FBR FGP 50/M EVO User manual

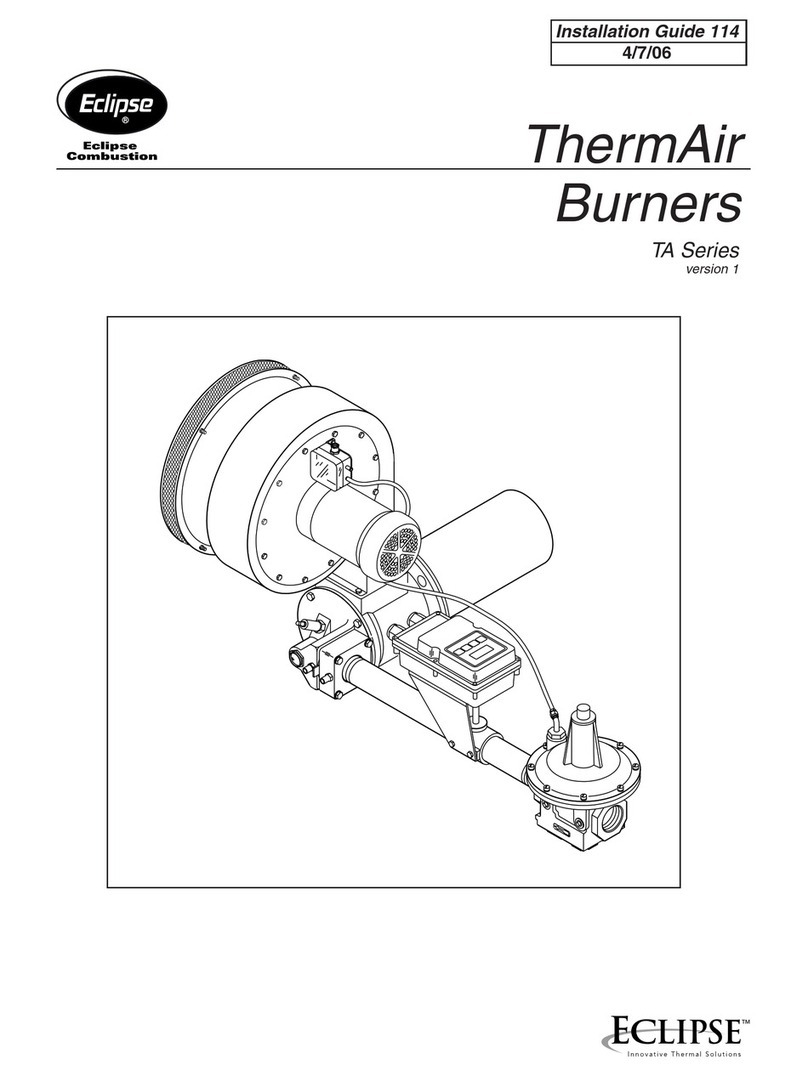

LIGHT-OILBURNERSTWOSTAGESPROGRESSIVEORMODULATINGSK070003_A_gbFGP50/MEVOBRUCIATORIDIGASOLIOBISTADIOPROGRESSIVIOMODULANTIFGP50/MEVOLight-oilburnerstwostagesprogressiveormodulatingoperation(ifequippedwithadditionofoptionalmodulationkitPIDandprobe;toguaranteeanidealproportionalityofthepowersuppliedtothethermalload).Composedby:fanathighpressurisationatreversebladesandcombustionheadwithadjustmentathighefficiencyandhighflamestability.Compactoveralldimensionsanddispositionrationalizedofthecomponentswithaccessibilityfacilitatedfortheoperationsofsettingandmaintenance.Completeofnozzle,flexiblepipesandlinefilter.Completeofflangeandgasketforinstallationongenerator.Fig. 1 FGP50/MEVO

SK070003_A_gbFGP50/MEVOTECHNICALDATAFGP50/MEVOOPERATINGRANGEDIAGRAMFGP50/MEVOFig. 2 X=ThermalpowerY=PressioninthecombustionchamberThefiringrateshasbeenobtainedbasedontestboilersinaccordancewithEN267standardsandareindicativeofmatchingtheburnertotheboiler.Forthecorrectoperationoftheburner,combustionchamberdimensionsmustbeinaccordancewithcurrentregulation.Incaseofnon-compliance,contactthemanufacturer.-1

1

3

5

7

9

11

13

0 100 200 300 400 500 600 700 800 900 1000 1100 1200 1300 1400 1500 1600 1700 1800 <kW><mbar>)*30(92

*Referenceconditions:Environmenttemperature20°C-Barometricpressure1013mbars-Altitude0metre(sealevel).MODELFGP50/MEVOThermalpowermin.1°st./min.2°st.-max.2°st.*[Mcal/h]107/204-542Thermalpowermin.1°st./min.2°st.-max.2°st.*[kW]124/237-630LIGHT-OILflowmin.1°st./min.2°st.-max.2°st.*[kg/h]10.5/20-53Fuel:LIGHT-OIL1.5°Eat20°C=6.2cSt=35secRedwoodN°1Intermittedworkingoperation(min.1stopevery24hours)twostagesprogressiveormodulatingEnvironmentalconditionsoperation/storage:-15...+40°C/-20...+70°C,rel.humiditymax.80%Max.temperaturecombustionair[°C]60Nominalelectricpower[kW]1.1Fanmotor[kW]0.55Pumpmotor[kW]0.37Nominalfanmotorcurrentabsorption[A]1.4Nominalpumpmotorcurrentabsorption[A]1.2Nominalauxiliaryabsorption[A]0.6Powersupply:3~400V,1/N~230V-50HzElectricprotectiondegree:IP44LIGHT-OILBURNERSTWOSTAGESPROGRESSIVEORMODULATING

SK070003_A_gbFGP50/MEVODIMENSIONS[MM]C2:Overalldimensionwiththeburneroutinpositionofmaintenance.*see"flametubelength"Fig. 3 DimensionsFGP50/MEVOMODELABCDEFOPFGP50/MEVO329274746150 416.5100207200

D

P

O

A B

TC - TL *C

FE

LIGHT-OILBURNERSTWOSTAGESPROGRESSIVEORMODULATING

SK070003_A_gbFGP50/MEVOFLAMETUBELENGTHFlametubelengthmustbeselectedbasedonthespecificationssuppliedbyboilermanufacturerand,inanycase,itmustbegreaterthanthethicknessoftheboilerdoorincludeditsinsulation.Incaseofboilerswithflameinversionorfrontfluecombustionchambers,itisnecessarytoinsulatetheareabetweentheflametubeandfrontdoorwithrefractorymaterial.Thisprotectionmaterialmustnotimpedeflametubeextraction.**Fordifferentflamelengths,pleasecontactourTechnical-SalesDepartment.MODELTCTL**FGP50/MEVOmm 250 335

BOILERPLATE*Suggesteddimensionofconnectionbetweenburnerandgenerator.Fig. 4 BoilerplateMODELFGP50/MEVOmm

M N min N max LminM10 205 226 160 L*Lmax160180

LIGHT-OILBURNERSTWOSTAGESPROGRESSIVEORMODULATING

SK070003_A_gbFGP50/MEVOFig. 5BurnersignaldescriptionLEGEND1)ON/OFFbutton2)Resetfromlockoutbutton+statuslampBURNERSIGNALDESCRIPTIONInthepicturebelowthereareindicatedallthesignalationpresentontheburner:

12

LIGHT-OILBURNERSTWOSTAGESPROGRESSIVEORMODULATINGThemulticolorsignallampinthelockoutresetbutton(pos.2)isthekeyindicatingelementforvisualdiagnosticsandinterfacediagnostics.Innormaloperation,thedifferentoperatingstatesareindicatedintheformofcolorcodes;pleaserefertoelectricaldevicehandbooksuppliedwiththepresentinstructions.Afteranon-alterablelockout,theredsignallampinthelockoutresetbutton(pos.2)lightsup.Bypressingthelockoutresetbutton(pos.2)formorethan3seconds,thevisualdiagnosticsofthecauseoffaultcanbeactivated;pleaserefertoelectricaldevicehandbooksuppliedwiththepresentinstructions.Forclosethediagnosticsmodeandforswitchontheburneragain,itisnecessarytoresettheburnercontrol.Pressthelockoutresetbutton(pos.2)forabout1second(<3seconds).Afteranon-alterablelockout,theredsignallampinthelockoutresetbutton(pos.2)lightsup.Forresetthecontrolboxpressthelockoutresetbutton(pos.2)forabout1second(<3seconds).

SK070003_A_gbFGP50/MEVOPRODUCTSPECIFICATIONSHORTDESCRIPTIONLight-oilburnerstwostagesprogressive(hi-lowflame)ormodulating(PIDfullymodulating)ifequippedwithadditionofoptionalmodulationkitandprobe.DETAILEDSPECIFICATIONLight-oilburnertwostagesprogressive(hi-lowflame)ormodulating(PIDfullymodulating)ifequippedwithadditionofoptionalmodulationkitandprobe;composedby:•Fanathighpressurisationatreverseblades;•Combustionheadwithadjustmentathighperformanceandelevatedflamestability;•Flangeandinsulatinggasketforfixingatboiler;•Three-phasepowersupply;•Photodiodeforflamedetection;•IP44electricprotectionlevel;•Servomotorforairshutterandforthepressureregulator;•Easyextractionofcombustionheadwithoutgetofftheburnersbybolier;•Maximumlight-oilpressureswitchtostoptheburnerincaseofthelight-oilpressureonthereturnishigherthenthesetpointvalue;•Safetyairpressureswitchtostoptheburnerinlock-out(bystoppingthepumpmotor)incaseoffailedoranomalousfanoperation;•Dedicatedmotorfortheactivationofthelight-oilpump;•Setupfortheadditionalspecifickitthattransformsburneroperationasmodulatingi.e.themodulatingkitallowstosupplyanypowerbetweentheminimunandthemaximumvaluebasedoninstantaneousloadingrequest.CONFORMINGTO:•CErules;•2014/30/UEDirectiveE.M.C.;•2014/35/UEDirectiveL.V.;•2006/42/CE-2006/42/EG-2006/42/ECDirectiveM.D.;•DirectivePED2014/68/UE(ART.4,PAR.3);•Referencerules:EN267(liquidfuel)-EN746-2(industrialthermoprocessingequipment).STANDARDEQUIPMENTOPTIONAL•Powermodulatingkitsfortemperatures;•Powermodulatingkitsforpressures;•Temperatureprobe0°C-400°C(PT100a0°C);•Temperatureprobe0°C-350°C(Jprobe);•Temperatureprobe0°C-1200°C(Kprobe);•Pressureprobe0-3bar,0-6bar.0-16bar,0-20bar,0-30bar;•Noiseprotection.Theillustrationsanddatahereshownareindicative.F.B.R.BruciatoriS.r.l.reservestherighttobring,withoutanyobligationofwarning,anychangesthatwouldbeappropriatetothecontinuingdevelopmentoftheirproducts.LIGHT-OILBURNERSTWOSTAGESPROGRESSIVEORMODULATING•Flexiblehosesforconnection;•Linefilter;•Isomartgasket;•Nozzle;•Flangewithinsulatinggasket;•Burnernameplate;•Warranty;•Instructionhandbookforinstallation,useandmaintenance.

Table of contents

Other FBR Burner manuals

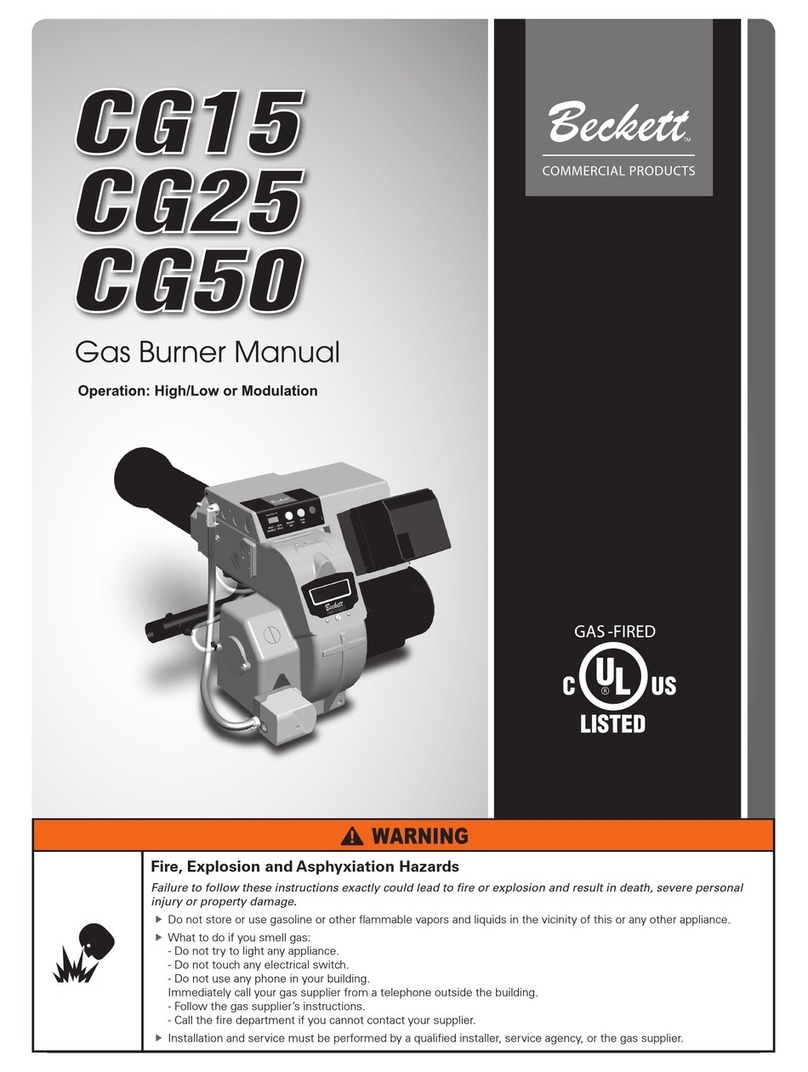

Popular Burner manuals by other brands

TriangleTube

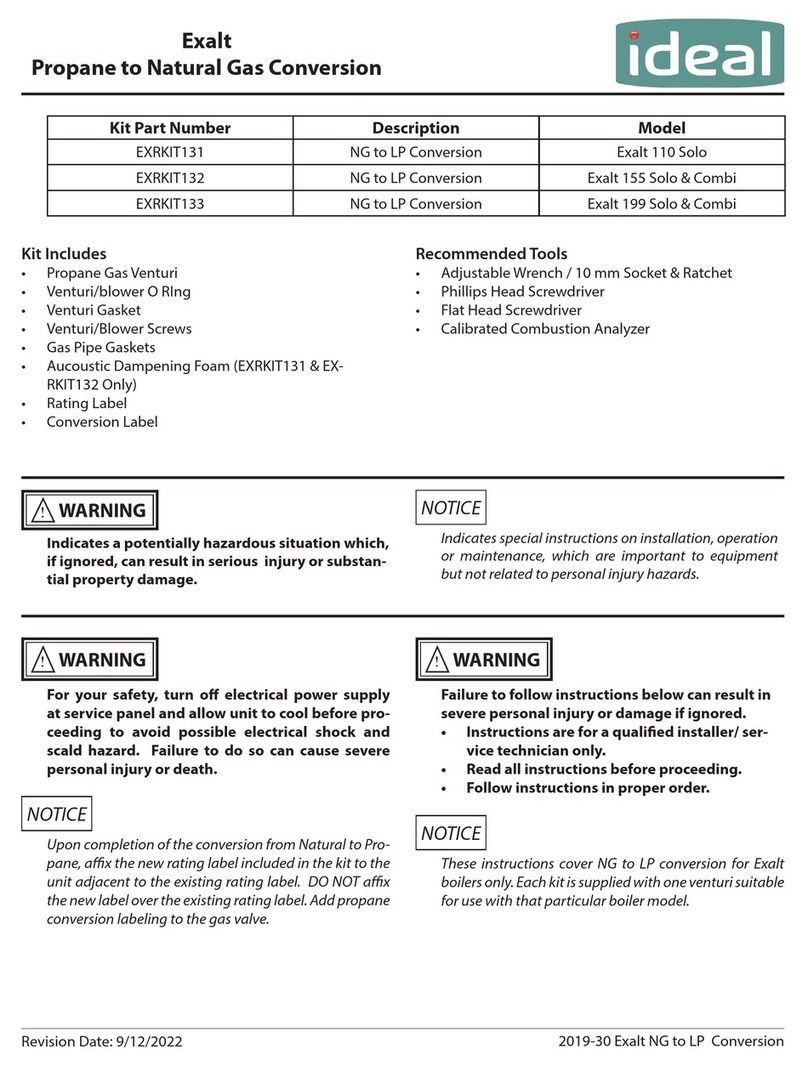

TriangleTube EXRKIT131 Conversion Kit Instructions

Yellow Heat

Yellow Heat Y-2100 Operation manual

Riello

Riello 4031067 manual

Unigas

Unigas P60 VS Manual of installation - use - maintenance

Enertech

Enertech Nu-Way NG Series Installation & maintenance manual

Carlin

Carlin 702G/O instruction manual

Riello

Riello RL 190/M Installation, use and maintenance instructions

Riello

Riello FS5 Installation, use and maintenance instructions

Riello Burners

Riello Burners 40 F20 Installation, use and maintenance instructions

Riello

Riello RS 160/M BLU Installation, use and maintenance instructions

Riello

Riello RS 810/E BLU Modulating operation

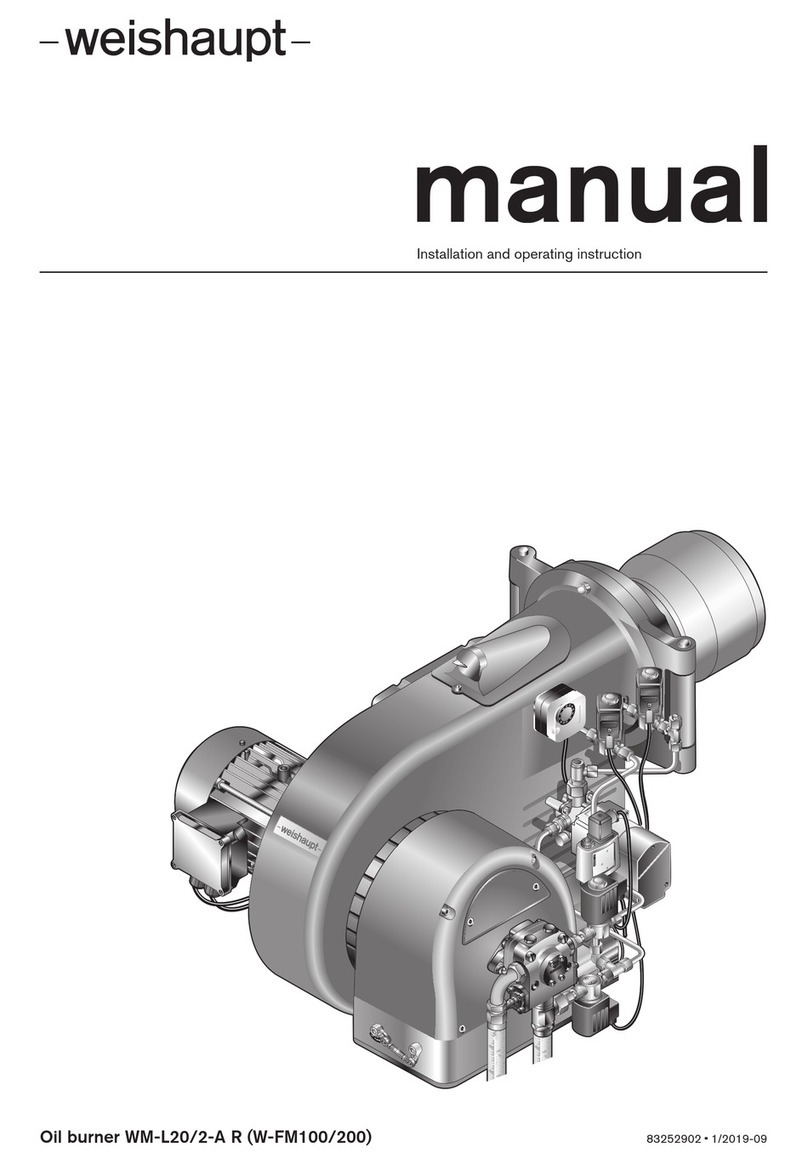

Weishaupt

Weishaupt WM-L20/2-A R manual