Faulhaber BLD 5606 Series User manual

BLD 5603 BLD 5606

Series

Operating Instructions

Servo Amplier

4-Quadrant PWM for Brushless DC-Servomotors

Series

http://www.minimotor.ch/minicatalog/pdf/DriveCircuits/Manuals/IM_e_BLD_5603_5606.pdf

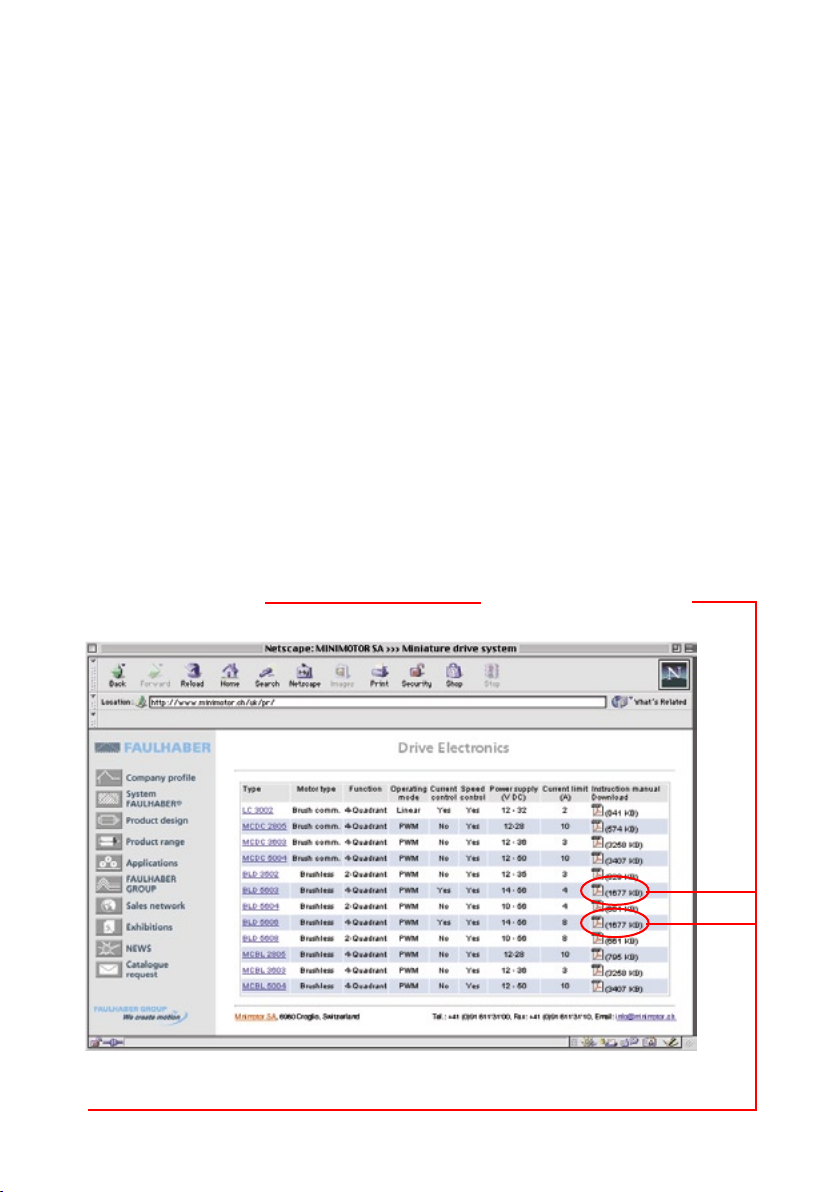

Surf to the following Internet

address and you will nd the

latest edition of the instruction

manual on-line: www.minimotor.ch/uk/pr/

For direct Download:

w

w

w

.

f

a

u

l

h

a

b

e

r

.

c

o

m

Miniature Drive Systems

Micro Drives

DC-Micromotors

Precision Gearheads

Servo Components

Drive Electronics

1

Index

General Information

1. Description

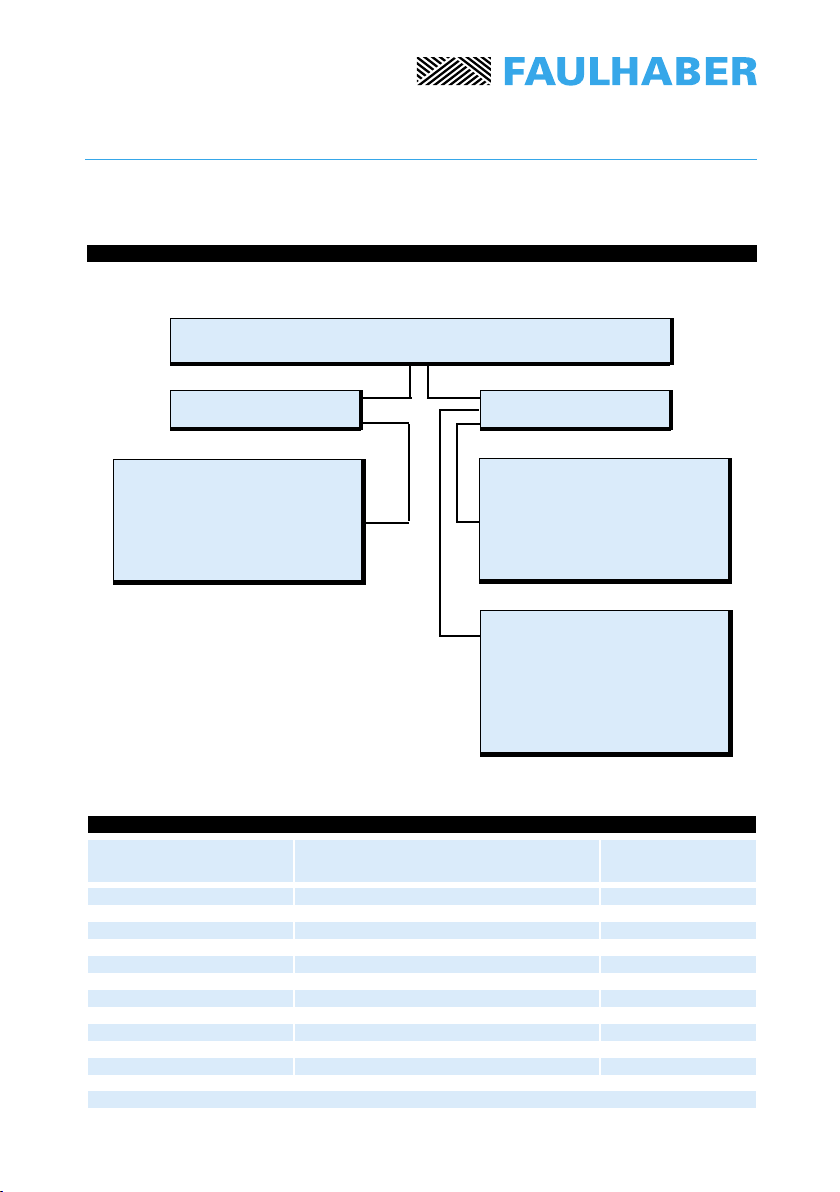

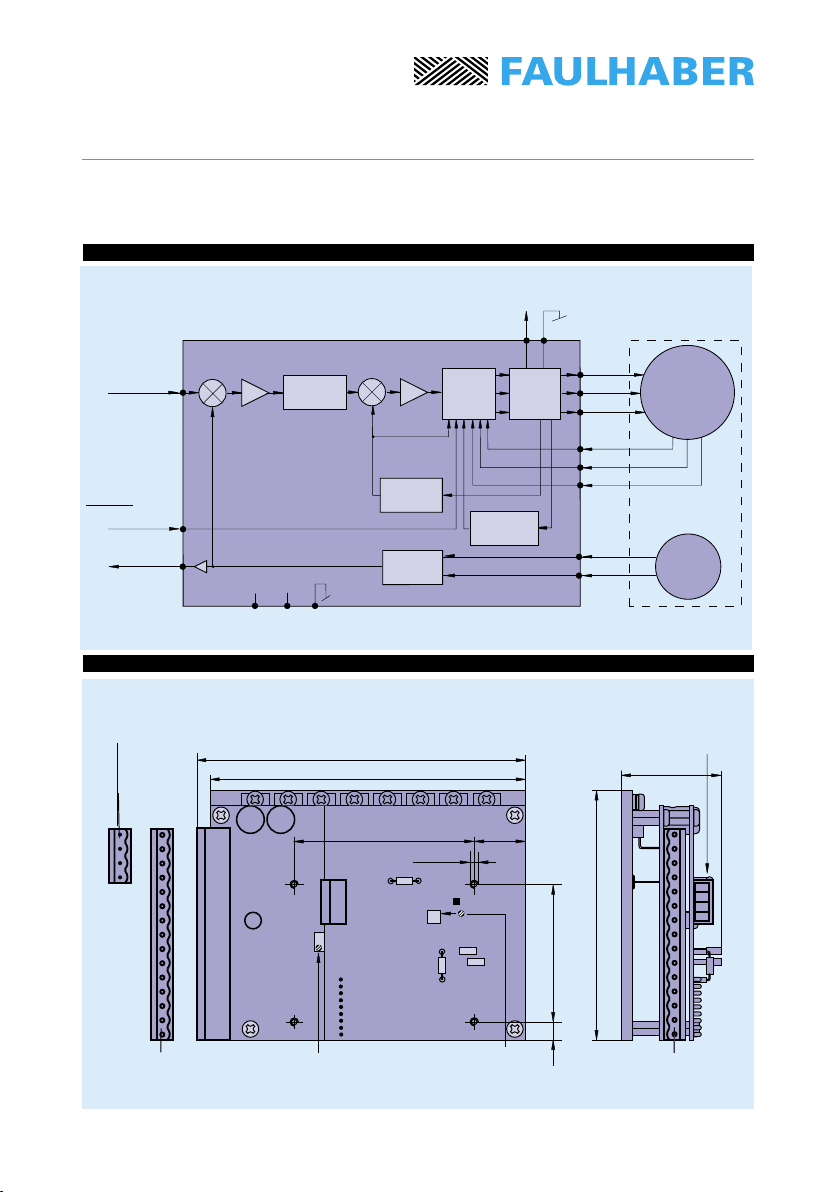

2. Application diagram

3. Combination possibilities

Technical Data

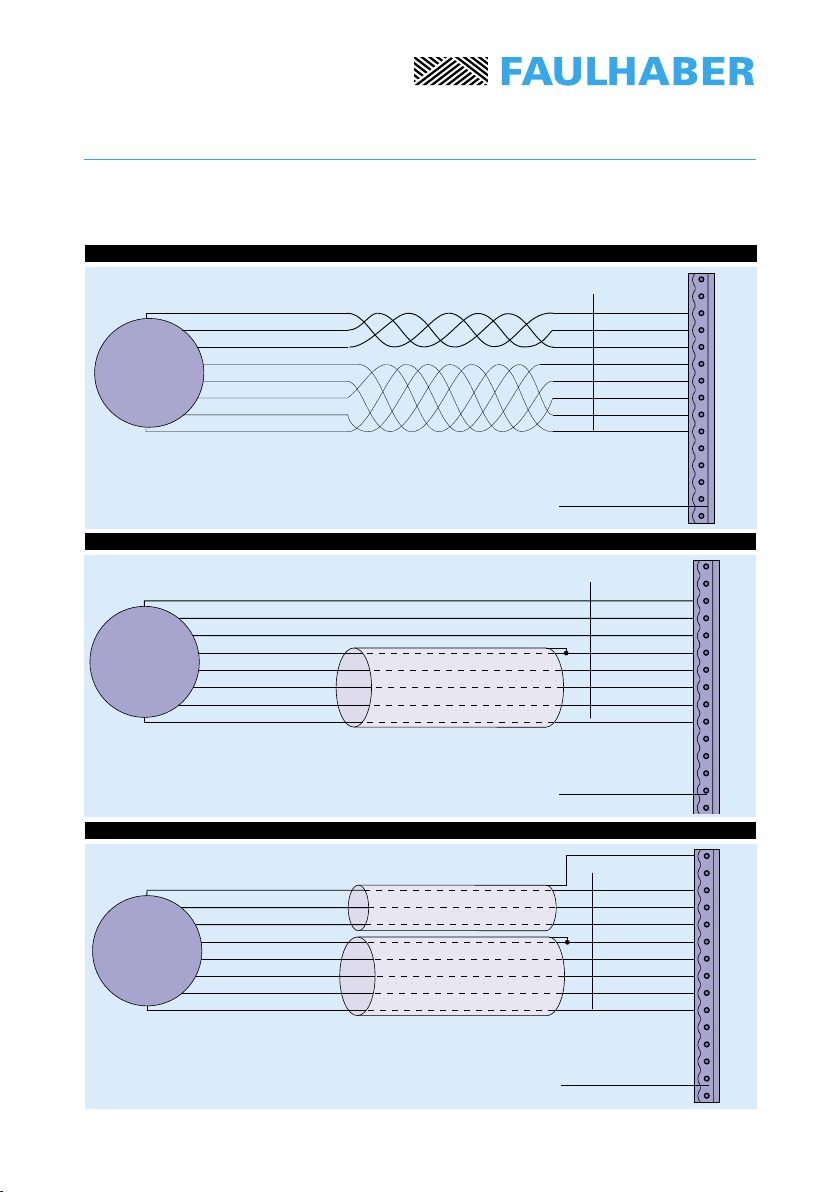

4. Dimensions and weight

5. Maximum ratings

6. Specic characteristics

General Characteristics

7.1 Speed regulator, type PI

7.2 Overheating protection

7.3 Current limiter, type I2t

7.4 Enable

7.5 Motor-Speed Monitor

7.6 High PWM frequency

Servo Ampliers BLD 5603-CC4P and BLD 5606-CC4P for Current Control

8. Basic circuit diagram

9. Dimensional drawing

10. Connection diagram

Servo Ampliers BLD 5603-SH4P and BLD 5606-SH4P for Speed Control

Notice of Use

Start-Up Procedure

18.1 Servo ampliers BLD 5603-CC4P and BLD 5606-CC4P for current control

18.2 Servo ampliers BLD 5603-SH4P and BLD 5606-SH4P for speed control

18.3 Servo ampliers BLD 5603-SE4P and BLD 5606-SE4P for speed control with encoder

18.4 Offset adjustment

18.5 Selection of R7 for servo ampliers BLD 5603-SH4P and BLD 5606-SH4P

18.6 Selection of R7 for servo ampliers BLD 5603-SE4P and BLD 5606-SE4P

18.7 Current limiter

18.8 Optimizing the speed regulator

18.8.1 Optimizing procedure

18.8.2 Optimizing R7

18.8.3 Load inuence

18.8.4 Function of R1, C1 and C2

Servo Ampliers BLD 5603-SE4P and BLD 5606-SE4P for Speed Control

11. Basic circuit diagram

12. Dimensional drawing

13. Connection diagram

14. Basic circuit diagram

15. Dimensional drawing

16. Connection diagram

17. Special considerations

17.1 Signal command

17.2 Power supply

17.3 Wiring

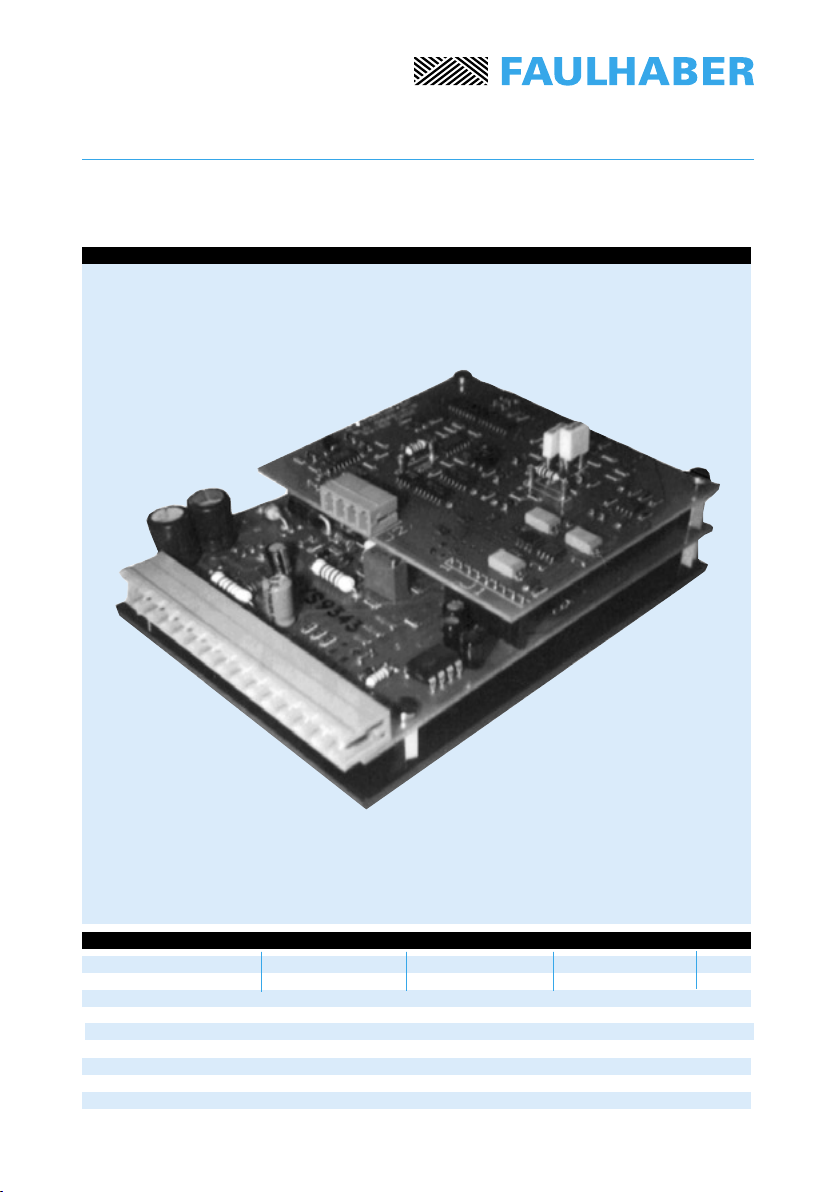

1. Description

The BLD 5603 and the BLD 5606 are 4-quadrant PWM servo ampliers suitable for the

three-phase brushless DC-servomotors, type 2036, 2444, 3056 and 3564.

The Servo Ampliers use a combination of SMD (Surface Mounted Device), MOSFET power

stage and PWM (Pulse-Width Modulation) technologies to achieve both, compact design and

high power efciency.

The basic board of the servo ampliers is a single level PCB structure, which performs all

the commutation and protective functions and contains the power stage mounted on the

heat sink plate.

The ampliers are available in two different function modes: Current control and Speed

control.

Current control (basic boards)

- BLD 5603-CC4P or BLD 5606-CC4P

In the ampliers the current owing in the active phases of the motor is regulated by the

analog current command. The ampliers are designed for use with a position controller or

in constant torque applications.

Speed control (two amplier congurations are available)

– BLD 5603-SH4P or BLD 5606-SH4P > the type SH4P uses the Hall sensor signals of the

brushless DC-servomotor to allow precise regulation at speed above 1000 rpm.

– BLD 5603-SE4P or BLD 5606-SE4P > the type SE4P is able to regulate at much lower

speeds, depending on the encoder resolution. Typical speed with 500 line encoder down

to 20 rpm.

These two servo ampliers consist of the basic board with optional modules.

These modules have a special frequency-to-voltage converter, allowing accurate

motor speed control and are provided with a current limiter function, type I2t.

The maximum continuous output power without additional heat sink is 220 W.

For ease of installation a loose female terminal block is supplied together with the main

board connector.

General Information

2Specications subject to change without notice

BLD 5603-CC4P

BLD 5606-CC4P

BLD 5603-SH4P

BLD 5606-SH4P

BLD 5603-SE4P

BLD 5606-SE4P

5500

5500

2036 U ... B, 2444 S ... B

3056 K ... B, 3564 K ... B

2036 U ... B, 2444 S ... B

3056 K ... B, 3564 K ... B

2036 U ... B, 2444 S ... B

3056 K ... B, 3564 K ... B

3.

3

2.

Servo Ampliers BLD 5603 and 5606

The Servo Ampliers type

BLD 5603-SE4P and

BLD 5606-SE4P are the

basic board with an additional

module for speed control of

brushless DC-Servomotors

with an additional encoder.

Current control Speed control

The Servo Ampliers type

BLD 5603-CC4P and

BLD 5606-CC4P are the

basic board suitable for the

current control (torque control)

of brushless DC-Servomotors.

The Servo Ampliers type

BLD 5603-SH4P and

BLD 5606-SH4P are the

basic board with an additional

module for speed control of

brushless DC-Servomotors

Application diagram

General Information

Servo Ampliers

Type

Encoders

Type

Brushless DC-Servomotors

Type

Combination possibilities

Specications subject to change without notice

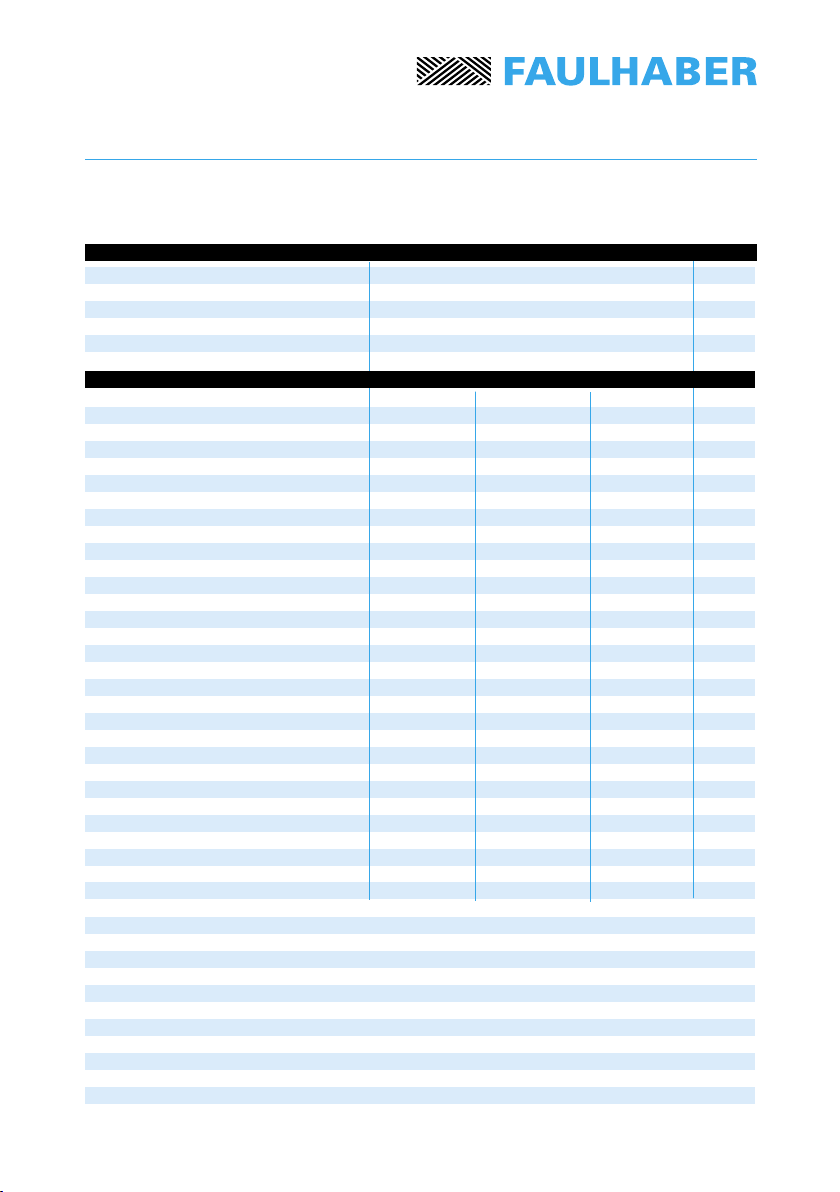

CC4P SH4P SE4P

119,3 x 90,5 x 29 119,3 x 90,5 x 37 119,3 x 90,5 x 37 mm

195 225 225 g

4

Technical data

Format (L x W x H)

Weight

Specications subject to change without notice

4. Dimensions and weight

5

Technical data

to

Specications subject to change without notice

14 ÷ 56 14 ÷ 56 14 ÷ 56 V DC

2,0 2,0 2,0 V DC

150 150 150 kHz

0,6 / 1,2 – – A/V

4 / 8 4 / 8 4 / 8 A

±5 ±5 ±5 V DC

20 220 150 kΩ

23 0.1 1 kHz

TTL TTL TTL

+5 +5 +5 V DC

–5 –5 –5 V DC

60 140 140 mA

40 000 1000 ÷ 40 000 40 000 rpm

– 40 40

0 … +70 0 … +70 0 … +70 ˚C

–20 … +80 –20 … +80 –20 … +80 ˚C

1)

2)

3)

4)

Power stage:

– Power supply

– Total output voltage drop (Imotor = 4A)

Switching frequency

Transconductance gain

(BLD 5603/BLD 5606)

Current limit1) (BLD 5603/BLD 5606)

Analog input command:

– Voltage range 2)

– Input resistance

– Frequency bandwidth

Logical input

Ouptput voltage for external use:

– Positive (50 mA max. load)

– Negative ( 5 mA max. load)

Total stand-by current, typical

(Hall sensors included)

Speed range 3) to to

Dynamic range 4)

Temperature range:

– Operating temperature

– Storage temperature

Cycle by cycle current limiting.

Analog input command (positive voltage = CW – negative voltage = CCW)

may be set by an external potentiometer or an external voltage.

Depending on the motor type and/or encoder characteristics.

Maximum to minimum controllable speed ratio: nmax/nmin.

6. CC4P SH4P SE4P

Specic characteristics

5.

56 V DC

–6 +6 V DC

4 A

Maximum ratings

Power supply

Analog and logic inputs

Continuous output current @TA = 25˚C

7.

0

n,I

Ilim

t

Ip1 Ip2

Ic2

Ic1

Ic3

t1t2t3t4t5

n=

I =

t =

6

General characteristics

7.1 Speed regulator, type PI

A Speed Regulator type Proportional Integrator (PI) controls a brushless DC-servomotor with

no steady-state error (step input command).

7.2 Overheating protection

The servo amplier automatically shuts off if the heat sink temperature exceeds +75 ˚C.

A temperature below +70 ˚C will restart the servo amplier.

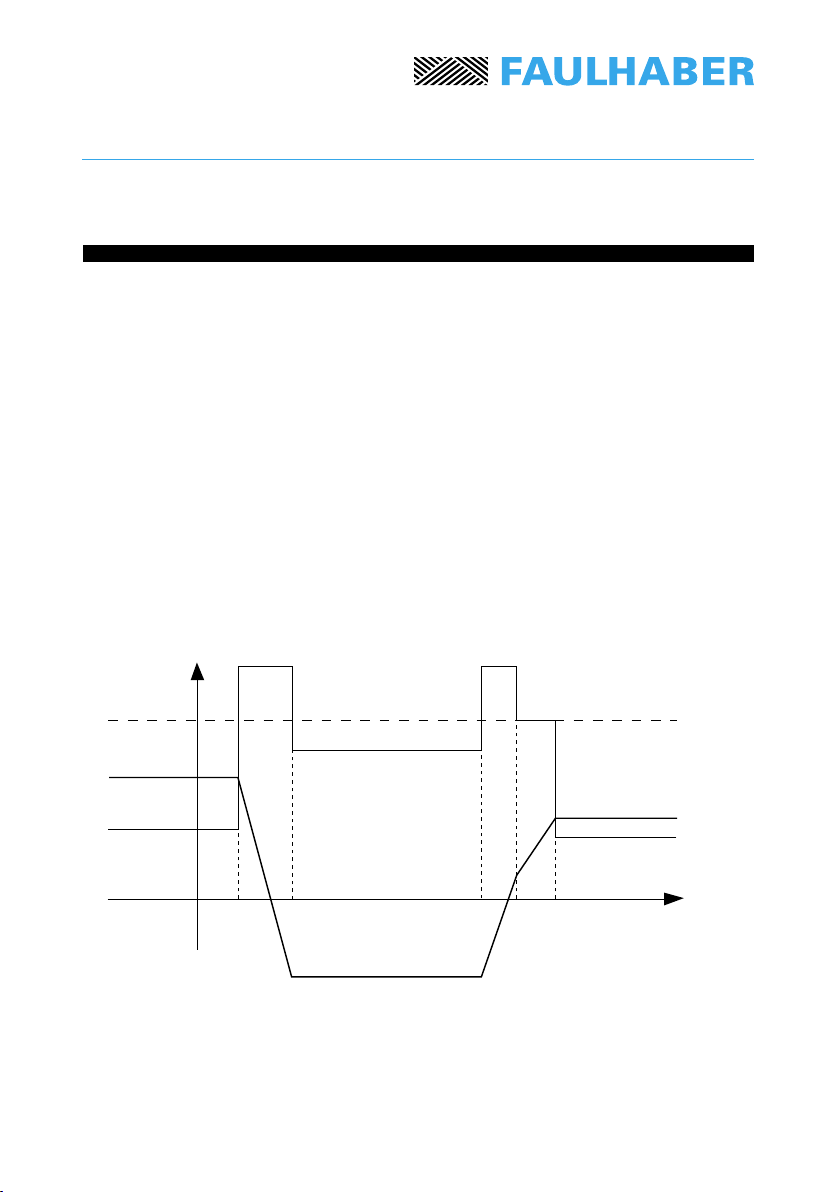

7.3 Current limiter, type I2t

A brushless DC-servomotor tolerates peak currents much higher than the maximum

continuous current admissible, though only for a limited period of time. A current limiter,

type I2t, takes these characteristics into account and, in addition, provides excellent protection

against a possible overload.

To illustrate the operation of this current limiter, the following gure provides an example of

a brushless DC-servomotor operating in an Acceleration-Constant Speed-Deceleration cycle.

motor speed [rpm]

motor current [A]

time [s]

General characteristics

Specications subject to change without notice

Ip[A] – Ic[A]

T[s] = 10,34 [s] loge

Ip[A] – Ilim [A]

7

peak current

continuous current

max. continuous admissible current

The continuous current limit, Ilim, is set according to the specic application. From the above

gure one can deduce that for t < t1, the motor is fed by a current less than the current limit.

In the deceleration phase (interval t1, t2), the current assumes the value Ip1 > llim.

The presence of the limiter allows the power rating to be exceeded without any risk to the

motor. The maximum overload period of the motor T[s] depends directly on the peak current

value and on the actual current before the overload:

In the event of an overload period longer than the maximum T period, the servo amplier will

impose the current Ilim which will continue for the duration of the overload (e.g.: interval [t4, t5]).

N.B.: When the limiter is active, the servo amplier has no control on the motor speed.

7.4 Enable

The servo amplier is disabled when contacts 7 and 11 are connected (high level).

Opening this connection (low level) enables the power stage. This input is for contact

closures only (e.g.: relay contacts).

7.5 Motor-Speed Monitor

The Motor-Speed Monitor (contact 15 of the connector), generates a voltage proportional

to the actual motor speed.

7.6 High PWM frequency

The high PWM frequency of 150 kHz allows the servo amplier to exploit the technical

characteristics of brushless DC-servomotors to the utmost.

Ip =

Ic =

Ilim =

General characteristics

Specications subject to change without notice

BLD 5603-CC4P

BLD 5606-CC4P

9.

8.

9.

+–

+5V –5V

114,3

24

90,5

119,3

18,8

65

4x M3

6,5 50

BLD 5603/06

MINIMOTOR SA

Swiss made

29

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

MSTB 2,5/15-ST

(Phoenix contact)

MSTBA 2,5/15-G

(Phoenix contact)

8

Current

command

GND logical

Current

amplier

Controller

Brushless

DC-Servomotor

Power

stage

Current

feedback

Thermal

shutdown

Ph A

Ph B

Ph C

Hs A

Hs B

Hs C

Dimensional drawing

GND

Enable

Vm

For combination with:

Brushless DC-Servomotors: 2036, 2444, 3056, 3564

Basic circuit diagram

Scale

reduced

Female terminal block,

type: Pot. : Offset

trimmer adjustment

Specications subject to change without notice

Servo Ampliers for current control

Male terminal block,

type:

BLD 5603-CC4P

BLD 5606-CC4P

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

+5V

+5V

+5V

+5V

–5V

10kΩ

9

10.

Servo Ampliers for current control

Connection diagram

GND

14 ÷ 56V Vm

Phase A

Phase B

Phase C

GND logical

Logical supply +5V

Hall sensor C

Hall sensor B

Hall sensor A

Enable

Supply -5V

Current command

Before connecting it is recommended to read chapter 17, Special considerations.

Logical supply

output

Power supply

Phase output

Hall sensors

Logical command

Analog

command

Brushless

DC-Servomotor

Brown

Orange

Yellow

Black

Red

Grey

Blue

Green

Specications subject to change without notice

For combination with:

Brushless DC-Servomotors: 2036, 2444, 3056, 3564

BLD 5603-SH4P

BLD 5606-SH4P

9.

11.

12.

+

–+–

I2t

+5V –5V

114,3

37

90,5

119,3

18,8

65

4x M3

6,5

50

BLD 5603/06

MINIMOTOR SA

Swiss made

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

R7

R1 C2

C1

Test point TP

10

MSTBA 2,5/15-G

(Phoenix contact)

MSTB 2,5/15-ST

(Phoenix contact)

Dimensional drawing

Servo Ampliers for speed control

For combination with:

Brushless DC-Servomotors: 2036, 2444, 3056, 3564

Speed

command

Controller

Brushless

DC-Servomotor

Power

stage

Current

feedback

Thermal

shutdown

Ph A

Ph B

Ph C

Hs A

Hs B

Hs C

GND

Speed

amplier

Current

limiter

Current

amplier

F/V

converter

GND logical

Enable

Motor-Speed

Monitor

Vm

Speed feedback

Scale

reduced

Pot.

:

Offset trimmer

adjustment

Pot. :

Current

Limiter

Female terminal block,

type:

Basic circuit diagram

Male terminal block,

type:

Specications subject to change without notice

13.

11

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

+5V

+5V

+5V

+5V

–5V

10kΩ

BLD 5603-SH4P

BLD 5606-SH4P

Servo Ampliers for speed control

Connection diagram

GND

14 ÷ 56V Vm

Phase A

Phase B

Phase C

GND logical

Logical supply +5V

Hall sensor C

Hall sensor B

Hall sensor A

Enable

Supply -5V

Speed command

Motor-Speed Monitor

Before connecting it is recommended to read chapter 17, Special considerations.

Logical supply

output

Power supply

Phase output

Hall sensors

Logical command

Analog

command

Brushless

DC-Servomotor

Brown

Orange

Yellow

Black

Red

Grey

Blue

Green

Specications subject to change without notice

For combination with:

Brushless DC-Servomotors: 2036, 2444, 3056, 3564

9.

14.

15.

114,3 37

90,5

119,3

18,8

65

4x M3

6,5 50

BLD 5603/06

MINIMOTOR SA

Swiss made

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

R7

R1 C2

C1

Test point TP

1a

2a

3a

4a

BLD 5603-SE4P

BLD 5606-SE4P

+

–+–

I2t

+5V –5V

12

Female terminal block,

type: MSTB 2,5/15-ST

(Phoenix contact)

Male terminal block,

type: MSTBA 2,5/15-G

(Phoenix contact)

Pot. :

Current

Limiter

Male terminal block,

type: MC 1,5/4-ST 3,81

(Phoenix contact)

Pot.

:

Offset trimmer

adjustment

Female terminal block,

type: MC 1,5/4-G-3,81

(Phoenix contact)

Scale reduced

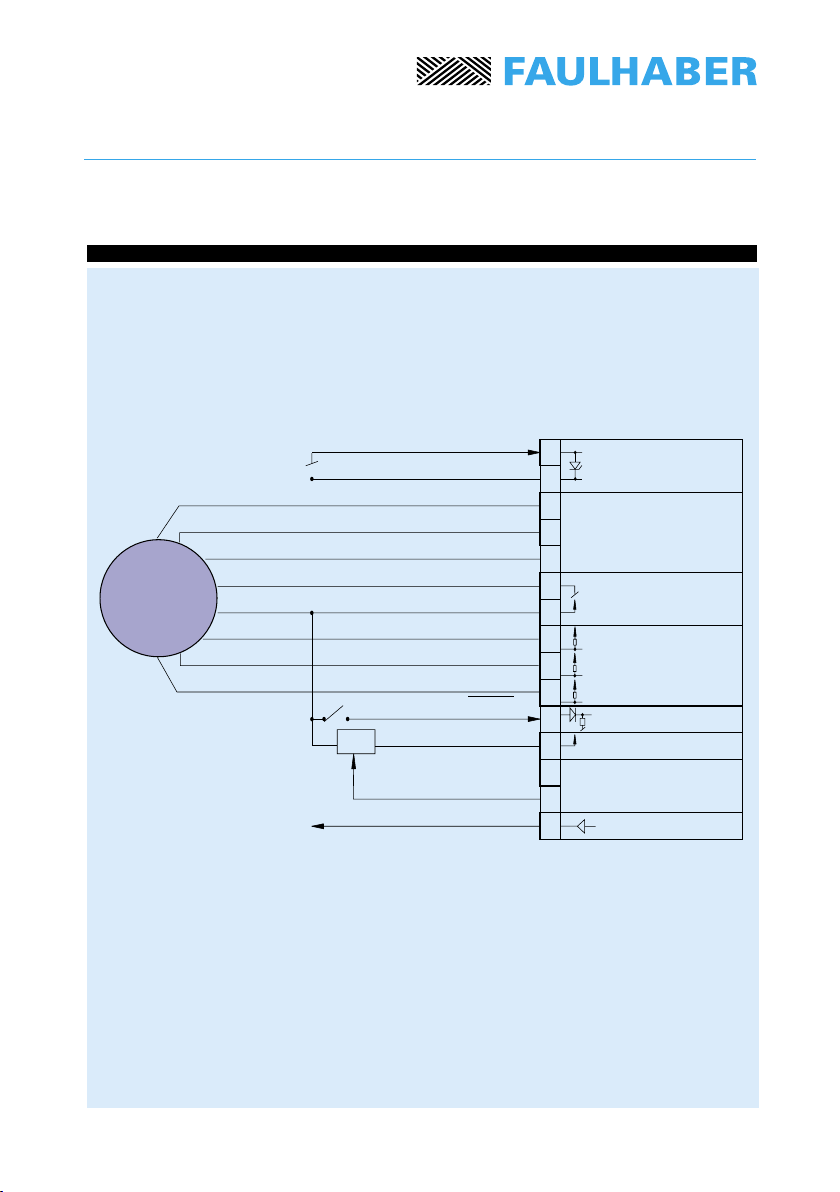

GND logical

Controller

Power

stage

Current

feedback

Thermal

shutdown

GND

Speed

amplier

Current

limiter

Current

amplier

F/V

converter

Ch A

Ch B

Brushless

DC-Servomotor

Encoder

Vm

Speed

command

Ph A

Ph B

Ph C

Hs A

Hs B

Hs C

Enable

Motor-Speed

Monitor

Dimensional drawing

Servo Ampliers for speed control

Basic circuit diagram

Speed feedback

Specications subject to change without notice

For combination with:

Brushless DC-Servomotors: 2036, 2444, 3056, 3564

Encoders: 5500

16.

BLD 5603-SE4P

BLD 5606-SE4P

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

+5V

+5V

+5V

+5V

–5V

10kΩ

1a

2a

3a

4a

+5V

+5V

+5V

13

Servo Ampliers for speed control

Connection diagram

GND

14 ÷ 56V Vm

Phase A

Phase B

Phase C

GND logical

Logical supply +5V

Hall sensor C

Hall sensor B

Hall sensor A

Enable

Supply -5V

Speed command

Motor-Speed Monitor

Before connecting it is recommended to read chapter 17, Special considerations.

Logical supply

output

Power supply

Phase output

Hall sensors

Logical command

Analog

command

Encoder Encoder

* Encoder cable supply on request

GND logical

Channel B

Channel A

+Vcc

Brown

Orange

Yellow

Black

Red

Grey

Blue

Green

* Black

* Brown

* White

* Red

Specications subject to change without notice

For combination with:

Brushless DC-Servomotors: 2036, 2444, 3056, 3564

Encoders: 5500

Brushless

DC-Servomotor

17.

14

Notice of Use

Special considerations

17.1 Signal command

The signal command is given by an external voltage of ± 5 Volts or by a potentiometer

connected directly to the servo amplier. The total potentiometer resistance must be between

10 kΩ and 47 kΩ. Before connecting it is recommended to read this chapter to obtain a good

operation of the brushless DC-Servomotor.

17.2 Power supply

Any unstabilized DC power supply voltage within the servo amplier range (14V ≤ Vm ≤ 56V)

may be used, although it is advisable to keep this voltage as low as possible in order to

minimize the EMI noise. Thus the optimum power supply is given by the following relation:

with: R, kE = Terminal resistance (phase to phase) and Back-EMF constant of the motor

Imax, nmax = Maximum current and speed reached by the motor in your specic application.

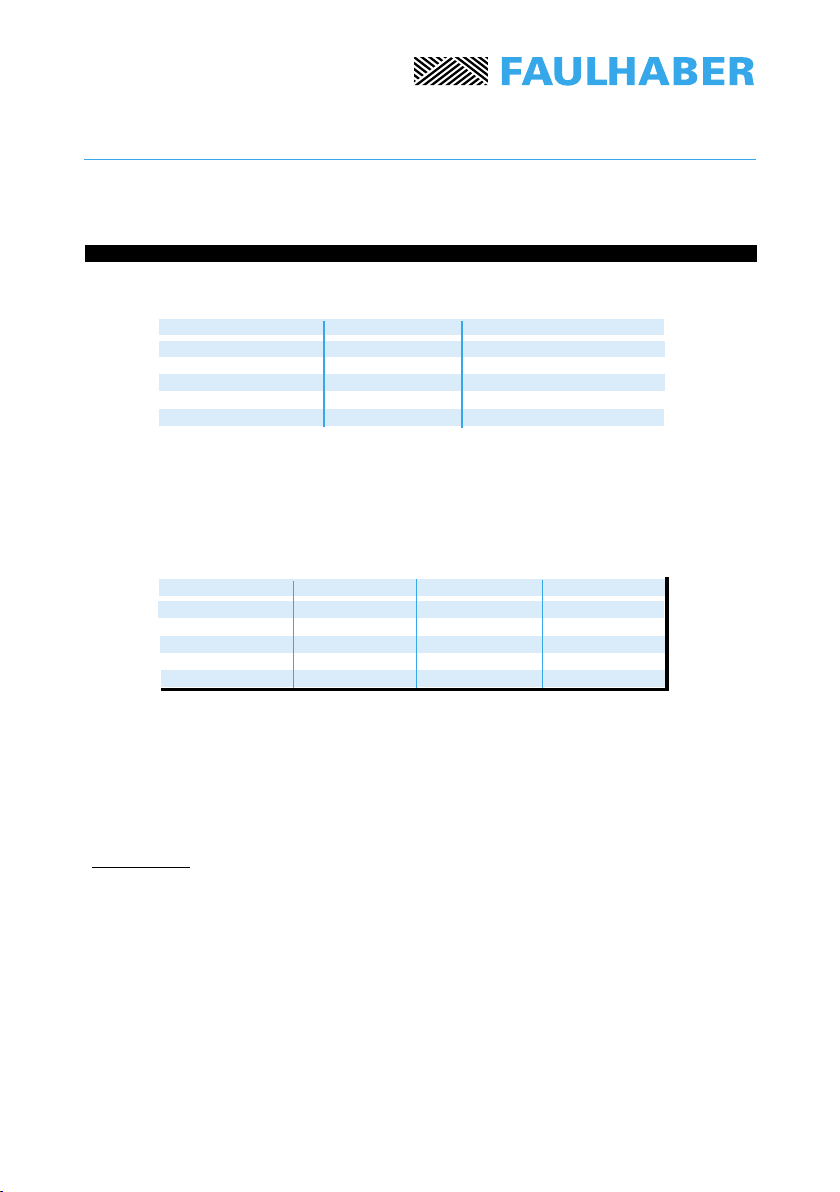

17.3 Wiring

A well known disadvantage of Pulse Width Modulation, PWM, is the large amount

of interferences generated. This has two consequences, namely perturbations to the

environment and self-perturbations.

The EMI is generated in the motor power leads and induced in the Hall sensor wires.

The smooth running of the motor is therefore perturbated and even in some cases,

the motor will not run at all.

In order to reduce the effect of these perturbations, there are some basic rules to follow:

• Use wires as short as possible;

• Avoid to run signal wires (logical and analog commands, Hall sensor and encoder signals)

in close proximity to power lead wires (power supply and servomotor phases);

• Connect shielded wires to ground at one end only to avoid ground loops.

Specications subject to change without notice

Vm [V] ≈ 5 [V] + R [Ω] · Imax [A] + kE [V/rpm] · nmax [rpm]

15

1. No special care no no no 0,3 m

2. Twisted wires (see gure 1) slightly slightly slightly 1,0 m

3. Shielded Hall sensor wires (see gure 2) no yes yes 5,0 m

4. Shielded Hall sensor and phases wires yes yes yes 5,0 m

(see gure 3)

To: perturbations To environment reduced

From: perturbations From environment reduced

Self: self-perturbations reduced

Length: maximum cable length

In case of wires longer than the standard product (0,3 m), it is recommended to use

the following cable sections:

Phase, brushless DC servomotors type, 2036 ... B, 2444 ... B: 1,0 mm2 / AWG 18;

Phase, brushless DC servomotors type, 3056 ... B, 3564 ... B: 1,5 mm2 / AWG 16;

Hall sensors, brushless DC servomotors 2036, 2444, 3056 and 3564: 0,5 mm2 / AWG 20;

Note: If wires longer than 5 m please consult us.

Notice of Use

Specications subject to change without notice

Action To From Self Length

Special care should be given to the motor connection.

The following table summarize the different solutions:

16

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Twisted wires

Shielded phase and Hall sensor wires

Figure 3

Brown

Orange

Yellow

Black

Red

Grey

Blue

Green

Phase A

Phase B

Phase C

GND logical

Logical supply +5V

Hall sensor C

Hall sensor B

Hall sensor A

Shielded Hall sensor wires

Figure 1

Figure 2

Brown

Orange

Yellow

Black

Red

Grey

Blue

Green

Phase A

Phase B

Phase C

GND logical

Logical supply +5V

Hall sensor C

Hall sensor B

Hall sensor A

Brown

Orange

Yellow

Black

Red

Grey

Blue

Green

Phase A

Phase B

Phase C

GND logical

Logical supply +5V

Hall sensor C

Hall sensor B

Hall sensor A

Brushless

DC-Servomotor

Notice of Use

Specications subject to change without notice

Brushless

DC-Servomotor

Brushless

DC-Servomotor

Connector

Connector

Connector

18.1

18.2

18.3

18.4

17

Start-up Procedure

Procedure

- Connect the servo amplier

- Power the servo amplier

- Adjust offset

References

10. Connection diagram

18.4 Offset adjustment

Procedure

- Connect the servo amplier

- Adjust offset

- Connect SE4P module to encoder

- Select R7, R1, C1 and C2

- Set current limit

References

16. Connection diagram

18.4 Offset adjustment

18.6 Selection of R7 for servo amplier

BLD 5603/06-SE4P

7.3 and 18.7 Current limiter

References

13. Connection diagram

18.4 Offset adjustment

18.5 Selection of R7

for servo amplier BLD 5603/06-SH4P

7.3 and 18.7 Current limiter

Procedure

- Connect the servo amplier

- Adjust offset

- Select R7, R1, C1 and C2

- Set current limit

Offset adjustment

The offset is adjusted changing potentiometer Pot. , (the position is indicated in

chapters 9,12 and 15 "Dimensional drawing").

Important: This setting is made by Minimotor (potentiometer Pot. sealed), hence

no other intervention is required.

Specications subject to change without notice

Servo Ampliers BLD 5603/06-CC4P for current control

Servo Ampliers BLD 5603/06-SH4P for speed control

Servo Ampliers BLD 5603/06-SE4P for speed control with encoder

9.

18.5

18

Start-up Procedure

Select resistor R7 adapted to the specic application considering also the motor

characteristics (see data sheets):

Selection of R7 for Servo Ampliers BLD 5603/06-SH4P

nmax [rpm] – max. controllable speed;

Gain [rpm/V] – gain factor of servo amplier; corresponds to ratio

between motor speed and speed command.

Resistor R7 mounted originally: 11KΩ / 0.6W / 1%.

Brushless DC servomotor 3564 K 024 B; max. speed of motor in this application

nmax = 8 000 rpm.

1. Selection of resistor R7:

R7 = 33 kΩ, resulting in a max. speed of 10 000 rpm, values slightly above 8 000 rpm

allows to operate in a broad speed range.

2. Knowing the dynamic range ( = 40) of the amplier allows to calculate the min.

controllable speed for this application, i.e.: 10 000 rpm / 40 = 250 rpm. However this

min. speed of 250 rpm is not reachable, the min. speed reachable with the SH4P

module is approx. 700 rpm and depends on a large extent of the specic application.

In general, for applications for a speed below 1 000 rpm, the use of servo amplier

BLD 5606-SE4P or BLD 5603-SE4P is recommended.

Application 1:

Table 1: Values of components R1, C1 and C2 recommended

for different speed ranges (R7)

For detailed description of components R7, R1, C1 and C2 see chapter:

18.8. “Optimizing the speed controller”.

40 000 8,2 8 140

30 000 11 6 090

20 000 16 4 180

15 000 22 3 040

10 000 33 2 040

nmax [rpm] R7 [kΩ] Gain [rpm/V]

8,2 240 1 22

11 240 1 22

16 150 1 22

22 150 1 22

33 120 1 33

Specications subject to change without notice

R7 [kΩ] R1 [kΩ] C1 [µF] C2 [nF]

This manual suits for next models

7

Table of contents

Other Faulhaber Amplifier manuals

Popular Amplifier manuals by other brands

WILSON PRO

WILSON PRO PRO 1100 installation guide

Axxent

Axxent AX-1121TS user manual

Teac

Teac A-X5030 owner's manual

Origin Acoustics

Origin Acoustics A1250 installation manual

Krell Industries

Krell Industries Evolution Owner's reference

Powerwave Technologies

Powerwave Technologies G3S-800-180-29 Installation & service manual