22

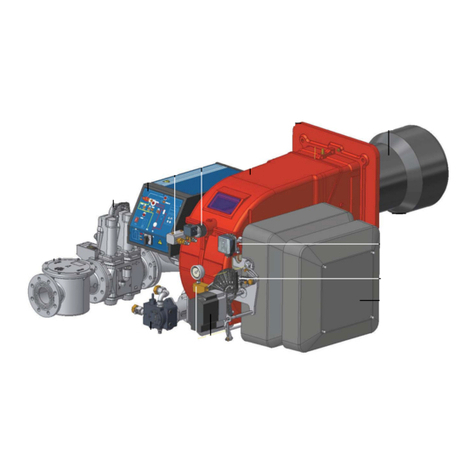

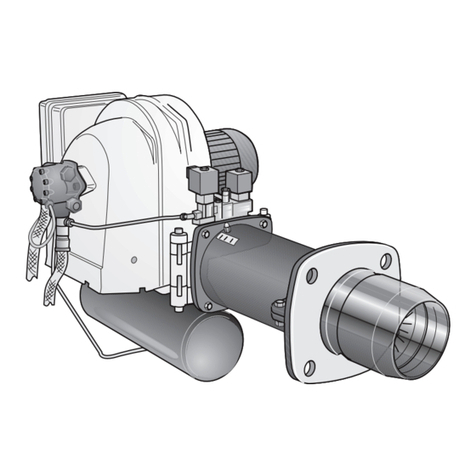

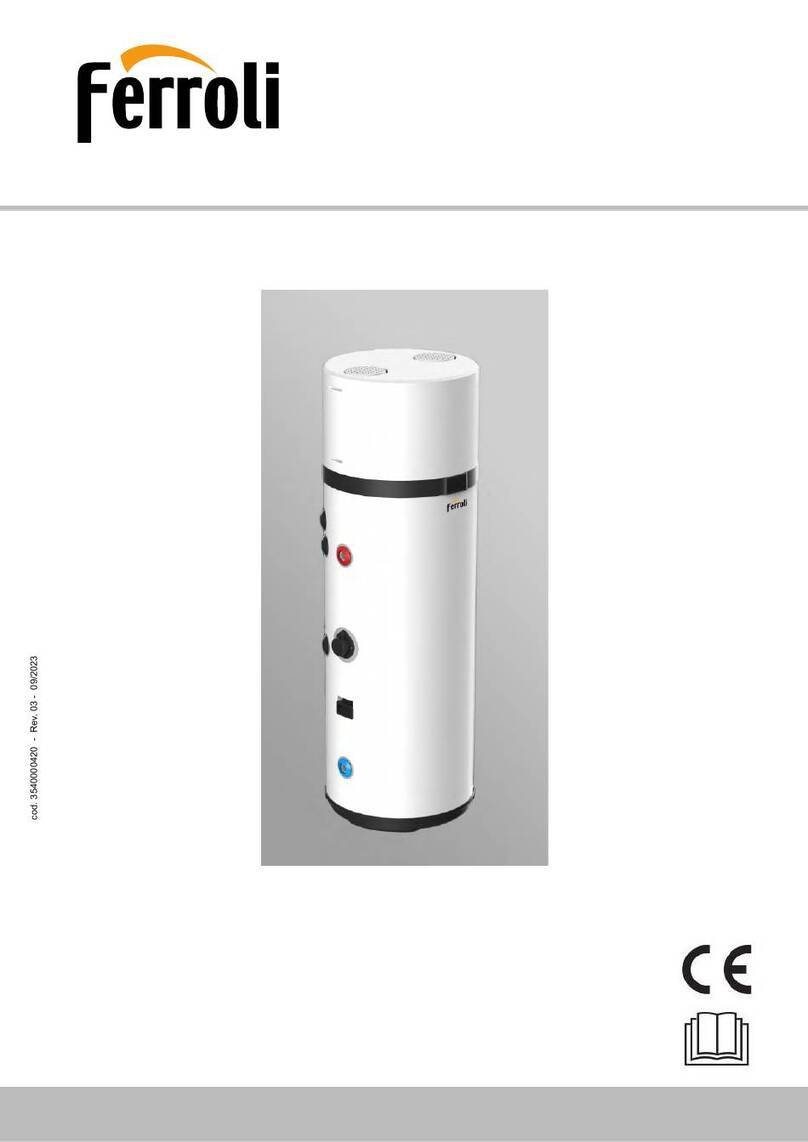

SUN G50 - G70

Italiano

English

Français

Deutsch

Español

This symbol indicates “Warning” and is placed near all warnings regarding safety. Such

provisions must be strictly adhered to so as to avoid danger and damage to people, animals

and things.

1. Operating instructions ........................................................................ 23

2. Installation........................................................................................... 24

3. Service and maintenance..................................................................... 31

4. Characteristics and technical specifications ........................................ 39

This symbol highlights a note or an important warning

• Carefully read the warnings in this

instruction booklet, as they provide

important indications on the safety of

installation,operationandmaintenance.

• The instruction booklet is an integral

and essential part of the product and

must be carefully kept by the user for

future reference.

• The installation and maintenance

operations must be performed

according to the standards in force, the

instructions of the manufacturer and

must be carried out by professionally

qualified personnel.

• Incorrect installation or poor

maintenance may cause damage to

people, animals or things. The

manufacturer declines all liability for

damage deriving from errors in the

installation and operation of the

appliance, and in any case from the

failure to observe the instructions

provided by the manufacturer.

• Before performing any cleaning or

maintenanceoperations,disconnectthe

appliance from the mains power supply

using the system switch and/or the

corresponding on-off devices.

• In the event of faults and/or poor

operation of the appliance, it should be

deactivated. Do not attempt to repair

the appliance. Contact professionally

qualified personnel only.

• After having removed the packaging,

check that the contents are intact.

• The parts of the packaging must not be

left within the reach of children, as they

are potential sources of danger.

Certification

TheCEMarkattests that Ferroli appliances conform to the requirements specified in the corresponding

European directives.

In particular, this appliance conforms to the following EEC directives:

• Directive 92/42, Efficiency, accepted into Italian law by Presidential Decree no. 660, 15.11.96

• Directive 73/23, Low Voltage, (amended by no. 93/68)

• Directive 89/336, Electromagnetic Compatibility (amended by no. 93/68) accepted into Italian law

by Presidential Decree no. 615, 15/11/96