FE PETRO STP Installation instructions

STP/ IST Fixed & Variable Length

Installation and Owner’s Manual

©2009 400604005 Rev. 15

Franklin Fueling Systems • 3760 Marsh Rd. • Madison, WI 53718 USA

Tel: +1 608 838 8786 • 800 225 9787 • Fax: +1 608 838 6433 • www.franklinfueling.com

2

Important Safety Messages

FE Petro equipment is designed to be installed in association with volatile hydrocarbon liquids such as gasoline and

diesel fuel. Installing or working on this equipment means working in an environment in which these highly ammable

liquids may be present. Working in such a hazardous environment presents a risk of severe injury or death if these

instructions and standard industry practices are not followed. Read and follow all instructions thoroughly before

installing or working on this, or any other related equipment.

As you read this guide, please be aware of the following symbols and their meanings:

This symbol identies a warning. A warning sign will appear in the text of this document when a potentially

hazardous situation may arise if the instructions that follow are not adhered to closely. A potentially

hazardous situation may involve the possibility of severe bodily harm or even death.

This is a caution symbol. A caution sign will appear in the text of this document when a potentially

hazardous environmental situation may arise if the instructions that follow are not adhered to closely. A

potentially hazardous environmental situation may involve the leakage of fuel from equipment that could

severely harm the environment.

Follow all applicable codes governing the installation and servicing of this product and the

entire system. Always lock out and tag electrical circuit breakers while installing or servicing this

equipment and related equipment. A potentially lethal electrical shock hazard and the possibility of

an explosion or re from a spark can result if the electrical circuit breakers are accidentally turned

on during installation or servicing. Do not smoke while working on or near this equipment, and use

only non-sparking tools.

Before entering a containment sump, check for the presence of hydrocarbon vapors. If these

vapors are inhaled they could cause dizziness or unconsciousness, and, if ignited, hydrocarbon

vapors could explode causing serious injury or death. Electronic and electrical petroleum

monitoring equipment is often housed in containment sumps designed to trap hazardous liquid

spills and prevent contamination of the environment, and, as a consequence, containment sumps

can trap dangerous amounts of hydrocarbon vapors. If these vapor levels reach unsafe amounts,

ventilate the sump with fresh air. While working in the sump, periodically check the atmosphere

in the sump, if vapors reach unsafe levels, exit the sump and ventilate it before continuing

work. Always have a second person standing by for assistance when working in, or around, a

containment sump.

Follow all federal, state, and local laws governing the installation of this product and its associated

systems. When no other regulations apply, follow NFPA codes 30, 30A, and 70 from the National

Fire Protection Association. Failure to follow these codes could result in severe injury, death,

serious property damage, and / or environmental contamination.

Always secure the work area from moving vehicles. The equipment in this manual is usually

mounted underground, so reduced visibility puts service personnel working on this equipment in

danger from moving vehicles entering the work area. To help eliminate these unsafe conditions,

secure the area by using a service truck to block access to the work environment, or by using any

other reasonable means available to ensure the safety of service personnel.

Do not modify the STP / IST, modifying any feature of the STP / IST can cause environmental and

safety issues. FE Petro’s submerged turbine pumps are subjected to rigorous quality control

testing during assembly. Field alteration of the pumps in any way, including shortening of the

column pipe and conduit, defeats these quality tests, and could result in a fuel leak or dangerous

electrical contact.

Thermal expansion can cause pressure to build up in the product lines. FE Petro’s STP / ISTs have

a built-in relief valve to release this excess line pressure back to the tank. Do not use an additional

check valve unless it has the capability to relieve excess pressure back to the tank, as this could

result in a buildup of abnormal pressure in the lines, causing a pipe or joint in the supply line piping

to burst, and release of fuel into the environment.

Warning

Caution

Warning

Warning

Warning

Warning

Caution

Caution

3

Note: Some underground storage tanks are ballasted

with water during construction. DO NOT use the

submersible pump to remove water from the tank.

The pump is designed for use with petroleum

products only, and pumping other uids will

seriously damage the unit. We do not recommend

immersing the pump in water, but, if this does

happen, immediately ll the tank with motor fuel

after the water is removed from the tank. Severe

corrosion takes place very quickly if the unit has

been submerged in water and is then exposed to

air. If the pump will not operate after gasoline is

put into the tank, remove the extractable portion,

remove the black plastic end cap from the pump

motor assembly (PMA), and turn the Allen screw

clockwise at the end of the PMA. This will break

free the PMA from any corrosion that may be

present. Reinstall the PMA end cap and the

extractable section into the pump housing.

Installer:

This instruction booklet MUST be left with the owner of the

service station at which the equipment is being installed.

Station Owner:

Retain these instructions for future use and provide them

to persons servicing or removing this equipment.

Installation Instructions

The piping and underground storage tank must be installed

using good standard industry practices. There are several

publications that can be used for reference, some of which

are:

Automotive and Marine Service Station Code, NFPA •

30A, Flammable and Combustible Code, NFPA 30, and

National Electrical Code, NFPA 70 (NEC), National Fire

Protection Association, Quincy, Mass.

Recommended Practices for Installation of Underground •

Liquid Storage Systems, The Petroleum Equipment

Institute, PEI / RP100, Latest Edition.

Recommended Practices for Installation of Aboveground •

Storage Systems for Motor Vehicle Fueling, The

Petroleum Equipment Institute, PEI / RP200, Latest

Edition.

Installation of Underground Petroleum Storage Systems, •

American Petroleum Institute, API Recommended

Practice 1615, Latest Edition.

Required Tools

Standard 3 / 4" drive ratchet wrench or breaker bar (no •

sockets required)

Standard at head screwdriver•

Wire cutter and stripper•

5 / 32" Allen wrench for securing set screw in telescoping •

pipe coupling (VL units only)

Pipe wrench (36" minimum) for tightening 4" Riser•

1 / 4" hex driver with socket and ratchet wrench, or 1 / 4" •

Allen wrench for attaching PMA

Measuring tape long enough to reach bottom of the tank •

from 30" to 70" above the tank

Note: All wiring must conform to applicable guidelines in

accordance with all federal, state, and local codes.

Failure to comply with all applicable guidelines

could result in an unsafe installation. Use the

following table for maximum wire length to wire

gauge ratios for submersible wiring:

Wire Size Maximum Run

10 gauge 650 feet

12 gauge 400 feet

14 gauge 250 feet

Preparation

1. Fill out the Warranty Registration Card and return

it to FE Petro.

Note: If your STP / IST does not operate correctly or

there are any questions concerning installation or

service, please contact FE Petro Technical Service

at (800) 225-9787.

2. Disconnect power to the submersible pump at the

electrical supply box (if already installed).

3. Tag and lock out electrical circuit breakers so they

are not turned on accidentally.

If installing xed length pump (non-•

variable) with PMA mounted, go to

“secure to tank” section.

If installing variable length pump•

continue with this section.

If installing xed length pump (non-•

variable) without PMA mounted,

complete “mounting PMA” section,

then go to “secure to tank” section.

Warning

4

Mounting the PMA

4. Lay packaged pump on a at, open surface and

remove the package.

5. Flatten pump packaging and lay the PMA on the

end of the pump in preparation for mounting.

6. The PMA mounting hardware kit (# 152350902)

is attached to the PMA packaging. It contains

a gasket, a tube of grease, and four 5 / 16" cap

screws with lockwashers.

7. Remove the two packaging ends and the

protective sleeve from the PMA.

8. Apply grease provided to the inside wall of the

pump motor electrical connector, and the rubber of

the lead assembly connector.

9. Place the gasket on the end of the PMA, aligning

locating pin and bolt holes (Figure 1).

Figure 1: Aligning Pins

10. Mount PMA onto discharge head by aligning

locating pin on PMA with hole in discharge head,

assuring that the lead assembly in the motor

discharge head is seated in its notched position,

and that the PMA gasket is properly in place.

11. Tighten PMA onto discharge head using four cap

screws and lock washers supplied. A cross bolt-

tightening pattern is recommended for securing

PMA (Figure 2).

Figure 2: Tighten Bolts

The motor discharge head must not be

rotated more than one full rotation in

either direction. Rotation could cause

damage to the electrical connections

in the conduit, creating a risk of lethal

electrical shock or equipment failure.

Note: Before assembling the PMA to the discharge

casting make sure the wire lead is properly set

and aligned in the discharge casting. Improper

alignment could damage the wire lead or motor

pins. Failure to push PMA up snug against the

discharge casting before tightening cap screws, or

failure to use a cross-pattern while tightening the

bolts could break the discharge casting or strip the

threads in the PMA.

Note: IST units without a VS4 sufx and STP units with a

VS2 sufx can only be electrically connected to an

IST-VFC or MagVFC.

STP or IST units with a VS4 sufx can only be

electrically connected to a MagVFC. Unlike FE

Petro’s standard pumps, the following pumps

cannot be interchanged with competitive models:

The variable speed PMA VS2 (which is part of IST •

units without the VS4 sufx or the STP units sufxed

with VS2)

The PMA VS4 (which is part of the IST and STP •

units with the VS4 sufx)

12. Apply a non-hardening, UL classied, gasoline-

resistant pipe sealing compound to the riser pipe

threads, if not already installed.

Failure to use a proper thread sealing

compound could result in a lack of

seal where the riser threads into the

tank opening, making it impossible to

perform a tank-tightness test. This may

also create a potential site for fuel to

leak into the environment and / or the

containment sump.

13. Slide riser over the PMA and tighten into manifold

threads (Figure 3). Maximum riser size is found

by taking the grade to tank mounting thread

measurement and subtracting the manifold height

and clearance (6" clearance recommended).

Figure 3: Attach Riser

Note: Riser material required for pump is 4.5" outside

diameter with a .188" wall. Minimum riser length

supplied by FE Petro is 7".

Warning

Warning

5

Example

Grade to tank mounting threads (bury depth) 48"

Minus manifold height without leak detector

(w / leak detector height = 12.50)

-11"

Minus 6" for top clearance (2" minimum) -6

= Maximum riser size 31"

Length Setting

14. Cut wire tie(s) securing the motor wire at the top of

the pump; lay the wires out above the pump head

so that wires can feed through conduit freely when

setting length (Figure 4).

Figure 4: Cut Wires

Failure to cut wire ties prior to setting

pump length could result in damage to

electrical motor wires, presenting a risk

of lethal electrical shock or equipment

failure.

15. Measure from the bottom of the tank to the top of

tank mounting threads. Subtract the distance for

clearance between the PMA and the bottom of the

tank (6" recommended). This is the length to which

the pump should be extracted, measured from the

bottom of the riser threads to the bottom of the

motor end bell.

Note: 6" clearance provides a 5" clearance from the

pump motor end bell to the bottom of the tank once

the riser is screwed into tank mounting threads.

Tank + thread measurement 96"

Distance from bottom (5") + riser thread

engagement (1")

-6"

= Length (bottom of riser to end bell) 90"

Figure 5: Measure Tank

16. Hold the manifold securely to the surface to

prevent damage while setting length.

To allow movement of the telescoping pipe,

verify that none of the pipe coupling setscrews

are in contact with the pipe. Lay a tape measure

out to accurately measure the distance from the

bottom of the riser to the bottom of the pump

motor end bell.

17.

Grasp the pump just above the PMA and pull rmly,

extending to the length required (from Step 15).

Note: Use care to ensure electrical conduit wires

at the top of the discharge manifold are not

damaged during length setting. If column pipe

is extended beyond desired length have a

second person retract conduit wires as column

pipe is shortened. This will prevent damage to

conduit wires.

Figure 6: Measure Riser

The motor discharge head must not be

rotated more than one full rotation in

either direction. Rotating could cause

damage to the electrical motor wires,

presenting a risk of potentially lethal

electrical shock or equipment failure.

Note: O-ring seals inside the locking coupling may have

sealed to the column pipe during shipping. Spin the

motor discharge head slightly (not more than one

full rotation) while pulling to loosen the O-ring seals.

Warning

Warning

6

18. Once the length is correct, lock the STP length by

tightening all three coupling setscrews. Tighten the

setscrews nger-tight, making sure they come into

contact with the pipe (Figure 7).

19. Tighten each setscrew an additional full turn

minimum. The head of the setscrews should be

ush or below ush with the outer surface of the

coupling (Figure 8).

Setscrews

3 places

Figure 7: Install Setscrews

5 / 32"

Allen

Wrench

Figure 8: Tighten Setscrews

Failure to properly tighten the coupling

setscrews at this stage could present

a risk of death, serious bodily injury

and / or equipment damage due to

movement of pipes during installation.

PMA Wiring

20. Measure approximately 6" of wire from the

discharge manifold; cut off excess wire and

discard (Figure 9).

Figure 9: Measure and Cut Wire

21. Place the three wires through the contractors plug

assembly (from hardware pack p / n 400301903)

as shown in gure 10.

Figure 10: Wire Through Contractor’s Plug

22. Using the screwdriver slide the contractors plug

into its seat in the discharge manifold. Tighten the

two screws in the contractor plug to secure it in

place (Figure 11).

Figure 11: Attach Contractor’s Plug

23. Strip the wire insulation back approximately 3 / 8"

on the three motor leads. Using the wire nuts

supplied (from hardware pack p / n 400301903)

connect to the wires from the electrical connector

orange to orange, black to black, and red to red.

24.

Coil the wires and push into the discharge manifold

cavity using care to ensure wires are not damaged

on discharge manifold threads (Figure 12)

.

Figure 12: Push Wires into Cavity

Damage to the electrical conduit wires

creates a risk of lethal electrical shock

and equipment failure. Do NOT use

equipment if electrical wires have

been damaged (contact FE Petro for

assistance).

25. Tighten the discharge head cover (from hardware

pack p / n 400301907) in place using a 3 / 4" ratchet

or breaker bar (Figure 13).

Warning

Warning

7

Figure 13: Tighten Discharge Head Cover

Secure to Tank

Note: The bottom end-bell of the PMA is not designed

to support the weight of the entire pump. Resting

or dropping the pump on this end-bell may

damage the plastic end-bell and the plastic pump

components inside. This type of damage is not

considered a manufacturing defect under FE

Petro’s warranty.

26. Measure the pump, from the bottom of the

threaded riser to the bottom of the pump-motor,

and compare this to the tank measurement,

measured from the mounting ange to the inside

of tank bottom. The STP / IST and riser are sized to

place the intake (at the bottom of the pump-motor)

approximately 5 inches off the bottom of the tank.

If the difference between the bottom of the pump

motor and the bottom of the tank is more than

6 inches or less than 4 inches, verify that this is

the correct pump for this tank installation. If it is

not the correct pump and is outside the above

specications, contact FE Petro, Inc. sales

representative or the FE Petro, Inc. factory.

27. Apply a non-hardening, UL classied, gasoline-

resistant pipe sealing compound to the riser pipe

threads.

Failure to use a proper thread sealing

compound could result in a lack of seal

where the riser threads into the tank

opening, making it impossible to perform

a tank-tightness test. This may also

create a potential site for fuel to leak into

the environment and / or the containment

sump.

28. Carefully lower the unit into the tank, and engage

the threaded riser of the pump into the threaded

ange on the tank. Tighten the riser into the tank

using a large pipe wrench until a water / air tight

joint has been made. Do this by turning in the

tightening (clock-wise) direction only.

Turning the pump in the loosening

direction during the tightening process

may scrape away the thread sealing

compound, making it impossible to

perform a tank-tightness test. This may

also create a potential site for fuel to

leak into the environment and / or the

containment sump.

29. Connect the supply line piping to the discharge

port in the discharge manifold assembly. The

discharge port is the 2-inch NPT vertical opening.

30. Connect the electrical conduit with approved

ttings per NFPA 30, NFPA 30A, and NFPA 70 to

the junction box (see Figure 15).

31. Remove the junction box cover (see Figure 15),

and remove the compression seal (contractors

plug) by loosening the screw(s) (do not remove

screw). A four hole compression seal (contractors

plug) is provided on all units,

On single phase units, two power wires, one •

ground wire and a blank (with celcon rod

supplied to ll forth hole).

For three phase units, three power wires and •

one ground wire.

32. Verify that the power is still OFF at the supply box.

33. Pull wires from power supply into the junction

box and feed through the compression seal

(contractors plug).

34. Replace the compression seal and tighten

into place securely. All wiring must be done in

accordance with the National Electrical Code

(NEC) and any other local, state, or federal

regulations required.

The compression seal (contractors

plug) is not intended to replace the

vapor explosion seals required by

the NEC. All materials used between

the power supply box and the pump

junction box must be gasoline and oil

resistant. Failure to comply with these,

and all applicable NEC guidelines,

could result in an unsafe installation.

35A. SINGLE PHASE UNITS: Connect the ground wire

to the lug in the junction box; using the wire nuts

supplied (from hardware pack p / n 400301901)

connect the wires from the power supply to the

orange and black wires in the junction box. A

capacitor is required and color-coding is not

necessary.

Warning

Caution

Warning

8

35B. THREE PHASE UNITS (except IST or STP units

with VS2 or VS4 sufx): Connect the ground wire

to the lug in the junction box. Connect any three

wires from the pump to any three wires from the

three-phase power source using the wire nuts

supplied (from hardware pack p / n 400301902).

Capacitors are not needed for three phase units.

Install a pressure gauge in the line test port

(see Figure 15), turn on the pump, and read the

pressure gauge. Turn off the pump at the power

supply, and change the connection of any two

wires at the pump. Turn the pump back on and

read the pressure gauge again. The electrical

connection that gives the higher reading on the

pressure gauge is the correct one.

35C. IST UNITS or STP units with a VS2 or VS4 sufx:

Connect the ground wire coming from indoors to

the ground lug in the junction box. Connect any

three wires from the pump connector assembly to

the three power wires coming from the Variable

Frequency Controller (VFC). Capacitors are

not needed for these units. Detailed installation

instructions for the VFC should be referenced

when connecting the VFC. These are supplied

with the VFC.

Not installing a ground wire increases

the risk of lethal electric shock and

equipment failure. All holes of the

compression seal (contractors plug)

must be lled with wires or a celcon rod

to enable it to seal.

36. Replace the junction box cover and tighten

securely.

The pump discharge manifold has

two labeled ports: one for the syphon

system and one for the tank. A piston

leak detector must be vented to the tank

port (lower port) only. Do not connect a

piston leak detector to the syphon port

because this will make the leak detector

inoperative, resulting in an increased

risk of contamination of the environment

(see tank port in Figure 14).

37. Connect power to the submersible pump at the

electrical supply box.

38. Test proper operation by dispensing product into

calibration can.

39. Turn off the dispenser switch. Feel the

submersible pump to make sure that the pump has

stopped running.

Note: If the pump does not turn off when the dispenser

switch is turned off, this may indicate an electrical

problem in the dispenser or other wiring error or

malfunction. Call this to the immediate attention of

a qualied electrician.

40. Visually check for leaks on the manifold head

during pump operation and after.

41. Install a pressure gauge in the line test port to

ensure that the STP / IST is providing proper line

pressure.

42. Turn on the STP / IST. While running, the pressure

should be above 24 psi (1.65 bar). PMA size will

affect psi.

43. Turn off the STP / IST and verify that the line

pressure is holding.

44. Remove the pressure gauge and replace the plug.

45. Turn on the STP / IST and, again, visually check for

any leaks.

Warning

Caution

9

Approximate STP / IST Specications

Operating

Pressure (PSI)

PMA

Length (in)

S.F.

Amps

Locked

Rotor Amps

Winding Resistance

Model Description R-B R-O B-O

STP33*208 / 230 V, 60 Hz, 1 ph 27 16 3.1 11 27 19 8

STP75*208 / 230 V, 60 Hz, 1 ph 30 18.25 6.1 27 20 17 3

STP150*208 / 230 V, 60 Hz, 1 ph 32 21 10.5 39 15 13 2

STPH150*208 / 230 V, 60 Hz, 1 ph 45 21.75 10.5 39 15 13 2

STP200+208 / 230 V, 60 Hz, 1 ph 36 23.75 11.4 41 4.6 3 1.8

STPH200+208 / 230 V, 60 Hz, 1 ph 46 24.5 11.4 41 4.6 3 1.8

STP75B++ 200 / 250 V, 50 Hz, 1 ph 37 20.5 5.6 23 27 23 4

STP150B++ 200 / 250 V, 50 Hz, 1 ph 38 22.75 10.2 28 16 13 3

STPH150B++ 200 / 250 V, 50 Hz, 1 ph 48 23.25 10.2 28 16 13 3

STP200B‡200 / 250 V, 50 Hz, 1 ph 37 25.75 10.9 36.5 5.5 3.5 2

STPH200B‡200 / 250 V, 50 Hz, 1 ph 44 26.25 10.9 36.5 5.5 3.5 2

STP75C 380-415 V, 50 Hz, 3 ph** 37 19.75 2.1 10 29 29 29

STP150C 380-415 V, 50 Hz, 3 ph** 38 21.75 3.4 14 14 14 14

STPH150C 380-415 V, 50 Hz, 3 ph** 48 22 3.4 14 14 14 14

STP200C 380-415 V, 50 Hz, 3 ph** 37 23.5 4.1 22.5 11.6 11.6 11.6

STPH200C 380-415 V, 50 Hz, 3 ph** 44 24 4.1 22.5 11.6 11.6 11.6

IST / STPVS2^190 V, 70 Hz, 3 ph†24-42 20 6.7 N / A 2.5 2.5 2.5

ISTVS4 / STPVS4^^ 190 V, 70 Hz, 3 ph†24-42 25 14.4 N / A 1.2 1.2 1.2

Symbol Key

* Use a 15 µF, 370 V, single phase, 60 Hz capacitor

+ Use a 40 µF, 370 V, single phase, 60 Hz capacitor

++ Use a 15 µF, 440 V, single phase, 50 Hz capacitor

‡ Use a 40 µF, 440 V, single phase, 50 Hz capacitor

† 190 V, 70 Hz, 3 ph power to variable speed units is output from IST-VFC or MagVFC only (VFC’s are powered

by 200-250 V, 50 or 60 Hz, single or 3 phase input)

^ Use with IST-VFC or MagVFC controller only, No Capacitor

^^ Use with MagVFC controller only, No Capacitor (3 phase input is required for full VS4 output))

** No capacitor is used with 3 phase pump motor assemblies

Note: The models listed in the table above may contain (ANZ) for ANZEX certied pumps, or (ATX) for ATEX certied

pumps.

Warning FE Petro’s STPs are designed for use with motor fuels, and they are UL listed for blend

concentrations of:

Standard Models AG (Alcohol / Gasoline) Models

0% - 15% ethanol or methanol and gasoline 0% - 85% ethanol or methanol and gasoline

20% MTBE with 80% gasoline 20% MTBE with 80% gasoline

20% ETBE with 80% gasoline 20% ETBE with 80% gasoline

17% TAME with 83% gasoline 17% TAME with 83% gasoline

Diesel, fuel oil, avgas, jet fuel, or kerosene may also be used with our PMAs. The maximum liquid

viscosity for a product is 70 S.S.U. at 60° F.

Using our PMA in liquids other than those mentioned above has not been tested. The reaction of

other liquids with seals and wetted surfaces of the pump is unknown. A hazardous situation may

result from using other liquids with our pump.

10

Manual Pressure Relief

The manual line pressure relief (see Figure 14) is located

in the center of the stationary manifold under a brass

cap. It is available on all pumps manufactured after April

of 1996. FE Petro makes it easy to relieve the pressure

in the piping system anytime routine maintenance or

troubleshooting must be performed.

Simply remove the brass cap at the top of the stationary

manifold, and turn the pressure relief screw counter-

clockwise until you come to the screw’s retaining ring

(approximately 4 complete turns). This allows the pressure

in the piping system to bleed back to the storage tank.

Next, turn the screw clockwise to its original position

to close the path (turn snug, do not over tighten); then

replace the brass cap. Line side pressure is now relieved

and maintenance or troubleshooting can be performed

without having to contain excess product that escapes

when the system is pressurized.

Clamp Valve (Check Valve Clamp)

The clamp valve (see Figure 14) is located directly

above the check valve inside the stationary manifold of

the submerged pump. It consists of a lead screw with a

sealing disk attached. The head of the screw is accessible

by removing the 1 / 4" line test port pipe plug on the check

valve cover of the STP / IST.

The cavity under the 1 / 4" pipe plug is

at full pump pressure and product will

be released through this opening. If

the pump is equipped with a manual

pressure relief, use it to relieve line

pressure prior to removing the plug.

For normal operation, the clamp valve should be rotated

fully counter-clockwise where a star washer locks it in

place. Be sure to replace the 1 / 4" pipe plug. During a

line test, the clamp valve should be rotated fully clockwise,

where the sealing disk secures against the check valve.

This blocks the pressure relief valve in the check valve so

it does not relieve line pressure back to the tank.

Syphon Systems (Optional)

Syphoned tanks should be of the

same diameter with tank bottoms

located on the same horizontal plane.

Using tanks of different diameter, or

installing the bottoms of the tanks on

different horizontal planes may create

a potential site for fuel to leak into the

environment and / or the containment

sump due to overll of the tank(s).

Some jurisdictions allow two or more tanks of the same

product grade to be manifolded together with a syphon

loop. These systems usually have a single submersible

pump, and the syphoning action keeps the tanks

level while pumping out of only one tank. All FE Petro

submersible pumps have syphoning capability built into

the pump. However, if a syphon check valve is required,

it must be ordered separately. The outlet of the syphon

check valve should be connected with a line to the highest

spot in the syphon loop. At this point the submersible pump

creates a vacuum of 20–28" Hg.

When correctly installed, the syphon action between the

tanks will continue whether the pump is running or not, as

long as the product level in the tanks is higher than the

bottom of the syphon loop vertical piping. The function of

the STP / IST in the syphon system is merely to prime the

syphon line, removing the air and allowing the syphon to

take place.

Note: The syphon port on FE Petro submersible pumps

was designed to be connected to the syphon piping

between tanks. Using the vacuum port (syphon

port) for other purposes may create complications

with the pump’s ability to draw a vacuum because

of excessive foreign materials being drawn into

pump components.

Note: A fuel lter, between the syphon check valve and

the syphon loop, may be useful to help eliminate

debris from entering the syphon check valve.

Debris can keep a syphon check valve from

operating properly. Be sure to use a fuel lter,

which is compatible with the application.

Warning

Warning

11

Wiring Diagram 1

12

Wiring Diagram 2

Note: For further wiring diagrams, see installation and owners manuals that came with pump controller. Wiring must

conform to all federal, state, and local electrical codes. Contact FE Petro Technical Support for further assistance.

13

PMA, Riser & Check Valve For VL & Fixed Length

Item # Part # Description Qty

1 400125001 3 / 16 x 1 5 / 8 Spiral Pin 1

2 400615001 Manual Relief Plug 1

3400211114 O-Ring, Plug 1

4400627001 Retaining Ring 1

5 400616001 Manual Relief Screw 1

6400333012 O-Ring, Relief Screw Top 1

7 400333007 O-Ring, Relief Screw Bottom 1

8 400628901 Manual Relief Plug Assembly

(includes items #2 and #3)

1

9 400629901 Manual Relief Screw Assembly (includes item

#4, #5, #6, and #7)

1

10 400259001 1 / 4 NPT Pipe Plug

(may purchase locally)

3

11 400137937 Syphon Check Valve –

12 400221930 Discharge Manifold 1

13 151213930 Lead Assembly 156" Length 1

151213932 Lead Assembly 240" Length 1

14 Purchase

Locally

Stationary Vapor Tube

3 / 8 OD x .035 Wall

–

15 4001689XX

(xx = length)

Riser 4 1 / 2 OD x .188 Wall Steel Tubing 1

16 Purchase

Locally

1 / 2 Steel Banding –

17 400600002 5 / 16-24 x 7 / 16 Set Screw

for VL units only

3

18 400333015 O-Ring, Motor Discharge 1

19 400264009 5 / 16-18 x 1 1 / 8 Socket Head Cap Screw 4

20 400263004 5 / 16 High-collar Lock Washer

(may purchase locally)

4

21 402449001 Gasket, PMA 1

22 PMAXXX

(XXX

indicates

options & HP)

Pump Motor Assembly

(includes item #35)

1

24 400981001 3 / 8-16 x 1 Hex Head Screw

(may purchase locally)

2

25 400285002 3 / 8 Standard Lockwasher

(may purchase locally)

2

26 400197930 Cover, Manifold Assembly

(includes one each of items #10 & #27, and

two each of items #24 & #25)

1

27 400333238 O-Ring (A / G compatible) 1

29 400147930 Valve, Clamp Assembly

(includes item #28)

1

30 400174930 Spring, Check Valve 1

34 400988931 Check Valve, Standard 1

400988932 Check Valve, Model R 1

400988933 Check Valve, Model W 1

402459931 Check Valve, Model 65 PSI 1

400988934 Check Valve, E85, Standard 1

402459932 Check Valve, E85, Model 65 PSI 1

(each Check Valve includes item #27)

35 152350902 PMA Hardware Pack

(includes item #21 and

four each of items #19 and #20)

–

Figure 14

14

Discharge Manifold Assembly

Item # Part # Description Qty

1400192930 Cover, Junction Box

(includes item #2)

1

2400210233 O-Ring 1

3400655001 Boot, Capacitor 1

4

(does

not

include

item

#3)

400170931 Capacitor Assembly

60Hz, 15 µF, 370V 1Ø

1

400170933 Capacitor Assembly

50Hz, 15 µF, 440V 1Ø

1

400170934 Capacitor Assembly

60 Hz, 40 µF, 370 V 1Ø

1

400170935 Capacitor Assembly

50Hz, 40 µF, 440V 1Ø

1

N / A Not required for 3Ø units

including IST / VS2

–

6400257001 Retaining Ring 1

7 400258002 3 / 8-16 x 1 1 / 4 Hex Head Bolt

(may purchase locally)

4

8 400285002 3 / 8 Standard Lockwasher

(may purchase locally)

4

9400280001 3 / 8 Standard Flat washer

(may purchase locally)

2

10 400651930 Junction Box Assembly

(includes two of each: Item #7, #8, & #9)

1

11 400210212 O-Ring 2

Item # Part # Description Qty

13 400200930 Wire Connector Kit

(includes male / female connectors,

(2) item #11, (1) each item #6, #12, & #20)

1

14 400589930 Cover

(includes item #15)

1

15 400210229 O-Ring 1

16 400236903 Plug, Contractors 2

17 400259002 3 / 8 NPT Pipe Plug

(may purchase locally)

1

18 400562901 Syphon Jet Assembly 1

400562903 Syphon Jet Assembly, E85 1

19 400211046 O-Ring 1

20 400249001 Retaining Ring 1

22 400250002 1 / 8 Dia. x 1 / 2 Roll Pin 1

23 400333343 O-Ring

(A / G compatible)

2

24 400333340 O-Ring

(A / G compatible)

1

25 400259005 2NPT SQ Head Plug 1

1

2

3

4

6

7

8

9

10

16

14

7

8

23

24

25

22

11

11

20

12

13 15

16

17

18

19

Line Test Port

Figure 15

15

Syphon Check Valve

Item # Part # Description Qty

1400137930 Syphon Check Valve 1

Control Box Assembly (STP-CBS)

Figure 16

Figure 17

Item # Part # Description Qty

1400575001 Power Switch

(for CBS and CBBS models)

1

2400574001 Bracket, Power Switch 1

3 400158901 Light Assembly, 120V (CBS) 1

400158902 Light Assembly, 240V (CBBS) 1

4400215931 Relay, 30A, 120V 1

400215933 Relay, 30A, 240V 1

5400278005 Terminal Strip 1

6 402410001 Label, Terminal Strip (CBS) 1

402410002 Label, Terminal Strip (CBBS) 1

7 400817901 Cover & Enclosure 1

8 400819001 Wiring Diagram (CBS) 1

400819002 Wiring Diagram (CBBS) 1

Enclosure dimensions: 8.5"H x 5"W x 3"D (215mm x 127mm x 76mm)

Figure 18

Discharge / Leak Detector

Centerline

Discharge / Leak Detector

Centerline

Line Test port

¼" NPT

Vapor Recovery

Discharge Port 1" NPT Riser / Column Pipe Centerline

Riser / Column Pipe Centerline

11.70"

7.55" R

10.45"

8.12" R

3.00"

5.80"

3.63"

Leak Detector Port

2" NPT

Discharge Outlet

2" NPT

12.50"

Riser Pipe

4" NPT

Tank Port

¼" NPT

Syphon Port

¼" NPT

10.65"

5.80"

©2009 FFS 400604005 Rev. 15

This manual suits for next models

21

Table of contents

Popular Water Pump manuals by other brands

AQUATECH

AQUATECH Aquajet RV Series User manual and installation guide

EUROPRO

EUROPRO MIXPRO 28 Manual instructions

Little Giant

Little Giant 10S-CIA-RFS manual

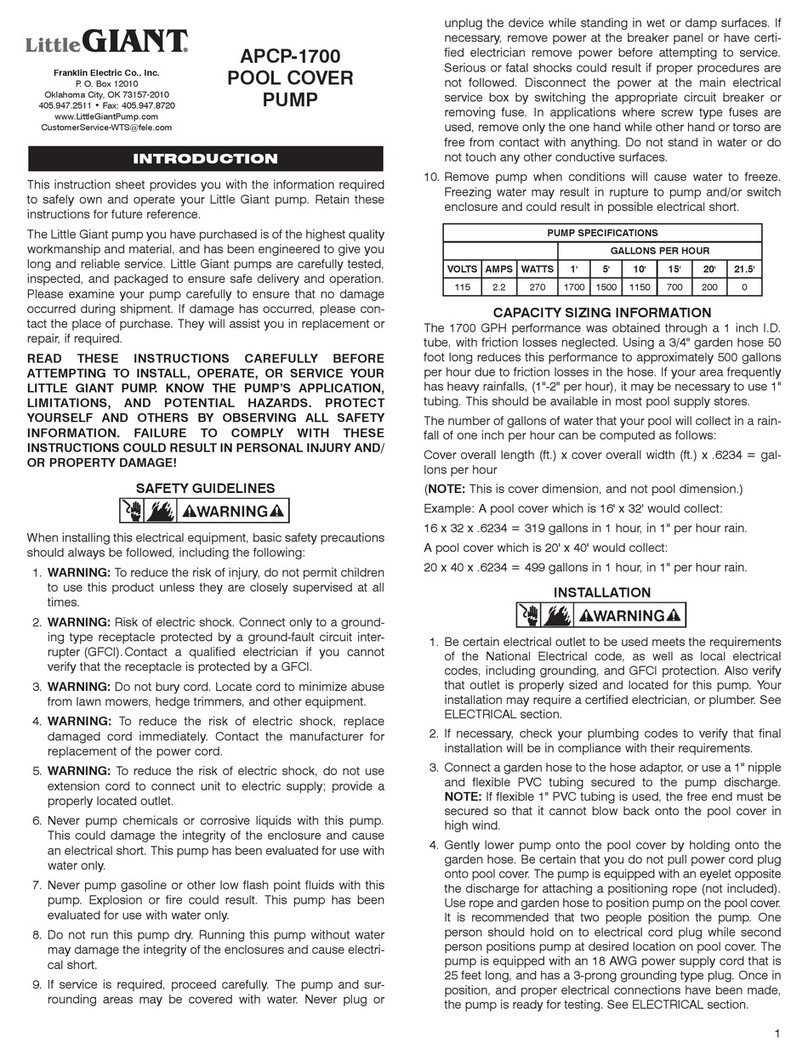

Little Giant

Little Giant APCP-1700 introduction

i-MO

i-MO CIRCOR D12DZ-250 Instruction manual and parts list

All Pond Solutions

All Pond Solutions FPP-600 manual