper set up of the PAMFast tool will lead to

incorrectly installed screws and could damage the PAMFast tool.

Please call 800·518·3569 or visit fastenmaster.com

to contact a technical specialist if assistance is needed.

Short Handle Conversion

Long Handle Extension 5.1

5.2

5.3

5.4

11 12

feature. If utilizing this feature the screw gun will automatically

turn off between drives and start upon depressing the nose piece.

FastenMaster recommends utilizing a continuous drive mode or

“auto on” mode when using the PAMFast Autofeed tool.

• Between drives it is critical that the tool is fully lifted from the

surface to allow the nose piece to completely recoil. (Fig 8-11)

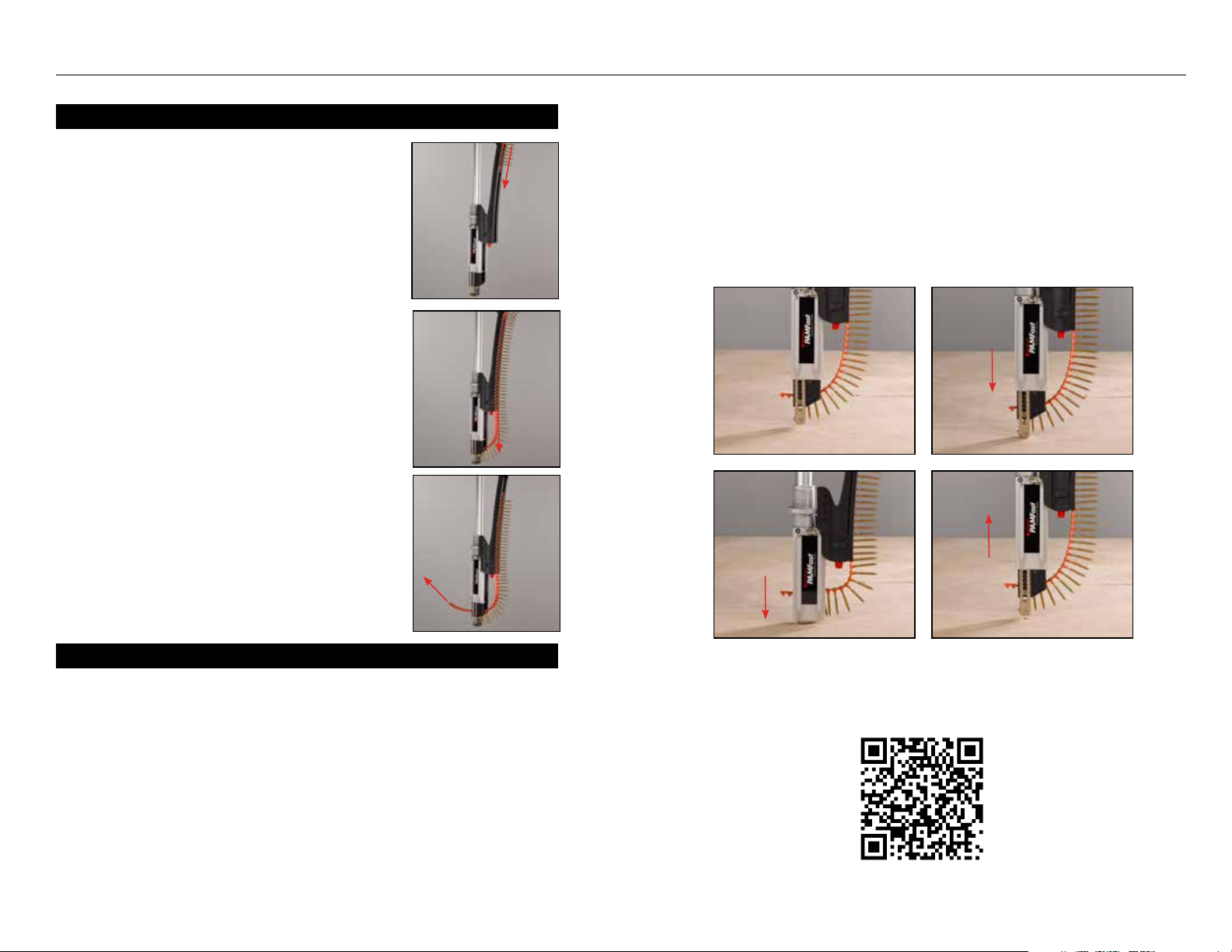

6) Loading Fasteners

• Feed the fastener strip into the belt guide

and load into the 1-3” attachment. (Fig

5-6). The fastener strip advances on the

down stroke, so the first screw should be

one spot prior to the drive position.

• If it is necessary to remove screws

from the PAMFast tool, pull the strip

forward, not backwards (Fig.7).

I Warning Only use genuine PAMFast

collated screws. Use of any other brand

fastener is not advised and will void the

limited warranty on your PAMFast tool.

7) Driving Fasteners

• Confirm that the motor is set to run in the forward

direction. Set the screw gun to “auto on” or “continuous” drive

mode. Refer to screw gun manufacturer’s operating instructions.

• With the motor running at full speed, apply and maintain

continuous pressure to drive the fastener until the drive bit

automatically disengages. For proper drive, it is critical that

the operator applies continuous pressure to fully depress

the nose piece when driving the fastener.

• When driving multiple fasteners consecutively, keep the motor

power on between drives. Some screw guns offer an “auto on”

Fig. 5

Fig. 6

Fig. 7

Operating Instructions (continued)Operating Instructions (continued)

Fig. 8 Fig. 9

Fig. 10 Fig. 11

For a video demonstration on how to setup and operate the

PAMFast Autofeed tool visit:

13 14

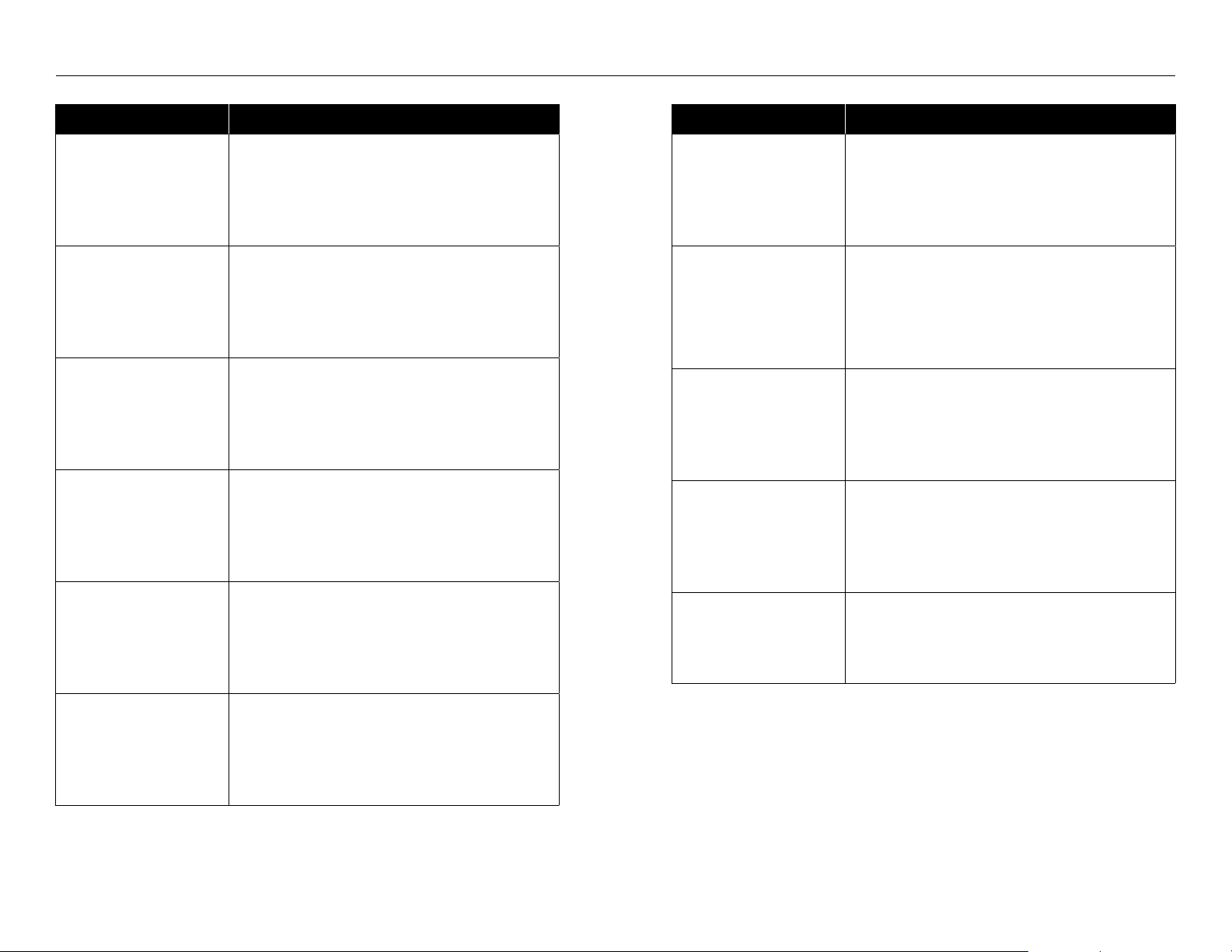

12

14

13

15

16

19

17

18 20

21

11

10

9

8

7

6

5

4

3

2

1

Parts Diagram Parts Diagram (continued)

Milwaukee Screw Gun

Corded 22a-b

Makita Screw Gun

Cordless 22c-d

DeWALT Screw Gun

Cordless 22e

POS. # PART # DESCRIPTION USED WITH

1 BGS0081 Depth Control 1"- 2" All 12K Series

1 BGS0083 Depth Control 1"- 3" All 13K Series

2 KFS0060 Depth Control Screws (2x) All Screw Guns

3 FXS0008 Gear Wheel Unit All Screw Guns

4 KFS0004 Screw with Roller All Screw Guns

5 EXS0070 Gliding Piece All 12K Series

5 EXS0060 Gliding Piece All 13K Series

6 NFS0305 Strong Yellow Spring * All 13K Series

6 NFS0227 Blue Spring All 12K Series

7 KBS0015 Spring Guide All Screw Guns

8 DXS0043P Plastic Belt guide All Screw Guns

9 BZS0002 Allen Key Set All Screw Guns

10 BAS0266 Milwaukee Adapter P12K & P13K Series

10 BAS0270 Adapter-F/Makita FS2200/ MAC13K/ MAC13K4

10 BAS0280 Adapter-F/Dewalt DCF622 DWC13K

11 BDS0012 BH- F/Milwaukee & D

e

WALT DCF622 P13K & DWC13K Series

11 BDS0068 BH- F/Makita FS4200 MAC13K Series

12 GXS0010 Stop Nut All Screw Guns

13 BITD2120 #2 x 120mm bit PAM Drive All 12K Series

13 BITP2120 #2 x 120mm bit Phillips Drive All 12K Series

13 BITD2140 PD #2X140mm F/P13 Series All 13K Series

13 BITP2140 PH #2X140mm F/P13 Series All 13K Series

14 KDS0022 Pin for Gear Wheel Unit All Screw Guns

15 BHS0218 Ext Pole-Milwaukee

All screw Guns w/ Milwaukee 6740 Motor

15 BHS0219 Ext Pole- Makita FS2200/FS4200

All Screw Guns w/ Makita XFS04 Motor

15 BHS0225 Ext Pole- Dewalt Cordless

All Screw Guns w/ D

e

WALT DCF622 Motor

16 BHS0208 Inner Rod All 13K Series

17 CXS0016 Housing Complete w/back plate & curve All 12K Series

17 CXS0064 Housing Complete w/ back plate & curve All 13K Series

18 NAS0394 Set Screw (2x) All 13K Series

19 ABS0044 1" – 2" Blank Attachment All 12K Series

19 ABS0047 1" – 3" Blank Attachment All 13K Series

20 BCS0011 Handle All 13K Series

21 KFS0066 Wing Nut Screw All Screw Guns

22a MILW01 Milwaukee 2500 rpm P12K/P13K/KDE/KUE

22b MILW02 Milwaukee 4000 rpm P12K4/P13K4

22c XSF04Z Makita 0-2500 rpm Bare Motor MAC13K Series

22d XSF03Z Makita 0-4000 rpm Bare Motor MAC13K4

22e DCF622B Dewalt 0-2000 rpm Bare Motor DWC13K

15 16

Nose Piece or Depth Control:

Nose Piece or Depth Control naturally

wears over time due to constant abrasion

of the screws and contact with the surface

being screwed down. If the nibs on the

front of the nose piece or the fastener

channel are worn, the nose piece may

be replaced. If it’s the channel that is worn,

the fastener may drive into the material off vertical,

causing countersink problems, jamming, and excessive bit wear.

Gear Wheel:

The gear wheel may wear with use.

If the gear wheel is worn, it will either

seize or spin freely instead of deliberately

advancing from one position to the next.

If the gear wheel does not advance

properly, it is likely damaged and may

need to be replaced. The purpose of the

gear wheel is to advance the fastener belt

forward but not allow it to roll back during

or after the advancing movement.

Spring for the Gliding Piece:

Over time, the spring for the gliding piece may become fatigued.

(Refer to part #6 in the Parts Diagram shown on page 14)

This may prevent the tool from properly recoiling between drives.

If the spring has worn replacement may be necessary.

I Warning: Do Not Use Oil

Oil will hold dirt and interfere with tool operation

• Graphite may be used to lubricate.

• To maintain proper operation of the PAMFast tool, ensure that

the gear wheel, inner spring, and gliding piece remain free from

debris and obstructions.

• Gliding piece must move freely in the housing.

Check periodically for damage. If burrs or obstructions

are found, smooth with a file.

Tips/Common Wear Parts Cleaning

Fig. 12

Fig. 13

17 18

Troubleshooting Troubleshooting (continued)

Symptom Remedy

Motor turns and bit engages,

but screw does not insert or

falls to the side when tool is

raised

•

Check that motor reversing switch is in forward position.

•

Check Depth Control screw setting as it may be too long.

Screw inserts but does not go

in all the way

•

Confirm the bit is the correct length for the attachment.

•

Check to be sure that collars on the depth control/nose

pieces screws are seated correctly (see Set Up,

Depth Control Adjustment).

Screw strip falls forward out

of belt guide when tool is

raised into position

•

Turn orange knob attached to the front of belt guide

to increase tension.

Screw does not countersink

properly

•

Turn countersink adjustment ring until the proper

countersink is achieved.

•

Check bit to be sure it is the right type and length.

Screw tip drags on surface

before installation of screw

•

Screw tip is likely beyond the outside of the Depth

Control. Adjust Depth Control until screw tip protrudes

halfway into Depth Control Throat.

First few screws advance then

the belt stops moving

•

Loosen tension control on the belt guide to allow

movement.

•

Check gear wheel movement as described under

Cleaning and Repair.

Call 800·518·3569 or access fastenmaster.com for a technical specialist

if assistance is needed

Symptom Remedy

Gliding piece will not retract

fully into housing on down-

stroke

•

Check that screws holding Depth Control in place are

fully seated into cut outs.

Gliding piece jams or is

difficult to move in the

housing.

•

Check first that there are no burrs on the front of the

housing that are interfering with the movement of the

gliding piece.

•

Check the width of the housing opening to ensure that

a bump or blow from something else has not forced the

front of the housing inward.

Screw is inserted only part

way before bit tip starts to

spin in recess.

•

Maintain constant downward pressure while screw is

being inserted. Too little or inconsistent pressure on

down-stroke will cause bit tip to lose full contact with

screw recess and potentially strip out recess.

Jammed fastener

•

Stop motor.

•

Pull screws completely through Gliding Piece.

Reinsert in belt guide and gliding piece.

•

To avoid jamming, be sure motor is running before

down stroke begins.

Screw becomes jammed in

Depth Control, gliding piece

or housing

•

Remove the fastener and test the tool.

Most of time the jam will cause no damage.

19 20

This warranty applies only to the original end-use purchaser.

Original proof of purchase is required. Proof of purchase must

clearly indicate purchase location, purchase date, and purchase

price. The purchase date indicated on the original proof of

purchase represents the start date of the Warranty Period. For the

avoidance of doubt, the screw gun supplied with the Products,

as the case may be, is not manufactured by or warranted by

FastenMaster.

This limited warranty is exclusive and replaces all other warranties,

conditions, representations and guarantees, whether express or

implied, whether by statute, at law or in equity, including the

implied warranties of merchantability or fitness for a particular

purpose. This limited warranty is your exclusive warranty from

FastenMaster and represents the sole remedy available to

any purchaser of the products. FastenMaster makes no other

representations, conditions, guarantees or warranties of any kind

other than stated herein. FastenMaster will not be liable in any

event for consequential, punitive, special, incidental, or other

similar damages of any kind, including damage to the interior or

exterior of any building, whether any claim against it is based upon

breach of this warranty, negligence, strict liability in tort, or for any

other cause. Some jurisdictions do not allow limitations on or the

exclusion of incidental or consequential damages, so the above

limitations may not apply to you.

For warranty assistance contact FastenMaster at 800-518-3569

or email your request to info@fastenmaster.com.

FastenMaster

153 Bowles Road

Agawam, MA 01001

800·518·3569

FastenMaster FrameFAST and PAMFast 3-year limited Warranty:

Effective 04/07/2022:

This warranty applies only to the following FastenMaster products:

FMFFTOOL-T2TP, FMFFTOOL-T2TP-MILC, FMFFTOOL-T2TP-DWC,

FMFFHEAD-P2R, FMFFHEAD-S2P, FMFFHEAD-T2TP, SD-20-P12K,

SD-20-P12K4, SD-20-P13K, SD-20-P13K4, SD-20-P13KUE, SD-20-

MAC13KUE, SD-20-DWC13KUE, (the “Products”).

OMG Inc. dba FastenMaster (“FastenMaster”) warrants that

the Products tool shall be free from defects in materials and

workmanship for a period of three (3) years from the date of

purchase (the “Warranty Period”). You must notify FastenMaster in

writing about any warranty claim within 30 days after you notice

a problem. If, after receiving prompt written notice, FastenMaster

determines that the Products are not as warranted, FastenMaster

will either, at its sole option, (a) repair the failed Product, or (b)

replace the failed Product, free of charge. The remedy under

this limited warranty is available only for those Products actually

exhibiting a manufacturing defect as set forth above. Any repaired

or replaced Product will be warranted only for the remainder of the

original warranty period. FastenMaster's liability under the terms of

this limited warranty will be limited to the direct cost of repairing or

replacing the failed Product.

This limited warranty does not apply where the Products have: (a)

been subjected to abuse, misuse, neglect, negligence, accident,

improper testing, improper installation, improper storage, improper

handling, abnormal physical stress, abnormal environmental

conditions (including corrosive or aggressive atmospheric

conditions such as chemical fumes or direct salt spray), metal

dust and shavings, or any use contrary to any instructions issued

by FastenMaster; (b) been reconstructed, repaired or altered by

persons other than FastenMaster or its authorized representative;

(c) been used with any third- party product, hardware or product

that has not been previously approved in writing by FastenMaster;

or (d) been damaged by other trades or materials substituted for, or

used in addition to, the Products. This limited warranty only covers

the Products and does not cover any other material obtained from

other sources.

Warranty Warranty (continued)

Table of contents