fergo Switchmaster M2 Operator's manual

Design and materials can be changed without notice. Errors and omissions excepted

DOCUMENTATION - SWITCHMASTER - 1 -

Content

Legend 1

Safety instructions 2

Mounting of the SWITCHmaster ® Adjusting of the cams 5

Technical data 6

Illustrations 7

1. Legend

2Grüne Markierung

Green marks

3Rotring

Red ring

4Einstellwerkzeug

Adjusting tool

5Universal-Schaltnocken

Universal cams

6Grünring

Green ring

7Nockenwelle

Stem

8Mikroschalter

Micro switch

9Klemmleisten

Te rminal strip

10 Induktiv-Schalter

Inductive switch

11 Montageplatte

Mounting plate

12 Gehäuse

Casing

13 Clips

Clips

14 Füße

Feet

1Klarsichtdeckel mit Bajonett-Verschluß

Tr ansparent cap with bayonet catch

1

2

3

4

5

5

6

7

8

9

9

10

11

12

13

13

14

14

Blindeisenweg 31

D-41468 Neuss

Tel.: +49(0) 2131 - 15 39 28-0

Fax: +49(0) 2131 - 15 39 28-99

Web: www.fergo.biz

E-Mail: info@fergo.biz

copyright © by

FERGO® Armaturen GmbH

Design and materials can be changed without notice. Errors and omissions excepted

DOCUMENTATION - SWITCHMASTER - 2 -

2. Sicherheitshinweise

Read this mounting instructions before initiation. The warranty claim will expire in case of not considering this instruction.

» The SWITCHmaster ® is designed for use as optical display and electric position indicator for actuators, which enable a valve to

perform a rated pivoting angle of 90°.

» Incorrect handling and non-adherence to the rules of usage lead to the total and irrevocable loss of cover provided in the warran-

ty.

» Check the correctness of the technical parameters, especially the temperature and voltage values before mounting and commissi-

oning SWITCHmaster ®.

» In explosion-protected areas connect SWITCHmaster ® only with intrinsically safe circuits.

» When working on the SWITCHmaster ®, always

- isolate the compressed air supply and

- isolate the voltage supply.

» Exchange the unit immediately, if there is any damage to the unit which could permit the entry of moisture into the unit.

» In explosion-protected areas, it may be necessary to provide direct sunlight protection, to shield the surface of the unit from the

overheating eects of too much direct sunlight.

» Clean the SWITCHmaster ® only with cleansing agents which do not attack the SWITCHmaster ® material. Do not use scouring

agents, alcohol or chemical thinners..

3. General information

This instruction shall help the user to make the mounting of the SWITCHmaster® easier as well as the adjusting of the cams. Thereby

the position indicator can be used optimal.

A. Packaging contents

1 complete SWITCHmaster® with 2 feet 1 bag with

» 2 clips: to arrest the feet

» 4 screws: to attach the feet to the actuator

» 1 mounting and cam adjusting instruction

B. Mounting of the feet

» Pull out both feet from the SWITCHmaster® casing.

» Before mounting consider inside or outside position of the feet:

inside position: 80 mm

outside position: 130 mm

After deciding the position of the feet, mount the feet with the enclosed self-locking screws.

Mounting of SWITCHmaster® onto actuator with valve 2/2-way valve: closed

In case of mounting the actuator in direction of pipeline:

Turn the double D of the stem of SWITCHmaster® into position as shown in the sketch.

In case of mounting the actuator in cross-direction of pipeline:

Turn the double D of the stem of SWITCHmaster® into position as shown in the sketch.

1

2

3

4

Blindeisenweg 31

D-41468 Neuss

Tel.: +49(0) 2131 - 15 39 28-0

Fax: +49(0) 2131 - 15 39 28-99

Web: www.fergo.biz

E-Mail: info@fergo.biz

copyright © by

FERGO® Armaturen GmbH

Design and materials can be changed without notice. Errors and omissions excepted

DOCUMENTATION - SWITCHMASTER - 3 -

Push the SWITCHmaster® over both feet until the double-D of the cam dips into the slot of the shaft:

When lock-in position of the feet is reached, do not push any further!

The projection of the shaft can be 20, 30, 40 or 50 mm.

Press the clips into the lateral openings until they lock into place. The lateral 4 round openings on each side of the foot and foot

guide have to suit exactly on top of each other.

C. Electrical connection

Only an electrical expert is allowed to connect the unit!

Take o the transparent cap.

Lift the red and green ring from the casing.

Pull out the mounting plate vertically up.

Unscrew the coupling ring of the cable gland and lead-in of the trip line.

Connection of the trip line according to the wiring diagram on the mounting plate.

Re-lock the mounting plate. The recess has to be aligned towards the tting (see drawing on the right). Tight the fastening screw (A).

Lay out the cable, so that the movement of the red/green rings is not restricted in any way (10 mm distance from black casing).

Tighten rmly the coupling ring of the cable gland.

+

5

6

7

8

9

10

11

12

13

A

Blindeisenweg 31

D-41468 Neuss

Tel.: +49(0) 2131 - 15 39 28-0

Fax: +49(0) 2131 - 15 39 28-99

Web: www.fergo.biz

E-Mail: info@fergo.biz

copyright © by

FERGO® Armaturen GmbH

Design and materials can be changed without notice. Errors and omissions excepted

DOCUMENTATION - SWITCHMASTER - 4 -

D. Adjusting of the cams

for electrical position indication.

Attention!!

The valve and actuator should be adjusted - in case of actuators with adjustable pivoting

angle - before adjusting

the cams.

» A suitable test control unit is necessary for adjusting. (e.g. our Uni-SwitCheck).

» Bring the SWITCHmaster® into neutral switching position!

The adjusting tool (E) has to be used for adjusting the reversing point.

» Fig. A: The lower cam can be adjusted, if the tool is inserted until mark 1: Delivery condition!

» Fig. B: For adjusting the upper cam the adjusting tool has to insert into the opposite recess

until mark 2 is reached

Allocation of the cams and switches

((arbitrary appointment of the allocation)

» The upper cam actuates the upper placed switch for the„Open-position”of the valve. (terminal strip 1-3)

» The lower cam actuates the lower placed switch for the„Closed-position”. (terminal strip 4-6)..

Adjusting of the„OPEN- and CLOSED-position”according to the matrix

Please adjust the lower cam at rst, and than the upper cam.

Attention!!

In the adjusting instruction (page 20/21) it is assumed, that the valve (viewed from top) will be closed clockwise!

After position adjusting...

» … the auxiliary tool is not allowed to turn any longer!

» …pull out the auxiliary tool upwards and insert it in the lower recess of the stem, so that the„ag” points to the

» opposite recess!

Abb. A:

Einstellen der

unteren Nocke

Abb. B:

Einstellen der

oberen Nocke

E

2

1

Fig. A Fig. B

Blindeisenweg 31

D-41468 Neuss

Tel.: +49(0) 2131 - 15 39 28-0

Fax: +49(0) 2131 - 15 39 28-99

Web: www.fergo.biz

E-Mail: info@fergo.biz

copyright © by

FERGO® Armaturen GmbH

Design and materials can be changed without notice. Errors and omissions excepted

DOCUMENTATION - SWITCHMASTER - 5 -

3. Adjusting of the cams

Micro switches operated switching

Inductive switches damped switching

Valve

„CLOSED” „OPEN”

2-fold

1. Close the valve.

2. Insert the adjusting tool according to g. A

3a The switch is ( I ) operated/damped:

Turn the adjusting tool clockwise until the switch is

( II ) no longer operated/ damped. Keep on turning

until ( III ) switching point is reached.

3b The switch is not operated/damped: ( II )

Turn the adjusting tool clockwise until switching

point is reached. ( III )

1. Open the valve.

2. Insert the adjusting tool according to g. B

3a The switch is already operated/damped: ( IV )

Turn the adjusting tool anticlockwise until the

switch is no longer ( V ) actuated/damped.

Keep on turning until ( VI ) switching point is

reached.

3b The switch is not operated/damped: ( V )

Turn the adjusting tool anticlockwise until swit-

ching point is reached. ( VI )

1-fold

„Open”

1-fold

„Closed”

1. Close the valve.

2. Insert the adjusting tool according to g. A

3a The switch is operated/damped: ( I ) Turn the ad-

justing tool clockwise until the switch is no longer

operated/damped. Keep on turning until ( II )

switching point is reached. ( III )

3b The switch is not operated/damped: ( II )

Turn the adjusting tool clockwise until switching

point is reached. ( III )

E. Positioning of the optical indication

2/2-way valve: closed

3/2-way valve: switching position is random.

Please control:

Red and green ring has to be placed as shown.

» Take hold the red and green ring as shown.

» Take care that lower anges of red and green ring are ush.

» Align the inner Double-D of the red ring onto the corresponding Double-D of the cam.

» Push the 4 gates of the green ring into the guides of the casing..

Check the green marks and install them so that they show the ow path of the valve

The lateral visible colors of the red or green ring show:

green = 2/2-way valve open

red = 2/2-way valve closed

14

15

Blindeisenweg 31

D-41468 Neuss

Tel.: +49(0) 2131 - 15 39 28-0

Fax: +49(0) 2131 - 15 39 28-99

Web: www.fergo.biz

E-Mail: info@fergo.biz

copyright © by

FERGO® Armaturen GmbH

Design and materials can be changed without notice. Errors and omissions excepted

DOCUMENTATION - SWITCHMASTER - 6 -

F. Closing of the transparent cap

Adjust the red arrow shown on the transparent cap to the marking on the casing:

1. press down the cap…

2. …and turn until the red arrow is showing on the marking l

General Data

Mounting measurements According to VDI/VDE 3845 for ange facing 30 x 80 and 30 x 130 (see dimensioned

drawing)

Materials

- Cap Lexan 143 R (PC)

- Stem Delrin (POM)

- Seals Perbunan (NBR)

- Cable gland/nut Polyamid (PA)

- Other parts of plastic Bayblend T45, (ABS + PC)

- Hexagon socket screw Stainless steel AISI 304

Protection IP67, VDE 0470/EN 60529

Temperature range -20 °C to +70 °C

Indication and switching range 0°...90° pivoting angle

Cable gland With strain relief,

Clamp range 7-13 mm

Cable Ø 7-13 mm, max. 2,5 mm²

Weight ca. 0,325 kg

SWITCHMASTER Versions

Typ M, Microswitches Typ SM - M2 (Signal„Open + Close“)

Voltage range 4 V/DC - 250 V/DC

Current range 1mA - 5A

Switches functions Change over contact, contacts old plated

Typ D, inductive sensor, direct switching,

three-wire system, with LED

Typ SM - D2 (Signal„Open + Close“)

Typ SM - DA (Signal„Open“)

Typ SM - DZ (Signal„Close“)

Voltage range 10 - 30 V/DC

Current range 100 mA

Switches functions puls schaltend, PNP Schließer, in Endlage bedämpft oder unbedämpft

Typ N, inductive sensor, Namur EN 60947-

5-6, with LED, explosion-proofed

Typ SM - N2 (Signal„Open + Close“)

Typ SM - NA (Signal„Open“)

Typ SM - NZ (Signal„Close“)

Voltage supply rated voltage 8 V/DC, max. 16 V/DC

Output current damped </= 1 mA; undamped >/= 3 mA

Switching function damped or undemped in end-position

Switching power max. 34 mW

ATEX- Version (dierent from„general data“)

Material ATEX- Series

Cover Lexan 143R CPC antistatic coated

Casting, feet Bayblend T45 (ABS + PC) antistatic coated

ATEX- Name EX II 2 G EEx ia IIB T6

-20°C C < Ta < +70°C

geschlossen

16

closed open

Blindeisenweg 31

D-41468 Neuss

Tel.: +49(0) 2131 - 15 39 28-0

Fax: +49(0) 2131 - 15 39 28-99

Web: www.fergo.biz

E-Mail: info@fergo.biz

copyright © by

FERGO® Armaturen GmbH

Design and materials can be changed without notice. Errors and omissions excepted

DOCUMENTATION - SWITCHMASTER - 7 -

1

5

9

13

2

6

10

14

3

7

11

15

4

8

12

16

Blindeisenweg 31

D-41468 Neuss

Tel.: +49(0) 2131 - 15 39 28-0

Fax: +49(0) 2131 - 15 39 28-99

Web: www.fergo.biz

E-Mail: info@fergo.biz

copyright © by

FERGO® Armaturen GmbH

This manual suits for next models

1

Table of contents

Popular Switch manuals by other brands

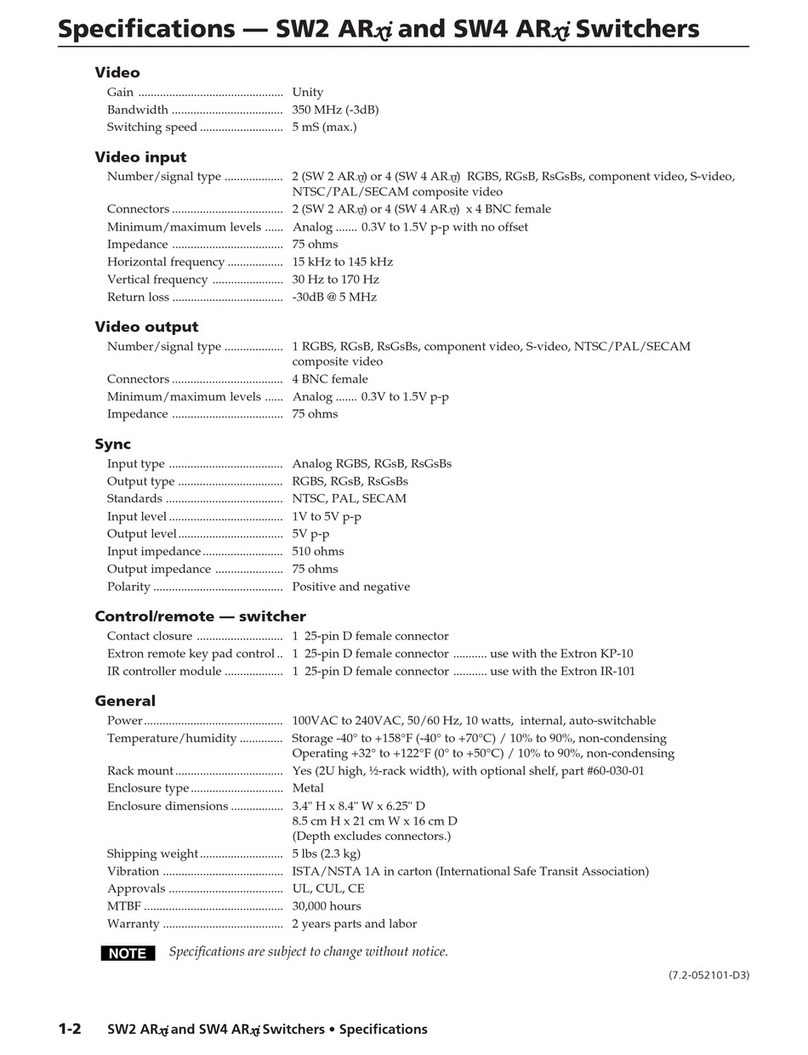

TJERNLUND

TJERNLUND PS1505 IN-LINE DRAFT INDUCER FAN PROVING SWITCH 8500135 REV 1... manual

Siemens

Siemens RUGGEDCOM RS8000 installation guide

StarTech.com

StarTech.com StarView SV221DD Instruction guide

Omega Engineering

Omega Engineering PSW2000 user guide

Belkin

Belkin F5U301 - CableFree USB Hub user manual

Arista

Arista 7060 Series quick start guide