Faulhaber MCBL 05002 Series User manual

MCBL 05002

Series MCBL 07002

Series

Servo Amplier

Sine Controller

for Micro Brushless DC-Motors

Operating Instructions

Subject to change without notication

ABOUT THIS HANDBOOK

1. GENERAL

1.1 BASICS

1.2 TECHNICAL DATA

1.2.1 MCBL 05002

1.2.2 MCBL 07002

2. CONNECTION

2.1 OVERVIEW

2.2 DESCRIPTION

2.2.1 Supply Voltages

2.2.2 Serial Interface

2.2.3 Analog Inputs

2.2.4 Digital Inputs

2.2.5 AUXIn as Fault Input

2.2.6 Power Outputs and Current Detector

3 CONTROL

3.1 ON THE MODULE

3.2 EXTERNAL INPUTS (PINS)

3.3 CONFIGURATION AND PROGRAMMING

3.3.1 Setup of the Programmable Interface

3.3.2 Command Syntax

3.3.3 Node Addresses and Additional Drives

3.3.4 Saving the Settings

3.4 DESCRIPTION OF OPERATING MODES

3.4.1 Continuous Mode

3.4.2 Stepper Motor Mode

3.4.3 Pointer Mode

3.5 VELOCITY CONTROL

3.5.1 Analog Speed Setup

3.5.2 Setting Velocity via Pulse Train

3.5.3 Speed and Ramps

3.5.4 Output Voltage and Back-EMF Compensation

3.5.5 Start/Stop and Direction of Rotation

3.6 POSITIONING

3.7 STEPPER MOTOR MODE

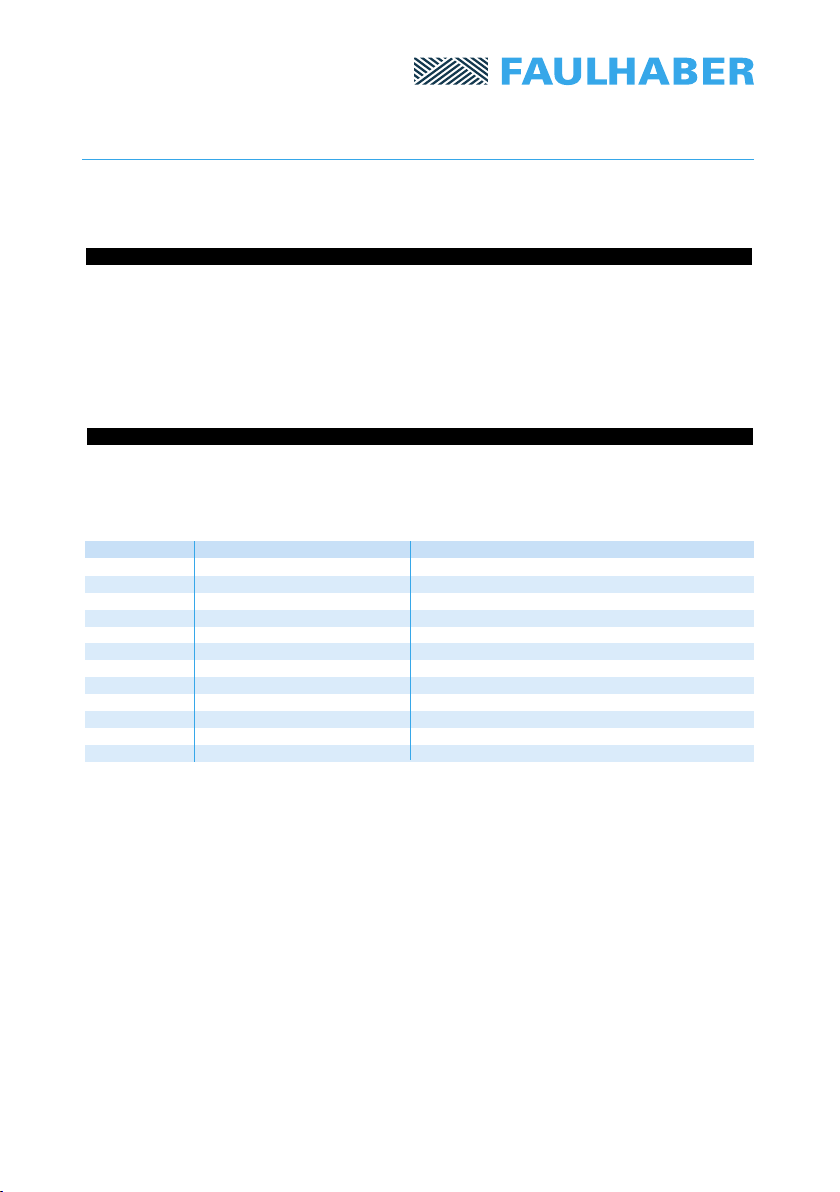

Table of Contents

Contents Page

III

1

1

3

3

3

5

5

6

6

6

6

7

7

7

8

8

9

10

10

10

11

12

13

14

15

15

16

16

18

19

20

21

22

24

Subject to change without notication

Subject to change without notication

3.8 POINTER MODE

3.9 OVERCURRENT LIMIT

4 INSTALLATION & VERIFICATION

4.1 STARTING THE MODULE

4.2 INSTALLATION WITH AN MCBL 07002

4.3 TROUBLESHOOTING

4.3.1 Drive stationary with analog input

4.3.2 Drive will not move

4.3.3 Faulty circuit or drive

4.3.4 Output voltage or speed incorrectly set

4.3.5 Other faults

5 APPENDIX

5.1 LIMIT VALUES

5.2 COMMAND SET

5.3 FACTORY CONFIGURATION

5.4 CONNECTING TO A COMPUTER

5.5 STARTER KIT MCBL 07002

5.5.1 Overview

5.5.2 Operation

Contents Page

26

27

28

28

29

30

30

30

31

31

31

32

32

33

38

39

40

40

41

Subject to change without notication

Subject to change without notication

About this Handbook

This handbook serves a number of purposes: to provide simple instructions for users so that

they can set up the electronics by themselves and put the unit into operation. This manual is

also designed to provide pertinent information on how to set and program parameters via

the command interface. It also serves as a reference manual for the drive in its daily opera-

tion, providing details of how to use commands and operate the drive according to the user’s

requirements.

The data sheet in Chapter 1.2 is very important. In Chapter 5.1 the permitted limit values of

the programming interface are listed.

Readers who are already familiar with the principles of the Faulhaber MotionController are

recommended to read Chapter 3, in which all the commands are described that are available

via the Programmer Interface. The Appendix in Chapter 5.2 gives an alphabetical overview

with brief examples of each type of command.

A summary of which input to use with which operating mode is contained in Table 1.

For the purposes of this manual is assumed that a motor without a gearbox is connected.

Otherwise, all position and speed-data must be adjusted by the gear ratio.

Conventions: Connection pins such as Start/Stop are shown in italics. Instructions for the Pro-

grammer Interface are shown in bold: ver.

© 2002 Dr. Fritz Faulhaber GmbH & Co. KG

Windows and Windows NT are registered trademarks of Microsoft Corporation.

Subject to change without notication

Subject to change without notication

1

1.1 Basics

1. General

The MCBL 05002 is a general-purpose controller for three-phase brushless motors. It has small

external dimensions and can be plugged into a normal IC-socket. It is ideally suited for effec-

tive operation of 0206 micromotors, but can also be used to control any other three-phase

motor. The drive will operate in open-loop mode, with no speed feedback from the drive to

the controller.

The controller has a range of inputs, making it suitable for various types of operation.

Potentiometers can be connected via analog inputs so that the drive can be manually controlled.

If the pulse input is used, the drive can operate as a stepper motor; via a serial interface the

drive can be connected to a PC or a PLC and operated accordingly. All drive parameters can be

adjusted via this programmer interface. Parameters can be stored and retained for re-use once

the unit is switched on again.

Technology

Extremely silent-running due to control via a three-phase sinewave signal (not PWM!).

Drives with low moment of inertia also run silently.

Smooth start-up and slowdown via acceleration and deceleration ramps in all drive modes.

Safer operation due to compensation of the induced back-EMF, so that the required

torque is near-constant.

Overcurrent protection via a peak current limiter, which operates when the maximum

permitted current is exceeded, to return the drive to a safe state.

Positioning moves the drive within 4 million revolutions with a resolution of 1/256th of a

revolution.

Fig. 1: Main components

Subject to change without notication

Subject to change without notication

2

Versatility

Multiple voltage-controlled inputs to adjust speed, acceleration ramps and output voltage.

Pulse input, permitting use as a stepper motor or alternatively as a rated-speed motor.

Pointer instrument input, with which the rotor can be deected from the zero-position

in proportion to an applied analog voltage.

Serial link (RS232, RS422), enabling all parameters to be adjusted from a PLC or a PC.

Features:

Small footprint: 42 x 24 mm

Enormous speed range, from 21 rpm to 120 000 rpm with ne resolution

Powerful: 200 mA running current

Selectable common-bus or individual supply for electronics and motor

Non-volatile memory: all parameters such as speed, drive mode, target position etc.

can be stored as required and are immediately available again after power-on.

The processing performance is achieved by using a powerful 24 MHz microcontroller.

In order to put the MCBL 05002 into service quickly and without problems, a Starter Kit

MCBL 07002 is available for the laboratory. This is described in Chapter 5.5.

Fig. 2: Schematic diagram of MCBL 05002

Subject to change without notication

Subject to change without notication

1.2 Technical Data

3

V DC

mA

°C

°C

V

V

baud

mm

g

6,5 – 7,5

400

0 ... + 30

0 ... + 60

low: -8 – -5

high: 5 – 8

9 600

126 x 81 x 34

190

V DC

V DC

mA

mA

V

V

V

Ω

V

V

kHz

Ω

rpm

%

V

mA

%

°C

°C

V

V

baud

mm

g

1.2.1 MCBL 05002

4,5 – 5,5

4,5 – 7,5

70

200

low: 0 – 0,8

high: 2,4 – 5,0

0 – 5,0

> 500

low: 0 – 0,5

high: 4 – 10

200

> 2 200

0 ... 120 000

± 0,5

2,4

50 – 900

20

0 ... + 45

-25 ... + 85

low: 0 – 0,5

high: 2,4 – 5,0

9 600

42 x 24 x 11

8

1.2.2 MCBL 07002

Supply voltage:

- Electronics VS

- Power stage V+

Current consumption:

- Electronics Is

- Power output (V+ = 7V, Tamb = 25 °C) I+ max. current

Analog inputs Digital input level

(all except AUXin; Vs = 5V) (TTL-level)

Analog input level

Input resistance

AUXin Input level

max. input frequency

Input resistance

Output signals Speed

Deviation from dened values

Voltage range Veff

Ammeter Range

max. error

Temperature range:

– in service (freely ventilated)

– in storage

Interface Level (Vs = 5V)

Baud rate

(No Parity, 1 Stop bit)

Dimensions (LxWxH)

Weight

Supply voltage: VS

Current consumption: Is max. current

Temperature range:

– in operation (freely ventilated)

– in storage

Interface Level (Vs = 5V)

Baud rate

(No Parity, 1 Stop bit)

Dimensions (LxWxH)

Weight

Subject to change without notication

Subject to change without notication

4

Dimensions of the MCBL 05002

Remarks

All pins are specied to a grid measurement RM 2,54 and therefore are only indicated in outline.

The MCBL 05002 can thus be tted into an ordinary DIL28-IC socket.

RastermaB 2,54mm

DIL 28

7,69

5,73

6

12

15,25

1,94

39,6

33,41

24,62

15,23

2,6

1,6

5,4

2

42

24

ø3,5

Fig. 3

Grid size

Subject to change without notication

Subject to change without notication

Viewing the MCBL 05002 from the front: If the two big black ICs are on the top left

and the plug on the right, Pin 1 will be located on the left below. It can also be recognized

by a rectangular soldered patch. Pin 14 is below on the right, and marked with the number 14.

5

2. Connecting Up

2.1. Overview

Fig. 4: layout of the operaring elements

Function Direction Pin Description

Serial Receive IN 14 RS 232 interface with TTL levels

Serial Transmit OUT 13 RS 232 interface with TTL levels

Ramp Slope ANALOG 12 Slope of the acceleration ramp

Output Voltage 1 ANALOG 11 Amplitude of output voltage

RPM 1 ANALOG 10 Speed of the drive (frequency of the voltage)

Output Voltage 2 IN 9 Amplitude of output voltage

RPM 2 IN 8 Speed of the drive (frequency of the voltage)

Reset IN 7 Reset the controller

Direction IN 6 Direction of rotation of the drive

Start/Stop IN 5 To start and stop the drive

Vcc IN 4 Digital section supply voltage: +5V stabilized

GND IN 3 Ground (earth)

V+ IN 2 Power section supply voltage: +7.5V

Isense OUT 1 Current detector output

AUXin IN 15 Multi-function input

Phase C OUT 16 Power output to drive

Phase B OUT 17 Power output to drive

Phase A OUT 18 Power output to drive

Explanation of ANALOG: This connection is internally connected to a potentiometer with

a 1 kΩ resistance. If this connection is not made, it can be used to measure the voltage at

the potentiometer, and it thus operates as an output. By means of a drive of sufciently

low impedance, the user may set this voltage to the level that he requires;

in this mode, the connection operates as an input. The potentiometer on the board

should be set in the middle of the scale. See also the description in 2.2.3.

Subject to change without notication

Subject to change without notication

6

2.2.1 Supply Voltages

2.2 Description

Explanation of ANALOG: This connection is internally connected to a potentiometer with

a 1 kΩ resistance. If this connection is not made, it can be used to measure the voltage at

the potentiometer, and it thus operates as an output. By means of a drive of sufciently

low impedance, the user may set this voltage to the level that he requires;

in this mode, the connection operates as an input. The potentiometer on the board

should be set in the middle of the scale. See also the description in 2.2.3.

The supply voltage Vcc to the electronics section must be + 5V stabilized, and for the power

section it may be between V+ = + 5V DC and + 7,5V DC. The range of output voltage however

is always at max. 2,4Veff, independent of the supply voltage (see data sheet).

If a drive with very high power is used, it is advisable to use a supply voltage greater than 5V

for the supply section to minimize distortion of the output signal. Note that at the same time

the power loss in the power section will increase.

When connecting a micromotor 0206, output signal distortion occurs with an output voltage

of > 2200 mVeff and a voltage supply of 5V. If a 7V supply is used for the power section, these

distortions disappear.

The pins Serial Receive and Serial Transmit implement a serial link with TTL levels. To create an

RS232 interface, in order to link the micromotor control with a PC, a signal converter (MAX232

or similar) must be used to raise the levels to the corresponding + 12V and – 12V.

An RS422 link can be made to another drive, for example a MAX488. This gives the advantage

of greater immunity to disturbance.

Setup of the interfaces is described in Chapter 3.3.1.

2.2.2 Serial Interface

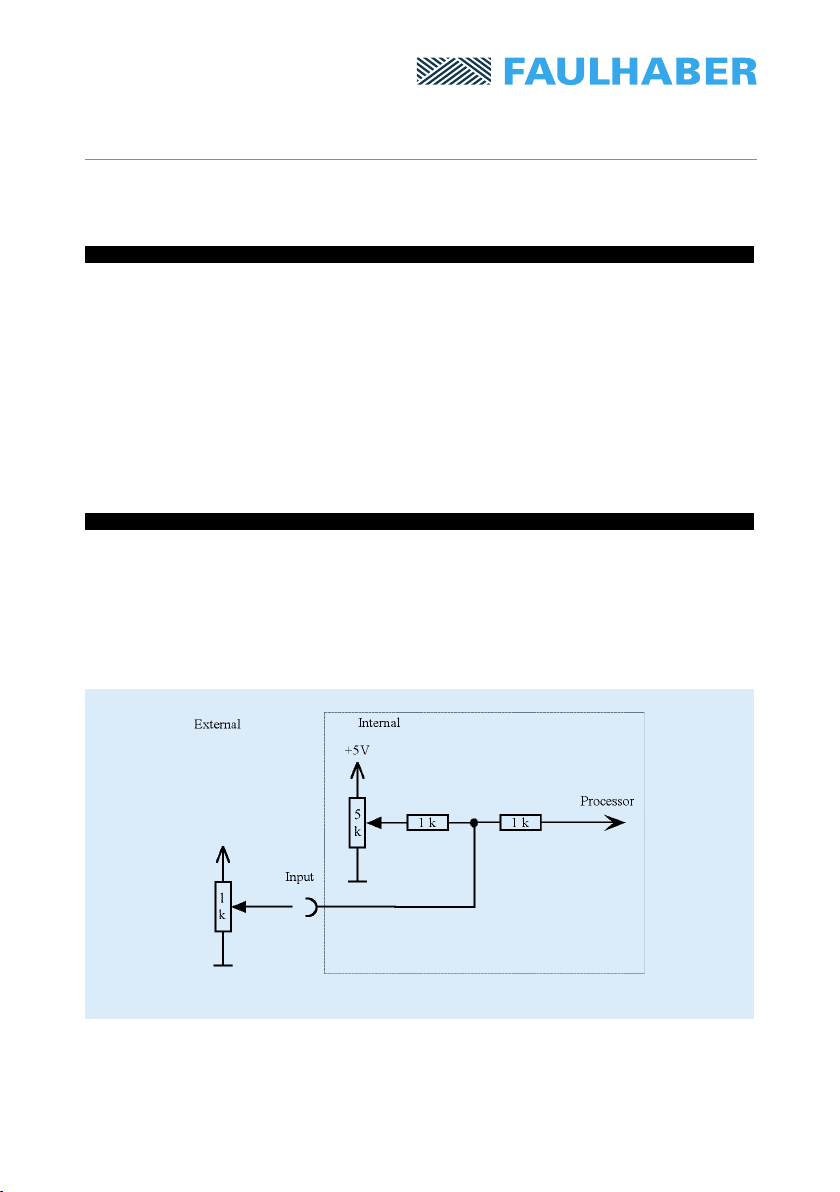

The analog inputs are suitable for voltage levels between 0V and 5V.

Ramp Slope: A voltage of 0V corresponds to a ramp of 0 revs/s2, and 5V corresponds to about

700 rpm/ms (= 11 700 1/s2). This input is shown in Fig. 5 connected via a 5 kΩ potentiometer.

If the pin is externally connected, the potentiometer should be set in the middle of its range,

in order to prevent an undesirable closed-circuit current.

Output Voltage 1 and Output Voltage 2: The voltage value of these two inputs is multiplied

internally and determines the level of the output voltage. Output Voltage 1 is connected

internally to a potentiometer as a potential divider (see also Fig. 5). This is used to adjust the

maximum voltage that can be supplied to the micromotor without damaging it. Then via

Output Voltage 2 – e.g. using an external potentiometer – the output voltage can safely be

adjusted between 0V and the preset maximum value. If Output Voltage 1 is also connected

externally, then the internal potentiometer should be set to its mid-range position, so as to

prevent a high closed-circuit current.

RPM 1 and RPM 2: Via these two inputs the speed can be adjusted over a wide range. The

measured voltages are multiplied internally to give the speed value. The response of these

inputs can be modied via the commands mv, mav and maxav.

2.2.3 Analog Inputs

Subject to change without notication

Subject to change without notication

7

2.2.4 Digital Inputs

Start/Stop is a push-button input: If a 5V signal is applied for a short time, the on/off status of

the drive is switched over. The switch occurs when the 5V signal drops again to 0V. The input

is linked internally to a pull-up resistor so that only a pushbutton to ground (earth) needs to

be connected.

Direction is a switch input: if a positive 5V signal is applied, the drive rotates to the right

(clockwise). If the signal is 0V, it rotates the other way. This input is linked internally to a

pull-up resistor so that an external switch merely has to be switched to ground (earth).

The wiring of the Start/Stop and the Direction inputs is shown in Chapter 3.2.

AUXin is an input which can be used for various purposes. If the module is operating in one

of the Position Control Modes, the user may connect a pulse train via this input, which will

determine the position/speed of the drive. The input is switched as a digital input and expects

TTL signal levels.

In Pointer Mode, the analog voltage which determines the position of the rotor is set via this

input. It expects a voltage level between 0 and 5V.

This input is triggered internally via a zener diode. When functioning as an analog input, this

may lead to a distortion of the transfer function close to 5V. If this happens, and the program-

mer interface is set to a somewhat greater amplication factor, then the full voltage range can

no longer be exploited. See Chapter 3.8.

Note: If AUXin is switched as a digital input and is expecting a pulse train, this signal must

comply with the TTL specications and be sufciently sharply-sloping to pass as quickly as pos-

sible through the undened range between LOW and HIGH. Pulse signals with very ill-dened

edges may cause oscillations in this range, which will be counted as denite pulses.

In this event, it is recommended to pre-treat the pulses via Schmitt triggers to improve the signal.

2.2.5 Fault Input

The drive is connected to the outputs Phase A, B and C. If two supply lines are changed

around, the direction of the drive will be reversed. The total current consumption of the

power supply section ows across a resistor which is shunt-connected to earth and generates

a voltage drop. This voltage drop can be monitored via the output Isense.

2.2.6 Power Outputs and Current Detector

Subject to change without notication

Subject to change without notication

8

3. Control

The module may be controlled using two different methods:

1. Electrically via the pins or via the built-in potentiometers. The speed of the drive

is proportional to either an applied analog voltage or an applied pulse train.

2. The serial interface accepts user-generated commands. Simple externally generated

commands permit a much more detailed control than is possible via the pins.

Control via electrical signals is described in Chapters 3.1 and 3.2. Control via the programma-

ble interface is covered in Chapter 3.3.

3.1 On the Module

On the module there are three potentiometers, with which the Acceleration Ramps, Output

Voltage and Speed can be set manually.

The outputs of these potentiometers are connected, via 1 kΩ resistors, to the analog inputs

of the microcontroller. Hence, these inputs can also be controlled via external potentiometers

(in this situation, the crosstalk will be minimized if the potentiometers on the module are set

to the middle of their range).

The relevant external pins are RPM 1, Output Voltage 1 and Ramp Slope.

Fig. 5: Input switching with internal potentiometer

Warning: If the voltage on an input is very close to 0V, the Analog/Digital converter will

register a 0. Then a voltage variation on the other input will produce no change in rotational

speed, since the two inputs are multiplied together internally. For such voltage variations to

produce an effect, both voltages must be sufciently far from 0V (at least 5 mV) so that a

value different from 0 can be read.

Subject to change without notication

Subject to change without notication

3.2 External Inputs (Pins)

The description of Start/Stop and Direction inputs is given in Chapter 2.2.4. Fig. 6 shows an

example of external switching.

Fig. 6: Input switching for Start/Stop and Direction

9

Subject to change without notication

Subject to change without notication

10

3.3.1 Setup of the Programmable Interface

The programmable interface is implemented as an RS-232 compatible interface (cf Chapter 2.2.2).

It enables connection to a Personal Computer (PC) or a digital controller such as a PLC or an IPC.

Communication with the PC is possible in either of two ways:

1. Via a simple ASCII terminal program, such as that included in any Windows-based operating

system. In Windows NT this is available under the name Hyperterminal.

2.

With the program Faulhaber Motion Manager available from Dr. Fritz Faulhaber GmbH & Co. KG

(can also be downloaded free of charge via the Internet at http://www.faulhaber.de), which

allows particularly simple operation of drives. In addition it can be used to display real-time

data, such as current speed, graphically.

The serial interface is congured according to the following setup. It is important to use the

same conguration in the PC and in the controller to ensure correct operation:

9600 Baud

8 Data bits

1 Stop bit

No Parity

If a terminal program is used, symbols entered will not be displayed because the local echo is

deselected. In this event the MCBL can send these symbols back to the PC, to be displayed to

the user. This is accomplished by the command echo 1.

3.3 Conguration and Programming

Communication is carried out via commands. The user types in a command to the terminal

program. When the ENTER key is pressed, the command will be sent to the MCBL and imple-

mented by it. If the command requires a feedback from the MCBL to the user, this will be

given automatically.

Commands are structured according to the following syntax:

[NODEADDRESS] [COMMAND] [PARAMETER] <Enter>

1) NODEADDRESS: If more than one drive is addressed via the same interface, this number is

the number of the corresponding drive. If it is omitted, the command will be sent to all the

connected drives (cf Chapter 3.3.3).

2) COMMAND: A character string, using only letters of the alphabet.

3) PARAMETER: In some commands the command word is followed by a number (without

alpha-characters) which is used as the argument.

4) The CR (carriage return) character is included at the end; it is entered in a terminal program

by pressing the ENTER key.

Blank spaces will be ignored, and may be added at will. No distinction is made between capital

letters and lower-case.

Some commands return data to the PC. This always takes the form of a character string, fol-

lowed by the CR and then LF (line feed) characters.

3.3.2 Command Syntax

Subject to change without notication

Subject to change without notication

11

3.3.3 Node Addresses and Additional Drives

With the assistance of an RS-232 Multiplexer Board it is possible to control several drives from

a single RS-232 interface. For this reason a feature has been included to address each drive

individually, because otherwise every command would be implemented by every drive.

This is achieved via the Node Number.

The user must give every drive an address before it is connected to the network, using the

command nodeadr, and store it with the command save (see Chapter 3.3.4).

Subsequently, the drive can be connected to the network of the RS-232 multiplexer board.

Every command will now be preceded by a number – this is the address of the drive for which

the command is intended. If no address is given, the command is sent to all the drives on the

network. If only a single drive is connected to the serial interface, the node address can be

omitted, since the command is only intended for that drive.

Command Function Description

nodeadr Dene Node Address Assign a node address (0 to 255)

gnodeadr Get Node Address Send back the node address to the system

save Save Conguration Record all drive parameters in a non-volatile

memory

Disconnect Asynchronous Response:

Some commands send a response straight back to the user. However, a few commands do

not do this immediately, but only when a certain condition is satised. For instance, np 1000

(notify position) sends a “p” back when the position 1000 has been reached.

Such asynchronous responses create a contention problem with the node addresses because

the response does not take place immediately after the sending of the command. If several

drives happen to send back a feedback at the same time, this leads to an unreadable signal.

The user or control program will be left waiting in vain for the right response. For this reason,

in any network with several drives connected, only one drive is ever allowed to send asyn-

chronous responses. For the other drives this response is deselected by answ 0.

Command Function Description

answ

Asynchronous Answer On/Off

0 – no asynchronous responses

1 – asynchronous responses enabled

Subject to change without notication

Subject to change without notication

12

3.3.4 Saving the Settings

When it is delivered, the drive has no parameters recorded. The controller selects velocity

control mode. However, the current setup conguration can be saved with the command save

by storing it in a non-volatile memory (an EEPROM). This conguration will then be recalled

when the drive is next switched on.

Warning: The command save returns the response “saved” when the data has been stored in

the memory. From commencement of the command until this response is received the power

supply must not be interrupted, otherwise the drive will be reset to its original state.

The command fcong resets the drive to its as-delivered state (i.e. factory conguration), in the

event that all the parameters become so out of adjustment that a functioning system can no

longer be set up. In this event, further assistance may also be obtained using the command base.

Command Function Description

save Save Conguration

Record all drive parameters in a non-volatile store

fcong Factory Conguration Reset everything to the as-delivered state

base Base Conguration Reset to a safe mode; the drive will rotate

slowly, with a low output voltage

Subject to change without notication

Subject to change without notication

13

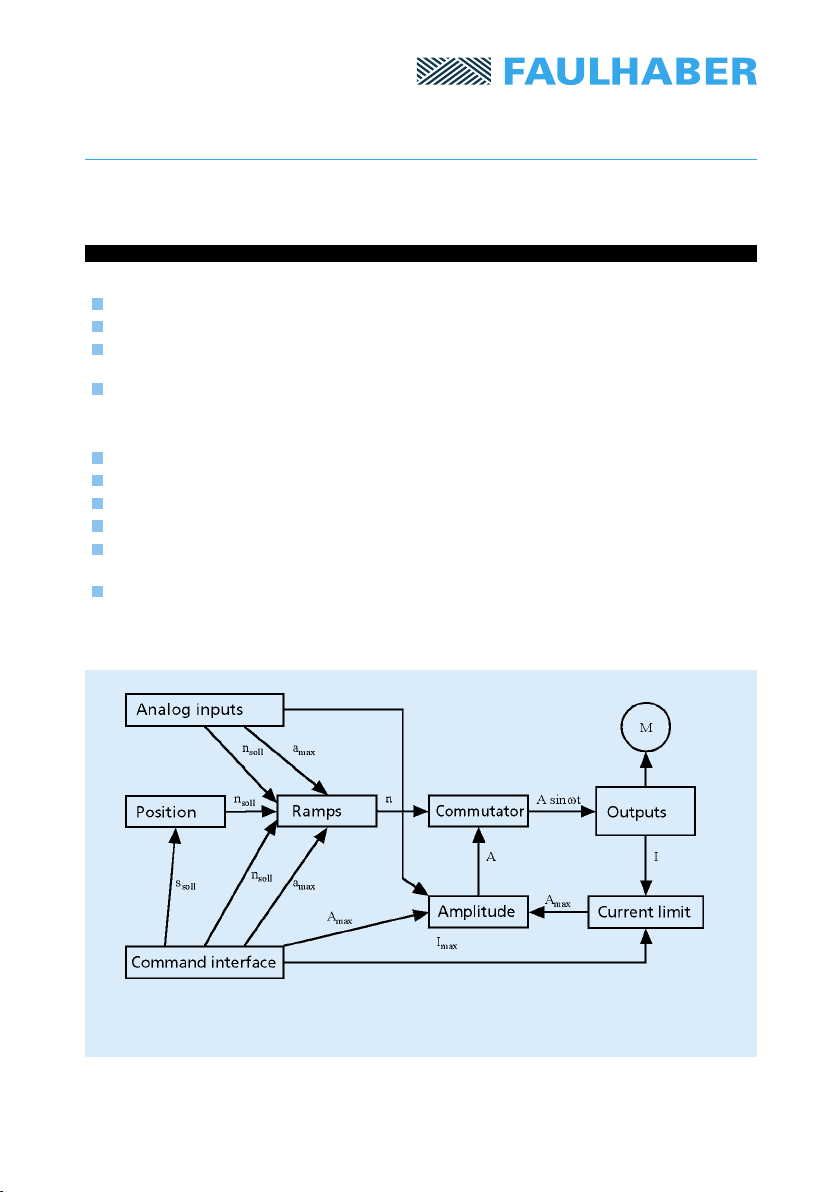

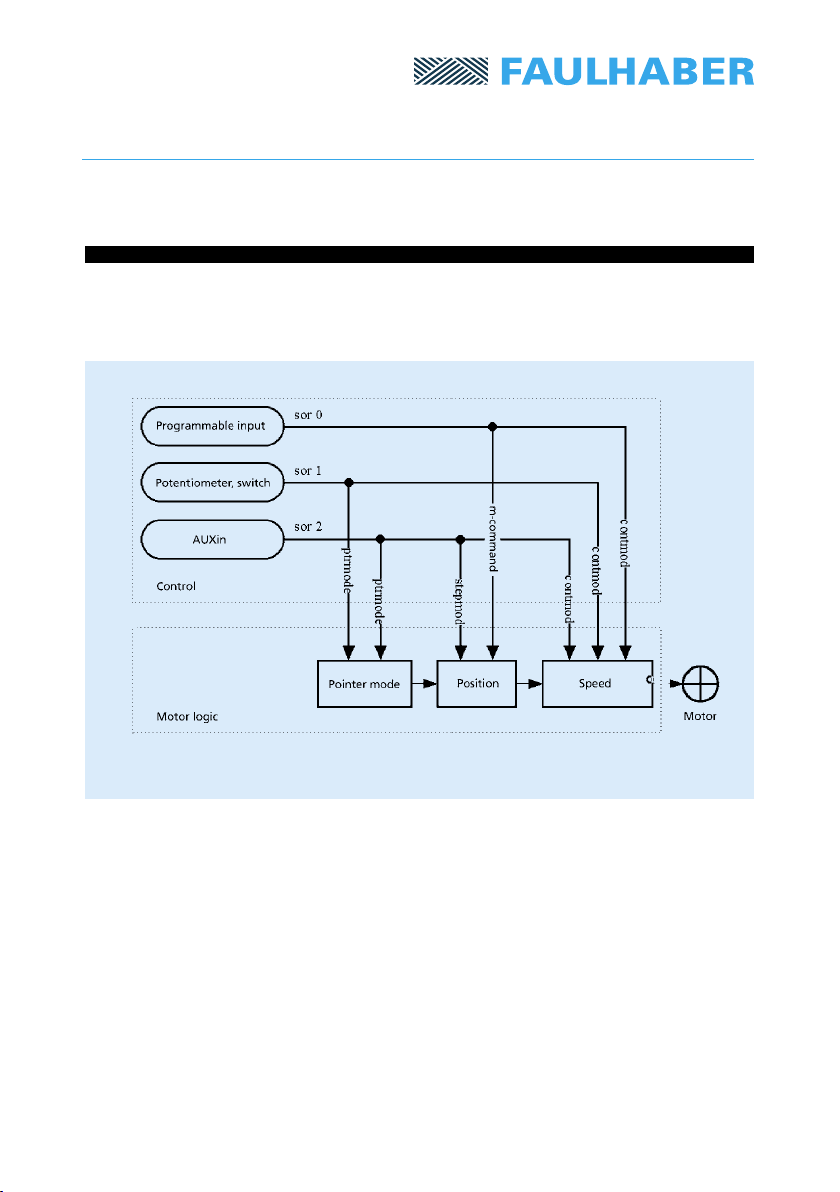

3.4 Description of the Operating Modes

The unit can be set up in either Speed Mode or Positioning Mode.

An additional Pointer Mode is available. These modes can be controlled from a variety of

input sources. The following diagram shows how the interaction between inputs and drive

modes is inuenced.

Fig. 7: Inputs and drive modes

The as-delivered MCBL application runs from analog inputs and is set to Normal Mode. This

corresponds to the commands sor 1 and contmod.

The user can control speed, output voltage and ramp rate either from built-in or external

potentiometers. If the external interface is deselected via sor 0, these parameters can be set

via the programmable interface.

Subject to change without notication

Subject to change without notication

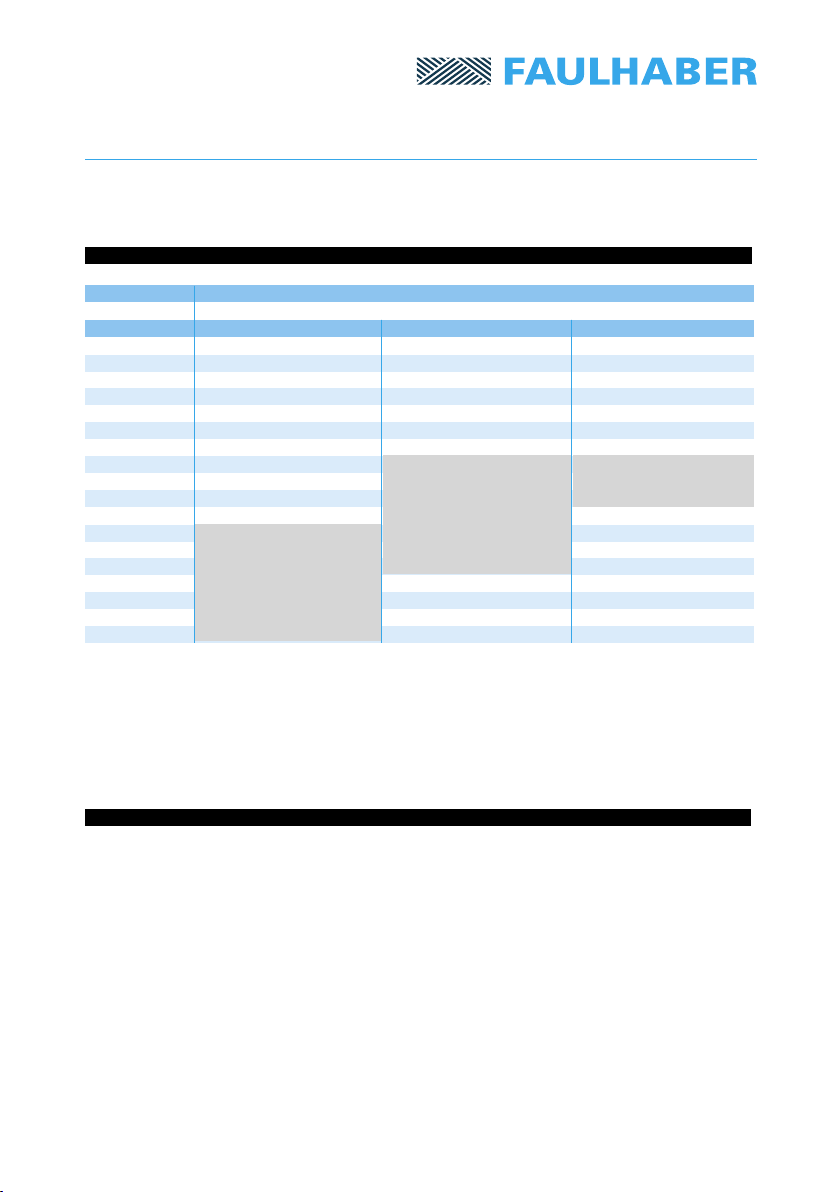

Table 1: Modes and input options

1) Remarks:

In modes sor 1 and sor 2 positioning is not possible; the m-command will be ignored.

The way in which the drive responds is always based on a combination of the mode selected

and the input source. This is shown in Table 1, in which impracticable combinations are shown

in gray. The operating modes are now briey described in turn in the following paragraphs:

3.4.1 Continuous Mode

If the normal mode contmod is selected, inputs are taken via sor commands from three

different sources:

1. sor 1 uses analog inputs: rotational speed, ramp rate and output voltage are determined

from a total of ve analog inputs. Three of these inputs are provided via potentiometers

on the board.

2. If the drive is controlled via the programmable interface, sor 0 must be used. In this case,

the drive’s external inputs will not function.

3. If sor 2 is used, the speed is determined by a pulse train input to AUXin. A more detailed

description of this option is given in the following chapters.

A special case is positioning with lr, la und m, whilst contmod is active. It functions only when

sor 0 is used. Positioning is deselected in the other two input modes because otherwise there

would be internal conicts with the speed setup.

14

Mode Input source

sor 0 sor 1 sor 2

No external input Input via pot. 1) Input is AUXin 1)

Contmod Speed via v-command Speed via pot. Pulse train dictates

speed

contmod and Position via m-command No effect (speed via pot.) No effect (pulse train

m-command dictates speed)

Stepmod No effect (pulses will be No effect (pulses will be Pulse dictates position

counted internally) counted internally) (do not use positioning

command!)

Ptrmod No effect Pot. “velocity 1“ Analog voltage sets the

sets the rotor deection rotor deection

Subject to change without notication

Subject to change without notication

3.4.2 Stepper Motor Mode

In stepper motor mode stepmod only a single input source is used, AUXin, which is connected

with sor 2.

If sor 0 or sor 1 are used, the drive will not receive a signal and will remain stationary.

Note that if a pulse train is applied to AUXin when operating in these modes the internal

counter will continue operating. If the input is then switched to AUXin via sor 2, the accumu-

lated pulse-count will be processed and the drive will be activated immediately.

3.4.3 Pointer Mode

Pointer Mode is selected by the command ptrmod, in which the rotor angle of the drive is

maintained proportional to a voltage input to AUXin (sor 2) or alternatively to the position of

the potentiometer “velocity 1“ (sor 1).

15

Command Function Description

sor Source 2 = AUXin is used as input

1 = Analog input (pot.) is used as input

0 = All external inputs will be ignored

stepmod Stepper Motor Mode Stepper motor with position preset

ptrmod Pointer Mode Instrument pointer mode

gmode Get Mode Display the selected mode in plain text

Subject to change without notication

Subject to change without notication

3.5 Velocity Control

3.5.1 Analog Speed Setup

There are several ways to set the velocity, i.e. the rotational speed: external control may be

selected via analog voltage (Chapter 3.5.1) or a pulse train input (Chapter 3.5.2). Presetting of

a rotational speed value via the programmable interface is described in Chapter 3.5.3.

The selected mode also has an indirect effect on the rotational speed: Positioning Mode (3.6),

Stepper Motor Mode (3.7) and Pointer Mode (3.8).

16

Rotational speed is setup via the analog inputs with contmod and sor 1 (see Chapter 2.2.3).

This is also the factory delivered state of the module. The programmable interface is not

relevant in this operating mode; however, the choice of speed mode can be changed via the

programmable interface.

Fig. 8: Transfer characteristic of the analog speed setup

The drive’s rotational speed will correspond to the analog voltage at the inputs Velocity 1 and

Velocity 2. The voltage must lie between 0V and 5V. In order to guarantee exible control,

the relationship between the analog voltages and the rotational speed can be varied. Direc-

tion of rotation is determined by the Direction input, not by negative analog voltages, which

are not permitted.

With the command mav, the user presets the voltage at which the drive will start up.

This is useful for applications in which no precise 0V level is available, and in which therefore

the drive cannot be brought to full standstill. The command maxav sets the voltage at which

the drive reaches its maximum rotational speed. Maximum rotational speed is set by the com-

mand sp. Minimum speed, which is different from zero, is determined via the command mv.

The drive will run when the minimum voltage applies. At lower-level voltages it will come to rest.

This manual suits for next models

1

Table of contents

Other Faulhaber Amplifier manuals