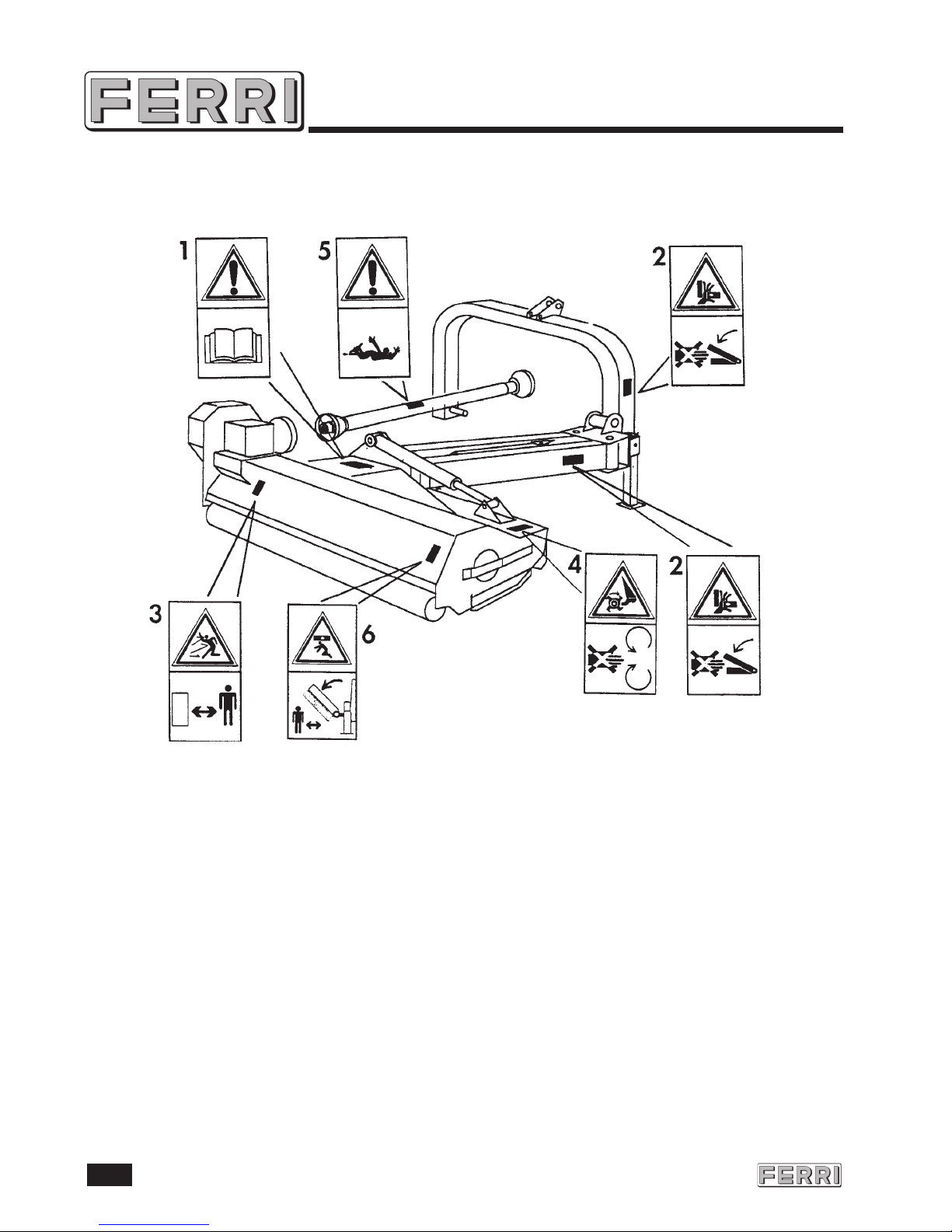

Ferris ZMT Offset User guide

Other Ferris Lawn Mower manuals

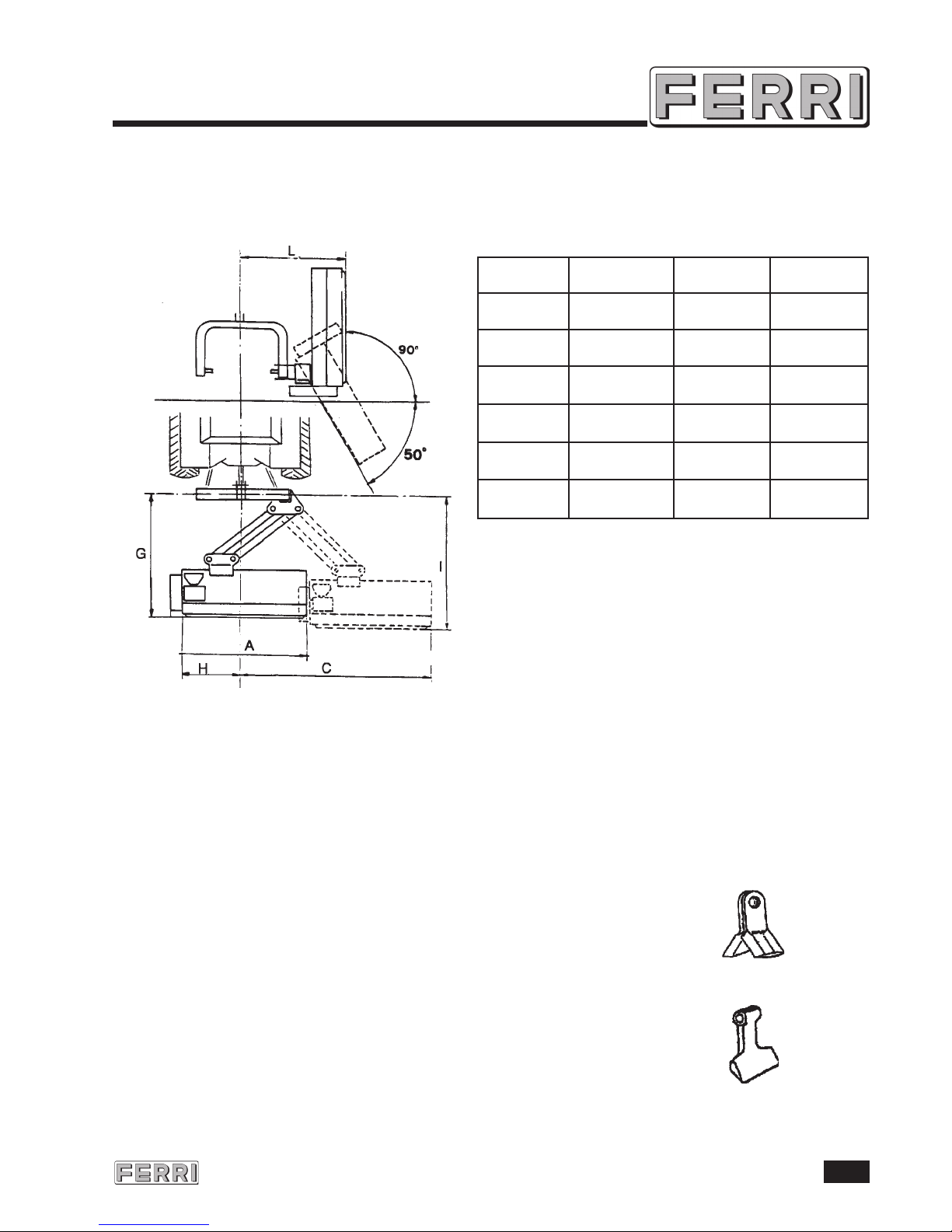

Ferris

Ferris FW35 Series User manual

Ferris

Ferris 5000/61RCE User manual

Ferris

Ferris IS600z series User manual

Ferris

Ferris SRS Z1 Series User manual

Ferris

Ferris HydroWalk DDSKAV15 User manual

Ferris

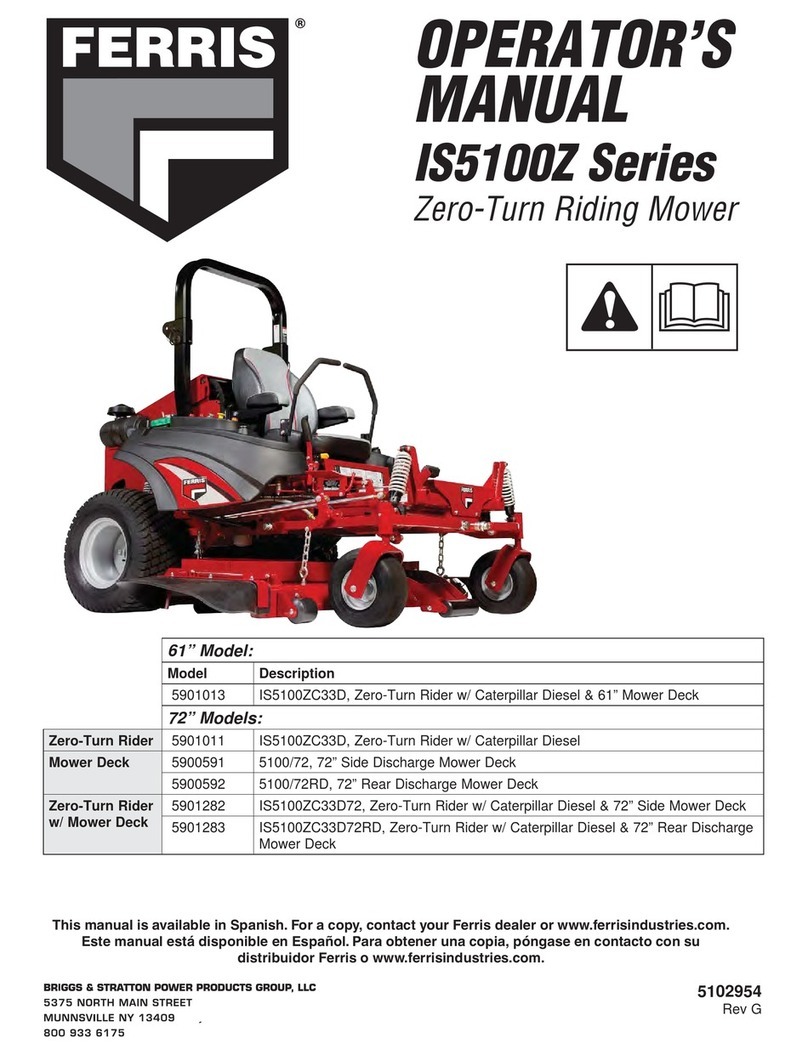

Ferris IS5100Z Series User manual

Ferris

Ferris IS3000ZKAV23/61 User manual

Ferris

Ferris IS2000ZSeries User manual

Ferris

Ferris IS600 Series User manual

Ferris

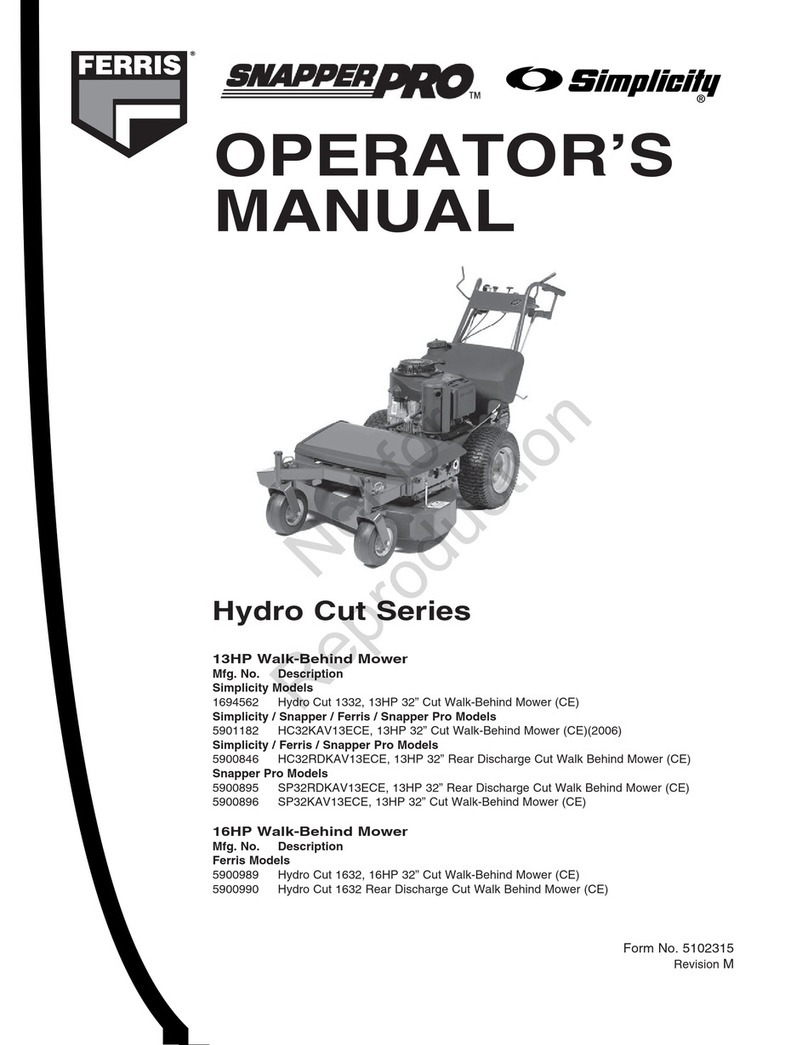

Ferris HydroCut Series User manual

Ferris

Ferris 5900619 User manual

Ferris

Ferris IS2000Z Diesel User manual

Ferris

Ferris IS2000Z Diesel User manual

Ferris

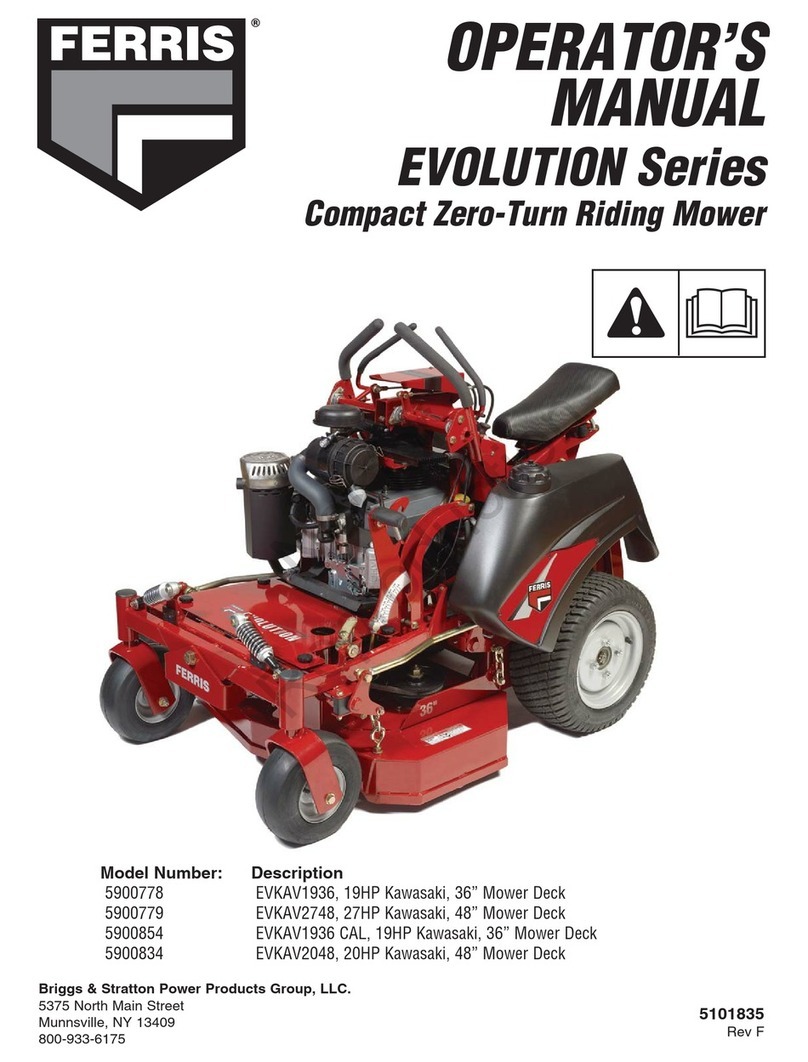

Ferris 5900854 User manual

Ferris

Ferris IS5100ZC33D72RD User manual

Ferris

Ferris HydroWalk Series User manual

Ferris

Ferris IS600ZB2544 User manual

Ferris

Ferris IS700Z series User manual

Ferris

Ferris Hydro Cut Series User manual

Ferris

Ferris IS5100Z Series User manual

Popular Lawn Mower manuals by other brands

TALEN TOOLS

TALEN TOOLS AVR HGM30 manual

DEWEZE

DEWEZE ATM-725 Operation and service manual

Weed Eater

Weed Eater 180083 owner's manual

Husqvarna

Husqvarna Poulan Pro PP185A42 Operator's manual

Better Outdoor Products

Better Outdoor Products Quick Series Operator's manual

Cub Cadet

Cub Cadet 23HP Z-Force 60 Operator's and service manual