Fenwal Controls 35-608 Series User manual

06-237172-002

October 2018

1

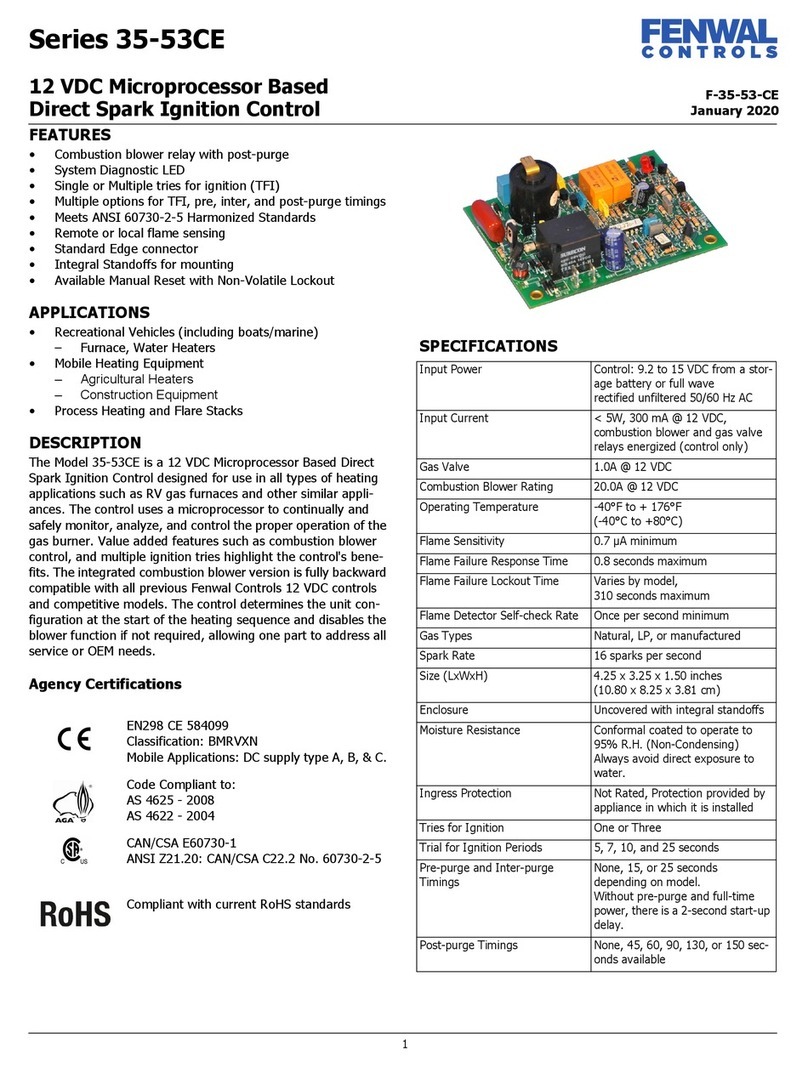

APPLICATIONS

The Fenwal 35-608 series Direct Spark Control (35-608) is a

microprocessor based control suitable for many types of heat-

ing applications including HVAC, commercial cooking, furnaces,

boilers, and water heaters that require direct spark ignition,

burner supervision through flame rectification, and safety shut-

off. It is designed for use with Natural, LP, and mixed gases

used in gas-fired appliances.

The microprocessor circuit design of the 35-608 provides pre-

cise, repeatable timing and operating sequences. High energy

spark output and excellent flame sense characteristics provide

reliable burner operation. The on-board diagnostics with LED

output make troubleshooting easy and ensure safe and efficient

operation.

FEATURES

• Safe start and full-time flame sensing

• Automatic 1 hour reset after lockout option*

• Wide variety of prepurge and interpurge timings**

• Single or three trials for ignition

• Diagnostic LED with Fenwal error codes

• Green power LED

• Remote or local flame sense options

• RoHS compliant

AGENCY CERTIFICATIONS***

EN298 Classification AMC/RLXK

* Automatic reset after 1 hour is not allowed for CE

approved models.

** Prepurge time cannot exceed interpurge time on CE

approved models.

*** Certification varies by model.

**** EMC emission requirements shall be verified after

incorporation of the burner control system into the end

use appliance.

CSA Design certified to ANSI Z21.20,

CAN/CSA C22.2 No. 199-M99

SPECIFICATIONS

Input Power Control: 18-30 VAC 50/60 Hz, 8W

(Class 2 Transformer)

Input Current Drain 300 mA @ 24 VAC with gas valve

relay energized (Control only)

Main Gas Valve 5.0A max (continuous)

Operating Ambient Temperature -40°F to + 176°F

(-40°C to +80°C)

Storage Temperature -40°F to + 185°F

(-40°C to +85°C)

Flame Sensitivity 0.7 μA minimum

Flame Failure Response or

Reignition Time

0.8 seconds minimum

Flame Detector Self-check Rate Once per second minimum

Flame Failure Lockout Time Varies by model, 300 seconds

maximum

Types of Gas Natural, LP, or manufactured

Spark Rate Remote sense (50/60 Hz)

Local sense (25/30 Hz)

Size (LxWxH) 5.20 x 3.95 x 2.50 inches

(13.21 x 10.03 x 6.35 cm)

Moisture Resistance Conformal coated to operate non-

condensing to 95% R.H.

Ingress Protection Not Rated, Protection provided by

appliance in which it is installed

Tries for Ignition One or three try versions available

Trial for Ignition Periods 4, 7, 10, and 15 seconds available

Pre-purge Timings None, 15, or 30 seconds available

Inter-purge Timings None, 15, or 30 seconds available

SERIES 35-608

INSTALLATION INSTRUCTIONS FOR FENWAL SERIES 35-608

DIRECT SPARK IGNITION CONTROLS

Effective: October 2018

2 06-237172-002

INSTALLATION GUIDELINES

MOUNTING AND WIRING

The 35-608 is not position sensitive and can be mounted verti-

cally or horizontally. The case may be mounted on any surface

with #6 sheet metal screws.

WIRING DIAGRAMS

Figure 1. 35-6086 5/6 Pin

CAUTION

Label all wires prior to disconnection when ser-

vicing or replacing controls. Wiring errors can

cause improper and dangerous

operation. A functional checkout of a replace-

ment control should always be performed.

WARNING

The control must be mounted and located in a

manner which protects components from expo-

sure to water (dripping, condensate, spraying,

rain). Any control that has been exposed to

water must be replaced.

WARNING

All wiring must be done in accordance with

both local and national electrical code. Wiring

must be at least #18 AWG rated for 105°C or

higher.

WARNING

The 35-608 uses voltages of shock hazard

potential. Wiring and initial operation must be

done by qualified service technician.

WARNING

Operation outside specifications could result in

failure of the Fenwal product and other equip-

ment with injury to people and property.

6-Pin Standard 35-608 Model (.156” Header)

Name Description Connection

MV Main Gas Valve Pin 1

TH Thermostat Pin 2

GND Ground Pin 3

GND Ground Pin 4

LAMP (NC) Normally Closed Pin 5

S1 Flame Sense Pin 6

6-Pin 35-6084 Model (.156” Header)

Name Description Connection

NC Alarm Lamp 24 Vac Pin 1

Reset Input (Special Order) Pin 2

TH Thermostat Pin 3

Valve GND Ground for Valve Pin 4

Valve Valve 24 Vac Pin 5

GND Control Ground Pin 6

S1 Remote Flame Sense Q.C. Terminal

.250” Wide

8-Pin CE (EN298) Special Model (35-608300-015)

(.156” Header)

Name Description Connection

ALARM Lockout Pin 1

24V 24 VAC Power Pin 2

RESET Manual Reset Pin 3

TH Thermostat Pin 4

GND Valve Return Pin 5

MV Main Gas Valve Pin 6

GND Ground Pin 7

GND Ground Pin 8

S1 Flame Sense Q.C. Terminal

.250” Wide

Remote Sense

BURNER

1

2

5

6

3

4

FL AM E

SENSOR

FC +

(2 CONTACTS)

FC -

H.V.

LAMP (NC)

GND

GND

GAS

VALVE

TH

MV

24 VAC

S1

Local Sense

BURNER

1

2

5

3

4

FC +

(2 CONTACTS)

FC -

H.V.

LAMP (NC)

GND

GND

GAS

VALVE

TH

MV

24 VAC

Effective: October 2018

06-237172-002 3

Figure 2. 35-6084 6 Pin Local Sense Figure 3. 8 Pin Local Sense Wiring

HIGH VOLTAGE AND REMOTE SENSE

CABLE REQUIREMENTS

The HV Ignition Cable must meet a voltage rating of 25 KV and

an insulation rating of 200 °C. Recommend length of 3ft (.9m)

or less. Consult factory for longer lengths.

Remote flame sense cable must meet a voltage rating of 250V

and an insulation rating of 200 °C. Recommended length of 10ft

(3m) or less. Consult Factory for longer lengths.

Remote Sense

BURNER

1

4

5

2

3

(2 CONTACTS)

H.V.

GND

GAS

VALVE

TH

VALVE

24 VAC

6

VALVE

GND

RESET

NC

S1

Local Sense

BURNER

1

4

5

2

3

(2 CONTACTS)

H.V.

GND

GAS

VALVE

TH

VALVE

24 VAC

6

VALVE

GND

RESET

NC

S1

FL AM E

SENSOR

Local Sense

BURNER

1

2

5

6

3

4

FC +

(2 CONTACTS)

FC -

H.V.

GND

GND GAS

VALVE

TH

MV

24 VAC

7

8

GND

RESET

24V

ALARM

Remote Sense

BURNER

1

2

5

6

3

4

FC +

(2 CONTACTS)

FC -

H.V.

GND

GND GAS

VALVE

TH

MV

24 VAC

7

8

GND

RESET

24V

ALARM

FL AM E

SENSOR

S1

Effective: October 2018

4 06-237172-002

SEQUENCE OF OPERATION / FLAME

RECOVERY / SAFETY LOCKOUT

START UP - HEAT MODE

When a call for heat is received from the thermostat supplying

24 volts to TH the following sequence occurs in the order listed:

1. The green power LED is illuminated.

2. The control resets and then performs a self check routine,

flashing the red diagnostic LED once in the first two sec-

onds.

3. The control begins a pre-purge delay.

4. Following the pre-purge period, the control energizes the

gas valve.

5. The control enables the high voltage spark output for the

trial for ignition period.

6. When the control detects the presence of flame during the

trial for ignition, the control terminates the sparking pro-

cess.

7. The thermostat and burner flame are constantly monitored

to assure the system continues to operate properly.

8. When the thermostat is satisfied and the demand for heat

ends, the main gas valve is de-energized immediately and

the green LED turns off.

FAILURE TO LIGHT - LOCKOUT

SINGLE TRIAL MODEL

Should the burner fail to light, or if the flame is not detected

during the trial for ignition period, the control performs the fol-

lowing actions:

1. The control enters ignition lockout.

2. The main gas valve is de-energized immediately.

3. The diagnostic LED indicates the fault code for lockout.

MULTI TRIAL MODEL

Should the burner fail to light, or if the flame is not detected

during the first trial for ignition period, the control performs the

following actions:

1. The main gas valve is de-energized.

2. The control then goes through an interpurge delay before

another ignition attempt.

3. The control attempts two additional ignition trials before

going into lockout and the main gas valve relay is de-ener-

gized immediately.

4. The diagnostic LED indicates the fault code for lockout.

LOCKOUT RESET

Recovery from lockout requires a manual reset by either recy-

cling the thermostat or removing 24 volts for a period of 5 sec-

onds. On models with automatic reset, if the thermostat is still

calling for heat after one hour the control will automatically reset

and attempt to ignite the burner.

CE versions have an option for non-volatile lockout. In this

case, only the external RESET input must be used to recover

from an ignition lockout.

FLAME FAILURE RESPONSE

RE-IGNITION MODE (STANDARD)

If the established flame signal is lost while the burner is operat-

ing, the control will respond within 0.8 seconds (max) by ener-

gizing the HV spark for the programmed TFI period in an

attempt to relight the burner. If the burner does not light within

the TFI, the gas valve is de-energized immediately and on

multi-try models a new TFI sequence begins.

If the burner does not relight, the control will lockout as previ-

ously described in “Failure to Light - Lockout”. Multi-try models

will make 2 more attempts to light the burner. If the flame is re-

established, normal operation resumes.

RECYCLE MODE (OPTIONAL)

With "recycle after loss of flame", upon loss of flame, the main

gas valve is de-energized within 0.8 seconds (max). After the

flame recycle delay, the control attempts to relight the burner.

Multi-try models allow three tries for ignition including inter-

purges. If the burner relights, normal operation resumes. If the

burner does not relight, the control will go into lockout as

described in “Failure to Light - Lockout”.

CHECKOUT

Test the gas control system after any service or component

changes to the appliance using the following method:

1. Perform a visual check of all piping, burners, and venting.

Check all wiring for integrity and proper electrical and

ground connections. Verify the burner is properly

grounded.

2. With the gas supply and thermostat off, turn on power to

the appliance.

3. Turn the thermostat to a setting high enough to initiate a

call for heat. Verify the ignition control proceeds through

the operating sequence to a safety shutoff (lockout) condi-

tion. (The burner will not light because the gas is shut off)

4. Turn off the thermostat.

5. Turn on the gas supply, and purge the gas lines of air.

Check for gas leaks on all joints upstream of the gas valve

with a soap solution.

6. Turn the thermostat to a setting high enough to initiate a

call for heat. Verify the ignition control proceeds through

the operating sequence to a normal run (burner lit) condi-

tion. Confirm there are no gas leaks downstream of the

gas valve using a soap solution.

7. Turn the thermostat setting down below the room tem-

perature. Verify the burner flame goes out.

WARNING

Risk of Explosion or Fire

Verify there are no gas leaks by using a rich

soap and water solution on all joints and

pipe connections. Never use a match or

lighter to test for the presence of gas. Fail-

ure to test properly before operation can

lead to explosion or fire and may result in

severe injury or death.

Effective: October 2018

06-237172-002 5

TROUBLESHOOTING

Before troubleshooting the system, check the following items:

• Verify all mechanical and electrical connections are secure

and tight.

• Verify all system wiring is correct.

• Verify there is a proper system ground. The igniter, flame

sensor, and ignition module must share a common ground

with the burner. Nuisance shutdowns are often caused by a

poor or erratic ground.

• Perform the instructions in “Checkout” on page 4, as the

first step in any troubleshooting.

• Verify that the system is powered and that the thermostat is

calling for heat.

• Verify the green power LED is lit, indicating 24 VAC power

to the control.

• If the control proceeds to an error code on the red

diagnostic LED, troubleshoot per the Fault Conditions table

below:

The LED will flash on for 1/4 second, then off for 1/4 second

during a fault condition. The pause between fault codes is 3

seconds.

FLAME CURRENT MEASUREMENT

Flame current is the current that passes through the flame from

sensor to ground. To measure flame current, connect a True

RMS or analog DC micro-ammeter to the FC+ and the FC-

terminals. The reading should be 1.0 micro-amps DC or higher.

If the meter reads negative or below “0” on the scale, the meter

leads are reversed. Re-connect leads with proper polarity.

Alternately, a Digital Voltmeter may be used to measure the DC

voltage between the FC+ and FC- terminals. Each micro-amp

of flame current produces 1.0 VDC, so a reading of 2.6 VDC

would equate to 2.6 micro-amps.

A good burner ground that matches the control ground is critical

for reliable flame sensing.

INTERNAL CONTROL FAILURE

If the control detects an error in its software or hardware, all out-

puts are turned off and the red LED displays a steady ON condi-

tion. If this condition persists after an attempt to restart then the

control must be replaced.

PROPER ELECTRODE LOCATION

Proper location of the electrode assembly is important for

optimal system performance. The electrode assembly should

be located so that the tips are inside the flame envelope and

about 1/2 inch (1.2 cm) above the base of the flame.

• Ceramic insulators should not be in or close to the flame.

• Electrode assemblies should not be adjusted or disassem-

bled. Electrodes should have a gap spacing of 0.125±

0.031 inch (3.12± 0.81 mm), unless otherwise specified by

the appliance manufacturer. If this spacing is not correct,

the assembly must be replaced. Electrodes are NOT field-

adjustable.

• Exceeding the temperature limits can cause nuisance lock-

outs and premature electrode failure.

• Electrodes must be placed where they are not exposed to

the appliance user in normal operation.

WARNING

Risk of Explosion or Fire

The 35-608 control cannot be serviced by the user.

If any control faults are detected, the 35-608 con-

trol must be replaced by qualified service person-

nel. Risk of explosion or fire can result if the control

module has been opened or with any attempts to

repair it, and the warranty is void.

Fault Conditions

LED Indication Fault Mode

Off Normal Operation

2 Flashes Flame without call for heat

3 Flashes Ignition Lockout

4 Flashes Manual Reset Error

Steady On Internal Control Failure

Troubleshooting Guide

Symptom Probable Cause

1. Control does

not start, green

LED is off.

A. Mis-wired

B. 24 VAC Transformer bad

C. Fuse/Circuit breaker bad (no power)

2. Thermostat

on - no spark or

valve

A. Mis-wired

B. Bad thermostat, no voltage at thermostat

terminal TH

C. Bad control, check red LED for steady

on or flashing codes.

3. Valve on - no

spark during

TFI

A. Shorted electrode

B. Spark gap not correct. Set to .094-.156

inch.

C. High voltage cable is faulty or has a poor

connection.

4. Spark on -

valve off

A. Gas Valve coil open

B. Valve wire disconnected

C. Bad control, check voltage between gas

valve terminal MV and GND.

5. Flame okay

during TFI - no

flame sense

after TFI

A. Check electrode position and cleanliness

B. Check high voltage wire

C. Poor ground at burner

D. Poor flame, check flame current

Effective: October 2018

6 06-237172-002

DIMENSIONS

Figure 4. 6-Pin 35-6086 and 35-6084 Model Dimensions

Figure 5. 8-Pin 35-608 Model Dimensions

TH

VALVE (GND)

GND

VALVE

NC

1.750 MAX.

2.50 MAX.

3.940

.910

5.200

3.380

.283

3.375

RED LED

.187 ± .010 DIA.

(4 MOUNTING HOLES)

GREEN LED

REMOTE FLAME SENSE TERMINAL

FC+FC-

5 or 6 PIN HEADER

1.750 MAX.

2.15 MAX.

3.940

.910

5.200

3.380

.283

3.375

PIN 1

RED LED

8 PIN HEADER

.187 ± .010 DIA.

(4 MOUNTING HOLES)

GREEN LED

.250" Q.C. MALE

XX SEC

1.56” SPACING

Fenwal Controls, Kidde-Fenwal Inc.

400 Main Street

Ashland, MA 01721

Tel: 800-FENWAL-1

Fax: 508-881-7619

www.fenwalcontrols.com

This literature is provided for informational purposes only. KIDDE-FENWAL, INC. assumes no responsibility for the product’s suitability for a particular application. The

product must be properly applied to work correctly. If you need more information on this product, or have a particular problem or question, contact KIDDE-FENWAL, INC.

06-237172-002 Rev BD ©2018 Kidde-Fenwal, Inc.

STANDARD PART NUMBER CONFIGURATION

35 – 6 0 8 X X X X X X–

TRIES FOR IGNITION & METHOD OF FLAME SENSE

0 = Single Try - Local Sense

1 = Single Try - Remote Sense

2 = Single Try - Local Sense with 1 Hour Automatic Reset

3 = Single Try - Remote Sense with 1 Hour Automatic Reset

5 = Three Tries - Local Sense

6 = Three Tries - Remote Sense

7 = Three Tries - Local Sense with 1 Hour Automatic Reset

8 = Three Tries - Remote Sense with 1 Hour Automatic Reset

PRE-PURGE

0 = None

1 = 15 Seconds

2 = 30 Seconds

INTER-PURGE

0 = None

1 = 15 Seconds

2 = 30 Seconds

TRIAL FOR IGNITION

1 = 4 Seconds

3 = 7 Seconds

5 = 10 Seconds

7 = 15 Seconds

ENCLOSURE

0 = Noryl Gray Enclosure

1 = Integral Stand-Offs

PRODUCT DESIGNATION

2 = CE (EN298) Standard Model

3 = CE (EN298) Special OEM Configuration

4= CE & CSA Hi Reliability

5 = Standard QC Terminal

6 = Multi-Pin Standard

9 = Special OEM Configuration

Description

EXPORT INFORMATION (USA)

Jurisdiction: EAR

Classification: EAR99

This document contains technical data subject to the EAR.

Fenwal Controls

400 Main Street

Ashland, MA 01721

Tel. (508) 881-2000

© Kidde-Fenwal Inc. 06-237657-001 Rev AC

EU DECLARATION OF CONFORMITY

We

Company Name: Kidde-Fenwal Inc.

Postal Address: 400 Main Street

City and Post Code: Ashland, MA 01721

Tel: 508-881-2000

Declare that the DoC is issued under sole responsibility and belongs to the following product:

Apparatus Model(s) Series 35-40, 35-53, 35-60, 35-61, 35-63, 35-608, 35-65, 35-66, 35-9X

Type: Fitting

Batch Number Date code and Revision Level Assigned per production lot, (YYWW RR)

Object of the Declaration:

Series 35-40, 12/24Vdc Direct Spark Automatic Gas Ignition Controllers

Series 35-53, 12Vdc Direct Spark Automatic Gas Ignition Controllers

Series 35-60, 35-61, 35-63, 35-608 24Vac Direct Spark Automatic Gas Ignition

Series 35-65 & 35-66 24Vac Hot Surface Automatic Gas Ignition Controllers

Series 35-9X Platform Ignition Module

SERIES 35-40 SERIES 35-53 SERIES 35-60/61/63/608 SERIES 35-65/66

SERIES 35-9X

The object of the declaration described above is in conformity within the relevant union

harmonization legislation:

Gas Appliance Regulation: (EU) 2016/426 Low Voltage Directive: 2014/35/EC

EMC Directive: 2014/30/EC Rohs 2011/65/EU

The following harmonized standards and technical specifications have been applied:

EN298:2012: Automatic Burner Control systems for Burners and appliances burning gaseous or liquid fuels.

EN13611:2007_A2:2011: Safety and control devices for Gas Burners and Gas burning appliances – General Requirements.

Name of Notified Body & Number: BSI Group, 0086, EU Type Examination Certification

Notified Body Certificate No.: Series 35-40: CE682407

Series 35-53 CE682404

Series 35-60/61/63/608 CE682405

Series 35-65/66 CE682406

Series 35-9x CE690652

Surveillance Audit Notified Body: BSI Group

For copies of the Installation Instructions and the EU DoC, got to www.fenwalcontrols.com, - Document Library - Data sheets.

Paul Finn

Kidde-Fenwal, Inc. Ashland, MA USA 01 Oct 2018 Paul Finn, Certification Engineer

Place of Issue: Date of Issue Name

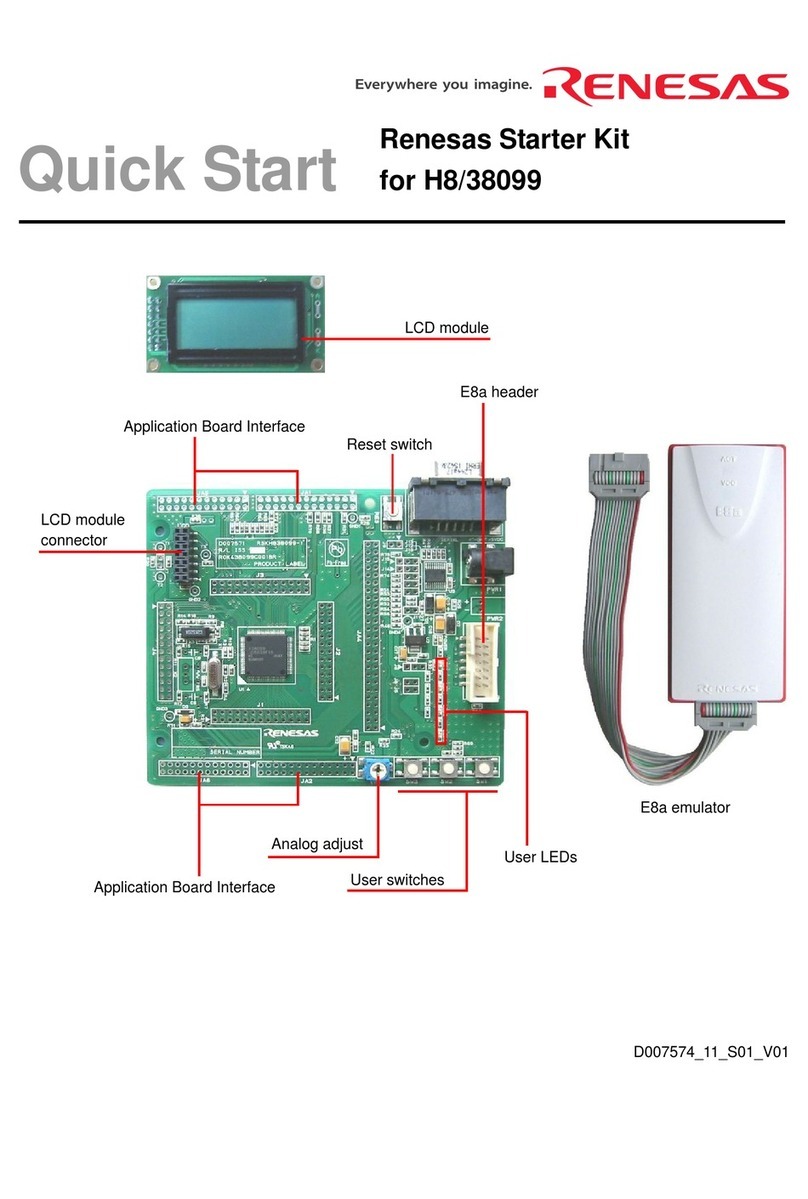

Table of contents

Other Fenwal Controls Computer Hardware manuals