Feider Machines FPV20V2B2B User manual

ORIGINAL INSTRUCTIONS

20V CORDLESS DRILL

FPV20V2B2B

READ THIS MANUAL BEFORE USING THIS TOOL

EN

BUILDER SAS

ZI – 32, rue Aristide Bergès, 31270 Cugnaux, France

MADE IN RPC 2021

EN 2

WARNING Read all safety warnings and all instructions. Failure to follow the warnings and

instructions may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference. The term "power tool" in the warnings

refers to your mains-operated (corded) power tool or battery-operated (cordless) power tool.

1) Work area safety

a) Keep work area clean and well lit.Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence of flammable

liquids, gases or dust. Power tools create sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while operating a power tool. Distractions can cause you

to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power tools. Unmodified plugs and matching outlets will

reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges

and refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power tool will increase

the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords

increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for outdoor use. Use

of a cord suitable for outdoor use reduces the risk of electric shock.

f) If operating a power tool in a damp location is unavoidable, use a residual current device

(RCD) protected supply. Use of an RCD reduces the risk of electric shock.

NOTE the term “residual current device (RCD)” may be replaced by the term “ground fault circuit

interrupter (GFCI)” or “earth leakage circuit breaker (ELCB)”.

3) Personal safety

a) Stay alert, watch what you are doing and use common sense when operating a power tool.

Do not use a power tool while you are tired or under the influence of drugs, alcohol or

medication. A moment of inattention while operating power tools may result in serious personal

injury.

b) Use personal protective equipment. Always wear eye protection. Protective equipment such

as dust mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate conditions

will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the off-position connecting to power

source and/or battery pack, picking up or carrying the tool. Carrying power tools with your finger

on the switch or energizing power tools that have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This enables better control of

the power tool in unexpected situations.

1. Safety instructions

EN 3

f) Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewellery or long hair can be caught in moving parts.

g) If devices are provided for the connection of dust extraction and collection facilities, ensure

these are connected and properly used. Use of dust collection can reduce dust-related hazards.

h) Do not let familiarity gained from frequent use of tools allow you to become complacent and

ignore tool safety principles. A careless action can cause severe injury within a fraction of a

second.

4) Power tool use and care

a) Do not force the power tool. Use the correct power tool for your application. The correct

power tool will do the job better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any power tool that cannot

be controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or the battery pack from the power tool

before making any adjustments, changing accessories, or storing power tools. Such preventive

safety measures reduce the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do not allow persons unfamiliar with

the power tool or these instructions to operate the power tool. Power tools are dangerous in the

hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts, breakage of parts

and any other condition that may affect the power tool’s operation. If damaged, have the

power tool repaired before use. Many accidents are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc. in accordance with these instructions,

taking into account the working conditions and the work to be performed. Use of the power tool

for operations different from those intended could result in a hazardous situation.

h) Keep handles and grasping surfaces dry, clean and free from oil and grease. Slippery

handles and grasping surfaces do not allow for safe handling and control of the tool in unexpected

situations.

5) Battery tool use and care

a) Recharge only with the charger specified by the manufacturer.A charger that is suitable for

one type of battery pack may create a risk of fire when used with another battery pack.

b) Use power tools only with specifically designated battery packs.Use of any other battery

packs may create a risk of injury and fire.

c) When battery pack is not in use, keep it away from other metal objects, like paper lips, coins,

keys, nails, screws or other small metal objects, that can make a connection from one terminal

to another.Shorting the battery terminals together may cause burns or a fire.

d) Under abusive conditions, liquid may be ejected from the battery; avoid contact. If contact

accidentally occurs, flush with water. If liquid contacts eyes, additionally seek medical help.

Liquid ejected from the battery may cause irritation or burns.

e) Do not use a battery pack or tool that is damaged or modified.Damaged or modified batteries

may exhibit unpredictable behaviour resulting in fire, explosion or risk of injury.

f) Do not expose a battery pack or tool to fire or excessive temperature.Exposure to fire or

temperature above 130 °C may cause explosion.

EN 4

NOTE The temperature „130 °C“ can be replaced by the temperature „265 °F“.

g) Follow all charging instructions and do not charge the battery pack or tool outside the

temperature range specified in the instructions. Charging improperly or at temperatures outside

the specified range may damage the battery and increase the risk of fire.

6) Interview

a) Have your power tool serviced by a qualified repair person using only identical replacement

parts.This will ensure that the safety of the power tool is maintained.

b) Never service damaged battery packs. Service of battery packs should only be performed by the

manufacturer or authorized service providers.

c) For tools for use in combination with an isolating transformer. Warning never to use the tool

without the transformer delivered with the tool or of the type as specified in these instructions

Drill safety warning

1) Safety instructions for all operations

a) Hold power tool by insulated gripping surfaces, when performing an operation where the

cutting accessory may contact hidden wiring.Cutting accessory contacting a "live" wire may

make exposed metal parts of the power tool "live" and could give the operator an electric shock.

2) Safety instructions when using long drill bits

a) Never operate at higher speed than the maximum speed rating of the drill bit. At higher

speeds, the bit is likely to bend if allowed to rotate freely without contacting the workpiece, resulting in

personal injury.

b) Always start drilling at low speed and with the bit tip in contact with the workpiece. At higher

speeds, the bit is likely to bend if allowed to rotate freely without contacting the workpiece, resulting in

personal injury.

c) Apply pressure only in direct line with the bit and do not apply excessive pressure. Bits can

bend causing breakage or loss of control, resulting in personal injury.

Instructions additionnelles

-The charger and the battery are sold separately. Please buy the battery and recommended charger.

-The electric current used must match the specifications of the battery charger;

-Read the instructions and technical specifications of the charger and drums.

-Never allow moisture, rain or splashes to reach the location of refill.

-The ambient temperature should never exceed 40ºC (temperature range: 5-40ºC) when using the

product, charging the battery and storing.

-A defective or damaged battery or no longer accepting charge must be eliminated in a special

collection point. -Respect the environment. Do not throw a battery unusable with garbage in the fire or

in the water.

-Keep the charger surface free of dust and dirt.

-Always remove the battery before performing any operation or maintenance on the device

-Do not recharge non-rechargeable batteries.

EN 5

Residual risks

Even with use of the tool as described, it is impossible to eliminate all residual risk factors. The

following hazards may be present in connection with the construction and design of the tool:

1. Pulmonary lesions if an effective mask is not worn.

2. Hearing damage if effective hearing protection is not worn.

3. Body injuries caused by vibration emissions if the electrical appliance is used improperly or for a

prolonged or poorly maintained period.

WARNING ! This device produces an electromagnetic field during operation. This field may interfere

in certain circumstances with active or passive medical implants. To reduce the risk of serious or fatal

injury, we recommend that people with medical implants consult with their physician and the medical

implant manufacturer before using this device.

Intended Use

This power tool is designed for drilling as well as for tightening and loosening screws. Specially

design to work with Hyundai range of battery and charger.

This power tool should not be used for purposes other than those described.

Explication des symboles

Do not dispose of old appliances with domestic rubbish .

To reduce the risk of injury, the user must read and understand this manual

before using this product.

Conforms to relevant safety standards

Do not expose batteries to temperatures exceeding 40 degrees.

Do not dispose of batteries in fire. They could explode and cause injury

Do not dispose of batteries in water.

Recycling

EN 6

2. ABOUT YOUR PRODUCT

a. Description

7. Touch ON / OFF

8. Handle

9. Unlocking the battery

10. Battery

11. Belt clip

The tool comes with a belt clip

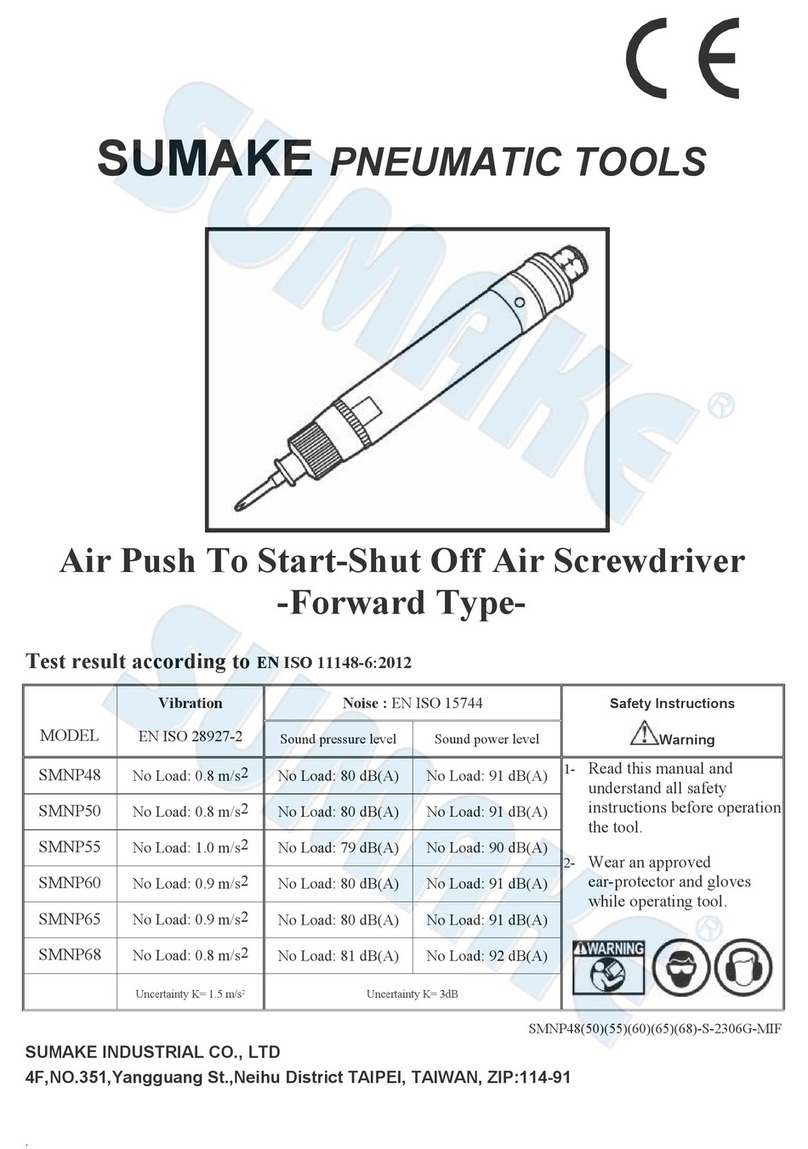

b. Technical specifications

ah,D =3.0m/s2, K=1.5m/s2;

impact drilling into concrete:

ah,ID =9.9m/s2,

K=1.5m/s2.

Battery:

Type: Li-Ion

Model: JDB515620

Capacity: 1,3Ah/1,5Ah/2Ah

Charger

Model: FCH20V (DL1051B)

Tension 20Vd.c.

No-load speed 0-450/0-1650/min

Mandrin ɸ13mm

Sound power level LwA : 82dB(A) K=5dB(A)

Sound pressure level LpA: 71dB(A) K=5dB(A)

Vibration drilling into metal:

1. Two speed gear

2. Torque adjustment ring for drilling

/ drilling /

3. Adjusting the chuck

4. Mandarin

5. LED light

6. Normal / reverse switch

EN 7

Informations

The total declared vibration value was measured using a standard test method and can be used to

compare one tool with another.

The total declared vibration value can also be used in a preliminary exposure estimate

Warning

The emission of vibration during actual use of the machine tool may differ from the total declared

value depending on how the tool is used. And

Need to identify safety measures to protect the user which are based on an estimate of the exposure

under real conditions of use (taking into account all parts of the operating cycle such as the moments

when the tool and off and when it is running in addition to the tripping time.

Wear hearing protection

3. OPERATION

a. Charging

FEIDER range battery and charger are not sold together with this tool. You must buy

separately these elements.

Battery has not been fully charged at the factory. Follow the instructions for charging

before use.

Before using it for the first time, charge the battery for 60min to 130min. Insert the charger plug

into the charging socket and plug the charger into a 230V/50Hz electrical outlet (check the

electrical specifications of battery and the charger before use and read carefully the instruction

manual for battery and charger).

Charge status

To display the amount of charge left on the battery, press the charge level indicator.

IMPORTANT

This tool is supplied without battery and battery charger. Please purchase a battery (battery +

charger) from the same brand as this tool. The product is recommended: FEIDER 20V

LITHIUM-ION BATTERY. Do not use non-recommended batteries

Drills are not supplied with this tool. You can use 1/4 hex drill bits with this tool. For more

information, ask your retailer for advice.

EN 8

The battery is fully charged when the 4 indicators are illuminating.

b.Battery instal

Warning! Always remove the battery from the tool when assembling accessories, making

adjustments, during transportation, or when the tool is not in use. Removing the battery will

prevent accidental starting which could result in serious personal injury

NOTE: To avoid serious personal injury, always remove the battery and keep hands away

from the lock button when carrying the tool

- Slide the battery into the base of the tool.

EN 9

- Make sure the battery locks in place and is securely attached to the tool before starting operations

Improper battery installation can damage internal components

c.Removing the battery

- Make sure the tool is not running

- Push and hold the battery release button. Then slide the battery out of the tool

d.Installation of a drill

- Put the normal / reverse button in the central position

- Turn the chuck until the opening is larger than the size of the drill to be used(1)

- Insert the bit into the chuck

- Tighten the mandarin on the drill

- Make sure you have installed the bit correctly. Improper installation will create injuries and

accidents

e.Remove the drills

- Switch off the tool and put the normal / reverse button in the central position

- Open the chuck then remove the drill

f.Belt installation

- Before positioning the belt clip, put the normal / reverse button in the central position or stop the

tool and disconnect the battery pack

- To reduce the risk of serious personal injury, do not hang the tool high or hang objects from the belt

hook. Only hang the clip on the work belt

- When attaching or replacing the belt clip, use only the screw that is provided. Make sure to tighten

the screw securely with a Phillips screwdriver

EN 10

- The belt clip can be attached to the other side of the tool, using only the screw provided, to fit right

or left handed users

- To change the place clip, remove the screw that holds it, then re-attach it on the other side. Be sure

to tighten the screw securely

Note: the belt is not supplied with the tool

g.Starting and stopping the operation

- Push the normal / reverse switch to the desired position (left for the reverse position and right for

the normal position)

- Move the bit into the workpiece. Press the ON / OFF trigger to start the operation

- Apply enough pressure to maintain proper work. Do not force the tool or apply lateral pressure. Let

the tool do the work. If necessary, increase the working speed by pressing the switch

- To change position, release the ON / OFF trigger. Put the reverse / normal switch in the central

position (never change the position directly). Press the reverse / normal button to change position.

Press the trigger to restart the operation

- To stop the operation, release the ON / OFF trigger. Then place the reverse / normal switch

towards the central position

h.Drilling

-Check that the direction of rotation button is in the correct position

-Put the workpiece in a vice to prevent it from turning when the drill turns

-Hold the drill firmly and place the drill on the drilling point

-Press the trigger to start the drill

-Rotate the bit in the workpiece with just enough pressure to cut. Do not force the drill or tilt it to

enlarge a hole. Let the tool do the work

Warning ! Be prepared for jamming when the drill bit crosses. When these situations occur, the drill

has a tendency to lock up and turn in the opposite direction and can cause you to lose control when

the material is passed through. If you are not prepared, this loss of control can lead to serious

injuries.

ADVICE FOR DRILLING HARD AND SMOOTH SURFACES

Place a piece of sticky tape on the surface at the approximate position of the hole. Mark the position

of the hole on the sticker, this will prevent the drill from slipping on the surface when it starts. Gently

pierce the surface.

ADVICE FOR DRILLING METAL

To drill metal, put light oil on the drill to prevent it from overheating. The oil will extend the life of the

drill and increase the drilling action

ADVICE FOR DRILLING MASSONNERIE

For best results, use drills with a carbide head to drill brick, tiles, concrete, etc.

For optimum results, use high speed steel drills.

Apply light pressure and medium speed for best results in the brick

Apply a little more pressure in sturdy materials like concrete

EN 11

i.Two-speed gear

Use slow speed (1) for high power and high torque, and fast speed (2) for rapid drilling or for

screwing

Do not change gears while the drill is running. Tool could be damaged

j.Torque setting

This device allows you to adjust the torque or tightening power of your drill, and depending on the

application, several levels of training are required. When screwing large diameter screws, a greater

torque is required so that the screw is properly tightened. Turn the torque clamp to the desired

torque by aligning the arrow on the body of the drill

When the torque is reached, the chuck stops. The correct torque depends on the type of material

and the size of the screw used

Note: Always start with the lowest setting

The drill symbol gives the highest torque, and is used for drilling and for large screws. For drill mode,

turn the torque until the drill symbol aligns with the arrow on located on the tool (as in the image

below)

EN 12

c.Chocking of the part

To prevent the bit from turning the part if it gets stuck in the hole, it is recommended to use a vice or

other fixing device to immobilize the part during drilling.

If the bit gets stuck in the work or if the drill stalls, stop the tool immediately. Remove the bit from the

workpiece and determine the reason for the wedge

Note: The drill is equipped with an electric brake. When the trigger is released, the chuck stops

rotating. When the brake works properly, sparks are seen in the body vents. This is normal and it is

the action of the brake

4. MAINTENANCE AND STORAGE

a.Maintenance

Clean the housing only with a damp cloth. Do not use solvents! Then wipe well.

Check the condition of the tool. If the tool is damaged or malfunctioning, do not use it and take it to

qualified service for inspection and repair.

To maintain optimal battery power, we recommend that the battery be discharged and recharged

every two months.

b.arrangement

Remove the battery from the tool.

Store the tool in a dry and frost-protected place, the ambient temperature should not exceed 50 ° c.

Keep it out of the reach of children.

5. DISPOSAL

Selective collection of electrical and electronic waste

Electrical products should not be disposed of with household products. According to

the European Directive 2012/19 / EU for the disposal of electrical and electronic

equipment and its execution in national law, used electrical products must be collected

separately and disposed of in collection points provided for this purpose. Contact local

authorities or your dealer for recycling advice.

EN 13

6. CE DECLARATION

Declaration of conformity

BUILDER SAS

ZI, 32 RUE ARISTIDE BERGES – 312070 CUGNAUX – FRANCE

Declares that the machinery designated below :

20V CORDLESS DRILL

Model : FPV20V2B2B

Also complies with the following European directives :

EMC Directive 2014/30/EU

ROHS Directive (EU)2015/863 amending 2011/65/EU

Also complies with European standards, with national standards and the following technical

provisions :

EN62841-1: 2015

EN62841-2-1: 2018

EN55014-1: 2017

EN55014-2: 2015

Philippe MARIE / PDG

Serial number : 20210724640-20210725139

Complies with the provisions of the Directive « machinery » 2006/42/CE and national laws

transposing it :

Done at Cugnaux, 01/06/2021

WARRANTY

The manufacturer guarantees the product against defects in material and workmanship for a period of 2

years from the date of the original purchase. The warranty only applies if the product is for household use.

The warranty does not cover breakdowns due to normal wear and tear.

The manufacturer agrees to replace parts identied as defective by the designated distributor. The

manufacturer does not accept responsibility for the replacement of the machine, in whole or in part , and/or

ensuing damage.

The warranty does not cover breakdowns due to:

• insucient maintenance.

• abnormal assembly, adjustment or operations of the product.

• parts subject to normal wear and tear.

The warranty does not extend to:

• shipping and packaging costs.

• using the tool for a purpose other than that for which it was designed.

• the use and maintenance of the machine done in a manner not described in the user manual.

Due to our policy of continuous product improvement, we reserve the right to alter or change specications

without notice. Consequently, the product may be dierent from the information contained therein, but a

modication will be undertaken without notice if it is recognized as an improvement of the preceding

characteristic.

READ THE MANUAL CAREFULLY BEFORE USING THE MACHINE.

When ordering spare parts, please indicate the part number or code, you can nd this in the spare parts list

in this manual. Keep the purchase receipt; without it, the warranty is invalid. To help you with your product,

we invite you to contact us by phone or via our website:

• +33 (0)9.70.75.30.30

• https://services.swap-europe.com/contact

You must create a "ticket" via the web platform.

• Register or create your account.

• Indicate the reference of the tool.

• Choose the subject of your request.

• Describe your problem.

• Attach these les: invoice or sales receipt, photo

of the identication plate (serial number), photo

of the part you need (for example: pins on the

transformer plug which are broken).

7. WARRANTY

14

WHAT TO DO IF MY MACHINE BREAKS DOWN?

If you bought your product in a store:

a) Empty the fuel tank.

b) Make sure that your machine is complete with all accessories supplied, and clean! If this is not the case,

the repairer will refuse the machine.

Go to the store with the complete machine and with the receipt or invoice.

If you bought your product on a website:

a) Empty the fuel tank.

b) Make sure that your machine is complete with all accessories supplied, and clean! If this is not the case,

the repairer will refuse the machine.

c) Create a SWAP-Europe service ticket on the site: https://services.swap-europe.com When making the

request on SWAP-Europe, you must attach the invoice and the photo of the nameplate (serial number).

d) Contact the repair station to make sure it is available before dropping o the machine.

Go to the repair station with the complete machine packed, accompanied by the purchase invoice and the

station support sheet downloadable after the service request is completed on the SWAP-Europe site

For machines with engine failure from manufacturers BRIGGS & STRATTON, HONDA and RATO, please

refer to the following instructions.

Repairs will be done by approved engine manufacturers of these manufacturers, see their site:

• http://www.briggsandstratton.com/eu/fr

• http://www.honda-engines-eu.com/fr/service-network-page;jsessionid=5EE8456CF39CD572AA2AEEDFD

290CDAE

• https://www.rato-europe.com/it/service-network

Please keep your original packaging to allow for after-sales service returns or pack your machine

with a similar cardboard box of the same dimensions.

For any question concerning our after-sales service you can make a request on our website https://

services.swap-europe.com

Our hotline remains available at +33 (9) 70 75 30 30.

8. PRODUCT FAILURE

15

THE WARRANTY DOES NOT COVER:

• Start-up and setting up of the product.

• Damage resulting from normal wear and tear of the product.

• Damage resulting from improper use of the product.

• Damage resulting from assembly or start-up not in accordance with the user manual.

• Breakdowns related to carburetion beyond 90 days and fouling of carburetors.

• Periodic and standard maintenance events.

• Actions of modication and dismantling that directly void the warranty.

• Products whose original authentication marking (brand, serial number) has been degraded, altered or

withdrawn.

• Replacement of consumables.

• The use of non-original parts.

• Breakage of parts following impacts or projections.

• Accessories breakdowns.

• Defects and their consequences linked to any external cause.

• Loss of components and loss due to insucient screwing.

• Cutting components and any damage related to the loosening of parts.

• Overload or overheating.

• Poor power supply quality: faulty voltage, voltage error, etc.

• Damages resulting from the deprivation of enjoyment of the product during the time necessary for repairs

and more generally the costs related to the immobilization of the product.

• The costs of a second opinion established by a third party following an estimate by a SWAP-Europe repair

station

• The use of a product which would show a defect or a breakage which was not the subject of an immediate

report and/or repair with the services of SWAP-Europe.

• Deterioration linked to transport and storage*.

• Launchers beyond 90 days.

• Oil, petrol, grease.

• Damages related to the use of non-compliant fuels or lubricants.

* In accordance with transport legislation, damage related to transport must be declared to carriers within 48

hours maximum after observation by registered letter with acknowledgement of receipt.

This document is a supplement to your notice, a non-exhaustive list.

Attention: all orders must be checked in the presence of the delivery person. In case of refusal by the

delivery person, it you must simply refuse the delivery and notify your refusal.

Reminder: the reserves do not exclude the notication by registered letter with acknowledgement within 72

hours.

Information:

Thermal devices must be wintered each season (service available on the SWAP-Europe site). Batteries must

be charged before being stored.

9. WARRANTY EXCLUSIONS

16

Other manuals for FPV20V2B2B

1

Table of contents

Other Feider Machines Power Screwdriver manuals