FERREX CSP50 User manual

Contents

PETROL CHAINSAW CSP50

User Manual

AFTER SALES SUPPORT 708115

1300 855 831

MODEL:

CSP50

3

YEAR

WARRANTY

AU

Made in China

FERREX®is a registered trademark of ALDI Stores

DISTRIBUTED BY:

ALDI STORES

1 SARGENTS ROAD

MINCHINBURY NSW 2770

www.aldi.com.au

AU

ALDI guarantees that our exclusive brand products are developed to our

stringent quality specifications. If you are not entirely satisfied with this

product, please return it to the nearest ALDI store within 60 days from the

date of purchase, for a full refund or replacement, or take advantage of our

after sales support by calling the supplier’s Customer Service Hotline.

04/2022

Explanation of the symbols on the device 08

Introduction 11

Device description 12

Scope of delivery 13

Proper use 13

Safety information 14

Technical data 20

Before commissioning 21

Commissioning 24

Basic working instructions for felling work 28

Working on tensioned wood 30

Transport 31

Cleaning and maintenance 31

Storage 36

Troubleshooting 37

Warranty Details 39

Repair and Refurbished Goods or Parts Notice 41

Package contents/part list

1 x Chainsaw

1 x Saw chain

1 x Guide bar

5 64

4

CD

E F

I

G

16

A23 4

9

10

11

12

131415

161718

202122

1 5 6 7

8

19

23242526

27

16

28

17

29

30

31

B

1

H

abc

J

K L

1 x Spark plug wrench / slotted screwdriver

1 x Mixing container

1 x Cover for the guide bar (chain guard)

1 x Round saw chain file

1 x Operating manual

1 x Screwdriver

1 x Warranty card

NM O

32

5

33

3

8

Symbole

Warning! When working with the chainsaw particular

safety measures are required. Read and observe all

warning information!

Warning! Risk of kickback. Protect yourself from

kickback from the chainsaw and avoid all contact

with the bar tip.

Do not use the chainsaw one-handed.

Always use the chainsaw with both hands.

Wear a safety helmet with face protection or safety

goggles and hearing protection.

Read through the whole operating manual carefully

before rst use and keep this safely for future

reference.

Wear protective gloves.

1. Explanation of the symbols on the device

Explanation of the symbols on the device

Bedienung

9

Explanation of the symbols on the device

Wear non-slip safety shoes!

Wear close-tting protective clothing with a cut

protection insert.

Fuel ller cap.

Never work without chain lubrication! Always check

chain lubrication before starting work.

CHOKE

Choke knob

10x

Press the fuel pump primer 10x

Adjustments for carburettor:

( L ) Low Speed

( H ) High Speed

( T ) Idle Speed

Chain brake (open/closed)

10

Symbole

Running direction of the chain

Guaranteed sound power level of the device

Warning - Hot surfaces!

On-/O Switch - “ON“

On-/O Switch - “STOP“

Weight

Fuel mixing ratio

Avoid contact with the bar tip.

Naked ames or smoking near the device is strictly

prohibited!

Explanation of the symbols on the device

11

Introduction

2. Introduction

Congratulations on choosing to buy a FERREX® product.

All products brought to you by FERREX® are manufactured to the highest standards of per-

formance and safety, and as part of our philosophy of customer service and satisfaction, are

backed by our comprehensive 3 Year Warranty.

We hope you will enjoy using your purchase for many years to come.

Note:

According to the applicable product liability law the manufacturer of this device is not liable

for damages which arise on or in connection with this device in case of:

• improper handling,

• non-compliance with the instructions for use,

• repairs by third party, non-authorised skilled workers,

• installation and replacement of non-original spare parts,

• improper use.

Recommendations:

Read the entire text of the operating instructions prior to the assembly and operation of the

device.

These operating instructions are intended to make it easier for you to get familiar with your

device and utilise its intended possibilities of use.

The operating instructions contain important notes on how to work safely, proper-

ly and economically with your machine and how to avoid dangers, save repair costs,

reduce downtime, and increase the reliability and working life of the machine.

In addition to the safety regulations contained herein, you must in any case comply

with the applicable regulations of your country with respect to the operation of the

machine.

Keep the operating instructions in a clear plastic folder to protect them from dirt and humi-

dity; store them near the machine.The instructions should be read and carefully understood

by each operator prior to using the machine. Only persons who have been trained in the use

of the machine and are aware of the related dangers and risks should be allowed to use the

machine. The local required minimum age must be met.

In addition to the safety notes contained in these operating instructions and any specic

regulations in your country, the generally recognised technical rules for the operation of

identically constructed machines must be observed.

12

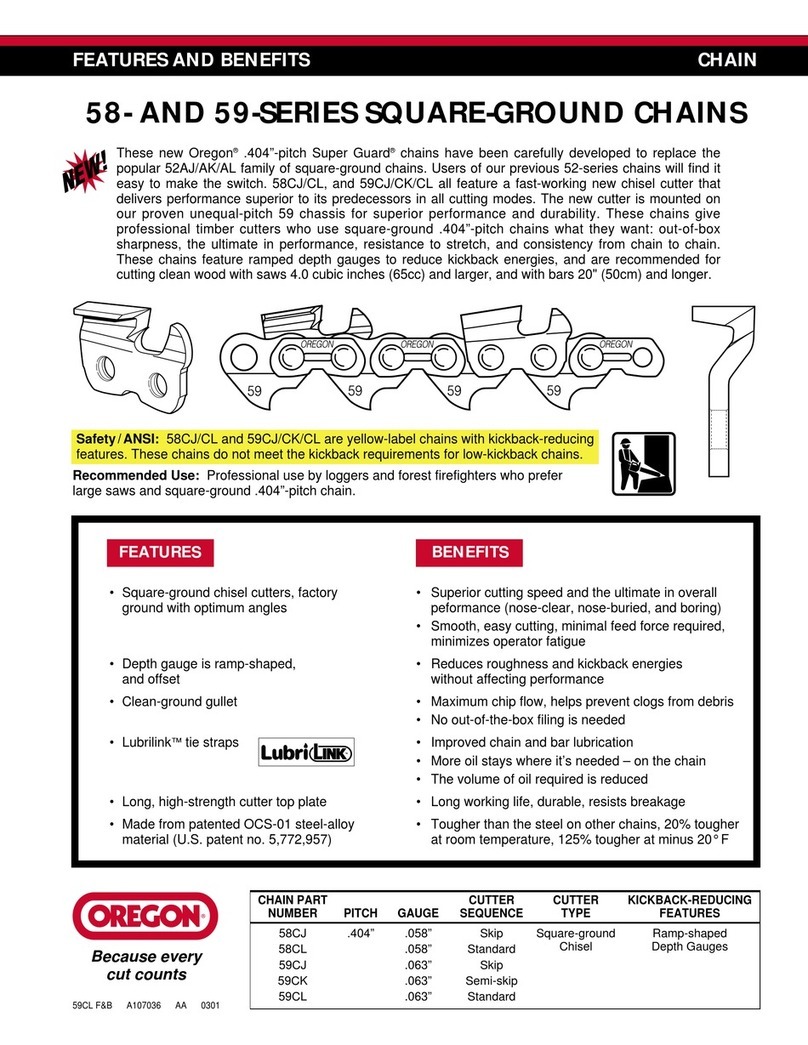

3. Device description (Fig. A , N, O)

1. Front hand guard

2. Front handle

3. Air lter cover

4. Start pull cord

5. Lock for the air lter cover

6. On/o switch

7. Fuel pump primer

8. Cold start lever (choke)

9. Throttle interlock

10. Throttle

11. Rear handle

12. Rear hand guard

13. Fuel tank cap

14. Chain oil tank cap

15. Claw stop (pre-assembled)

16. Guide bar

17. Saw chain

18. Bench grinder aid

19. Oil adjustment screw

20. Fixing nuts

21. Chain tensioning screw

22. Chain cover

23. Chain tensioning pin

24. Chain catcher

25. Hole for the chain tensioning pin

26. Chain wheel

27. Guide bar cover

28. Spark plug wrench / slotted screwdriver

29. Round saw chain le

30. Screwdriver

31. Mixing container

32. Air lter

33. Spark plug connector

Device description

13

Scope of delivery/Proper use

4. Scope of delivery

• 1 Chainsaw

• 1 Guide bar

• 1 Saw chain

• 1 Spark plug wrench / slotted screwdriver

• 1 Cover for the guide bar (chain guard)

• 1 Mixing container

• 1 Round saw chain le

• 1 Screwdriver

• 1 Operating manual

• 1 Warranty card

5. Proper use

The chainsaw may only be used for cutting wood outdoors. The chainsaw must not be used

for any other purpose.

Do not make any modications to the chainsaw. Safety may be compromised as a result.

The user/operator, not the manufacturer, is responsible for damages or injuries of any type

resulting from this. Please note that this device was not designed for commercial use.

We assume no guarantee if the equipment is used in commercial or industrial applications,

or for equivalent work.

First-time users must be instructed to familiarise themselves with the features of the device.

Attend a state chainsaw training course for your safety.

Please observe that our equipment was not designed with the intention of use for commer-

cial or industrial purposes. We assume no guarantee if the equipment is used in commercial

or industrial applications, or for equivalent work.

5.1 Non-approved operators:

People who are not familiar with this operating manual, children under the age of 16 and

people under the inuence of alcohol, drugs or medication are not permitted to operate the

device.

National regulations may restrict the use of the device!

14

6. Safety information

IMPORTANT!

READ CAREFULLY BEFORE USE AND STORE SAFELY FOR FUTURE REFERENCE.

mDANGER

For an imminent danger that will lead to severe personal injury or death.

m WARNING

For a potentially dangerous situation that can lead to severe personal injury or death.

mCAUTION

Information on a potentially dangerous situation that can lead to minor injuries.

m ATTENTION

Information on a potentially dangerous situation that can lead to property damage.

6.1 General safety instructions

m WARNING

Always remain attentive, pay attention to what you are doing and be sensible when working

with the device. Do not use the device while ill or tired or under the inuence of drugs, al-

cohol or medication. A moment of carelessness when using the device can result in serious

injuries.

Avoid misuse, use the machine only as described under“Intended use”.

■Before start-up, read the operating manual for your device and pay particular attention to

the safety instructions.

■Warning and information labels attached to the device provide important information for

safe operation.

■In addition to the information in the operating manual, the general safety and accident

prevention regulations of the legislature must be observed.

■Keep packaging material away from children, there is a risk of suocation!

■Inadequately informed operators can endanger themselves and others through improper

use. The operator is responsible for the safety of third parties.

■Be very attentive when handling the device. Go about your work sensibly and pay close

attention to what you are doing.

■Do not work for more than 10 minutes at a time. It is advisable to take a break of 10 - 20

minutes between operations.

Safety information

15

Safety information

■Only lend the device to users who have experience with the device.The operating manual

must be handed over at the same time.

■Some cutting tasks require special training and skills. If you have any doubts, consult a

specialist.

■First-time users must be instructed to familiarise themselves with the features of the de-

vice. Attend a state chainsaw training course for your safety.

■When not in use, the device must be set down in such a way that no one is endangered.

Secure from unauthorised access.

■The user of the device is responsible for all accidents and hazards that cause damage to

other people or their property.

■Children, young people and persons with reduced physical, sensory or mental abilities

must not use the chainsaw. Exceptions exist only for young people over 16 years of age in

the context of training under the supervision of a professional.

■The electric ignition system of the device generates a low electromagnetic eld. If you

wear a pacemaker or similar implant, consult your doctor before using the device to avoid

health risks.

■Please note that improper maintenance, the use of non-compliant spare parts, or the re-

moval or modication of safety devices can result in damage to the device and serious

injury to the person working with it.

6.2 Personal Protective Equipment (PPE)

mDANGER

Always wear personal protective equipment (PPE)!

-Wear a safety helmet with face protection or safety goggles and hearing protection.

-Wear close-tting protective clothing with a cut protection insert.

-Wear non-slip safety shoes.

-Wear protective gloves.

■Avoid loose clothing that can get caught.

■Do not wear a scarf, tie or jewellery!

■If you have long hair, use a hair net!

■Wear a safety helmet for all work in the forest.This provides protection from falling branch-

es. Check the safety helmet regularly for damage. This must be replaced after 5 years at

the latest. Only use approved safety helmets.

■The face guard or safety goggles protect against shavings and wood splinters. To prevent

injuries to the eyes, you must always wear a face guard or safety goggles when working

with the device.

■Always wear hearing protection.The noise emitted by the device may cause hearing dam-

age.

■Wear robust protective gloves made of tough material, such as leather.

■Wear a dust protection mask when sawing dry wood. Sawdust may form.

16

6.3 Storage and transport

■Switch o the chainsaw before any transport, even over short distances. Engage the chain

brake and t the chain guard.

■Use the chain guard during transport and storage.

■Secure the machine against tipping over during transport (including in vehicles) to pre-

vent fuel loss, damage or injury.

■Carry the device only by the front handle. In doing so, the guide bar points backwards,

away from your body (see g. L).

■Keep the hot silencer away from your body.There is a risk of burns!

■Clean and maintain the chainsaw before storage.

■Store the device in a safe and dry location. Also secure it from unauthorised access.

6.4 Environmental safety

■National and/or municipal regulations may impose time restrictions on the use of

noise-generating, motorized devices. Ask your local administration about this.

■The device must not be operated indoors or in other poorly ventilated areas. There is a

danger of suocation due to the toxic exhaust gases / lubricating oil vapours.

■Only carry out work in daylight.

■Also, do not work in adverse weather conditions, such as rain or wind.There is an increased

risk of accidents here.

■Keep your work area clean and tidy.

■Keep children, other people and animals away before and during work. If distracted, you

can lose control of the device.

■Before starting work, make sure that there are no persons, animals or property in the dan-

ger zone.

■Do not work near wire fences or in areas with loose old wire.

■Have re extinguishers ready when working in highly ammable environments such as

dry grass, etc. There is a risk of re!

6.5 Filling with fuel

■Petrol is very easily ammable. Keep away from naked ames when refuelling and do not

smoke while doing so.There is a risk of re!

■Be careful not to spill petrol. Ensure that no petrol or chain oil gets into the soil. Use suita-

ble sheeting or similar to help with this.

■Refuel only in well-ventilated areas. Petrol vapours can easily ignite or explode.

■Switch o the engine before refuelling and allow the device to cool down. If petrol has

been spilled, clean the aected areas immediately. Also, do not let any fuel get on your

clothes, otherwise change immediately.

■Also avoid skin and eye contact with petrol or lubricants (oil).

■Do not breathe in fuel vapours/lubricating oil vapours.

■Watch out for leaks. If petrol is leaking, do not start the engine. There is a danger from

burns.

Safety information

17

Safety information

■Carefully open the tank cap so that any overpressure can slowly escape and no petrol

sprays out.

6.6 Before start-up

m WARNING

Always carry out checks before use and with the engine switched o.

Check the device before each use and after it has fallen to the ground to ensure that it is in

safe operating condition.

Check that all moving parts are working properly. Many accidents are caused by poorly

maintained tools. Have damaged parts repaired by qualied specialist personnel.

Only use the chainsaw and accessories in accordance with these instructions. taking into

account the working conditions and the work to be performed. Using power tools for oper-

ations other than those intended can lead to hazardous situations.

■Regularly check the chain brake for proper functioning (front hand guard, see g. D).

■Check the guide bar to make sure it is mounted correctly.

■Check that the saw chain is properly tensioned. Follow the instructions for lubrication,

chain tensioning and replacing accessories. An improperly tensioned or lubricated chain

can break or increase the risk of kick-back.

■Keep cutting tools sharp and clean. Sharpen regularly and replace worn parts in good

time. Properly maintained cutting tools with sharp cutting edges are less likely to bind

and are easier to control.

■Check that the throttle and the throttle interlock move easily. The throttle lever must

spring back to the starting position.

■Check that there is enough fuel and chain lubricating oil in the tank.

■Check that the handles are clean, dry and free from oil and dirt.

■Never carry out the work alone. In an emergency, someone must be nearby.

■Only use the chainsaw when standing on rm, safe and level ground. Do not overreach.

Slippery ground or unstable standing surfaces (e.g. on a ladder) can cause loss of balance

or loss of control of the chainsaw. Keep proper footing and balance at all times. This will

allow you to better control the chainsaw in unexpected situations.

■Do not work with the chainsaw in a tree. There is a risk of injury when operating in a tree.

■Never saw above shoulder height.

■Always hold the chainsaw with your right hand on the rear handle and your left hand on

the front handle (see g. D). Holding the chainsaw using the opposite grip increases the

risk of injuries and must be avoided.

■Keep all body parts away from the saw chain when the chainsaw is running. Before start-

ing the chainsaw, ensure that the saw chain is not touching anything.When working with

a chainsaw, a moment of carelessness can result in clothing or body parts being caught

by the saw chain.

18

■Switch o the chainsaw immediately if you notice any noticeable changes in the device’s

behaviour.

■If the chainsaw has come into contact with stones, nails or other hard objects, stop the

engine immediately and check the saw chain and guide bar for damage.

■Do not drop the chainsaw, do not hit it against obstacles and never use the guide bar as

a lever.

■Only saw in wood with the chainsaw.

■When cutting a branch that is under tension, expect it to spring back. If the tension in

the wood bres is released, the tensioned branch can hit the operator and/or wrest the

chainsaw from control.

■Be especially careful when cutting undergrowth and young trees. The thin material can

get caught in the saw chain and hit you or throw you o balance.

6.7 Vibrations

m WARNING

Avoid the risks associated with vibration, e.g. the risk of white nger syndrome (circulatory

disorders) by taking frequent breaks from work where you rub your palms together, for ex-

ample.

■Always wear protective gloves and make sure your hands are warm.

■Make sure that the chain is always sharp.

■Take regular breaks from work.

6.8 Precautionary measures against kick-back

m WARNING

Watch out for kick-back when working with the device. There is a danger of injury. Avoid

kick-backs through caution and correct sawing technique.

■Touching with the tip of the guide bar can sometimes lead to an unexpected backward

reaction, whereby the guide bar whips up and in the direction of the operator.

■Kickback can arise if the tip of the guide bar touches an object or if the wood bends and

the saw chain jams in the cut.

■If the saw chain jams on the top edge of the guide bar, the chainsaw can jerk back sudden-

ly in the direction of the operator (g. I).

■If the saw chain jams on the lower edge of the guide bar, the chainsaw can jerk forward

suddenly away from the operator (g. J).

■Be extremely careful when using the chain of the chainsaw to continue cutting into a cut that

has already been started.

■Do not saw branches or pieces of wood that could change their position during the saw-

ing process or where the cut closes during the sawing process.

Safety information

19

Safety information

■Each of these reactions can lead to you losing control of the saw and possibly suering a

serious injury. Never rely solely on the safety equipment integrated in the chainsaw. As a

chainsaw user, take various measures to work without accidents and injuries.

Kick-back is the result of incorrect or decient use. It can be prevented by suitable precau-

tionary measures, as described in the following:

■Hold the saw rmly with both hands, with the thumbs and ngers enclosing the chainsaw

handles. Bring your body and arms into a position in which you can absorb the kickback

forces. If suitable measures are implemented, the operator will be able to withstand the

kick-back forces. Never let go of the chainsaw (see g. D).

■Avoid an unusual body stance and never saw above shoulder height. This will help to avoid

unintentional contact with the guide bar tip, and enable improved control of the chainsaw in

unexpected situations.

■Always use replacement guide bars and saw chains prescribed by the manufacturer. In-

correct replacement guide bars and saw chains may cause the saw chain to break and/or

lead to kick-back.

■Adhere to the instructions of the manufacturer when sharpening and maintaining the

saw chain. If the depth limiter is too low, this increases the tendency towards kick-back.

■Do not saw with the tip of the guide bar. There is a risk of kick-back.

■Make sure that there are no nails or metal pieces in the cutting area. Pay special attention

to nails or pieces of iron around the cutting area. Also be careful when sawing hardwoods

where the chain can get caught. This can cause kick-back.

■Start cutting at full power and always keep the chainsaw at maximum speed while sawing.

■Make sure that there are no objects on the oor that you can trip over..

6.9 Residual risks

mDANGER

RISK OF INJURY !

Contact with the saw chain can lead to fatal cuts.

Never touch the saw chain with your hands while it is running.

RISK OF KICK-BACK !

Kick-back can lead to fatal cuts.

DANGER OF BURNING !

The chain and guide bar heat up during operation.

20

7. Technical data

Weight unfuelled, without cutting gear approx........5.2 kg

Weight unfuelled, with cutting gear approx. ............6.4 kg

Fuel tank ......................................................ca. 550 cm3(550 mL)

Tank for chain lubricating oil................ca. 260 cm3(260 mL)

Usable cutting length* /

Guide bar.......................................................................44 cm (18“)

Max. chain speed..................................................................22m/s

Chain pitch...................................................... 8.255 mm (0.325“)

Driving link thickness....................................... 1.5 mm (0.059”)

Type of saw chain ........................KANGXING : 325-058-72BL

Type of guide bar .......................KANGXING: BE18-72-5810P

Chain wheel tooth pitch............ 7 teeth/8.255 mm (0.325“)

Engine displacement ....................................................................... 45 cm3

Max. engine power output per ISO 7293.................................. 1.8 kW

Idle speed n0........................................................................................ 3400 min-1

Speed nmax ............................................................................................ 12000 min-1

Spark plug............................................................................................ L8RTF

* The actual cutting length may be less than the specied cutting length.

Noise

Sound pressure level LpA per ISO 22868.............111.4 dB(A)

Uncertainty KpA ..........................................................................3 dB

Sound power level LWA

per ISO 22868 ..............................................................113.0 dB(A)

Uncertainty KWA .........................................................................3 dB

Wear hearing protection.

Excessive noise can result in a loss of hearing.

The specied device emissions values have been measured in accordance with a standard-

ised test procedure and can be used for the comparison of one tool with another.

The specied noise emission values can also be used for an initial estimation of the exposure.

Technical data

21

Technical data/Before commissioning

Vibration

Vibration value at the rear

Handle per ISO 22867......................................................6.4 m/s2

Vibration value at the front

Handle per ISO 22867...................................................6.96 m/s2

Uncertainty K ......................................................................1.5 m/s2

m WARNING

Avoid the risks associated with vibration, e.g. the risk of white nger syndrome (circulatory

disorders) by taking frequent breaks from work where you rub your palms together, for ex-

ample.

8. Before commissioning

• Open the packaging and carefully remove the device.

• Remove the packaging material, as well as the packaging and transport safety devices (if

present).

• Check whether the scope of delivery is complete.

• Check the device and accessory parts for transport damage.

• If possible, keep the packaging until the expiry of the warranty period.

ATTENTION

The device and the packaging are not children‘s toys! Do not let children play with plastic

bags, lms or small parts! There is a danger of choking or suocating!

8.1 Mounting the guide bar and tensioning the saw chain

m ATTENTION

Always carry out assembly with the engine switched o.

m WARNING

Risk of injury!

Always wear protective gloves when touching the saw chain (17). Danger of injury due to

the sharp cutting teeth!

Note

A new saw chain (17) stretches and needs to be retensioned more often. Check and adjust

the chain tension regularly after each cut.

Depending on wear, the guide bar (16) can be turned.

22

• Set the chainsaw down on a level and stable surface.

• Pull the front hand guard (1) back as far as it will go to release the chain brake (see g. B).

• Remove the two xing nuts (20) with the spark plug wrench (28).

• Remove the chain cover (22).

• Slide the slotted hole of the guide bar (16) over the two protruding pins.

• Place the saw chain (17) over the teeth of the chain wheel (26). Insert the saw chain (17)

accurately in the direction indicated on the guide bar (16). In the tip of the guide bar (16)

there is a guide wheel into whose teeth the saw chain (17) must be inserted.

• Pull slightly on the guide bar (16) to slightly pre-tension the saw chain (17).

• Fit the chain cover (22) back on. Make sure that the internal chain tensioning pin (23) ts

into the matching hole (25) in the guide bar (16). If necessary, adjust the chain tensioning

screw (21) with the spark plug wrench / slotted screwdriver (28).

• Screw on the two fastening nuts (20) by hand. However, make sure that you do not tighten

them yet.

• Use the spark plug wrench / slotted screwdriver (28) to turn the chain tensioning screw

(21) clockwise until the lower part of the saw chain (17) slides into the guide bar (16). The

saw chain (17) must be in contact with the underside of the bar. When the chain brake is

released, it must be possible to pull the saw chain (17) over the guide bar (16) by hand.

Note

A new saw chain (17) stretches and needs to be retensioned more often.

• Tighten the two xing nuts (20) with the spark plug wrench / slotted screwdriver (28).

8.2 Mixing fuel

The engine must be operated with a fuel mixture of petrol and engine oil.

m WARNING

Avoid direct skin contact with fuel and inhalation of fuel vapours.

Use only a mixture of unleaded petrol (min. RON 95) and special 2-stroke engine oil (JASO

FD/ISO - L - EGD). Mix the fuel mixture as per the fuel mixing table.

Put the correct amount of petrol and 2-stroke oil into the enclosed mixing bottle (31) (see

“Fuel mixing table”). Then shake the mixing container (31) well.

Before commissioning

23

Before commissioning

8.2.1 Fuel mixing table

Mixing process: 40 parts petrol to 1 part oil

Petrol ............................................................2-stroke oil

0.5 litre.................................................................12.5 ml

8.3 Filling with fuel

m WARNING

Only ll the fuel when the engine is switched o and has cooled down.There is a risk of re!

• Always clean the area around the fuel tank cap (13) before lling to prevent dirt from fall-

ing into the fuel tank. Use a dry, lint-free cloth for this purpose.

• Lay the device on its side with the fuel tank cap (13) facing upwards.

• Turn the fuel tank cap (13) anti-clockwise and open it. The fuel tank cap (13) is connected

to an anti-loss device in the fuel tank and thus cannot fall o.

• Pour the fuel mixture into the fuel tank. Do not spill fuel when refuelling and do not ll the

fuel tank to the brim.

• Wipe up spilled fuel immediately.

• Turn the fuel tank cap (13) clockwise to close it.

NOTE

Also check the chain oil after each fuel ll.

8.4 Filling with chain oil

m WARNING

Only ll the saw chain oil when the engine is switched o and has cooled down. There is a

risk of re!

Never work without chain lubrication! If the saw chain runs dry, the cutting gear will be

irreparably destroyed in a short time.

Always check chain lubrication before working.

NOTE

Use only saw chain oil. Preferably biodegradable. Do not use waste oil, engine oil, etc.

Check during work that the chain lubrication is working.

• Always clean the area around the chain oil tank cap (14) before lling so that no dirt falls

into the chain oil tank. Use a dry, lint-free cloth for this purpose.

• Lay the device on its side with the chain oil tank cap (14) is facing upwards.

• Turn the chain oil tank cap (14) anti-clockwise and open it. The chain oil tank cap (14) is

connected to an anti-loss device in the chain oil tank and thus cannot fall o.

24

Symbole

• Pour the chain oil into the chain oil tank. Do not spill chain oil when refuelling and do not

ll the chain oil tank to the brim.

• Wipe up spilled chain oil immediately.

• Turn the chain oil tank cap (14) clockwise to close it.

8.5 Tensioning and checking the saw chain

m WARNING

Put on protective gloves! Danger of injury due to the sharp cutting teeth!

Check the chain tension regularly before each start-up.

• Before tensioning, loosen the two xing nuts (20) a little with the spark plug wrench /

slotted screwdriver (28).

• Turn the chain tensioning screw (21) clockwise with the spark plug wrench / slotted

screwdriver (28) to increase the tension.

• Tighten the two xing nuts (20) with the spark plug wrench / slotted screwdriver (28).

• The saw chain (17) must be in contact with the underside of the guide bar. Check whether

the saw chain (17) can be pulled over the guide bar (16) by hand (with the chain brake

released, pull the front hand guard (1) back).

NOTE

A new saw chain (17) stretches and needs to be retensioned more often.

9. Commissioning

mCAUTION

Please observe the legal provisions from the noise protection ordinance.

Before each start-up, check the device for the following:

• Check the fuel system for leakage

• Faultless condition and completeness of the guards and the cutting device

• Tight t of all screw connections

• Smooth running of all moving parts

Working instructions

Familiarise yourself with handling the chainsaw before use.

Before commissioning/Commissioning

Table of contents

Other FERREX Chainsaw manuals

Popular Chainsaw manuals by other brands

Echo

Echo CS-8000 TYPE1-E instruction manual

Garland

Garland MONTANA 920 instruction manual

Husqvarna

Husqvarna T540 XP II Operator's manual

Craftsman

Craftsman 358.350380 instruction manual

Scotts

Scotts LCS31440S owner's manual

Pattfield Ergo Tools

Pattfield Ergo Tools PE-EKS 1835 Original operating instructions