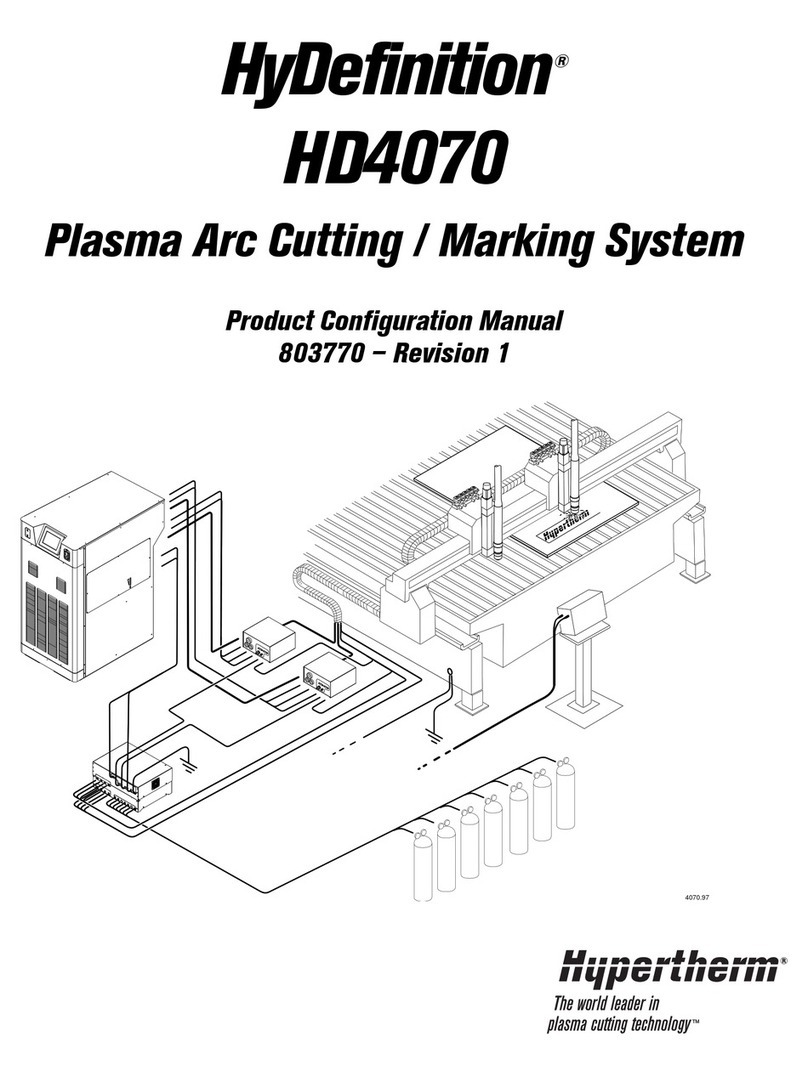

Feider FPSI140A User manual

ORIGINAL INSTRUCTIONS

FEIDER

WELDING MACHINE

FPSI140A

READ TTHE INSTRUCTIONS BEFORE USE THE TOOL

FEIDER

ZI, 32, rue Aristide Bergès –31270 Cugnaux –France

Safety Caution!

This welding machine complies with international safety standards. Safety is an important

issue in the design and manufacture of equipment. There are always some risks associated

with the use of welding equipment. In order to ensure your safety and that of your work

environment, please read carefully and observe these safety instructions.

1. General safety points

• Properly install the unit in accordance with the standards and instructions given in this

manual.

• Do not touch the tool and the pliers when you have hands without protective gloves, with

wet hands, or when you have wet clothes.

• Make sure there is proper insulation between you and the floor and the room.

• Make sure your work position is secure.

• Connect the welding machine only to a grounded electrical network.

• Respect the recommended size of the fuses

• Avoid putting the welding machine inside a container, container or similar.

• Avoid placing the welding machine on a wet surface and avoid working on a wet surface.

• Do not expose the power cable to water.

• Make sure that the cable holder or welding electrode is not squeezed by heavy objects and

that they are not exposed to sharp edges or a hot workpiece.

• Make sure the welding electrode holder is not damaged or faulty. If this is the case, the

media must be replaced immediately.

• Remember that the cable, plugs and other electrical equipment should only be installed or

replaced by a qualified electrician or authorized engineer.

• Turn off the welding machine when not in use.

Smoke - Possibility of causing damage to health!

• Keep any part of the body away from the fumes caused by the operation.

• Provide good ventilation or use a smoke extractor during operation to avoid gas breathing.

• Always wear a protective mask when using the machine.

• Take precautions when working on metals or materials containing lead, cadmium, zinc,

mercury or beryllium.

X-ray arc - Ability to damage your eyes and burn your skin!

Use the supplied welding mask, glass filter and protective equipment to protect your eyes

and body (goggles, gloves, protective clothing, etc.).

Splash and fire

The welding operation creates sparks. These can cause a start of fire. Make sure there are

no flammable elements near the work area. It is strongly recommended that you have a fire

extinguisher nearby or any device that can quickly extinguish a fire.

Welding is a risky job. Please pay attention to the fire safety rules during and after welding.

During special welding work, pay attention to the risks that can be caused by this work

(fires, explosions, etc.), especially when welding workpieces of the container or tank type.

Never point sparks or splashes to the welding machine or flammable materials.

Be careful of hot objects or splashes that may fall on the machine during work.

Welding in flammable or explosive objects is strictly forbidden.

Noise - Excessive noise will damage your hearing!

Use a hearing protection device to protect your ears.

Warn the audience that the noise could cause potential damage to their hearing.

Problem - Seek professional help in case of problems. Please contact your supplier or the

service center of our company immediately to request the assistance of a professional staff.

When you encounter difficulties in the installation or operation, please seek help from a

qualified service.

Do not use of a welding power source for pipe thawing

Warning !

1. Install the leakage protection device when using the equipment!

2. Install a fuse or circuit breaker when using the machine.

3. People who do not work (spectators) must move away from the 5 m operation site.

The workplace must be protected by a fence.

4. Do not use the device as a pacemaker, air hose welder

2. Important points of safety

This welding machine is supplied with a protection circuit against overvoltage, overcurrent and overheating. When the

mains voltage, the output current and the indoor temperature exceed the set standard, the welding machine stops

automatically. But the surge could damage the machine. You must therefore ensure the following:

Ensure excellent ventilation!

This welding machine is a mini welding machine. During its use, a current passes through the machine

Natural ventilation is not enough for the cooling of the welding machine. An integrated fan is therefore provided to

effectively cool the welding machine and make it work more efficiently.

The operator must ensure that ventilation is not covered or blocked. The distance between the welding machine and the

surrounding objects must be at least 0.3m. The user must maintain good ventilation, vital for the perfect operation and

long life of the welding machine.

Overload forbidden!

The operator must observe and check the maximum permitted charging current from time to time (depending on the

selected duty cycle) to ensure that the welding current does not exceed the maximum permitted charging current.

Current overload could significantly reduce the service life of the welding machine and even deteriorate it.

Meaning of the duty cycle: The percentage of the equipment running time in 10 minutes of service cycle, when the

welding current decreases, the duty cycle increases, when the welding current increases, it decreases.

When the welding machine exceeds the normal working cycle, it may enter protection and pause mode. The yellow

indicator on the front panel will glow. Under these circumstances, the power plug must not be disconnected (the fan

cooler must continue to operate normally to cool the welding machine). The yellow indicator goes off when the

temperature is back to normal. The machine can be restarted.

Warning

When the output exceeds the duty cycle level, the internal temperature of the equipment increases, at which point the

protection circuit operates and disconnects the power source output. The equipment will resume operation only after

cooling to normal temperature.

Note: A persistent overload could damage the welding power source.

Over-voltage forbidden!

The supply voltage is listed in the "Main Performance Parameter" table. In general, the automatic voltage compensation

circuit in the welding machine will ensure that the welding current is within the allowed range. When the power source

voltage exceeds the allowed value, the welding machine may be damaged. The operator must take this into account and

take the corresponding preventive measures.

3. Use of personal protective equipment

• The arc and its reflexive radiation damage unprotected eyes. Protect your eyes and face properly before starting or

observing the welding. In addition, please follow the different requirements of the darkness of the mask screen when

the welding current changes.

• Arc radiation and splashing could burn unprotected skin. Always wear gloves, protective clothing and footwear during

welding.

• Always wear the hearing protection if the ambient noise level exceeds the permitted limit (eg 85 dB (A)).

4. Other operating safety

• Be careful when handling heated solder parts. For example, the tip of the electrode support, the end of the welding rod

and the workpiece become hot, during the welding time, the elements can reach several hundred degrees, so there is a

risk of burns.

• Never wear the appliance on the shoulders during welding and never hang it by the carrying strap during welding.

• Avoid exposing the machine to high temperatures as this may cause damage to the machine.

• Keep the electrode support cable and the earthing cable as close as possible. Straighten the folded parts of the cables.

This action reduces exposure to dangerous magnetic fields that could interfere with a stimulator for example.

• Avoid wrapping cables around the body.

• In environments classified as hazardous, use only welding machines with the S mark and a safe level of idle voltage.

These working environments include, for example, small spaces, humid or hot spaces in which the user will be directly

exposed to the surrounding conductive parts.

• You must be careful to prevent the unit from tipping over if the welding power is tilted.

• It is forbidden to use the power plug to thaw the network.

• Isolate yourself from the welding circuit using dry equipment and unprotected protective clothing.

• Never touch the work piece and work rod, welding electrode or contact tip at the same time.

• Avoid placing the electrode holder on the welding machine and other electrical equipment.

5. Transport, lifting and suspension

• Never press or lift the machine with an electrode holder or other parts. Always use lifting points or handles designed

for this function.

• Use only a protective platform designed for the equipment.

• Always try to transport the machine upright if possible.

• Never use a welding machine while it is hanging.

• Never exceed the maximum permissible limit for the load of wheels, suspensions or carts of welding equipment.

6. Environment

• When the action of the operator is limited by the environment (in particular: could only work when lowered on the

knees, on the floor or even lying down), any direct contact with the room carrying the current should be avoided with

the body .

• Do not use the machine when the environmental operating space is very narrow and would not allow the user to work

safely.

• Avoid using the machine in a humid environment in which operators can sweat and this is a high risk of electrocution.

• Avoid welding in a dusty environment under a corrosive gas environment.

• For welding machines intended to perform welds with a gas supply, avoid carrying out the welding work under a large

air flow environment.

• The inclination between the placement and the welding machine and the flat horizon is ≤10 °.

• The welding power source is not suitable for use in rain or snow, although it could use and store outdoors. Protect the

environment against rain, water and the sun very strong.

• Store the machine in a dry and clean area. Protect against rain and temperatures should not reach + 25 ° C in direct

sunlight.

• Protect the machine against sand and dust during use and storage.

• Place the machine so that it is not exposed to hot surfaces, sparks or splashes.

• Ensure that the flow of air and from and to the machine is unlimited.

• The EMC classification for this product is Class Ain accordance with EN 60974-10 for electromagnetic compatibility.

The product is therefore designed to be used only in an industrial environment.

• Arc welding equipment still creates electromagnetic problems in hospitals. To minimize the hazardous effects, only

use the equipment in accordance with the instruction manual and other recommendations.

WARNING: This Class A equipment is not intended for use in private homes having a power supply provided by a low

voltage power system. In such locations, it may be difficult to ensure electromagnetic compatibility due to radiation and

driving problems.

Make sure that the welding rod is placed according to the following instructions:

• Ambient air temperature range: during operation -10 °C to +40 °C; after transport and storage: -20 °C to +55 °C;

• Relative humidity: up to 50% at 40 ° C; up to 90% at 20 ° C;

• Ambient air, free of quantities of dust, acids, corrosive gases or abnormal corrosive substances, etc. apart from those

generated by the welding process;

• Altitude above sea level at 1000 m;

• Without hydrocarbon mud oil, water vapor and corrosive gas.

• No vibration and movement

• Waterproof and with shelter

• Ventilation more than 300mm from the wall to ensure a cooling air flow and excellent ventilation.

7. Other information about the machine:

• Cooling method: Fan cooling

• Handle provided for moving

• Characteristic of the welding machine: falling characteristic

• Contents of attachments: Welding cable, welding electrode holder and earth clamp, face mask, welding brush, carton

box.

Electric shock——may lead to death !!

·Set the earth fitting according to applying standard.

·It is forbidden to touch the electric parts and electrode when the skin is naked, wearing wet gloves

or clothes.

·Make sure you are insulated from the ground and the workshop.

·Make sure you are in safe position.

Gas——may be harmful to health!

·Keep your head out of the gas.

·When arc welding, air extractor should be used to prevent from breathing gas.

Arc radiation——Harmful to your eye and burn your skin.

·Use suitable helmet and light filter, wear protective garment to protect eye and body.

Fire

·Welding spark may cause fire, make sure the welding area no tinder around.

Noise——extreme noise harmful to ear.

·Use ear protector or others means to protect ear.

·Warn that noise harmful to hearing if looker-on around.

Malfunction——When trouble, count on the professionals

·If trouble in installation and operation, please follow this manual instruction to check up.

·If fail to fully understand the manual, or fail to solve the problem with the instruction, you should

contact the suppliers or our service center for professional help.

CAUTION!

Creepage-protecting switch should be added when using the machine!!!

INSTALLATION

The machine is equipment with power voltage compensation equipment. When power voltage

moves between±15% of rated voltage, it still can work normally.

When use long cable, in order to prevent voltage form going down, bigger section cable is suggested.

If cable is too long, it may affect the performance of the power system. So we suggest you to use

configured length.

1. Make sure intake of the machine not blocked or covered, lest cooling system could not work.

2. Use inducting cable whose section is not less than 6 mm²to connect the housing to the ground.

The way is from the ground-connecting screw at the back to the earth device.

3. Correctly connect the arc torch or holder according to the sketch. Make sure the cable, holder and

fastening plug have been connected with the ground. Put the fastening plug into the fastening socket at

the “-”polarityand fasten it clockwise.

4. Put the fastening plug of the cable to fastening socket of “+” polarity at the front panel, fasten it

clockwise, and the earth clamp at theotherterminal clamps thework piece.

5. Please pay attention to the connecting polarity,

DC welding machine has two connecting ways:

positive connection and negative connection.

Positive connection: holder connects with “-”

polarity, while work piece with the “+”polarity.

Negative connection: work piece with the

“-”polarity, holder with the “+” polarity.

Choose suitable way according to working

demands. If unsuitable choice, it will cause

unstable arc, more spatters and conglutination.

If such problems occur, please change the

polarity of the fastening plug.

6. According to input voltage grade, connect power cable with power supply box of relevant

voltage grade. Make sure no mistake and make sure the voltage difference among permission

range. After the above job, installment is finished and welding is available.

If distance of work piece and machine is too far (500-100m), and the cables

(torch cable and earth cable) are too long, please choose cable of bigger

section to minimize the reduction of the voltage.

OPERATION

1. Open the power switch, screen will show set current volume and ventilator is beginning to revolve.

2. Adjust knobs of welding current and arc-striking push, make welding function complies with

demands.

3. Generally, welding current is adequate to welding electrode according with as following:

Specification

φ2.5

φ3.2

φ4.0

φ5.0

Current

70-100A

110-140A

170-220A

230-280A

4. Knob of arc-striking drive is use to adjust welding function, specially in low current arrange, that is

cooperated with knob of welding current adjustment, they may adjust current of arc striking and be

out of control of knob of welding current adjustment .

5. If welding machine has been coordinated remote control device:

1) Make sure the switch position of remote control device before operation .

2) Insert plug of remote control in socket of remote control correctly and tighten firmly in

order to prevent poor contact.

3) If remote control device is not be used, make sure the switch is on “OFF” position, or welding

current will not be adjusted on panel.

warning!

Before connecting operation please make sure all the power is turned off. The right order is to

connect the welding cable and ground cable to the machine first, and make sure they are firmly

connected and then put the power plug to the power source.

NOTES OR PREVENTIVE MEASURES

1、Environment

1)The machine can perform in environment where conditions are dry with a dampness lever of max

90%.

2)Ambient temperature is between 10 to 40 degrees centigrade.

3)Avoid welding in sunshine or drippings.

4)Do not use the machine in environment where condition is polluted with conductive dust on the air

or corrosiveness gas on the air.

5)Avoid gas welding in the environment of strong airflow.

2、Safety norms

The welding machine has installed protection circuit of over voltage and current and heat. When

voltage and output current and temperature of machine are exceeding the rate standard, welding

machine will stop working automatically. Because that will be damage to welding machine, user

must pay attention as following.

1)The working area is adequately ventilated!

The welding machine is powerful machine, when it is being operated, it generated by high currents,

and natural wind will not satisfy machine cool demands. So there is a fan in inter-machine to cool

down machine. Make sure the intake is not in block or covered, it is 0.3 meter from welding machine

to objects of environment. User should make sure the working area is adequately ventilated. It is

important for the performance and the longevity of the machine.

2)Do not over load!

The operator should remember to watch the max duty current (Response to the selected duty cycle).

Keep welding current is not exceed max duty cycle current.

Over-load current will damage and burn up machine.

3)No over voltage!

Power voltage can be found in diagram of main technical data. Automatic compensation circuit of

voltage will assure that welding current keep in allowable arrangement. If power voltage is

exceeding allowance arrangement limited, it is damaged to components of machine. The operator

should understand the situation and take preventive measures.

4)There is a grounding screw behind welding machine, there is grounding marker on it Mantle must

be grounded reliable with cable which section is over 6 square millimeter I order to prevent from

static electricity and leaking.

5)If welding time is exceeded duty cycle limited, welding machine will stop working

for protection. Because machine is overheated, temperature control switch is on “ON’’ position and

the indicator light is red. In this situation, you don’t have to pull the plug, in order to let the fan cool

the machine. When the indicator light is off, and the temperature goes down to the standard range, it

can weld again.

QUESTIONS TO BE RUN INTO DURINGWELDING

Fittings, welding materials, environment factor, supply powers maybe have something to do with

welding. User must try to improve welding environment.

A、Arc-striking issues

1. Make sure quality of tungsten electrode is high.

2. If the electrode is not dried, it will cause unstable arc, welding defect increases and the quality is

down.

3. If use extra-long cable, the output voltage will decrease, so please shorten the cable

.

B、Output current not to rated value:

When power voltage departs from the rated value, it will make the output current not matched with

rated value; When voltage is lower than rated value, the max output may lower than rated value.

C、Current is not stabilizing when machine is been operating:

It has something with factors as following :

1. Electric wire net voltage has been changed .

2. There is harmful interference from electric wire net or other equipment

.

D、When use MMA welding,too much spatter

1. Maybe current is too big and stick’s diameter is too small.

2. Output terminal polarity connection is wrong, it should apply the opposite polarity at the normal

technics, which means that the stick should be connected with the negative polarity of power source,

and work piece should be connected with the positive polarity. So please change the polarity.

MAINTENANCE

1、Remove dust by dry and clean compressed air regularly, if welding machine is operating in

environment where is polluted with smokes and pollution air, the machine need remove dust

everyday.

2、Pressure of compressed air must be inside the reasonable arrangement in order to prevent damaging to

small components of inter-machine.

3、Check inter circuit of welding machine regularly and make sure the cable circuit is connected

correctly and connectors are connected tightly (especially insert connector and components).

If scale and loose are found, please give a good polish to them, then connect them again

tightly.

4、Avoid water and steam enter into inter-machine, if them enter into machine, please dry inter-machine

then check insulation of machine.

5、If welding machine will not be operated long time, it must be put into packing box

and store in dry environment.

CHECK FAULT

Notes: If user wants to operate machine as following, the operator must be a personnel in a

specific field of electricity and safety and hold the relevant certificate that proves there ability

and knowledge. Before maintenance, contact with our company for authorization is suggested.

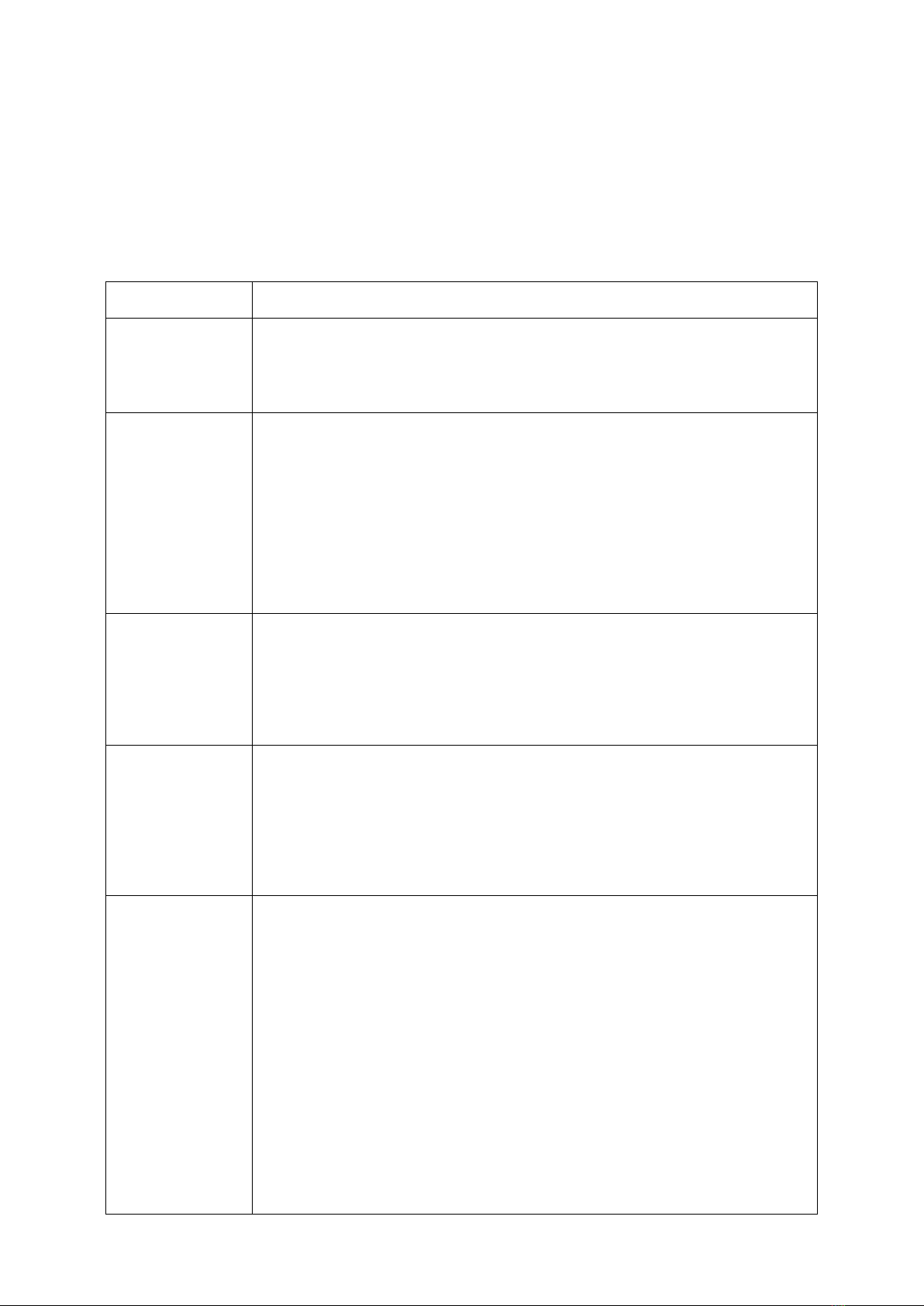

Technical information

FEIDER

32, rue Aristide Bergès - ZI 31270 Cugnaux -

France

WELDING MACHINE

145AH 160AH MAX

FPSI140A

S/N.:

EN 60974-1, EN6074-10

Class A

20A/20.8V -160A/26.4V

X %

20

60

100

U0=21V

I2A

160

90

70

U2V

26.4

23.6

22.8

U1:230V

I1max=35.5A

I1eff=15.9A

IP21S

H

3.70kg

Symbols

U1: Nominal input voltage AV (with a tolerance of ±10%)

I1max: Maximum nominal input current

I1eff : Maximum effective input current

X: Cycle of service

Ratio of the given time duration / complete cycle time

Note1: This ratio should be between 0 ~ 1, and could be represented as a percentage. Note2: In this

standard, the entire cycle is 10 min.

For example, if the duty cycle is 60%, the load applying all the time must be 6 min and the next no load time

will be 4 min.

U0: No charge voltage

Open the voltage circuit for a second winding.

U2: Tension charge

Output voltage of rated load: U2 = (20 + 0.04I2) V

A / V-A / V: Current regulation range and corresponding charging voltage.

IP: Degree of protection, IP21S

Can be used in environments with a high risk of electrocution.

:Read instruction manual

Warning symbol

:Rectifier Single Phase Static Frequency Converter - Converter

Transformer

AC single phase symbol and nominal frequency

: Manual arc welding symbol with covered electrodes

Do not use outdoor when it is raining

H:Insulation class

DISPOSAL

Electrical products should not be discarded with household products. According to the European Directive

2012/19/EU on waste electrical and electronic equipment and its implementation into national law, electrical

products used must be collected separately and disposed of at collection points provided for this purpose. Talk

with your local authorities or dealer for advice on recycling.

faults and resolvable methods

Fault

Resolvable methods

Indicator of power

switch is not lit, fan

is not working and

there is not welding

output.

A. Make sure power switch is close.

B. Make sure electrify wire net (which is connected to input cable) is in work.

Power indicator is

lit, fan does not

work and there is

no welding output.

A. Maybe be connected wrong to 380v power cause machine is in protection

circuit, connect to 240v power and operate machine again.

B. 240v power is not stabilizing (input cable is too slender) or input cable is

connected to electrify wire net cause machine is in protection circuit. Increase

the section of input cable and tighten input connector firmly. Close machine

2-3 minutes then open it again.

C. Open and close power switch in short time cause protection circuit is working.

Close machine and open it again after 2-3 minutes.

D. Cables are relaxed between power switch and power source board, tighten

them again.

Fan is working,

welding current is

not stabilizing or

out of potential

control, current is

sometimes low and

sometimes high.

A. Quality of 1K potential is bad, replace it.

B. Terminal of output is broken circuit or poor connect.

Fan is working and

indicator is not lit,

there is no welding

output.

A. Check if components are poor connects.

B. Check if connector of output terminal is break circuit and poor connect.

C. Check voltage between power source board and MOS board (VH-07) is about

DC 308v.

D. If green indicator is not lit in assistant power of MOS board, please connect

with seller or our company and replace it.

E. If there is some question in control circuit, please connect with seller or our

company and replace it.

Fan is working and

abnormal

indicator is lit, but

there is no

welding output.

A. Maybe over-current protection is working, please close machine and waiting.

After abnormal indicator is not on, open machine.

B. Maybe overheated protection is working, wait for 2-3 minutes.

C. Maybe inverter circuit is in fault; please pull up the power plug of main

transformer (near VH-07 fan), which is on MOS board, then open the machine

again.

(1) If abnormal indicator is still lit, some of MOS board is damaged, check

and replace it.

(2) If abnormal indicator is not lit:

i. Maybe transformer of middle board is damaged, measure primary

inductance volume and Q volume of main transformer by inductance

bridge.

ii. Primary volume is parallel circuit, L=1.2-2.0Mh, Q>40

If inductance volume and Q volume is low, replace it.

iii. Maybe some of secondary rectifier tube of transformer is broken,

check and replace rectifier tube.

D. Maybe feedback circuit is in fault.

Declaration of conformity

FEIDER

ZI, 32, rue Aristide Bergès –31270 Cugnaux –France

Declare that this machine

WELDING MACHINE

FPSI140A

Serial number:

Responsible of technical file: M. Oliver Patriarca

Is in conformity with the Directive 2006/42/CE and to the regulation

transposing it;

Also in conformity with the following Directives

EMC Directive 2014/30/UE

ROHS Directive 2011/65/UE

Also in conformity with the following standards

EN 60974-1:2012

EN 60974-10:2014+A1

EN 50445: 2008

Cugnaux, le 16/09/2018

Philippe MARIE / PDG

Table of contents

Popular Welding System manuals by other brands

Linde

Linde RYVAL 200 AC/DC dave operating manual

Miller

Miller Gold Seal 442 owner's manual

Schulz

Schulz SOMAR MTS 150 Compact instruction manual

Miller

Miller SRH 2000 STICK 400 owner's manual

widos

widos 4002 S WI CNC Working Instructions Translation

CEA

CEA SMARTMIG T21 Operator's manual & spare parts list