Feelgood mr. steam Club Therapy CT6E Instruction manual

mr

.steam

®

Feel Good Inc.

Clu Therapy Steam ath Generator Systems

Installation, Operation & Maintenance Manual Models: CT6E, CT9E, CT12E, CT15E

Installation, Operation & Maintenance Manual

Club Therapy®Steambath Generator Systems

INSTALLATION, OPERATION & MAINTENANCE MANUAL

Table of Contents

Read Me First! & Warning Placard .....................................1

Select Your Clu Therapy Model .......................................2

Specification Chart .............................................................2

Before Installing .................................................................3

Steam Room Guidelines.....................................................3

Locating the Steam Generator Unit ...................................4

Typical Installation ..............................................................5

Installation: Plum ing, Water Supply, Drain, Steam

Outlet, Safety Valve, Condensation Pan, AromaSteam ....6

Water Quality Information..................................................6

AromaSteam SteamHead Installation ................................7

Generator Dimensions .......................................................8

Electrical Specifications & Field Power Wiring ..................9

Wiring Diagrams...............................................................10

Initial Start-Up & Checkout, Maintenance, Generator

Operations and Trou leshooting..................................11

System Status Codes, Liquid Level Control Board ..........12

AutoFlush®System ...........................................................13

Condensation Pan, Express Steam®.................................14

Replacement Parts List.....................................................14

Replacement Parts Diagram.............................................15

Controls

Before Installing, Control Rough-In..................................16

CT SteamStop ..................................................................17

Care Tips for Controls and Steamhead............................17

General

Warranty ...........................................................................18

PUR

100426

REV

1.20

mr.steam®Sussman-Automatic Corp.®[email protected] www.mrsteam.com

43-20 34th Street, Long Island City, NY 11101 TEL: 1 800 76 STEAM

9410 S. La Cienega Blvd. Inglewood CA 90301 TEL: 1 800 72 STEAM

USA

Designed, Engineered

and Assembled in the

READ ME FIRST!

IMPORTANT NOTE:

As you follow these

instructions, you will notice warning and caution

sym ols. This locked information is important

for the safe and efficient installation and opera-

tion of this generator. These are types of poten-

tial hazards that may occur during this installa-

tion and operation:

states a hazard may cause seri-

ous injury or death if precautions are not fol-

lowed.

signals a situation where minor

injury or product damage may occur if you do

not follow instructions.

is used to address practices not

related to physical injury.

IMPORTANT NOTE:

This highlights infor-

mation that is especially relevant to a pro lem-

free installation.

All information in these instructions is ased on

the latest product information availa le at the

time of pu lication. Sussman-Automatic

Corporation reserves the right to make changes

at any time without notice. More current instruc-

tions may e availa le at

www.mrsteam.com.

When installing and using this electrical equipment, asic safety precautions

should always e followed, including the following:

IMPORTANT SAFETY INSTRUCTIONS

1. READ AND FOLLOW ALL INSTRUCTIONS

2. Do not permit children under the age of 16

to use this steam ath.

3.

To reduce the risk of injury:

A. The wet surfaces of steam enclosures may e slippery. Use care when

entering or leaving.

B. The steam head is hot. Do not touch the steam head and avoid the

steam near the steam head.

C. Prolonged use of the steam system can raise excessively the internal

human ody temperature and impair the ody’s a ility to regulate its

internal temperature (hyperthermia). Limit your use of steam to 10-15

minutes until you are certain of your ody’s reaction.

D. Excessive temperatures have a high potential for causing fetal damage

during the early months of pregnancy. Pregnancy or possi ly pregnant

women should consult a physician regarding correct exposure.

E. O ese persons and persons with a history of heart disease, low or high

lood pressure, circulatory system pro lems, or dia etes should consult

a physician efore using a steam ath.

F. Persons using medication should consult a physician efore using a

steam ath since some medication may induce drowsiness while other

medications may affect heart rate, lood pressure and circulation.

A warning placard has een provided in the Information

envelope. This placard is an essential part of providing

a safe environment for steam room users. This placard

must e mounted to the wall of the shower or steam

enclosure, at a point visi le to all users. Failure to

mount this placard may result in serious injury or death.

SAVE THESE INSTRUCTIONS

1

mr

.steam®

C L U B T H E R A P Y Installation, Operating & Maintenance Manual

_________________________________________________________________________________________

STEAM ROOM BENEFITS

Steam bathing is a communal activity. Enjoy steam together with friends. Relax, knowing

that steam may be a natural detox. Here are some possible benefits of steam bathing:

- Cleanses, nourishes, and hydrates skin

- Boosts metabolism

- Provides relief for respiratory ailments such as colds, flu, allergies, and asthma

- Reduces stress and promotes restful sleep

Follow your steambath with a refreshing shower.

If you would like your own personal steam bath at home contact us at mrsteam.com

REDUCE THE RISK OF OVERHEATING AND SCALDING

1. Exit immediately if uncomfortable, dizzy or sleepy. Staying too long in a

heated area is capable of causing overheating.

2. Children under the age of 16 should not use the steam bath.

3. Check with a doctor before use if pregnant, diabetic, in poor health or

under medical care.

4. Breathing heated air in conjunction with consumption of alcohol, drugs or

medication is capable of causing unconsciousness.

5. Do not contact steam head or steam at the steam head.

REDUCE THE RISK OF SLIPPING AND FALL INJURY

Use care when entering or exiting the steam room, floor may be slippery.

Note:

For additional safety considerations see owner's manual.

MrSteam 43-20 34th Street, Long island City NY 11101 1-800-76-STEAM www.mrsteam.com

HYPERTHERMIA occurs when the internal temperature

of the ody reaches a level several degrees a ove the

normal ody temperature of 98.6° F. The symptoms of

hyperthermia include an increase in the internal tem-

perature of the ody, dizziness, lethargy, drowsiness,

and fainting. The effects of hyperthermia include:

a) Failure to perceive heat;

) Failure to recognize the need to exit the steam ath;

c) Unawareness of impending risk;

d) Fetal damage in pregnant women;

e) Physical ina ility to exit the steam ath

and

f) Unconsciousness.

The use of alcohol, drugs, or medica-

tion can greatly increase the risk of hyperthermia.

not actual size

mr

.steam®

C L U B T H E R A P Y Installation, Operating & Maintenance Manual

_________________________________________________________________________________________

2

In considering a purchase of this steam-

ath system, please note that if users are pregnant,

have a coronary condition, are in poor health, are eing

treated for any other medical condition, or are using

medication or drugs, MrSteam recommends that you

o tain the approval of their physician efore use.

For information a out this product and safety issues,

please call us at 1-800-76-STEAM or log onto

www.mrsteam.com

IMPORTANT NOTES:

•

The guidelines for selecting the steam ath generator is

a recommendation only. Because of varia les in con-

struction, these sizing instructions and specifications

should e considered as guidelines only. MrSteam will

review the model selected provided we receive com-

plete information, including working drawings, specifi-

cations, and pertinent electrical and construction

details. Otherwise, the manufacturer disclaims respon-

si ility for the sizing of a model selected.

• For steam rooms constructed of acrylic or synthetic

materials, select next lower-rated CT model.

• The total adjusted room volume allows for up to 60

feet of insulated steam piping from the CT generator

to the steam room. If the 60 feet piping is exceeded

consult with factory. When locating the steam gener-

ator consideration of the control and external tem-

perature pro e must e taken into account. The max-

imum length for a control ca le is 60 feet. The maxi-

mum length of the MSTS is 60 feet. MSTS connects

to the steam generator and is required to e installed

inside the steam room when the control is mounted

outside the steam room.

Steam Generators Specification Chart

Amps (for Total A j Wire Water Usage Shipping

Mo el No. KW 240v/1PH)† Room Vol. Size‡ gallons†† Dimensions* Wt. (lbs)**

CT6E 6 25 150 8 0.80 17"L x 18½"H x 77⁄8"D 40

CT9E 9 38 360 8 1.2 17"L x 18½"H x 77⁄8"D 40

CT12E 12 50 575 6 1.6 17"L x 18½"H x 77⁄8"D 40

CT15E 15 63 675 4 2.0 17"L x 18½"H x 77⁄8"D 40

IMPORTANT NOTES:

• A C1 suffix to Mo el No. for 240V/1Ph; A B1 suffix to Mo el No. for 208V/1Ph.

• All CT MS Mo els are cUL us Liste an CE; approve .

All CT Generators availa le in 240v/1PH, 208v/1PH and other voltages/phases.

† Amps are for 240/1PH rated units.

‡Wire size (AWG) ased on minimum 90˚C rated THHN copper conductors. Refer to the

National Electrical Code for other types of conductors.

*Dimensions are for generator only, with-

out AutoFlush®or plum ing features.

**Shipping weight and pricing are for

generator only, without control or

steamhead.

†† Water usage ased on 20 minutes of

operation.

Materials of construction, room size and special design features such as

large glass areas, all affect the steam generator model selection.

1.

Measure length, width & height in feet of the steam/shower or tu /shower

Multiply the Length ____ x Width____ x Height _____ =

2. Construction Materials:

For natural stones: natural mar le, Add 110%

stone, shale, glass lock or concrete

For ceramic or porcelain tile on Add 40%

cement oard or mortar ed

3. Ceiling Height: For each foot a ove 8 feet

(max. of 10 feet) Add 15%

4. Add all figures a ove to o tain

the Total Room Volume required

ROOM

VOLUME

TOTAL ADJUSTED

ROOM VOLUME

Select Your Club Therapy Mo el

Compare your TOTAL ADJUSTED ROOM VOLUME to the Specification Chart

elow and select the appropriate model.

Visit www.mrsteam.com to size your generator automatically.

mr

.steam®

C L U B T H E R A P Y Installation, Operating & Maintenance Manual

_________________________________________________________________________________________

3

If acrylic, fi erglass or other non-heat resistant materials are

used as part of the steam room enclosure. Consult with the material manu-

facture and see pg. 7, “Installing the AromaSteam Steamhead" for addition-

al details.

IMPORTANT NOTES:

This document contains important safety, operation and maintenance infor-

mation. Leave this document with the clu /spa management.

Do not discard this document.

The following general information should e used in conjunction with con-

sultations with an architect, designer and contractor in determining factors

necessary in providing a suita le and safe steam room.

MrSteam CT steam generators are intended to e operated with MrSteam’s

iTempo/Plus™, iSteam®and CT SteamStop®only, and are to e installed

strictly in accordance with the specific instructions contained in this manual

and as supplied in the manuals provided with the controls or accessories.

Never use damaged equipment, doing so may

result in an inoperative or hazardous installation.

Discontinue use of the steam generator and control if the steam

generator or control are damaged or otherwise not functioning

properly. Doing so may result in an inoperative or hazardous

installation

ELECTRICAL SHOCK HAZARD. MrSteam steam generators are

connected to 208V or 240V line voltage and contain live electri-

cal components. All installation and service to e performed y

qualified and licensed electricians and plum ers only. nstallation

or service y unqualified persons or failure to use MrSteam parts

may result in property damage or in a hazardous condition.

Do Not alter or modify any MrSteam product.

Doing so may result in an inopera le or hazardous

installation and will void the warranty

8. Steam room tile construction information is availa le from the Tile

Council of America, Inc. y purchasing

the TCA Hand ook for Ceramic Tile Installation.at (864) 646-8453

or www.tileusa.com.

9. Windows that are part of the steam room should e dou le

paned and tempered safety glass.

10. Limit steam room ceiling height to 8 feet. Exceeding 8 feet may

require a higher-rated steam generator.

The warning

placard is located in the docu-

mentation envelope. This plac-

ard is an essential part of provid-

ing a safe environment for steam

room users. This placard must e

mounted to the wall of the

shower or steam enclosure, at a

point visi le to all users. Failure

to mount this placard may result

in serious injury or death. For a

replacement placard contact

MrSteam customer service at 1-

800-76-STEAM or

Before Installing

Carefully inspect the CT steam generator and packaging for

shipping damage. In the event of shipping damage, please

contact the carrier for claim information. Our customer service

department can assist you with any missing or damaged parts.

Read these instructions efore installation or service. Although

this CT steam generator has een fully qualified

for shipment y MrSteam, the following must e reviewed for

proper, safe and enjoya le steam athing:

1. Verify that the model and accessories specifications are cor-

rect for the incoming line voltage.

2. Insure steam ath generator has een correctly sized for the

steam ath room. Pay particular attention to room volume

Steam Room Gui elines

IMPORTANT NOTE:

Owners/Operators should o tain a

copy and familiarize themselves with the latest edition of the

American College Sports Medicine Health/Fitness Facility

Standards and Guidelines, or a similar resource and reference

pu lication, and refer to those guidelines for the proper and

safe operation of a spa facility including steam rooms.

1. Steam room must e completely enclosed, with full

walls, door, floor and ceiling.

2. It is recommended that a gasketed door is used for

steam containment.

3. If tile-type or other smooth surfaced flooring is used

provide suita le anti-skid strips or equivalent, to

prevent a slipping hazard.

4. Check the suita ility of any materials with the

manufacturer. Walls and ceilings must e constructed

of water-resistant, non-corrosive surface, such as tile,

mar le, molded acrylic, or other non-porous material.

5. The ceiling should e sloped to prevent dripping of

condensate.

6. Provide a floor drain.

7. No heating, venting or air conditioning devices

should e installed inside the steam room.

and construction. If any questions, please refer to MrSteam sizing

and selection guide on page 2.

3. Mar le or glass walls or ceilings “enlarge” the room’s size requir-

ing a generator larger than one ased only on the room’s cu ic

foot (L x H x W) volume.

4. The physical size of the unit, clearance for plum ing servicing,

and its distance from the steam room must all e considered

efore final installation.

5. Consider any controls and accessories efore initiating installa-

tion. Read the Installation & Operation Manual of all controls

and accessories availa le at

www.mrsteam.com/products/technical-downloads.html

STEAM ROOM BENEFITS

Steam bathing is a communal activity. Enjoy steam together with friends. Relax, knowing

that steam may be a natural detox. Here are some possible benefits of steam bathing:

- Cleanses, nourishes, and hydrates skin

- Boosts metabolism

- Provides relief for respiratory ailments such as colds, flu, allergies, and asthma

- Reduces stress and promotes restful sleep

Follow your steambath with a refreshing shower.

If you would like your own personal steam bath at home contact us at mrsteam.com

REDUCE THE RISK OF OVERHEATING AND SCALDING

1. Exit immediately if uncomfortable, dizzy or sleepy. Staying too long in a

heated area is capable of causing overheating.

2. Children under the age of 16 should not use the steam bath.

3. Check with a doctor before use if pregnant, diabetic, in poor health or

under medical care.

4. Breathing heated air in conjunction with consumption of alcohol, drugs or

medication is capable of causing unconsciousness.

5. Do not contact steam head or steam at the steam head.

REDUCE THE RISK OF SLIPPING AND FALL INJURY

Use care when entering or exiting the steam room, floor may be slippery.

Note:

For additional safety considerations see owner's manual.

MrSteam 43-20 34th Street, Long island City NY 11101 1-800-76-STEAM www.mrsteam.com

Not Actual Size

4

Locating the Steam Generator Unit

IMPORTANT NOTE:

The control ca les should e run in dedicated 1" conduit to

facilitate installation and service Select a location as near as practical to the steam room.

Typical locations include: closet, vanity ca inet, heated attic or asement.

The maximum length of the MSTS is 60 feet. MSTS connects to the steam

generator and is required to e installed inside the steam room when the control is mounted

outside the steam room.

(Items 1-7)

1. DO NOT install steam ath generator or plum ing lines in unheated attic or any

locations where water could freeze.

2. DO NOT install steam ath generator inside steam room.

3. DO NOT install steam ath generator outdoors or wherever environmental condi-

tions may affect the safety and/or performance of the generator.

4. DO NOT install steam ath generator near flamma le or corrosive materials or

chemicals such as gasoline, paint thinners, or the like. Installation in areas having

high concentrations of chlorine (such as pool equipment room) must e avoided.

5. Install steam ath generator on a solid and level surface. Provide supports under

steam generator when wall mounting. Keyhole slots are provided for wall mounting.

Insure the steam generator is properly secured and level when mounting with

keyhole slots.

6. Install steam ath generator in an upright position only.

7. Burn Hazard.

Steam piping, safety valve, drain valve, plum ing and steamheads

ecome hot during operation and remain hot after shutdown for a period of

time. Provide appropriate protection, including insulating plum ing lines.

Avoid plum ing runs and steamhead locations that can come in contact

with athers.

IMPORTANT NOTE:

(Items 8-11)

8. Install anti-water hammer device as necessary.

9.

Provide a minimum of 12 inches at oth ends and

top of the steam generator or as required for servicing. See page 8.

10. Provide unions as required to facilitate installation and disconnection of piping.

11. The controls should e placed in a location only accessi le y the facility’s staff.

The CT SteamStop®and remote sensor are required to e installed inside the

steamroom.

MrSteam Generators and controls are CE and UL listed.

The CT series of steam generators are for commercial use only.

mr

.steam®

C L U B T H E R A P Y Installation, Operating & Maintenance Manual

_________________________________________________________________________________________

mr

.steam®

C L U B T H E R A P Y Installation, Op rating & Maint nanc Manual

_________________________________________________________________________________________

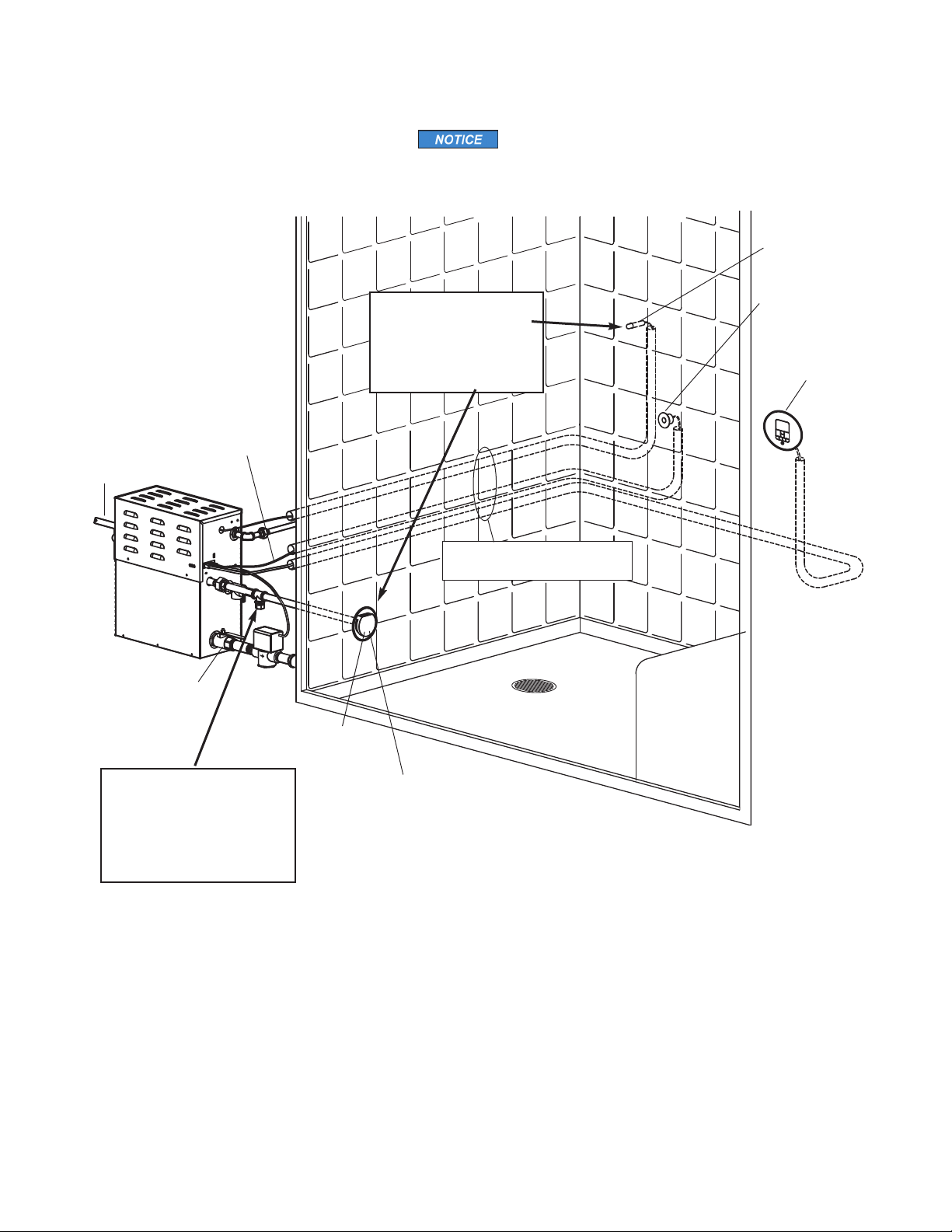

5

Provid unions as r quir d

to facilitat installation and

disconn ct of piping

St am

G n rator

Fi ld install d

pow r supply

Fi ld install d

st am piping

Drain Valv should

b clos d wh n

AutoFlush is not

install d

Control cabl s run in 1” conduit

(locat d b hind th wall)

St am H ad (shown with optional

acrylic shi ld) S pag 7 for

St am H ad Installation information

R mot S nsor

s pag 16

CT St amStop®

Control. S pag

17 for installation

information.

iT mpo/Plus®

or iSt am

Control. S

pag 16

Fi ld install d

wat r supply lin

IMPORTANT: Locat th

r mot s nsor in a location

r pr s ntativ of th d sir d

st ambathing t mp ratur s.

Do not locat th control abov

or n ar th st am h ad or

dir ct st am missions.

Typical MrSteam®Installation

Wh n installing th optional

AromaSt am, install a downward

facing 90-d gr T in th st am

piping. S th AromaSt am

Installation Manual for

compl t information.

FOR ILLUSTRATIVE PURPOSES ONLY

Som compon nts may b omitt d or alt r d for clarity. Do not us for

wiring, r pair or oth r purpos s not r lat d to compon nt id ntification.

mr

.steam®

C L U B T H E R A P Y Installation, Op rating & Maint nanc Manual

_________________________________________________________________________________________

6

Installation

Plumbing

All plumbing shall b p rform d by a qualifi d lic ns d plumb r

and in accordanc with applicabl National and local cod s.

•Us unions on all pip conn ctions.

• Us only brass piping or rigid copp r tubing as

p rmitt d by cod s.

• Do not us black, galvaniz d, PVC, or PEX pip .

Water Supply (3⁄8"N P T )

1. Conn ct to cold wat r lin .

2. Provid a shut off valv in th wat r supply lin upstr am

of th st ambath g n rator.

3. Do not ov rh at inl t sol noid valv with sold r conn ctions.

Ov rh ating will damag parts.

4. Flush inl t wat r lin thoroughly b for making conn ction

to unit.

5. Strain r r comm nd d upstr am of f d wat r conn ction.

6. For b st p rformanc wat r pr ssur should b 15 to 20 psig.

R duc pr ssur as r quir d.

7. Provid anti-wat r hamm r d vic as r quir d.

8. Install an approv d backflow pr v nt r as r quir d by local

cod s.

Drain

(1" N P T )

The drain from the generator should not share an undersin

trap, unless the generator is mounted higher than the sin .

A drain valv is provid d to facilitat

s rvicing. Provid a drain lin conn ction from st ambath

g n rator drain valv according to National and local Cod s.

Ch ck local plumbing cod for r c ptor, trap

and v nt r quir m nts. Do not conn ct Drain lin and Saf ty

Valv lin tog th r. Unit drains by gravity.

Do NOT conn ct th drain valv to th st am piping.

Safety Valve (3⁄4"

N P T

)

Wh r p rmitt d by local cod s, provid an outl t plumbing

conn ction for saf ty valv .

To insur prop r and automatic saf ty valv

op ration: DO NOT conn ct a shut off valv or a plug at saf ty

valv outl t. DO NOT conn ct a shut off valv or any construc-

tion in st am supply piping.

Condensation Pan

MrSt am strongly r comm nds th us of a cond nsation pan in

th unlik ly v nt of a plumbing l ak. Ch ck local plumbing

cod s for r c ptor, trap and v nt r quir m nts. Cond nsation

pans drain by gravity. Th cond nsation pan is quipp d with an

int gral 3⁄4" fitting. S pag 14 for additional cond nsation pan

installation information.

AromaSteam

If th optional AromaSt am El ctronic Oil D liv ry Syst m

(

PN

:

MS AROMA

) is to b install d, a 90 d gr Tplumbing fitting

must b install d at a d signat d location on th st am outl t lin .

S th MrSt am Aroma-St am Op ration and Instruction Manual

for installation information b for th st am piping is install d at

www.mrst am.com t chnical downloads.

Steam Piping (1⁄2"N P T )

1. Do not install any valv in st am piping. Flow of st am must

bunobstruct d.

2. Us 1⁄2inch brass pip or copp r tubing from unit to st am

h ad as p rmitt d by cod s.

3. Insulat st am piping with fib rglass pip insulation or

similar insulation rat d 212° F or high r.

4. Pitch st am piping 1⁄4"p r foot towards st am h ad or st am

g n rator to avoid vall ys and trapping of cond nsat .

Failur to pitch th st am piping as r quir d for

cond nsat to drain, may caus cond nsat to block th flow of

st am. Blocking th st am flow may caus st am pr ssur to dis-

charg boiling wat r through th st amh ad, r sulting in a scald-

ing hazard. Blocking th flow of st am may caus st am to dis-

charg through th saf ty valv , r sulting in a scalding hazard.

A 1.5" hol in th st am room is r quir d to

mount th st amh ad.

Water Quality Information

For optimum r sults, th wat r supply should b t st d prior

to installation. If th min ral cont nt xc ds th following

r comm nd d limits, various xt rnal tr atm nt proc ss s ar

r comm nd d to corr ct th probl m.

An analysis of th on-sit wat r must b mad

by a r cogniz d and r liabl wat r tr atm nt company to

asc rtain th xisting condition and tr atm nt r quir d.

Poor wat r quality can aff ct ffici ncy or r sult in st am

g n rator damag . Wat r contains impuriti s in solution and

susp nsion. Th s impuriti s conc ntrat in th g n rator. Th

conc ntration of th s impuriti s incr as s as mor f dwat r

is introduc d into th g n rator and st am is produc d. If th

susp nd d solids ar allow d to conc ntrat b yond c rtain

limits, a d posit or “scal ” will form on th g n rator int rnal

surfac s. This d posit can int rf r with th prop r g n rator

op ration and caus g n rator failur . Th conc ntration of

th s impuriti s is g n rally controll d by th wat r quality

and by p riodic draining of th g n rator.

RECOMMENDED FEEDWATER QUALITY

Hardn ss, ppm 8 – 85 (~0.5 – 5 gpg)

P-Alkalinity, ppm 85 – 410 (~5 – 24 gpg)

T. Alkalinity, ppm 200 – 500 (~7 – 0 gpg)

pH (str ngth of alkalinity) 8.0 – 11.4

Th CT AutoFlush Syst m f atur automatically drains th

CT g n rator following ach us . A tim d lay allows th

wat r to cool down (about two hours) b for it drains by

gravity for a saf and g ntl op ration.

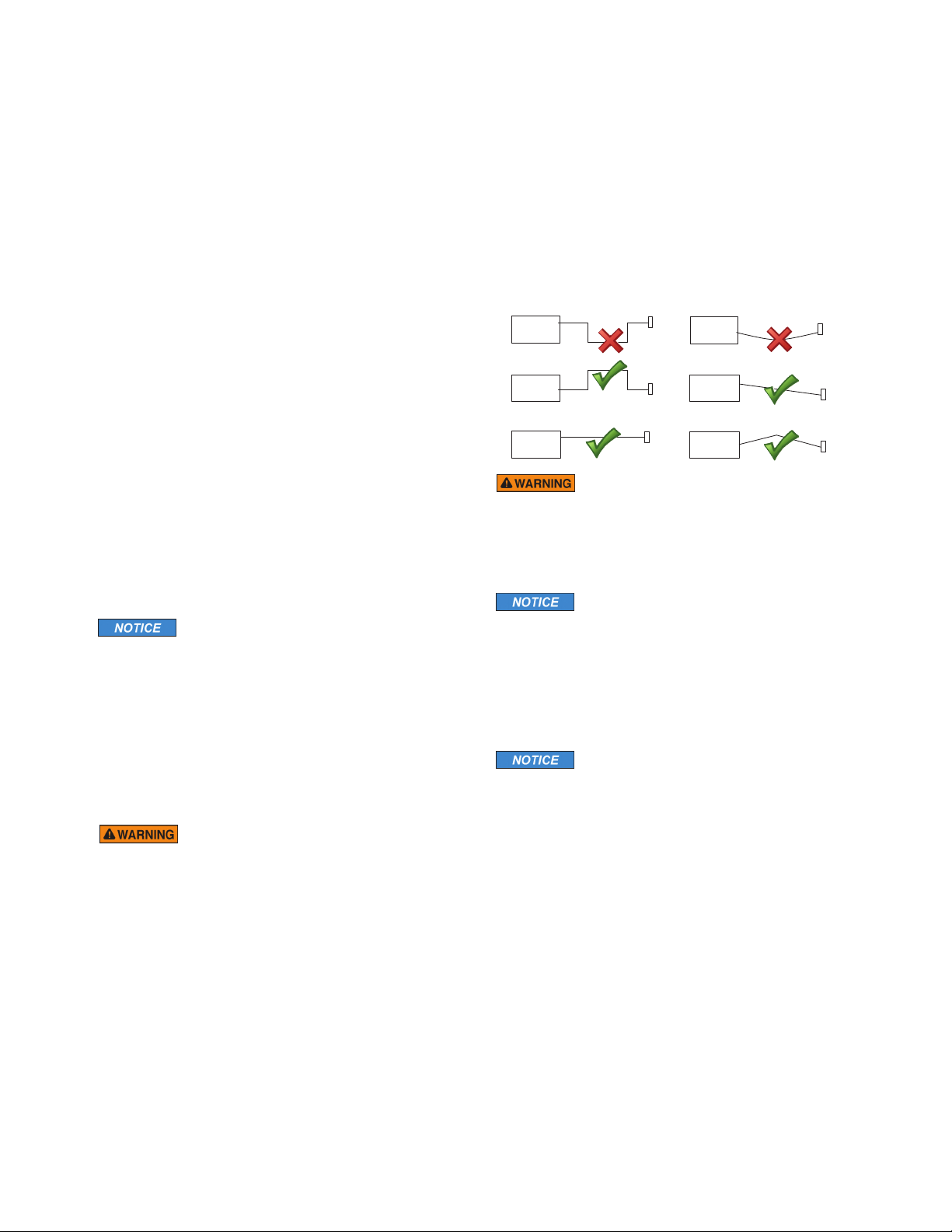

Steam

Generator

Steam

Generator

Steam

Generator

Steam

Generator

Steam

Generator

Steam

Piping

Steam

Head

Steam

Piping

Steam

Head

Steam

Piping

Steam

Head

Steam

Piping

Steam

Head

Steam

Piping Steam

Head

Steam

Generator

Steam

Piping

Steam

Head

mr

.steam®

C L U B T H E R A P Y Installation, Operating & Maintenance Manual

_________________________________________________________________________________________

7

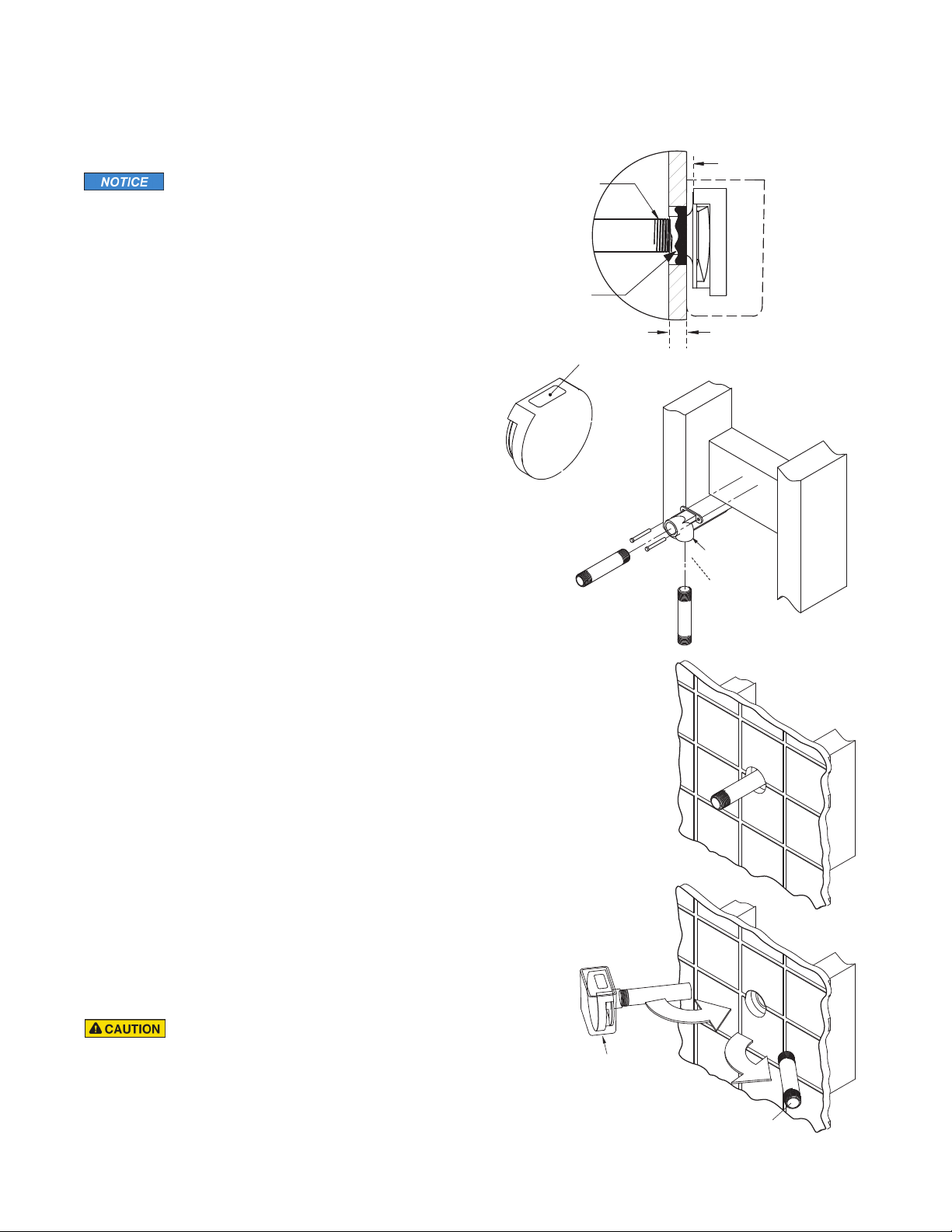

Steam Pipe

End of pipe to

be recessed 1/8"

1/8" minimum clearance

required for Acrylic Shield.

Apply with silicone

or equal sealant

as required for

moisture seal.

Use Teflon®or

equal sealant on

pipe threads

A 1

1⁄2

" clearance hole around the steam pipe is

needed to mount the steamhead.

STEP 1

Locate steam head 6-12 inches a ove floor, except for:

1. Tu /shower enclosures, install 6 inches a ove tu top edge.

2. Consult with supplier of acrylic, fi erglass and other non-heat

resistant enclosures for recommended steamhead location.

3. Use Acrylic Shield MS 103412. See instructions provided with

steam shield.

4. To reduce noise do not locate the steamhead within 12" from

a wall.

STEP 2

Install steamhead with the oil well facing up as shown.

Hand tightening is sufficient when teflon or equal pipe thread

sealing compound is used.

STEP 3

Secure a ronze drop ear fitting to a header and run a

1⁄2

"

copper steam pipe from the steam generator to the drop ear

fitting. Install a temporary nipple (6" or longer) in the drop ear

fitting to locate the steamhead after the wall is finished.

STEP 4

After the wall has een finished, mark on the nipple where the

surface of the wall is. Remove the nipple and measure the por-

tion that was in the wall (the end to your mark). Su tract 1⁄8" from

that dimension and select a rass nipple of that length to finish

the installation.

STEP 5

Wrap teflon tape around the threads of the new nipple and screw

the nipple into the steamhead. Do not use wrenches or tools which

would damage the steamhead's finish.

Wrap teflon tape around the threads of the nipple and screw the

nipple and steamhead assem ly you just made into the drop ear fit-

ting in the wall. The steamhead should e flush with the wall and

the well must e facing up.

__________________________________________________________

IMPORTANT NOTE:

•Do not disassem le steamhead. MrSteam’s steamhead is

shipped fully assem led and requires no additional assem ly.

• To preserve steam head finish, do not use wrenches or other

tools to tighten. DO NOT use a rasive cleansers or chemicals.

Use only water with mild soap and a non-a rasive sponge.

Because the steam head and direct steam emissions are very hot,

locate the steam head where incidental contact y ather with

the steam head or direct steam emission cannot occur.

Oil Well

STEP 3

STEP 4

STEP 5

Installing the AromaSteam Steamhea (1⁄2" NPT)

Steamhead

(shown with acrylic shield)

Locating ipple

Drop Ear

Fitting

All drawings are for illustrative purposes only

mr

.steam®

C L U B T H E R A P Y Installation, Operating & Maintenance Manual

_________________________________________________________________________________________

8

17"

(432)

2

3/8

"

(60)

23/8"

(60)

71/4"

(184)

121/2"

(310)

13/4"

(45)

183/4"

(466)

4"(102)

6"(152)

97/8"

(251)

13/8"

(35)

63/8"

(162)

77/8"(200)

12”(305)

for servicing

WATER INLET 3/8” NPT

STEAM OUTLET 1/2” NPT

SAFETY VALVE 3/4” NPT

MANUAL DRAIN VALVE 1” NPT

AUTOFLUSH VALVE 1” NPT

1. M= Optional AutoFlush

2. All units in inches (MM)

Water Inlet

Steam Outlet

Safety Valve

AutoFlush

Manual

Drain Valve

Generator Dimensions

IMPORTANT NOTES:

• Provide a minimum of 12 inches at oth ends and top

of the steam generator or as required for servicing.

Alternately, provide unions as required to facilitate

installation and disconnection of the steam generator.

• The minimum clearance from com usti le surfaces is

zero all around.

TO AVOID EQUIPMENT DAMAGE DO NOT CONNECT

POWER SUPPLY DIRECTLY TO ELEMENTS !!!

All drawings are for illustrative purposes only

Water Inlet

Control &

Accessory

Connections

Steam Outlet

Safety Valve

Manual

Drain Valve

Side View

Showing Element

Access Panel

mr

.steam®

C L U B T H E R A P Y Installation, Operating & Maintenance Manual

_________________________________________________________________________________________

Electrical

All electrical wiring to e installed y a qualified licensed elec-

trician in accordance with National Electrical Code and local

electrical code.

Power Wiring-

See “Field Power Wiring” Diagrams ( elow)

1. Check power voltage. Use 240V rated unit when supply is

greater than 208V. Use 208V rated unit for 208V power.

2. Use minimum 90˚ C/300V rated insulated copper conductors

only, sized in accordance with National Electrical Code and

local electrical code for the current in Ampere Chart. If

allowed y codes, NM ca le may require a larger wire size

than as listed on the chart.

3. Connect suita ly sized equipment grounding wire to ground

terminal provided.

4. Install a separate circuit reaker etween supply and unit.

Provide a power supply disconnect within sight of the steam

generator or one that is capa le of eing locked in the open

position.

5. For single phase units, use two-wire supply source and equip-

ment grounding wire. Neutral (white) wire is not required.

CHART

___________________________________________________________________________

Model Max Room KW Volts Wire Size Wire Size

o. Vol (Cu. Ft.*) 1 PH

†

Phase Amps (AWG) for 40˚C (AWG) for 45˚C

Ambient Ambient

___________________________________________________________________________

208 1 29 88

CT6E 150 6.0 3 17 10 10

240 1 25 88

314 12 12

___________________________________________________________________________

208 1 44 8 6

CT9E 360 9.0 3 25 88

240 1 38 88

3 22 10 10

___________________________________________________________________________

208 1 58 64

CT12E 575 12.0 3 34 88

240 1 50 66

3 29 88

___________________________________________________________________________

208 1 73 43

CT15E 675 15.0 3 42 86

240 1 63 44

3 36 88

____________________________________________________________

*See page 2 for room sizing.

†All specifications shown are for 208V and 240V. Consult factory for

other voltage specifications.

Provi e a power supply isconnect within sight of the steam

generator or one that is capable of being locke in the open position as permitte by co e.

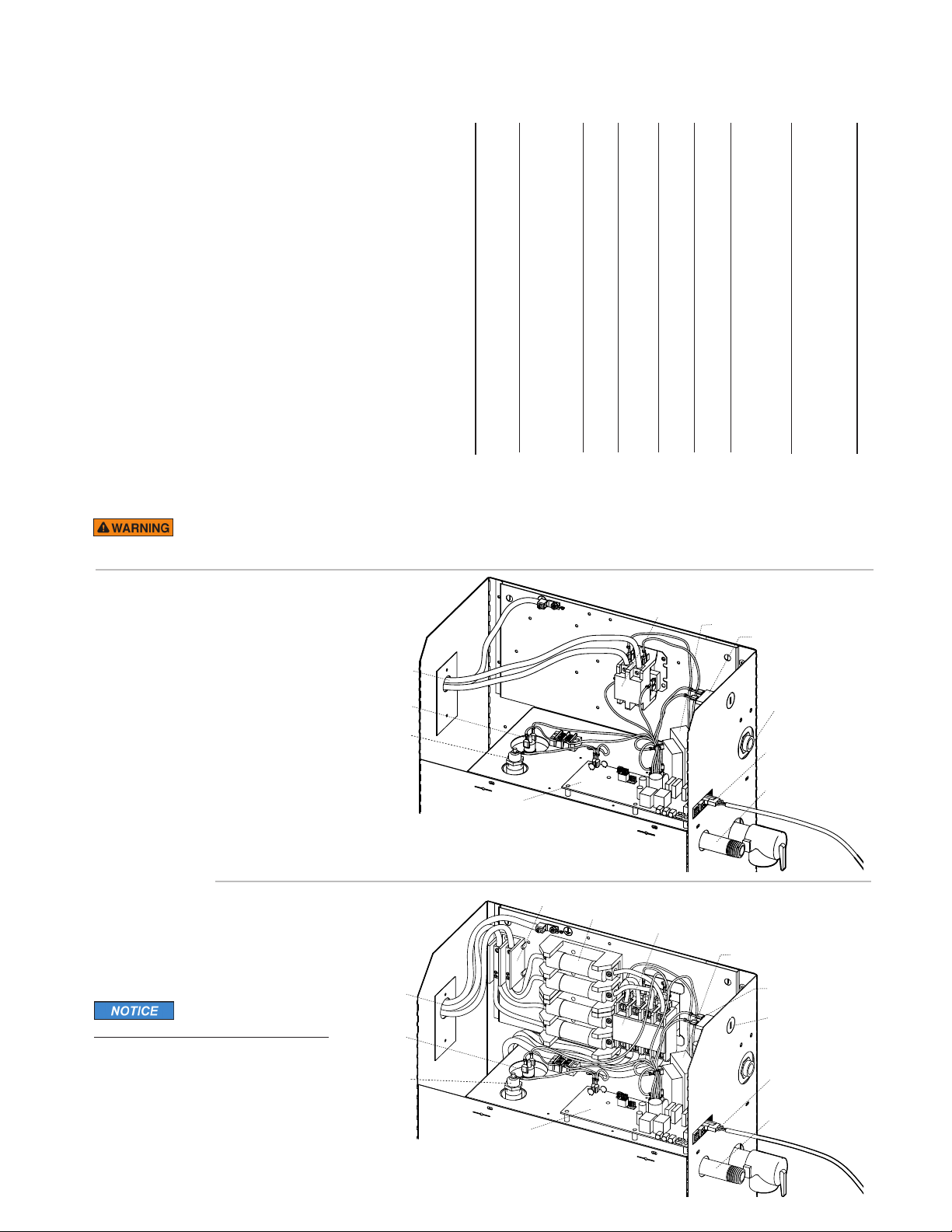

Transformer

Liquid Level

Control Board

Water Feed

Solenoid

Water Inlet

Thermostat

Liquid

Level Probe

Power Block

Power Supply

Knock-Out

Contactor

Steam Outlet

Fuses

AutoFlush Plug and

Play Connector

(see page 13)

Transformer

Liquid Level

Control Board

Water Feed

Solenoid

Water Inlet

AutoFlush Plug and

Play Connector

(see page 13)

Thermostat

Liquid

Level Probe

Power Supply

Knock-Out

Contactor

Steam Outlet

Fiel Power Wiring

1. TO AVOID EQUIPMENT DAMAGE

DO NOT CONNECT POWER SUPPLY

DIRECTLY TO ELEMENTS!!!

2. L1, L2, Ground to e field wired

Mo els CT6E – CT9E

(single phase wiring shown)

Mo els CT12E & 15E

(single phase wiring shown)

FOR ILLUSTRATIVE PURPOSES ONLY

Some components may e omitted

or altered for clarity. Do not use for

wiring, repair or other purposes not

related to component identification.

9

mr

.steam®

C L U B T H E R A P Y Installation, Operating & Maintenance Manual

_________________________________________________________________________________________

10

CONTACTOR

To Probe

HEATING ELEMENT

MSTS

TEMP. PROBE

AutoFlush

CT-SteamStop

iTempo/Plus or

iSteam Control

Transformer

POWER INPUT

L1 L2

GROUND

Express

Steam

WATER

FEED

SOLENOID

VALVE

THERMOSTAT

THERMOSTAT

HEATER

C

PURPLE

CONTROL BOARD

WHT/GRAY

WHT/BLUE

RED

WHT/RED

Remove Jumper

when CU-HTC

is installed

CONTROL BOARD

CONTACTOR

Heating Element To Probe

AutoFlush

CT-SteamStop

iTempo/Plus or

iSteam Control

TRANSFORMER

POWER INPUT

L1 L2

FUSES

GROUND

WATER

FEED

SOLENOID

VALVE

Express

Steam

THERMOSTAT

HEATER

Remove Jumper

when CU-HTC

is installed

AutoFlush

CT-SteamStop

iTempo/Plus or

iSteam Control

RED

MSTS

TEMP. PROBE

THERMOSTAT

Remove Jumper

when CU-HTC

is installed

Single Phase

Wiring Diagrams

MODEL CT6E & CT9E

MODEL CT12E & 15E

Three Phase

Wiring Diagrams

MODEL CT6E, CT9E

CT12E & CT15E

FACTORY

WIRING

FIELD

WIRING

L E G E N D

(All Diagrams)

mr

.steam®

C L U B T H E R A P Y Installation, Operating & Maintenance Manual

_________________________________________________________________________________________

Maintenance

MrSteam steam ath generators require little maintenance.

Other than draining, maintenance procedures are minimal. When

AutoFlush is not installed the manual drain valve should e opened

fully flushing out accumulated materials, salts and other particles

which are natural y-products of oiling water, after each use.

Flush a minimum of two-three hours after the control

has een turned off to insure that the water has cooled.

Draining immediately after a steam cycle may

expose PVC and other piping to high temperature water. Check

local codes. The unit will refill automatically after 10 minutes. In

areas of hard water, a MrSteam AutoFlush®system is recommended

for generator longevity.

Steam Generator Operation

MrSteam recommends eginning steam athing at a low tempera-

ture setting to gauge comfort and safety levels. Set the duration at

10 minutes max. to gauge comfort and safety levels. This will allow

the steam generator to heat up and egin producing.

11

Initial Start-Up an Checkout

1. Turn on control. Follow specific instructions provided

with controls.

2. Steam will egin to appear in approximately 5 min-

utes at the steam head. Steam will shut off when

desired temperature is reached and will automatically

resume when room temperature drops elow set

point.

3. Steam will shut off automatically when control counts

down to zero. To shut steam off manually, turn con-

trol OFF. To clear steam from enclosure area, turn

shower on efore opening door.

4. If unit does not start and control does not turn ON

(control display does not light up) then turn reaker

off for 20 seconds and try again.

5. Refer to specific instruction sheets for installation,

operation and maintenance of optional equipment

and Control.

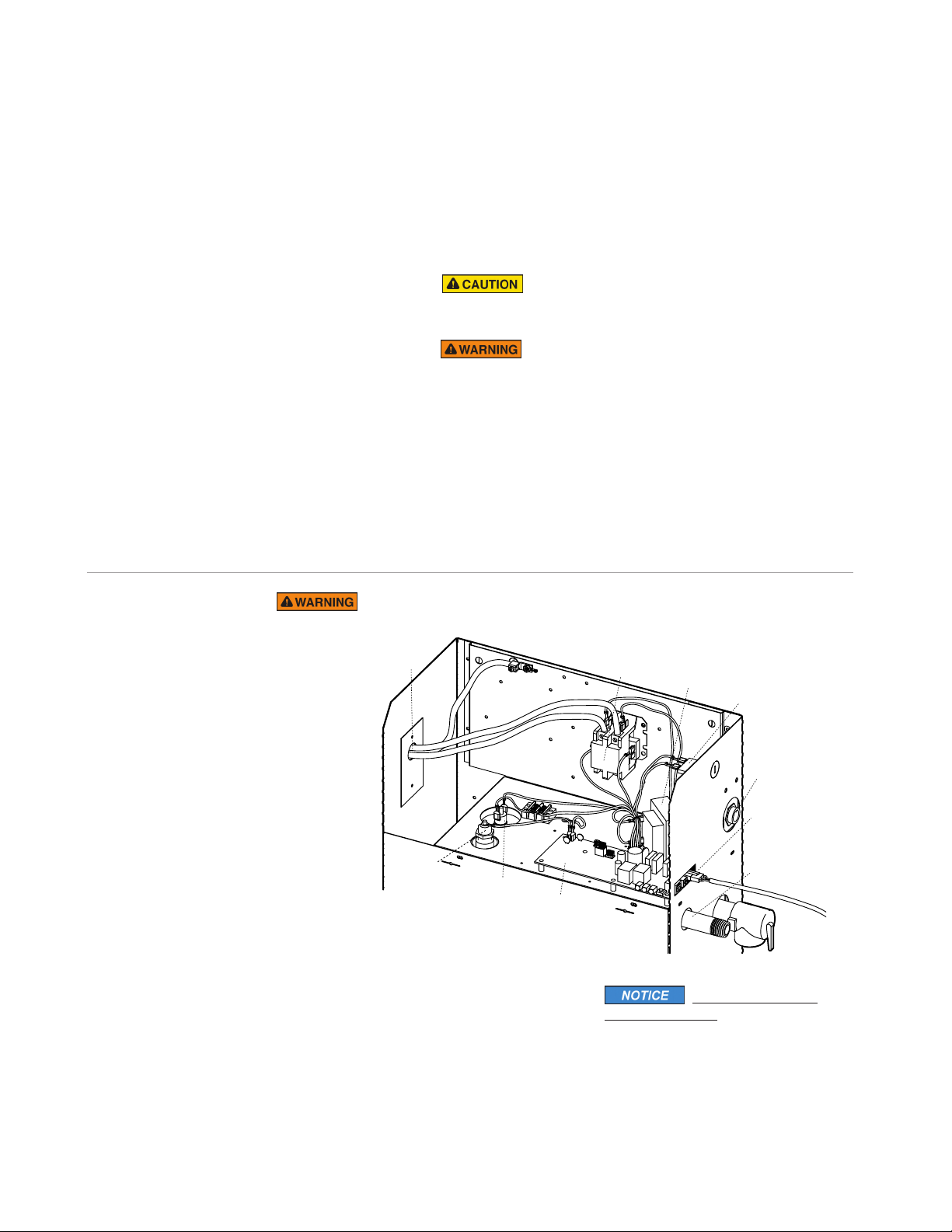

Transformer

Liquid Level

Control Board

Water Feed

Solenoid

Water Inlet

AutoFlush

Plug and Play

Connector

Thermostat

Liquid

Level Probe

Power Supply

Knock-Out Contactor

Steam Outlet

Troubleshooting

Step 1

Check your main incoming power

to the unit.

Step 2 Verify the transformer is receiving

208/240 VAC.

Step 3 Verify that you have 24VAC coming

out of the transformer, WHT & WHT/BLU

wires, into the oard.

Step 4 Verify that you have the green light

on the PC oard.

Step 5 Push the white test utton to run

the generator on a 10 minute test cycle.

Step 6 Verify that you have 24 VAC to the

water feed solenoid, GRY & WHT/GRY

wires (will fill when needed).

Step 7 Temporarily short out the WLS

(Purple wire) and GND (Green wire)

terminals and verify the contactor engages.

Step 8 When the red light is on, verify that

you have 24 VAC, RED & WHT/RED wires,

to the contactor.

Step 9 Check to see that you have your

main voltage on the load side of the

contactor when it is engaged.

Step 10 If all steps on the power path

were verified, turn off power to the unit

and pull the heating element via the left

hand access panel for inspection.

Do not isassemble internal components, internal components contain no serviceable parts.

FOR ILLUSTRATIVE

PURPOSES ONLY.

Some components may e omitted

or altered for clarity. Do not use for

wiring, repair or other purposes not

related to component identification.

All electrical trou leshooting to e performed y a qualified licensed electrician.

mr

.steam®

C L U B T H E R A P Y Installation, Operating & Maintenance Manual

_________________________________________________________________________________________

12

Force On

Test Button

Yellow (Water Level)

Green (Power)

Red (Heater)

System Status Co es

The iTempo/Plus control may display a status code if the steam generator is not functioning properly.

Co e Co e Meaning Probable Cause Suggeste Reme y

H20 Water level is not Water Supply is off Turn on Water Supply

satisfied within 5 min. Defective water feed solenoid Check/replace water solenoid valve

Water feed pro e not functioning Check/clean pro e.

Check pro e wiring.

Drain Valve Open Check/Close drain valve

AutoFlush not functioning Check/Replace AutoFlush

Prr1 Temperature Pro e Error Control/Remote sensor ca le cut Replace Control Ca le/Sensor

or Prr2 Internal pro lem with control/Remote Sensor Replace ControlSensor

Err1 Incorrect Field Supply Voltage Incorrect voltage supplied Supply steam generator with the correct

(green light on liquid level to Generator voltage noted on the data plate la el.

control oard will e off)

Err2 Button on control is pressed Control cover misalignment Remove and reinstall control cover

for more than 5 minutes De ris ehind control cover Remove control cover and clean cover,

control and keypad with a damp cloth

Err7 Liquid Level Control Board Memory error in LLCB Press ON/OFF to clear.

malfunction Replace control if code remains.

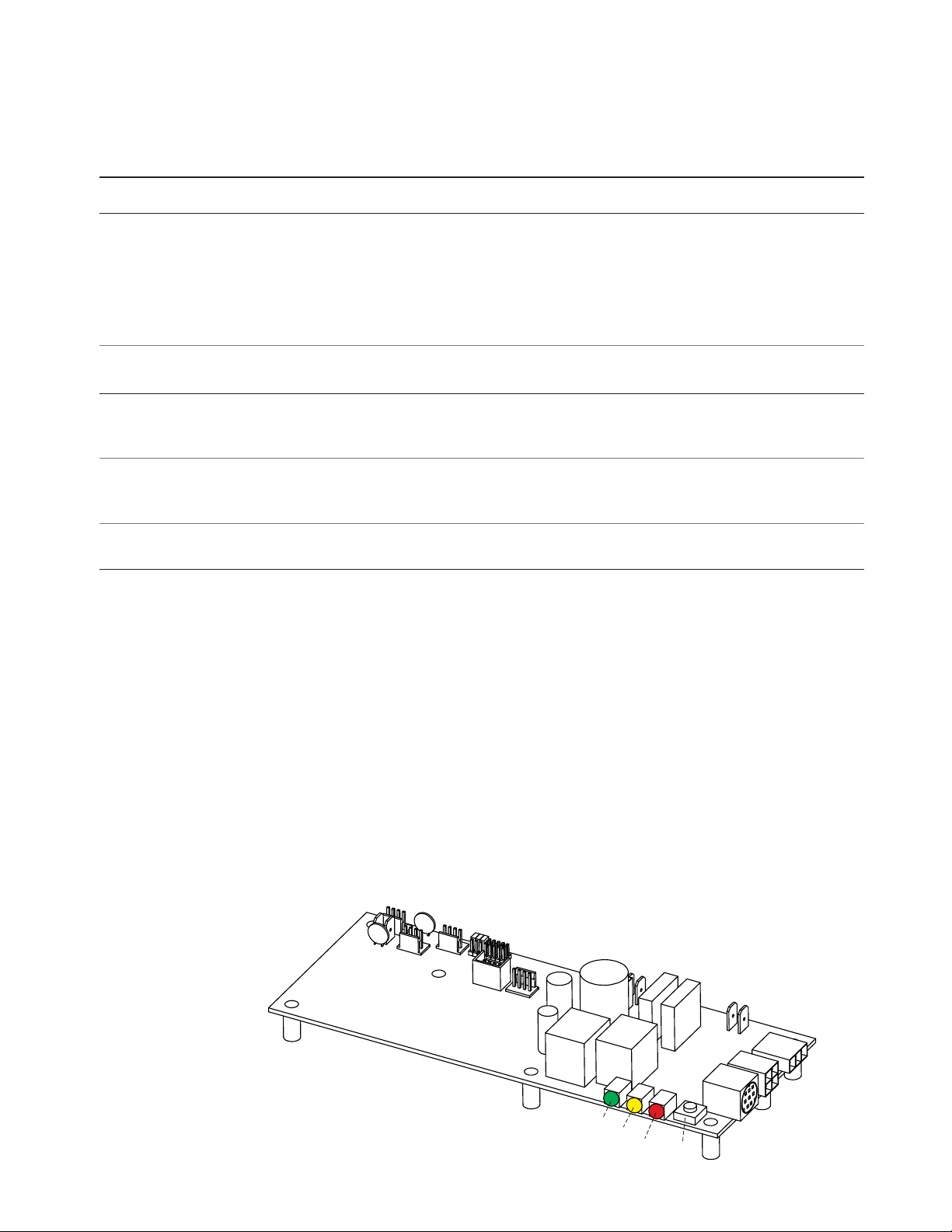

Liqui Level Control Boar -

EXPLANATION OF LED INDICATORS

_____________________________________________________________________________________________________________________________________________

GREEN LED is ON when there is 208/240 Volt incoming power connected,

24 Volt transformer secondary output and on- oard 5 Volt DC control power are present.

_____________________________________________________________________________________________________________________________________________

YELLOW Water level indicator–LED is OFF when no water is detected (for more that 5 seconds). ON when

water level is satisfactory. For units with AutoFlush, if more than five hours have elapsed since

last usage and this LED is ON it is indicative of an AutoFlush or water level pro e circuit malfunction.

_____________________________________________________________________________________________________________________________________________

RED Contactor relay indicator–LED is ON when relay is closed and sending 24 Volts to the

contactor coil. (This LED comes ON if the generator is ON.)

_____________________________________________________________________________________________________________________________________________

FORCE ON This utton is for trou le shooting only and will operate if a control is connected or not.

TEST BUTTON Pressing the utton again will shut the generator OFF.

The test utton will only allow the generator to operate for 10 minutes.

_____________________________________________________________________________________________________________________________________________

Liqui Level Control Boar

PN 104288

(shown without wiring)

mr

.steam®

C L U B T H E R A P Y Installation, Operating & Maintenance Manual

_________________________________________________________________________________________

13

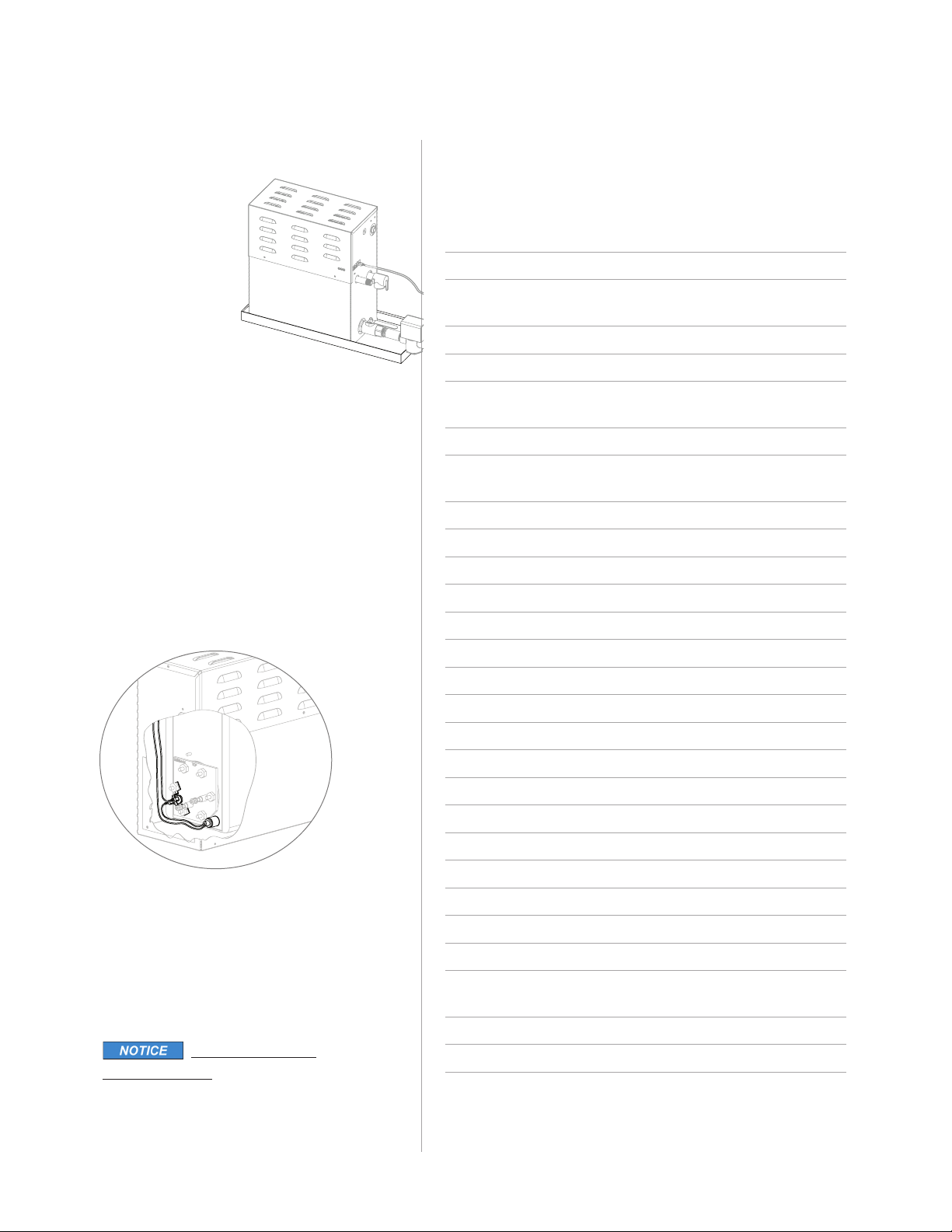

AutoFlush®

Box Contents

•AutoFlush Valve with Cord

• Installation instructions.

Operation

The AutoFlush System feature automatically

drains the CT system following each use.

A time delay allows the water to cool down

(a out two hours) efore it drains y gravity for a

safe and gentle operation. Unit drains by gravity.

Installation Instructions

1. Plum ing to e performed y a qualified

plum er and shall e in accordance with

applica le national and local codes. Unit drains

y gravity. A drain line that is lower than the

AutoFlush assem ly must e availa le. The

AutoFlush System valve outlet is 1" NPT. Check

plum ing code for receptor, trap and vent requirements.

2. Use copper or rass nipple 1" NPT x 31⁄2" or longer

(not supplied) to connect AutoFlush valve to the Drain Valve,

noting the direction of flow on the valve ody.

DO NOT REMOVE THE DRAIN VALVE

Removal may cause equipment and property damage.

If there is not enough room for the valve, an el ow and

a short nipple (not provided) can e added.

3. Open Drain Valve (handle must e aligned with rass nipple).

4. Connect the AutoFlush System cord connector to

the three pin connector as shown.

Do not drain into a steam enclosure or any

location where accidental contact with drain water may occur.

In the event of a power failure the AutoFlush System valve will

open and may discharge oiling water.

Sweat Fittings

When using sweat fittings use only tin ase solder with a melt-

ing point elow 600 degrees F. Do not overheat. Ends of water

supply tu ing must e thoroughly clean for a minimum distance

of 1" from ends. Do not remove valve cover.

To Check Operation

1. Turn on MrSteam and allow tank to fill with water.

2. Turn off MrSteam control. Water should stay in tank.

3. Turn off power at the panel ox. Water should

discharge from tank.

4. Turn on power at panel ox.

5. Repeat

Drain Valve

DO NOT TURN OR REMOVE

THE DRAIN VALVE

(shown in the correct open position)

Steam Generator

ipple Plumb to

Drain Line

AutoFlush Valve

AutoFlush Cord

AutoFlush Valve

3 Pin Connector

for AutoFlush

AutoFlush Cord Connector

Drain Valve

(shown in the correct open position)

DO OT REMOVE THIS DRAI VALVE

Steam Generator

ipple

copper or brass

nipple 1" PT x

31⁄2"or longer

(not supplied)

Plumb to

Drain Line

Arrow indicates correct

direction of flow

PROVIDE DRAIN PLUMBING ACCORDING

TO LOCAL CODES. PLUMB AS REQUIRED

FOR AUTOFLUSH SYSTEM.

mr

.steam®

C L U B T H E R A P Y Installation, Operating & Maintenance Manual

_________________________________________________________________________________________

14

Con ensation Pan

MrSteam provides a

condensation pan in

the unlikely event of

a plum ing leak.

Locate the conden-

sation pan on a solid

level surface and

place the steam

generator inside the

condensation pan.

Insure the steam

generator is level (see page 4 for locating

the steam generator).

All plum ing shall e performed y a qualified

licensed plum er and in accordance with appli-

ca le national and local codes. Check local

plum ing code for receptor, trap and vent

requirements.

Condensation pans drain y gravity. The conden-

sation pan is equipped with an integral 3⁄4" NPT

fitting.

Express Steam

®

(Factory installed)

All CT models have Express Steam standard.

Express Steam is equipped with a low power

heating element and thermostat to keep the

water in the tank warm enough to ring up

steam quicker. All Express Steam components

and wiring are installed at the factory. No

additional wiring or plum ing is required y

installers.

FOR ILLUSTRATIVE

PURPOSES ONLY

Some components may e omitted or altered

for clarity. Do not use for wiring, repair or other

purposes not related to component identification.

Replacement Parts List

____________________________________________________________

Part No. Description Pro uct

____________________________________________________________

99178CT Drain Valve All models

99297 Safety Valve 15PSI All models

100479-2 Water Feed Solenoid All models

Valve w/filter

100477-3 Transformer 24VAC All models

104288 Liquid Level Control Board All models

103990-60 Ca le for iTempo/Plus iTempo/Plus only

Control (60 ft.)

MSTS-60 Remote Temperature Pro e iTempo/Plus only

100476-2 Contactor 50A 2-pole CT6E & CT9E,

Single phase

99012 Contactor 50A 3-pole All 3-Phase models

103453 Contactor 50A 4-pole CT12E

100471-2 Pro e Assem ly All models

99096MS Heating Element Gasket All models

103412 Acrylic Shield All Models

99314 Power Fuse 60A 250V CT12E, Single phase

29061BMS Heating Element 6 KW 208V CT6E

29061CMS Heating Element 6 KW 240V CT6E

29091BMS Heating Element 9 KW 208V CT9E

29091CMS Heating Element 9 KW 240V CT9E

29121BMS Heating Element 12 KW 208V CT12E

29121CMS Heating Element 12 KW 240V CT12E

29151BMS Heating Element 15 KW 208V CT15E

29151CMS Heating Element 15 KW 240V CT15E

103978-60 Ca le for CT-SteamStop (60 ft.) All models

104016 Thermostat All models

104015 Express Steam Thermostat All models

104019 Heating element All models

for Express Steam

104117-30 Ca le for iSteam (30 ft.) iSteam Only

104117-60 Ca le for iSteam (60 ft.) iSteam Only

mr

.steam®

C L U B T H E R A P Y Installation, Operating & Maintenance Manual

_________________________________________________________________________________________

Mo els CT6E & CT9E

shown with cover removed

FOR ILLUSTRATIVE

PURPOSES ONLY.

Some components may e

omitted or altered for clarity.

Do not use for wiring, repair

or other purposes not related

to component identification.

Mo els CT12E & 15E

shown with cover removed

FOR ILLUSTRATIVE

PURPOSES ONLY.

Some components may e omitted

or altered for clarity. Do not use for

wiring, repair or other purposes not

related to component identification.

15

Transformer

Drain

Line

Liquid Level

Control Board

Fuses

Water Inlet

Water Feed

Solenoid

Safety

Valve

AutoFlush

Valve

Stainless

Steel Tank

Heating

Element

Access Cover

Thermostat

Liquid Level Probe AutoFlush Plug and

Play Connector

(see page 13)

Power Block

Power Supply

Knock-Out

Steam Outlet

Express

Steam

Contactor

Contactor

Transformer

(100477-3)

Drain

Line

Liquid Level

Control Board

(104288)

Water Feed

Solenoid (100479-2)

Water Inlet

Safety

Valve

AutoFlush

Valve (CT81500)

Stainless Steel Tank

Heating Element

Express Steam

(104019)

Access Cover

Thermostat

(104016)

Liquid Level

Probe

(100471-2)

AutoFlush Plug and

Play Connector

(see page 13)

Power Supply

Knock-Out

Steam Outlet

Do not route iSteam, iTempo/Plus, iTempo,

HomeWizard or iGenie control wiring inside conduit

together with power lines or close to hot water or steam

piping. Doing so may result in an inoperative or hazardous

installation.

Do Not alter or modify any MrSteam prod-

uct. Doing so may result in an inopera le or hazardous

installation and will void the warranty

IMPORTANT NOTES:

1. Turn power to the steam generator OFF efore con-

necting the control to the generator. Failure to turn the

power off will result in an inopera le control.

2. Do not operate iSteam, iTempo/Plus, iTempo,

HomeWizard or iGenie controls with other than a

MrSteam iSteam or iTempo compati le steam genera-

tor. MrSteam steam generators with serial num ers

lower than 900000, or any other rand of steam gener-

ator are not to e operated with iTempo controls.

Doing so may result in an inoperative or hazardous

installation. If iSteam is used with a generator having

serial num er less than 1174000, contact MrSteam

technical support for an upgraded PC oard.

3. This document contains important safety, operation and

maintenance information. Leave this document with

management. Do not discard this document.

4. Discontinue use of the steam generator or control if the

steam generator is damaged or otherwise not function-

ing properly. Operating a damaged steam generator

may result in an inoperative or hazardous installation

16

mr

.steam®

CLUB THERAPY Controls

_________________________________________________________________________________________

Control Rough In

Refer to Installation Instructions for the specific control

IMPORTANT NOTE: The control ca les should e run in dedicated 1" conduit to facilitate installation and service.

1. Determine the desired installation location of the

control. The iSteam®, iTempo™and iTempo/Plus™

controls are designed to e installed inside or out-

side the steam room as a matter of personal prefer-

ence. If the control is installed inside the steam

room the control must e located:

2.

4-5 feet a ove the floor near the ather seating area

3. The control features an integral temperature sensor.

Locate the control in a location representative of the

desired steam athing temperatures.

Do not locate the control a ove or near the steam

head or direct steam emissions.

4. on a vertical wall

The control ca le length is 30 feet. Insure that the

control and/or steam generator are located according-

ly. An optional 60 foot ca le is availa le, PN 103990-60 for

iTempo and PN 104117-60 for iSteam. Contact a MrSteam

technical service representative if a 60 foot ca le is required.

IMPORTANT NOTE: If the control is installed outside the

steamroom a Remote Temperature Pro e Part Num er MSTS

must e installed inside the steam room, depending on the

control. Insure MrSteam steam generator is iSteam or iTempo

compati le and has a serial num er 900000 or higher. If

iSteam is used with a generator having serial num er less than

1174000, contact MrSteam technical support for an upgraded

PC oard.

See instructions for the MSTS Temperature Pro e (located in

the Control Installation Manual related to your specific control

package) efore rough-in or installation of control.

Before Installing

Turn power to the steam generator OFF efore connecting the

control to the generator. Failure to turn the power off will result in

an inopera le control.

To avoid unintentional steam ath operation,

do not locate the control where other controls, accessories,

shower heads, valves, ody sprays or similar within the show-

er could cause confusion or interfere with the MrSteam con-

trol’s intended use and function.

Do not use any iSteam®, iTempo/Plus™,

iTempo™, HomeWizard™or iGenie®controls without reading

and understanding its own manual and the MrSteam steam

generator Installation and Operation Manual. Failure to read

and understand these instructions may result in an inopera-

tive or hazardous installation.

The warning placard located in the documenta-

tion envelope must e read and permanently affixed in a con-

spicuous location near the steam room. Failure to read and affix

this warning placard in a conspicuous location may result in seri-

ous injury or death.

Install the iSteam, iTempo or iTempo/Plus controls according

to installation instructions. Failure to install according to

instructions will result in an inoperative control or hazardous

overheating or inadequate heating of the steam room.

If an iSteam, iTempo or iTempo/Plus control is installed out-

side the steam room a Remote Temperature Pro e (PN

MSTS) must e installed inside the steam room per installa-

tion instructions supplied with the Remote Temperature

Pro e. Failure to install according to instructions will result in

an inoperative control and overheating of the steam room.

Control Installation

Refer to Control Manual for specific installation re uirements

mr

.steam®

CLUB THERAPY Controls

_________________________________________________________________________________________

17

30' ca le

Switch Plug & Play

Connector

Diagram 1

Diagram 2

Diagram 3

Diagram 4 Diagram 5

Diagram 6

CT SteamStop®

On/Off Switch for iTempo/Plus®

Dimensional Information

Box Contents:

• CT SteamStop Control

• Owner’s Manual

• 60’ CT SteamStop Ca le

IMPORTANT NOTE: The control ca les should e run in

dedicated 1" conduit to facilitate installation and service.

Installing the CT SteamStop Control

The CT SteamStop has a 60 foot ca le with a Plug & Play connector at oth

ends. (Diagram 1) The CT SteamStop must e installed inside the steamroom.

Step 1 Diagram 2

Drill a 7

⁄8inch diameter hole in

a preferred wall location. Do not oversize

or undersize the hole.

Step 2 Diagram 3

Route the ca le from the wall to the steam

generator. Be careful not to strain, pinch or

otherwise damage the control ca le.

Step 3 Diagram 4

Remove and discard the peel-off paper

from the switch housing to expose the

adhesive as shown in Diagram 4.

IMPORTANT NOTE: Use care not

to apply silicone to the adhesive gasket.

The connector is keyed and will only connect in one

orientation with the ta facing up.

LED indicator will light up

when the generator is ON.

Using the CT SteamStop®Control

The CT SteamStop control should e installed in the steam room for

the user to start and stop the steam ath

If an error code is detected y the system the LED

indicator will flash. Refer to the iTempo/Plus or iSteam display for

error code or call a MrSteam’s service technician.

For Illustrative Purposes Only. Drawings Not to Scale

Step 4 Diagram 5

Apply silicone (provided with the

iTempo/Plus control) to the hole in

the wall as required to create a

moisture seal. Apply silicone to

the ack of the switch as required

to seal grout lines or as required

for additional adhesion.

Step 5: Push ca le and switch

housing into the hole firmly.

Step 6 Diagram 6

Firmly connect the Plug & Play

connector to the steam generator

connector la eled CT SteamStop.

Care Tips for all Controls an Steamhea s

1. Use only mild soap and water on a soft cloth to clean the control

and steamhead.

2. Do not use a rasive cleansers.

3. If the decorative cover is damaged on the iTempo/Plus

call MrSteam technical service for replacement parts.

Replacement of the decorative

covers requires removal and reinstallation of

the control from the mounting surfaces.

mr

.steam®

Feel Good Inc.

www.mrsteam.com

mr.steam®

43-20 34th Street, Long Island City, NY 11101 1 800 767 8326

9410 S. La Cienega Blvd. Inglewood CA 90301 1 800 727 8326

2019 © Sussman-Automatic Corporation I MrSteam and des., A Lifetime of Pleasure, AirTempo, AromaFlo, AudioWizard, AutoFlush, AutoSteam, Butler Package, ChromaSteam, Clean Steam...Every Time,

Clu Therapy, Digital 1, Express Steam, Feel Good Inc., From Bathroom to Spa, HomeWizard, iButler, iGenie, iSizing, iSteam, iTempo, iTempo/Plus, Making Wellness a Way of Life, Music Therapy, Spa Package,

Steam Genie, Steam on Demand, Steam@Home,SmartSizing, SteamStart, SteamStop, SteamTherapy, Sussman, Tala, The Intelligent Steam ath, Valet Package, Virtual Spa System, Voice Genie and Voice

Wizard are registered trademarks of Sussman-Automatic Corporation.

PUR

100426 REV 1.20

Warranty:

To view or download the MrSteam Steam Generator Warranty

and register your product go to: blog.mrsteam.com/wr

Products, information and specifications are su ject to change without notice.

Please call Sales & Support at 1.800.76.STEAM (East Coast) or 1.800.72.STEAM (West Coast) for more information.

18

This manual suits for next models

3

Table of contents

Other Feelgood Portable Generator manuals

Popular Portable Generator manuals by other brands

Full Boar

Full Boar FBT-3000 instruction manual

Tomahawk

Tomahawk TG5500i Operation manual

Thurlby Thandar Instruments

Thurlby Thandar Instruments TE TGR1040GP instruction manual

Westinghouse

Westinghouse WGen2000 user manual

Clarke

Clarke IG950C Operation & maintenance instructions

Briggs & Stratton

Briggs & Stratton PRO6500 owner's manual