Enertech Nu-Way NG Series Instruction Manual

This manual suits for next models

9

Table of contents

Other Enertech Burner manuals

Enertech

Enertech Bentone BENTOFLEX ST120KA Technical specifications

Enertech

Enertech Bentone BENTOFLEX ST 133 KA/K Technical specifications

Enertech

Enertech Bentone BG 300-2 Technical specifications

Enertech

Enertech Bentone BFG1 User manual

Enertech

Enertech Bentone B60-2FH Technical specifications

Enertech

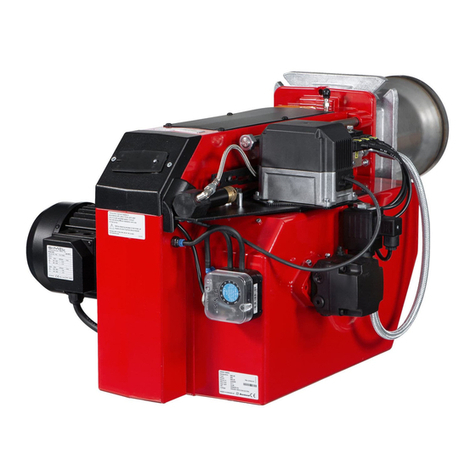

Enertech Bentone B40A Technical specifications

Enertech

Enertech Nu-Way Owner's manual

Enertech

Enertech Bentone BG400 User manual

Enertech

Enertech Bentone BG400 Technical specifications

Enertech

Enertech BENTOFLEX ST108FUV Technical specifications

Enertech

Enertech Bentone B65 RME Technical specifications

Enertech

Enertech Nu-Way MG1190-LN T3D Instruction Manual

Enertech

Enertech Bentone BFG1 Technical specifications

Enertech

Enertech Nu-Way G200 Universal Instruction Manual

Enertech

Enertech Bentone B1FUV Classic Technical specifications

Enertech

Enertech Nu-Way MGN 190 T1L Instruction Manual

Enertech

Enertech Bentone B 45A2.2H Technical specifications

Enertech

Enertech Bentone BG 550 CN Technical specifications

Enertech

Enertech Nu-way MOL795 T3N 273 3R Technical specifications

Enertech

Enertech Bentone B2S Classic Technical specifications

Popular Burner manuals by other brands

Riello

Riello RS 190 Installation, use and maintenance instructions

Riello

Riello GAS 3 Installation, use and maintenance instructions

Hozelock

Hozelock 4187 manual

Riello

Riello 3473784 Installation, use and maintenance instructions

Jackson Grills

Jackson Grills JGSBDBL-LP owner's manual

Bentone

Bentone ST 108 R Installation and maintenance instruction

Mag-Torch

Mag-Torch MT200C instruction manual

Eco-Smart

Eco-Smart AB Series Installation, operation and maintenance manual

RYNO WORX

RYNO WORX RY10MK-PRO-V4 Operator's manual

Magic Chef

Magic Chef MCSDB15W user manual

Algas SDI

Algas SDI Phoenix SH Operation & maintenance manual

PROPOINT

PROPOINT 8933640 manual

GGM gastro

GGM gastro GKK1 instruction manual

Sunsystem

Sunsystem WBS-A 20 manual

Vulcan-Hart

Vulcan-Hart ECONOLINE Series Installation & operation manual

Carlin

Carlin 702CRD instruction manual

Travis Industries

Travis Industries 864 HO NB installation instructions

elco

elco GHO-Tron 7.15000 R operating instructions