FERPINTA Herculano H2RS User manual

// OPERATOR’S MANUAL

SPREADERS •H2RS | H2RS-RG | H4R

EN

ÍNDEX

INTRODUCTION____________________________________________

GENERAL MODEL IDENTIFICATION___________________________

EQUIPEMENT IDENTIFICATION______________________

AXLE IDENTIFICATION _____________________________

SIMBOLOGY_______________________________________________

EC” DECLARATION OF CONFORMITY _______________

SAFETY ALERTS ____________________________________

GENERAL SAFETY RULES_____________________________________

STARTING WORK___________________________________________

SAFETY____________________________________________________

WARNING LABELS POSITION ________________________________

TECHNICAL SPECIFICATION_________________________________

TRANSMISSION CARDAN ___________________________________

INITIAL COUPLING TO TRAILER_______________________________

HYDRAULIC SYSTEMS_______________________________________

HYDRAULIC SYSTEM CONNECTIONS ________________

HYDRAULIC DRAWBAR_____________________________

HYDRAULIC BRAKING SYSTEM______________________

SELF-STEERING AXLE SYSTEM _______________________

FORCED STEERING AXLE SYSTEM____________________

HYDRAULIC REAR DOOR___________________________

HYDRAULIC MOVING FLOOR_______________________

PNEUMATIC BRAKING SYSTEM_______________________________

PARKING / EMERGENCY BRAKE SYSTEM______________________

GENERAL CARE____________________________________________

4

5

5

5

6

6

6

7

9

10

11

13

15

16

17

17

17

18

21

22

25

26

27

28

29

SIGNALING ____________________________________________

CONNECTION AND LIGHTNING SCHEMES ________________

SUSPENSION ___________________________________________

OPCIONALS____________________________________________

DEVICES TO PREVENT UNAUTHORIZED USE ________________

MAINTENANCE AND SERVICE____________________________

TIMETABLE - MAINTENANCE AND SERVICE________________

MALFUNTIONS / POSSIBLE SOLUTIONS____________________

EQUIPMENTS END OF LIFE________________________________

WARRANTY CONDITIONS________________________________

HOW TO ORDER PARTS__________________________________

30

31

33

34

38

39

46

48

50

51

52

OPERATOR’S MANUAL: H2RS | H2RS –RG | H4R

4

INTRODUCTION

Dear Customer,

Congratulations on your choice, as you have just purchased equipment built with high technology and

strict quality standards.

All our efforts are put into research, innovation, development and improvement of this product, so that you

can take advantage of the quality, performance, and work in safety.

This manual was created to help you and to advise about safety, maintenance and how to use the

equipment. Thereby, you will be able to use it with confidence in order to ensure a good performance.

Please start by reading it carefully in order to become familiar with all the equipment and the most

important aspects of safety, its usage as well as other useful information.

Anyone operating, maintaining, or transporting this equipment must read and thoroughly understand the

instructions outlined in this manual before starting to work.

Please take note of all issues related to safety and instructions included in this manual, complying with them

in order to guarantee your safety and others safety.

Please keep the manual in an accessible and safe place, so that you can refer to it whenever necessary.

It is essential that this equipment is inspected periodically, that it is maintained and fitted with suitable spare

parts.

HERCULANO will provide you with any necessary support, solving problems or clarifying questions that you

may have when using the equipment.

HERCULANO –ALFAIAS AGRÍCOLAS S.A.

3720-051 Oliveira de Azeméis

PORTUGAL

OPERATOR’S MANUAL: H2RS | H2RS –RG | H4R

5

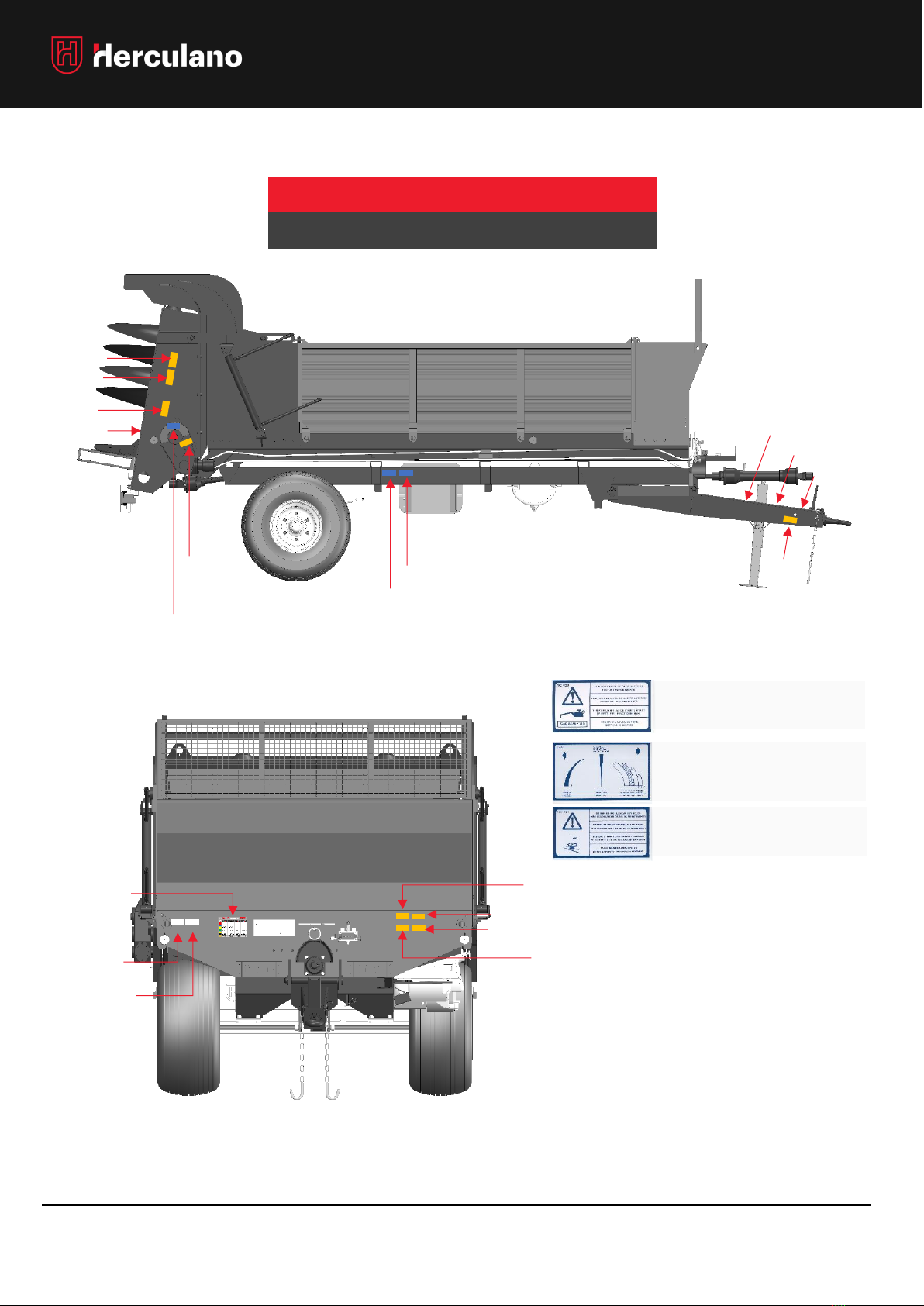

GENERAL MODEL IDENTIFICATION

•Improves safety in the event of an accident

•Minimizes the consequences of a rear-end

collisions;

•Prevents underride accidents of the rear-end of

vehicle;

300x60 AXLE

LABEL

ID1

ID2

ID3

ID4

EB/AMB

MF ou

MFG

300x60V

5886

36102919

400x80 AXLE

EB / AMB

FF

400x80V

7848

36103119

EB / AMB

FF

400x80V

6867

36106718

ADR

TG or

TC

408E

7848

36105319

406x120 AXLE

ADR

VC

412E

11282

36106111

EB/AMB

6J

406x120V

11282

36110811

406x140 AXLE

EB/AMB

WC

406X140V

414E

12263

36110512

420x180 AXLE

EB/AMB

8K

420x180V

12753

36110712

ADR

XC

4218E

10791

36106616

ADR

XC

4218E

12753

36106511

EQUIPMENT IDENTIFICATION

The plates can be metallic or stickers. They enclose

important information as they identify the type of

axle and in case it is needed a repair or

replacement of parts.

APROVED UNDERRUN BAR

- Category

- Homologation No.

- Identification No.

- Maximum load

Technically allowable

- Load on the device

- Load on the 1st axle

- Load on the 2nd axle

- Load on the 3rd axle

ID TAG PLATE

IDENTIFICATION NO.

TX7 ********* * * * * *

WMI

Code

Vehicle

Id.

Serial

manufatur

e NO.

AXLE IDENTIFICATION

The information of the serial number and type of

axle is stamped on the identification plate located

at the following place:

Example of an (ADR) axle identification sticker.

The trailer is equipped with homologated bumpers.

Axle identification plate

(or)

OPERATOR’S MANUAL: H2RS | H2RS –RG | H4R

6

SIMBOLOGY

EC DECLARATION OF CONFORMITY

This equipment complies with the requirements of the European Parliament and Council Directive,

2006/42/EC, of 17 May 2006, transposed into Portuguese law by Decree-Law No. 103/2008 of 24 June

2008.

The EC Declaration of Conformity is attached to the Trailer User Manual.

SAFETY ALERTS

DANGER!

Failure to comply with this signal may cause damage

to the equipment and cause serious injuries to people,

endangering your own life.

•

All "Danger" instructions must be followed and

respected!

WARNING!

If you do not respect this signal, you will be subject to

severe injuries and possible damage to the

equipment.

•

All "Warning" instructions must be followed

and respected!

INFORMATION

Additional useful information goes next these symbols!

•

Please read all the points with additional

information carefully since they are useful to

become familiar with your equipment.

CAUTION!

The special caution signals go next this symbol!

•

Please take the necessary precautions and

follow the recommended operating

instructions to avoid problems or accidents.

MAINTENANCE!

Iconography used for Maintenance and/ or Cleaning!

•

Carefully carry out the recommended

maintenance and cleaning procedures to extend

the equipment's service life and keeping the safety

conditions.

LUBRIFICATION!

The Lubrication and Oil Level Replacement

Instructions go next to this symbol!

•Please pay attention to the lubrication points and

periodicity, or the replacement of grease or oil

level. Failure to follow this instruction may

jeopardize the proper performance of the

equipment.

OPERATOR’S MANUAL: H2RS | H2RS –RG | H4R

7

GENERAL SAFETY RULES

•H2RS | H4R spreader’s, were developed for the

public and agricultural market. They must not be

used for any other purposes than those

mentioned, as they could jeopardize your safety

and that of third parties.

•Before carrying out any maintenance or a repair

operation on the equipment that requires tipping,

make sure that the vehicle is properly stabilized

and on flat ground. Switch off the engine and

properly put the tractor’s brake on before

proceeding with any operation that may

jeopardize your safety and others' safety.

•Serious fatal errors can occur if precautions are

not taken and safety measures are not

respected.

•Equipment must only be repaired, and damaged

components only replaced, by certified or

qualified people for this purpose.

•Always use the most suitable tools as well as

personal protective equipment during vehicle

maintenance operations and repairs.

•Make sure that all spare parts and components

are compatible with the equipment and that

they do not affect the safety of the vehicle, your

safety, or others' safety.

•It is recommended that you always use original

replacement parts / spare parts from the

manufacturer to ensure that they fit properly

and that they do not affect the vehicle’s

structural capacity or safety.

•Make sure that you carry out all inspections and

services on your equipment at specific time

ranges.

GENERAL SAFETY RULES

Changes to the Trailer:

The chassis structure, wheels, braking system, hydraulic/pneumatic system and electrical system must not be

modified or reconverted, as they are important safety elements and, if they are altered, they may jeopardize

the safety of the equipment.

OPERATOR’S MANUAL: H2RS | H2RS –RG | H4R

8

GENERAL SAFETY RULES

•Whenever carrying out coupling / decoupling of

the equipment, it is strictly forbidden to stand

between the tractor and trailer unless they are

properly immobilized with the parking brake on,

if applicable, and with wheel chocks.

•When it is necessary to couple the trailer to the

tractor, please stand in one side of the tractor

and make sure that you properly fit the safety

pins or chains.

•Always wear suitable clothes and shoes,

avoiding the use of loose or baggy clothing.

•Do not allow people to remain or ride in the

trailer.

•Always check the pressure and general

condition of the trailer's and tractor's tires prior to

each use.

•Always comply with your tractor’s towing load

limits.

•Regularly check the general condition of the

hydraulic and pneumatics hoses, if applicable.

Replace them in case they are damaged or

worn out. Replacement hoses must meet the

technical requirements specified by the

manufacturer.

•Check oil levels regularly and keep the

lubrication points properly lubricated with

grease and check if they are not dirty.

•Before starting transportation, check if the

braking system is working properly.

•When driving on public roads, comply with the

rules in force. Always check if the lightning

devices fitted to the rear, side, and front of the

vehicle, work correctly.

•Never carry out maintenance work with the

trailer tipped without first installing the safety

prop between the upper frame and the lower

frame.

•Depending on the characteristics of the

equipment and the type of product loaded,

the total weight of the vehicle under full load

may exceed the Maximum Allowable Mass

regulated in the country in which it travels. In

the case of traffic on public roads, the user must

ensure compliance with the dimensions and

masses defined in the legislation and highway

code applicable in the country. Herculano will

not be held responsible for any consequences

arising from non-compliance with legal

requirements.

OPERATOR’S MANUAL: H2RS | H2RS –RG | H4R

9

STARTING WORK

BEFORE STARTING WORK

BEFORE STARTING THE OPERATION

Before starting work, the operator must be aware

of all the equipment and its functions. Getting to

know the systems after starting to work may be too

late!

The equipment must always be tested before each

operation and before driving on public roads!

Follow the instructions and always keep in mind all

warnings and safety signs included in the manual

and on your spreader.

1. Make sure that all safety equipment is in good

working and maintenance condition.

2. Make sure to keep the joints / lubrication points

properly lubricated with grease. Check oil levels

regularly and check for any looseness in the axles or

damaged bearings.

3. Make sure that the tires are inflated to with the

proper pressure and that they are in good general

condition.

4. Check the tightness of level wheels.

5. Connect the spreader electrical plugs to the tractor

and make sure the electrical system works properly.

6. Ensure the proper functioning of the spreader with

only the accessories / equipment provided.

7. Connect all hydraulic and / or pneumatic sockets (if

applicable) to the tractor.

•Check the hydraulic hoses for wear or

leakage.

•Make sure you connect the hoses correctly.

8. Check the parking brake system as well as the

service brake.

OPERATOR’S MANUAL: H2RS | H2RS –RG | H4R

10

SAFETY

PERSONAL PROTECTIVE EQUIPMENT

It is very important that the operator wears personal

protective equipment daily to minimize the risks of

an accident.

The instructions in this manual are essential, please

always use PPE's - Personal Protective Equipment.

PLEASE WEAR –PROTECTION FOOTWEAR

PLEASE WEAR –PROTECTION GLOVES

PLEASE WEAR –PROTECTION HELMET

PLEASE WEAR –PROTECTION VEST / CLOTHING

WARNING LABELS

Warning stickers are part of the User Manual. Please

follow all procedures, keep the stickers legible and

immediately replace any lost or damaged labels.

Please always read the user manual!

7 AC 001

Danger! Articulated machine!

7 AC 004

Danger! Articulated machine!

7 AC 007

Tire pressure indicator. Inflation pressure varies

depending on the fitted wheel!

7 AC 024

Product check - OK

7 AC 047

0

Lubrication point!

7 AC 082

Danger of dragging!

Power take-off transmission shaft connected to a machine.

7 AC 008

Turn off the tractor!

7 AC 002

Danger of arm dragging!

7 AC 010

Do not climb onto the loading platform if the PTO is connected to the

tractor and the engine is running.

7 AC 014

Power take-off

(When applicablel)

7 AC 022

Power take-off

(When applicablel)

7 AC 104

Indication off wheel and torque tightening!

7 AC 111

Manual valve of the braking system

Min / MED / MAX

(When applicable)

7 AC 124

Warning to adjust the manual valve of the

hydraulic braking system, accordingly to the load

transportation..(WhenApplicablel)

7 AC 124.1

Matching timetable of the hydraulic

function by colour.

7 AC 116

Warning to check the stopcocks on the

steering axles!

(when applicable)

7 AC 118

Warning to check the stopcocks on the steering

axles.

(when applicable)

7 AC 118.1

OPERATOR’S MANUAL: H2RS | H2RS –RG | H4R

11

SAFETY

Warning!

Compatibility of new tires and pressure

regulation.

(When applicable)

7 AC 126.2

Warning to read the instruction Manual and ensure

the AMB/ADR assembly dimension = 250mm

(When applicable)

7 AC 132

Elevation points –Wheel change

7 AC 134.1

7 AC 134.2

Warning to adjust the electric valve of the

braking system, according to the load

transportation needs (When applicable)

7 AC 135

Warning!

Lubrication and Oil Change Periodicity

WARNING LABELS POSITION

7 AC 010

7 AC 014

7 AC 022 or

7 AC 104

7 AC 007

7 AC 008

7 AC 004

7 AC 137.1

7 AC 137.2

7 AC 126.2

7 AC 111

7 AC 124

7 AC 124.1 or 7 AC 135

7 AC 132

7 AC 024

7 AC 118

7 AC 118.1

7 AC 001

7 AC 002

7 AC 124

7 AC 116

LUBRICATION

SYSTEM

7 AC 047

7 AC 082

Matching timetable of the hydraulic function

by colour.

(When applicable)

7 AC 128

H2RS | H2RS-RG (EXCEPT H2RS 6)

OPERATOR’S MANUAL: H2RS | H2RS –RG | H4R

12

SAFETY

WARNING LABELS POSITION

7 AC 004

7 AC 008

7 AC 022

7 AC 010

7 AC 014

7 AC 007

H2RS 6 | H4R

7 AC 082

7 AC 111

7 AC 082

7 AC 024

7 AC 026**

7 AC 023***

SISTEMA DE

LUBRIFICAÇÃO

7 AC 047

7 AC 128

7 AC 001

7 AC 002

7 AC 124*

7 AC 124.1*

*It varies according to the country of use.

** Only for mechanical moving floor.

*** Only for hydraulic moving floor.

Check the oil level before setting in

motion.

7 AC 023

Instruction for reversing lever.

7 AC 026

Rools immobilization syetem.

7 AC 027

7 AC 027**

OPERATOR’S MANUAL: H2RS | H2RS –RG | H4R

13

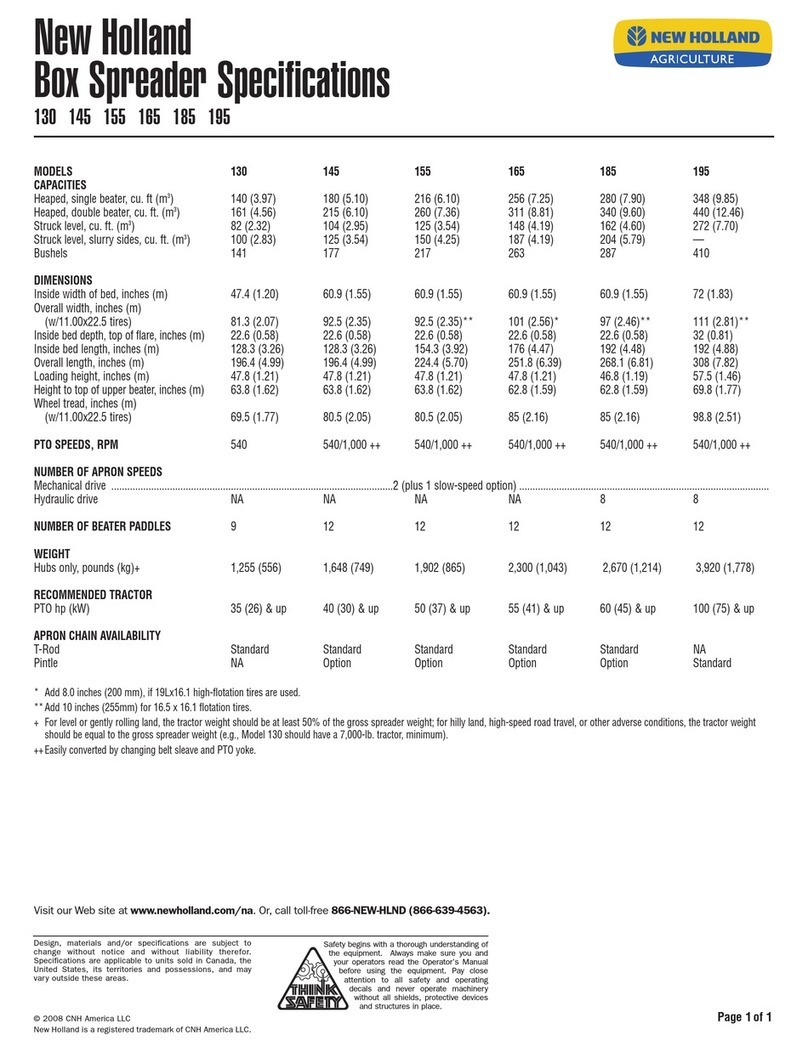

TECHNICAL SPECIFICATIONS

SPREADERS: H2RS

H2RS6

H2RS9

H2RS11 RG

H2RS12

H2RS14

H2RS18

H2RS18 RG

INDICATIVE EMPTY

WEIGHT (t)

2,8

3,8

4,4

4,93

5,27

6,61

8,16

CAPACITY(m3)

5,2

8,7

10,4

11,5

13,1

17,8

17,8

INTERIOR (mm)

3650x1930x700

4650x1800x1000

5550x1440x1320

4700x2150x1220

4700x2150x1420

5700x2360x1420

5700x2150x1420

TOTAL LEGHT (mm)

6500

7580

8200

7210

7210

8320

8530

TOTAL WIDTH (mm)

2300

2480

3000

2500

2500

2540

2500

TOTAL HEIGHT (mm)

1180

1290

1380

1380

1530

1580

1700

SUSPENSION TYPE

-

-

-

BOGGIE

BOGGIE

BOGGIE

BOGGIE

AXLE TYPE

(Series EQ.)

Fixo

Fixo

Fixo

2 FIXED AXLE

2 FIXED AXLE

2 FIXED AXLE

2 FIXED AXLE

AXLE SQUARE (mm)

80

100

110

100

100

100

150

NO. STUDS

6

10

10

8

8

10

10

HUBS

300 x 60

406 x 120

406 x 140

400 x 80

400 x 80

406 x 120

406 x 120

AXLE TRACK (mm)

1600

1750

2150

1750

1750

2000

1900

P.T.O. (R.P.M)

540

540

540

540

540

1000

1000

DIAMETER - BEATERS

(mm)

990

800

755

755

755

755

755

CARDAN

(Series EQ.)

Semi-

Homokinetic

Homokinetic

Homokinetic

Homokinetic

Homokinetic

Homokinetic

Homokinetic

H2RS | H4R MAIN FEATURES

STEEL MONOCOQUE BODY

(H2RS9 OR ABOVE)

2 SPREADING BEATERS

(H2RS)

4 SPREADING BEATERS

(H4R)

REMOVABLE GROUP OF BEATERS

(SÉRIE H2RS9 OR ABOVE)

FIXED / FORCED STEERRING / SELF-STEERING AXLES

HYDRAULIC / PNEUMATIC BRAKING

LED LIGHTNING

(H2RS9 OR ABOVE | H4R, NOT APPLICABLE)

POWER TAKE OFF (PTO)

•The presented values refer to “STANDARD” models;

•Dimensions vary depending on the type of tires that the trailer is fitted with, taking into account their dimensions.

OPERATOR’S MANUAL: H2RS | H2RS –RG | H4R

14

TECHNICAL SPECIFICATIONS

SPREADERS: H4R

H4R4

H4R5

H4R6

INDICATIVE EMPTY WEIGHT

(t)

1.6

1.9

2.4

CAPACITY(m3)

4.2

5.2

6.0

INTERIOR (mm)

3180x1500x700

3420x1700x700

3680x1900x700

TOTAL LEGHT (mm)

5250

5500

5780

TOTAL WIDTH (mm)

1850

2050

2300

TOTAL HEIGHT (mm)

2370

2370

2300

SUSPENSION TYPE

-

-

-

AXLE TYPE

(Series EQ.)

Fixo

Fixo

Fixo

AXLE SQUARE (mm)

70

80

80

NO. STUDS

6

6

6

HUBS

300 x 60

300 x 60

300 x 60

AXLE TRACK (mm)

1400

1500

1600

P.T.O. (R.P.M)

540

540

540

DIAMETER - BEATERS (mm)

390

390

390

CARDAN

(Series EQ.)

Semi-Homokinetic

Semi-Homokinetic

Semi-Homokinetic

•The presented values refer to “STANDARD” models;

•Dimensions vary depending on the type of tires that the trailer is fitted with, taking into account their

dimensions.

•

OPERATOR’S MANUAL: H2RS | H2RS –RG | H4R

15

TRANSMISSION CARDAN

HOMOKINETIC

GENERAL AND SAFETY RULES

NOTE: Carefully read the Transmission

Cardan Instruction Manual!

The following recommendations do not in any way replace those

existing in the Cardan Manual. Consult it and respect all

instructions and safety recommendations contained therein.

SEMI-HOMOKINETIC

Homokinetic joint

Simple joint

If your cardan is SEMI-HOMOKINETIC (with only one homokinetic

joint on the tractor side), its shaft must be as close as possible to

the tractor's coupling shaft.

If your cardan is HOMOKINETIC (with two homokinetic joints), the

tractor hitch shaft must be (as much as possible) in the middle of

the space between the two joints.

•In the transmission simple joint (tank side), it is

recommended to work with angles that do not

exceed 16º at 540r.p.m. and the 9th to 1000r.p.m.

(See cardan manual).

•The homokinetic joint allows a maximum working

and rest angle of 70º.

•Always respect the cardan safety regulations and

existing warning labels. Keep them in good condition

or replace them if necessary.

Danger of dragging!

Power take-off transmission shaft connected to a machine!

7 AC 008

•Never remove the cardan's plastic protections!

•Attach safety chains at suitable points on the tractor and in

the tank!

•ATENTION! Before starting work, make sure that there are

no loose safety guards and parts or tools on the cardan

axle!

•Never step on or climb onto the

cardan at any time!

•Never use the cardan with damaged

safety guards

•Before starting work, check the length of the

Transmission cardan in the transport position and in the

working position. Make sure that the cardan assembly

respects its safety parameters. (See cardanl manual)

•If the cardan is excessively long or short, it can cause

damage, both in the tractor and in the cistern. This type

of damage is not covered under the warranty.

Serious fatal errors can occur if the proper precautions

are not taken and if the safety measures are not

respected.

OPERATOR’S MANUAL: H2RS | H2RS –RG | H4R

16

TRAILER COUPLING TO THE TRACTOR

ACOPLAMENTO INICIAL AO TRATOR

When you need to couple / uncouple the trailer to

the tractor, no one should be present in the area

between the two vehicles! This is considered a

danger zone!

NOTE: Before starting the coupling, make sure that the

trailer is on a level ground and that the parking brake

is properly on. If you have chocks, always make sure

that the trailer wheels are chocked before starting

the following procedures.

TRAILER COUPLING TO TRATOR

1º Align and move the tractor’s coupler towards the

coupler's device of the trailer’s drawbar.

2º Connect the drawbar’s safety chains to the

tractor;

3º Connect all trailer's hydraulic and pneumatic

hoses (if applicable) to the tractor's hydraulic

sockets;

Note: The tractor must be off;

4º Connect the plugs of the trailer electrical systems

to the tractor’s socket;

5º Operate the drawbar’s rest hydraulic cylinder in

order to level the coupling device with the

tractor’s coupler;

6º

! WARNING !

6º Slowly move the tractor in reverse until it aligns

the tractor's coupler with the coupler's device

of the trailer’s drawbar. When they are properly

aligned, proceed to the coupling.

7º Make sure you have completed the previous

step correctly and retract the hydraulic cylinder

from the drawbar to the operating position;

8º Remove the chocks from the wheels (if fitted)

and proceed to work safely by releasing the

hand brake / parking brake.

PEOPLE IN THE DANGER ZONE BETWEEN THE

TRACTOR AND THE TRAILER MAY BE CRUSHED OR

RUN OVER!

KEPP OUT ALL PEOPLE FROM THE DANGER ZONE WHEN TO

COUPLING / UNCOUPLING THE TRAILER;

NO ONE IS AUTHORIZED TO RAMAIN ALONGSIDE THE

TRAILER AXELS / TRATOR WHEN THEY ARE BEING COUPLED;

THE OPERATOR MUST ALLWAYAS KEEP WELL AWAY FROM

FRO THE VEHICLE WEELS.

OPERATOR’S MANUAL: H2RS | H2RS –RG | H4R

17

HYDRAULIC SYSTEMS

CONNECTION OF HYDRAULIC SYSTEMS

NOTE: For safety reasons, never connect or

disconnect the hydraulic systems while the box is

tipped! When connecting or disconnecting the

hydraulic systems, make sure that the edges of the

quick-connect valves are not dirty!

The connections of the tractor’s hydraulic functions

must not exceed 180 bar. Pressures above this value

may damage the systems.

HYDRAULIC SYSTEMS

•DRAWBAR REST

•HYDRAULIC BRAKING SYSTEM - (OPTIONAL)

•SELF STEERING AXLE - (OPTIONAL)

•FORCED STEERING AXLE - (OPTIONAL)

•HYDRAULIC REAR - (OPTIONAL)

•ESTEIRA HIDRÁULICA

1st. Move the tractor closer and lower the tractor’s

linkage in order to have access to the hydraulic

sockets area;

2nd. Turn off the tractor engine;

3rd. With the trailer properly immobilized and with

chocks on the wheels, connect the hydraulic

hoses of all systems to the corresponding

hydraulic sockets on the tractor. Follow all

Hydraulic Systems connection procedures on the

following pages;

4th.Connect the electrical plug of the Lightning

System and the function control to the tractor,

5th.Switch on the tractor's engine and reposition the

linkage in an elevated position to prevent collision

with the drawbar during transport.

6th.Test systems one by one and safely. If all work

properly, you can start work.

DRAWBAR REST

T

P

1. Properly put the tractor’s brake on and then

switch it off;

2. Close the safety tap on one of the hydraulic

hoses on the drawbar;

3. Connect the two appropriate hoses to the

tractor;

If you experience difficulties connecting the hose

that contains the stopcock, first make sure that it

is closed and try to activate the quick attachment

valve, in order to depressurize the short link

present between the two elements. In doing so, it

should be easy to make the coupling.

4. After connecting the hoses to the tractor, open

the safety stopcock.

5. Before reconnecting the tractor, make sure to

complete the connection of all the other systems.

NOTE: Never disconnect the hoses from the tractor without

first closing the safety stopcock.

NOTE: The Forced Steering axle system works independently,

requiring no hydraulic connection to the tractor.

OPERATOR’S MANUAL: H2RS | H2RS –RG | H4R

18

HYDRAULIC SYSTEMS

The discharge line of this valve must be connected to a tractor

line connected to the oil tank of the trailer's braking system. This

line can be the floating line, if it exists and if it matches the

requirement mentioned above. When in doubt, check the

tractor's manual or ask the manufacturer for support.

NOTE: A poor connection can damage the tractor!

HYDRAULIC BRAKING SYSTEM

WITH 3-POSITION VALVE (WHEN APPLICABLE)

This hydraulic braking system is equipped with a 3-

position valve that allows the intensity of the braking

forces to be adjusted according to the load it carries

Therefore, before driving with the trailer empty, half

full or completely full, you can adjust the valve to the

corresponding position in order to adjust the braking

forces to the load you are carrying.

The connection of this system is guaranteed using two

hydraulic hoses that must be connected to the brake

valve and a line with connection to the oil tank of the

tractor's braking system.

Make sure that you connect this system correctly

each time you proceed to the trailer's coupling.

Always respect speed limits to not jeopardize your

safety and the safety of others.

1º Carefully bring the tractor to the tow boom in

order to engage, lock the tractor an turn of the

engine;

2º Connect the hydraulic hoses of the braking

systems ti the respective lines of the tractor;

When connecting, make sure that the quick

connection valves are free from dirt.

3º Start the tractor engine and teste the braking

system and check if the system works correctly.

NOTE: The braking system must be connected to the tractor on

the appropriate lines and it must not exceed 115 bar.

NOTE: Do not drive on

public roads if the

braking system is not

working properly or if

you detect any

anomaly that could

jeopardize the safety

of the vehicle or

people's safety!

BRAKING VALVE –3 POSITIONS

MIN = EMPTY

MÉD = ½ LOAD

MAX. = FULL (MAX PRESURE = 115 bar)

! WARNING!

!

CONNECT THE HYDRAULIC

HOSES TO THE TRACTOR

ADJUST BRAKINGPRESSURE

ON THE 3-POSITION VALVE!

MIN. / MED. / MAX

BRAKE’S

HYDRAULIC

CYLINDER

OPERATOR’S MANUAL: H2RS | H2RS –RG | H4R

19

HYDRAULIC SYSTEMS

HYDRAULIC BRAKING SYSTEM

(WHEN APPLICABLE)

The simple hydraulic braking system is installed, which

must be connected to the tractor, through the hose

that contains the ½ female quick valve, as shown in

the following diagram:

If you notice overheating in the brake drums, or if you

feel that braking is insufficient, you may need to adjust

the brake, especially after the first few runs.

For that, and only if your equipment is equipped with

adjustable handles, proceed to tighten / loosen the

adjustment screw in them (BIELLETTES) in order to

obtain the necessary looseness between the jaws and

the drum.

ADJUSTING

SCREW

CLOCKWISE

=

INCREASE TENSION

ANTICLOCKWISE

=

DECREASE TENSION

Long use of the equipment is likely to cause

considerable wear on the pads. In this

case, check if it is necessary to replace

them or if the tightening of the adjustment

screw on the handles is sufficient to

guarantee the braking effect. Check

"Brake / Jaw Adjustment".

do Travão/Maxilas” no capítulo

Manutenção.

BIELLETTE

CONNECT THE HYDRAULIC

HOSES TO THE TRACTOR

BRAKE’S

HYDRAULIC

CYLINDER

OPERATOR’S MANUAL: H2RS | H2RS –RG | H4R

20

HYDRAULIC SYSTEMS

HYDRAULIC BRAKING SYSTEM

3 POSITION CONTROL + ELECTRICALLY CONTROL VALVES

(WHEN APPLICABLE)

This system was specifically developed to assist the

user to easily adjust the braking pressure and without

leaving the tractor, according to the load it transports

on the trailer, from an electric control placed on the

tractor.

This way, with the help of the control, the driver can

change the braking pressures to:

0= EMPTY (35bar)

½= HALF LOAD (75bar)

1= FULL (115bar)

(MAX PRESSURE = 115 BAR)

VALVE BLOCK

(example)

NOTE: The valves and

control setting may

change depending on

supplier or product

changes.

TRAILER HYDRAULIC BRAKING

LINE

HYDRAULIC BRAKE LINE FROM

THE TRACTOR TO THE TRAILER

CONNECTION TO THE TRACTOR

12V-DC

0= EMPTY

½= HALF LOAD

1= FULL

(MAX PRESSURE = 115 BAR)

This manual suits for next models

2

Table of contents