Ferroflex Aluminum Rolling Up High Speed Door User manual

Instruction manual

Aluminum rolling-up door

ALUMINUM ROLLING-UP DOOR

MOT-A14

Rev.1

DECLARATION OF PERFORMANCE

Model: Aluminum Rolling Up High Speed Door

For the use as Industrial High Speed door for pedestrian and vehicle traffic.

Evaluation and Verification System of constancy of performance.

System 3. According with European Standards 13241-1:2003

Notified body: Cidemco nº1239

Document issued and date: Certificate 12707 del 09/03/2006

Performance declared.

Water tightness

Not Proceeding

Emissions of hazardous substances

Qualify

Air Behaviour

Class 2

Thermal resistance

Not Proceeding

Air permeability

Not Proceeding

Safe Opening

Qualify

Mechanical resistance

Qualify

Setting force

Qualify

Durability

100,000 cycles

For the present, the manufacturer, declares, under his responsibility, that the rapid door

does not contain dangerous products included in the list published by the European Union

and therefore it is in accordance with the essential safety requirements of the following

Directives:

•Construction Products Regulation (EU) 305/2011, laying down harmonized conditions for

the marketing of construction products.

•European Directive 06/42/CE, on the approximation of laws of Member States relating

Machinerys.

•European Directive 06/95/CE, on the approximation of laws of Member States relating

electrical equipment designed for use within certain voltage limits.

•European Directive 04/108/CE, on the approximation of laws of the Member States

relating to electromagnetic compatibility.

2

For the specific requirement of this equipment, the following harmonized standard have

been applied:

•UNE-EN 13241-1:2004 + A1:2011. Industrial, commercial and garage door and gates. Part

1: Products without fire resistance or smoke control characteristics.

•UNE-EN 12453:2000. Industrial, commercials, and garage doors and gates. Safety in use

of power operated doors. Requirements.

•UNE-EN 12604:2000. Industrial, commercial and garage doors and gates. Mechanical

aspects. Requirements.

•UNE-EN 12424:2000. Industrial, commercial and garage doors and gates. Resistance to

wind load. Classification.

•UNE-EN 12635:2000. Industrial, commercial and garage doors and gates. Installation and use.

•UNE-EN 1037:1996 + A1:2008. Safety of machinery. Prevention of unexpected star-up.

•UNE-EN 60204-1:2007 + A1:2009. Safety of machinery. Electrical Equipment of Machines.

Part 1. General Requirements.

•UNE-EN 61000-6-2: 2006. Electromagnetic compatibility (EMC). Part 6. Generic standards.

Section 2. Inmunity for industrial environments.

•UNE-EN 61000-6-3:2007. Electromagnetic compatibility (EMC). Part 6.Generic standards.

Section 3.Emission standard for residential, commercial and light-industrial environments.

The described products are exclusively destined for the assembly with a control box

corresponding to the class 2 according to DIN 954 standard. The starting remains prohibited if the

whole installation, including the assembly, has not been validated in terms of conformity

regarding the applicable dispositions mentioned on above European Directives.

The declaration will be automatically cancelled if any modification is done on the installation

by user or any other part.

3

IDENTIFICATION CARD

4

Table of contents

1. Product’s description ............. PAG. 6

1.1. Door’s operating mode and Frame

1.1.1. Principle

1.1.2. Electrical Control box

1.2. Electrical security Devices

1.3. Motor

1.4. Technical Characteristics

1.5. Principle drawing

1.6. Fixing map

1.7.Inspection rules

2. Security information ............. PAG. 11

2.1. Application area and suitable use

2.2. User’s obligations

2.3. Explanation of used security symbols

2.4. General security information

3. Storage and handling ............. PAG. 13

3.1. Storage

3.2. Dimensions and weight

3.2.1. Dimensions of the palette with the door

3.2.2. Dimensions of the door, once installed

3.2.3. Weight of the door

3.3. Handling

3.4. Handing on the installation place

3.5. Gravity centre

4. To assemble and to dismantle ............. PAG. 14

4.1. Inspection of the delivery

4.2. Preparation of the installation

4.3. Door assembly

4.4. Control box assembly

4.5. Test and reception

4.6. Adjustment and starting

4.7.To dismantle

4.8. End of assembly

5. Breakdown ............. PAG. 29

5.1. Mechanics failures

5.2. Electrical failures

5.3. Manual operation in case of power failure

6. Maintenance ............. PAG. 31

6.1. After-Sale service

6.2. Control and maintenance

6.3. Cleaning

6.3.1. Cleaning and maintenance of the protector blade

6.3.2. Cleaning and maintenance of the door frame

6.3.3. Cleaning of surrounding areas

5

1. Description of the product

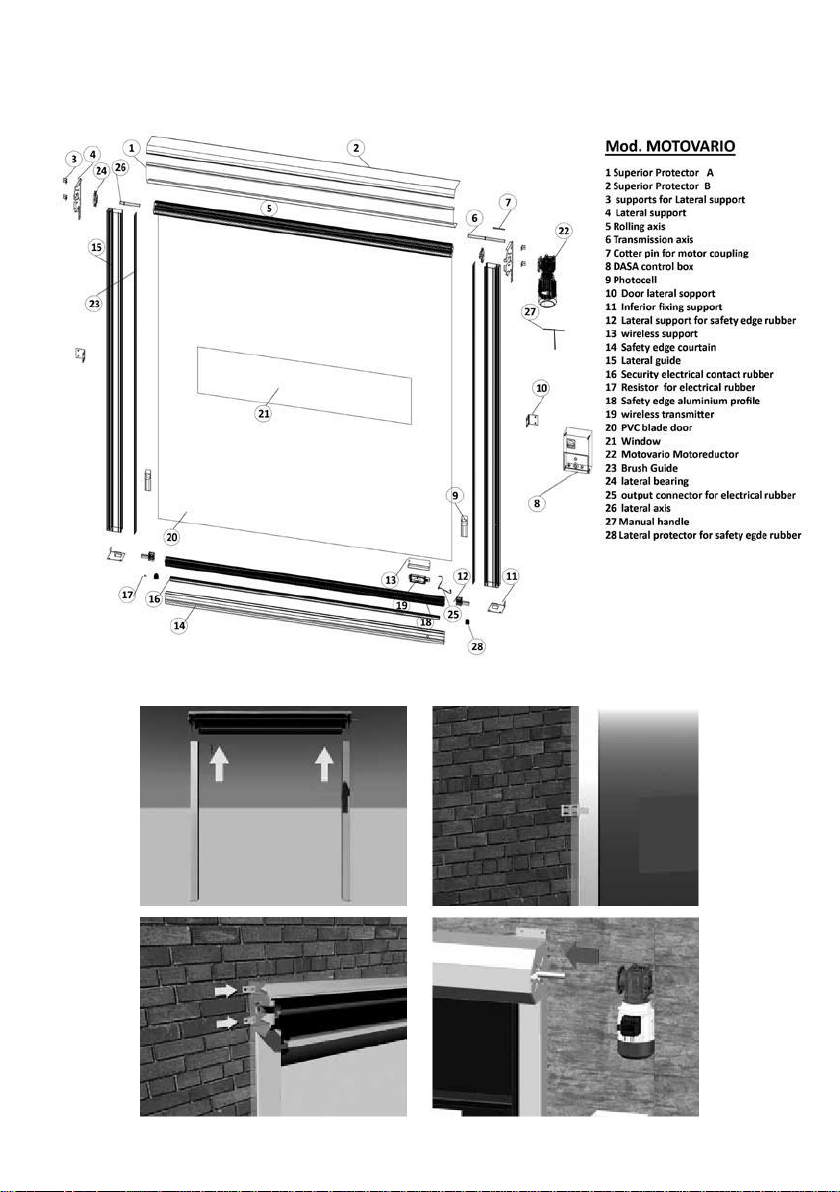

· 1.1. Door’s operating mode and Frame

The Aluminium rolling-up door is a vertical high-speed door with a top-mounted mechanism.

Lateral frames are used to drive the flexible blade. This blade is vertically opened and rolled up

on the superior part. The rolling axis roll-up the door thanks to the motoreductor.

For the closure, the blade goes down thanks to the weight on the inferior part,

guarantying the air-tightness.

· 1.1.1. Description

The door is composed by two lateral frames, a PVC blade as well as a rolling axis.

The door goes up and down thanks to the traction done by a motor allowing the movement.

The power of this last is done on an axis allowing to instantaneously vary the operating way.

On the inferior part of the blade there is a contactor safety allowing to invert its way as soon

as the minimum chock is detected; therefore to open the door by security. More over, on

the inferior part of the door, there is a security photocell to open the door if there is any

obstacle.

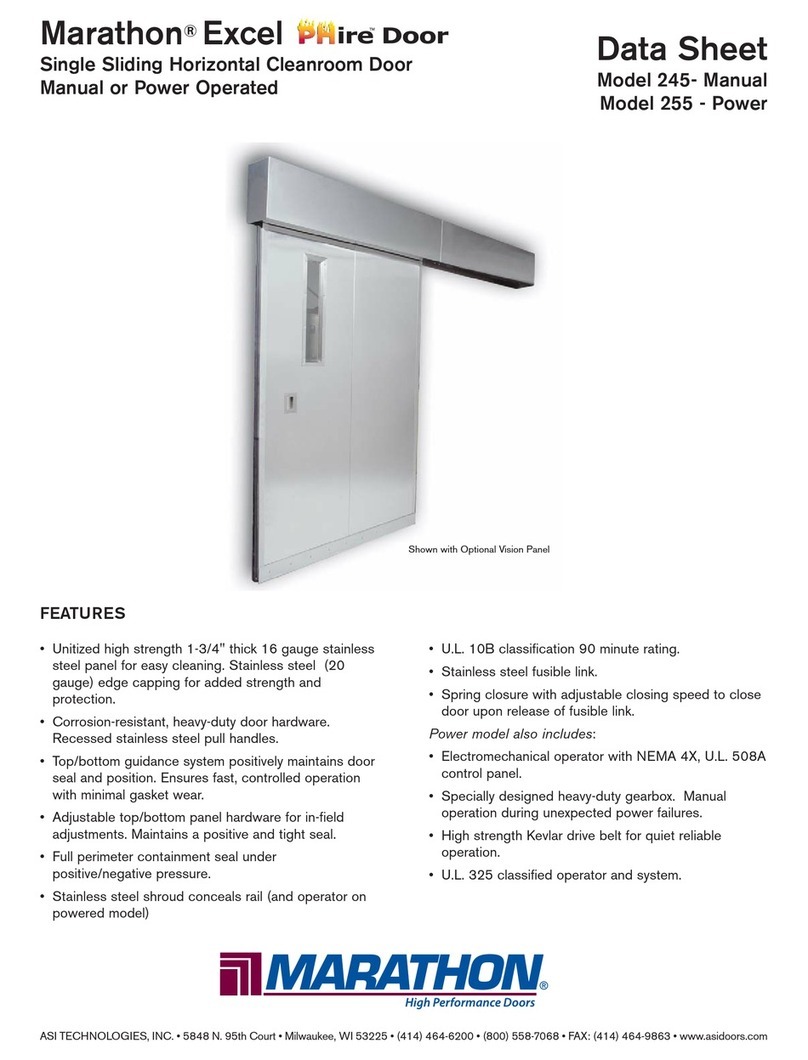

· 1.1.2. Electrical Control Box

The electrical control box is our Ref. MATRIX 6. This control box has been designed to be

used with motors supplied by the manufacturer which included mechanical limit switch. Its

corresponding instruction manual is supplied together with this assembly and Instruction

manual. Homologated according to UNE EN 12453 rule.

· Technical Data

For all MATRIX 6 boards.

For motor up to 3,0 KW.

Supply voltage: 3x230V/PE;

3x400V/PE. Control Voltage: 24 VDC.

Dimensions: 220 x 305 x 140 mm. IP56.

For bad weather or continuous water spray uses, we recommend the additional protector

cover.

Electronic board protected by a cover.

Pattern and fixing elements supplied.

Box with integrated push buttons (OPEN-CLOSE-EMERGENCY STOP-VOLTAGE LUMINOUS

INDICATOR).

Entry with corrugated pipe coupling elements.

6

· Functions

Operating mode selection: Present man or Automatic. Automatic

recognizing and evaluation for safety edge’s status.

Adjustable waiting time up to 90 sec. The door will be closed once the programmed time

finished.

Input for pull cord or remote control.

Input for intermittent indicator light or Traffic Light

. Slot for magnetic detector included.

Connection time adjustment for the motor break.

Input for the 3º micro switch of the limit switch.

Input for operating through frequency

inverter. LEDS status information.

Enclosure with Motor Circuit Protector, inversor and motherboard.

The operating door is impossible without original traction motor and

electrical control box.

· 1.2. Electrical security device

Before each descent movement, an internal test is done on the photocell and the electrical

control box (security category Nº2 according to the DIN EN-954-1 rule). In case of technical failure,

and for security reasons, the door will be automatically rolled up. If the contact of the safety edge

is damaged, the door will be also automatically rolled up for security reasons.

Photocell and safety edge must to be controlled per authorised staff each year.

· 1.3. Motor

The Folding up door is electrically activated through a motoreductor allowing the door to

operate is placed on the superior part of this one, being indistinctly installed on the right or

the left side according to the installation requirements. If there is no enough space for the

installation of the motoreductor, it is always possible to place it in frontal position with a

chain. The electrical control box includes a motor protector allowing to disconnect the

motor’s supply in case of over temperature of this one.

7

· 1.4. Technical Characteristics

Principle

High Speed Rolling-up Door

Opening way

Vertical

Application

Door for Exterior and Interior installations

Dimensions*

Maximum width: 4000mm / Maximum height: 4000mm

*It is possible to manufacture other dimensions under request

Opening Speed

0.9 m/s

Closure Speed

0.9 m/s

Assembly

Position interior and exterior

Motor

Electrical

Power supply

230/400v Three phases without Neutral

Motor Power

0,75 CV (According to door’s dimensions)

Electrical control box

MATRIX 6

Motor protection level

Motor Circuit Protector to 4A

Lateral frames

Aluminium

Blade

Polyester PVC with a thickness of 900g/m2,

and M2 Class for fire resistance

Dimensions

See herewith drawing

Frame fixing

See herewith fixing drawing

The manufacturer can feel free to technically modify the door, if these modifications

don’t break the Obligatory European Rule EN 13241-1:2003

8

·

·

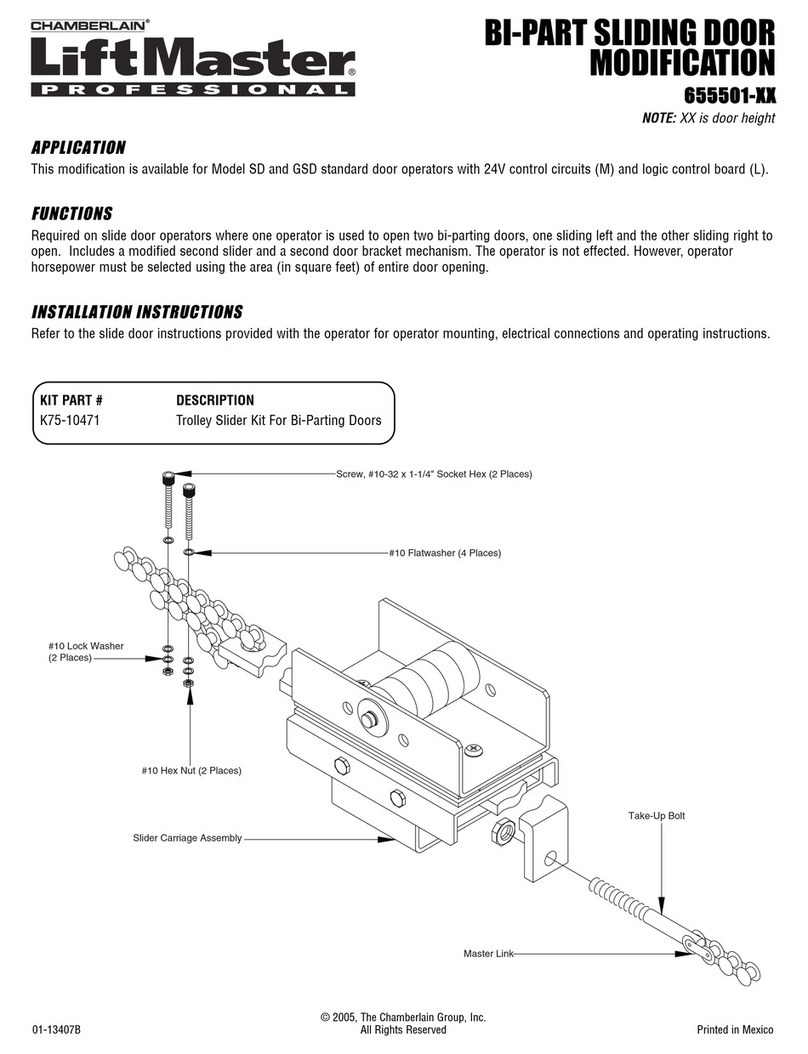

1.5. Principle drawing

1.6. Fixing map

9

· 1.7. Inspection Rules

Examination

Aluminium

rolling-up

METALLIC FRAME:

Assembly fixing

To tighten screws.

Once per year

To verify the soldering cord.

Once per year

Motoreductor

To verify the state and the wear of the break, as well as the correct

Once per year

operating mode of the break lever.

To verify the fixings motor screws.

Once per year

Rolling axis

To tighten fixings and bearings.

Once per year

Door blade

To verify the absence of fissures and stripes on the whole blade.

Once per year

To control blade fixings on the rolling axis as well as reinforcement bars.

Once per year

To control the electrical safety edge operating mode.

Once per year

Safety Edge

To verify the WIFI system.

Once per year

To verify the blade fixing, and the state of guides, cables spout and friction

pieces. Substitute all deformed friction pieces.

Once per year

To verify the state of contacts connector, cables and the electrical safety edge.

Once per year

Lateral frames

To verify the fixing and the vertical guides state.

Once per year

To control the cable way as well as the chain charged to conduct the energy.

Once per year

To verify the assembly and the operating mode of the photocell.

Once per year

To clean the photoelectrical barrier and the beam.

Once per year

Electrical control box and Added optional boards

To verify the entirety of the wiring map.

Once per year

To control the main switch and the closure of the control box.

Once per year

To verify the fixing.

Once per year

ELECTRICAL FUNCTIONS:

Run of the door

To control the opening and closure positions of the closure guides.

Once per year

To verify the fixing and the operating mode of the end of run switches.

Once per year

Security mechanisms and drive

To clean the optical of the security photoelectrical barrier.

Once per year

To verify the fixing and the operating mode of the end of run switches.

Once per year

Electrical components

To visually control and look for any kind of mechanical damage.

Once per year

Mechanical Functions

To verify the operating mode and the state of the couple support during the

Once per year

operating.

To examine the behaviour of the blade roll up.

Once per year

10

2. SECURITY INFORMATION

· 2.1. Application area and suitable use

If this data hasn’t be expressly mentioned, our high-speed doors have been designed and

tested to be used in normal conditions. For a use in particular conditions (excessive

temperature on a single side, over/under pressure or specific environment influences, etc…)

you have to select the more suitable and adapted option required by the situation. We will

be pleased to advice you, if you need it.

· 2.2. User’s obligations

The high-speed door has been designed ad manufactured according to a risks analyse and

to rigorous selection of rules to respect, as well as other technical specifications. Then, this

door corresponds to the updated state of the technique and guarantees an optimal security.

Nevertheless, this security level can only be obtained in the professional practice if you have

taken all required and necessary measures to this effect. Therefore, we strongly suggest you

to read these service instructions and to keep them:

The user has to specially check that:

·The installation, the starting, the inspection, the maintaining, the repair, the dismantle;

have to be only done by staff authorised by the manufacturer or by competent staff.

·Only authorised and enough experimented staff activate the high-speed door.

·The door must be only used according to expected application (see previously).

·The door must only be used if it is in perfect state, and mainly that security mechanisms

must be frequently controlled.

·These service instructions are always available close to the door’s installation, readable

and completes.

·The personal must be frequently prepared to all important matters concerning the door

and its correct use.

·All security information and warning notices marked on the machine are always available

and readable.

·Door maintenance must be done by qualified and authorised personal.

· 2.3. Explanation of used security symbols

These service instructions include following security symbols. The aim of these symbols is

to mainly attract the reader attention regarding the placed security texts:

They indicate risks of death, to damage machines, against health, or properties or environment.

11

Attention: danger for people or door’s installation.

Attention: Electrical voltage.

This symbol is used for information allowing a better understanding regarding

the door-operating mode.

Important Information

Information directly marked on the door and on the electrical control box have to

obligatory and entirely be observed and kept readable.

·2.4. General security information

·Please read carefully these service instructions and keep them.

·Security prescriptions described on these service instructions have to be respected.

·Do not use this door for unexpected applications. In the case of cession of this door to a

third person, these service instructions have to obligatory be transmitted.

·In case of damage of the electrical system activation, the door blade can be unlocked and

folded up unblocking the motor. Then, you have to use the crank supplied for this purpose.

·During the door’s operating, don’t touch lateral parts.

·The door operating area has to be free of people. These doors are destined to staff

circulation.

·Don’t run across the door opening. Cross it upright and at a normal speed.

·Maintain clean the area close to the door operating. Otherwise, accidents can occur.

·Don’t climb up the high-speed door.

·Don’t matter the labour done on the door, the mains switch has to be in ”OFF” or “0”

position and protected against any involuntary reactivation of the voltage.

·The door has to immediately be in out of order in case of damage (mechanical or electrical).

·The door can only be used at the mentioned and authorised feed voltage.

·Use only accessories or complementary devices homologated and authorised by the

manufacturer.

·Do not use the door if there are wind gusts. The door must to be maintained opened.

It is very important to respect these mentioned general security information as well as

points added in other chapters.

12

3. Storage and Handling

· 3.1. Storage

The high-speed door partially assembled is supplied on handling palette ant it is packaged

into transparent protector film.

Do not store the door at building outside.

The wooden cage has to be placed on a flat basis. It doesn’t be removed before

the beginning of the assembly.

The wooden cage has to be protected against any kind of mechanical damages.

· 3.2. Dimensions and weight

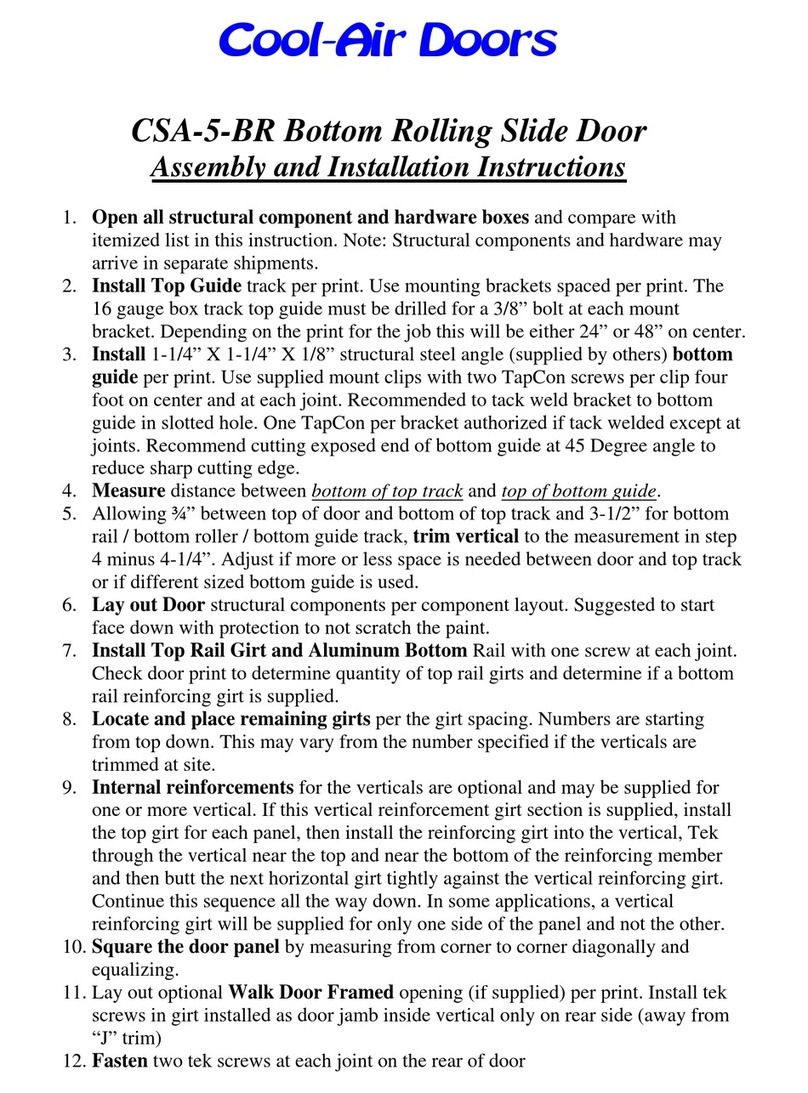

· 3.2.1. Dimensions of the handling palette with the door

The packaging dimensions are usually 450mm (Width) x 450mm (Height) x longer measure

(vertical or horizontal) + 1000mm

· 3.2.2. Dimensions of the door, once installed

13

Weight of the door

Weight of the door with the palette (in Kg).

Dimensions

2x2

3x3

4x4

Weight

110

180

210

· 3.3. Handling

During the handling to the installation place, you have to respect public security indications.

Be careful and avoid that the door slide or balance.

The door has to be lifted up to avoid any lateral swing.

· 3.4. Handling on the installation place

The different components of the door can only be removed of wooden cage, once wooden

cage on the installation place.

· 3.5. Gravity centre

It is possible to interpose intermediaries values.

4. To assemble and to dismantle

· 4.1. Inspection of the delivery

The door is preassembled at the delivery and it is composed by

3 components into the wooden cage:

·The first component is composed by 2 lateral guides

·The second component is Superior protection guide

including blade door with safety edge and Motoreductor.

·The third component is a box with fixing materials and

electrical components.

14

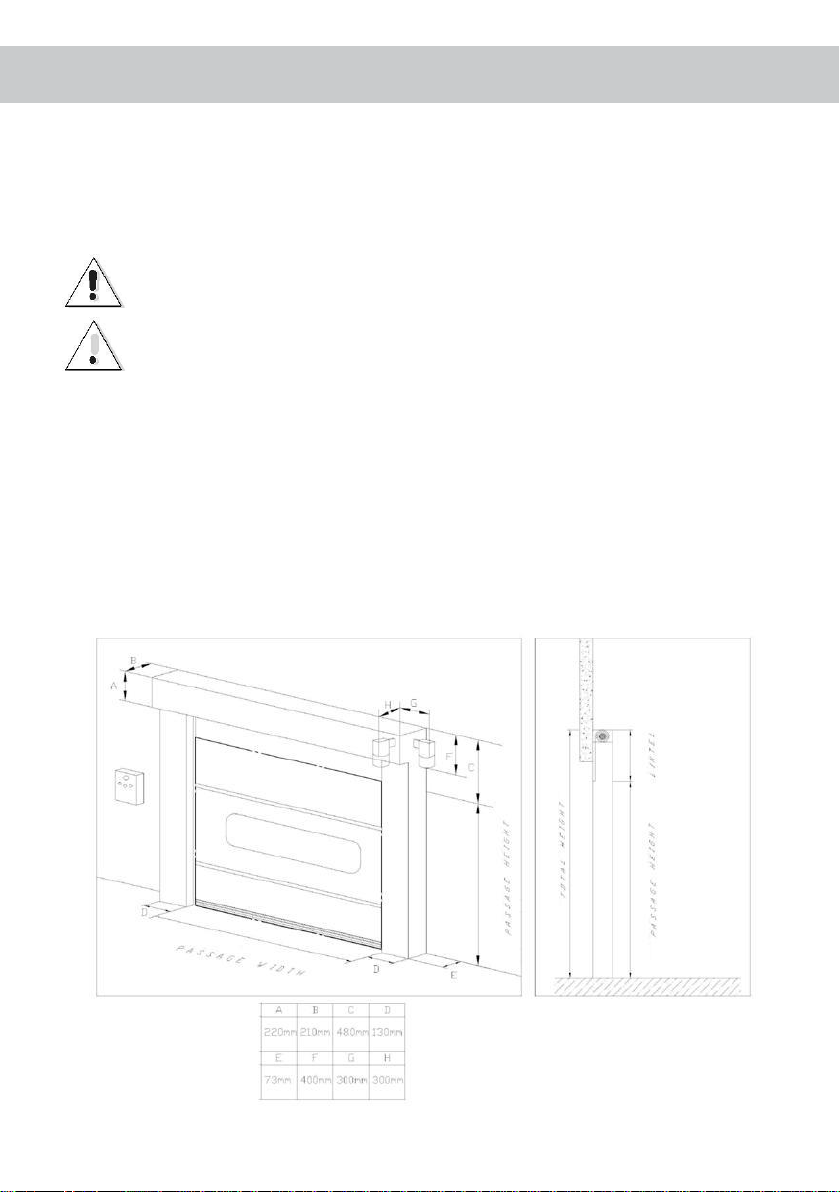

· 4.2. Preparation of the installation

You have to verify on the place that the measures are corrects and fixing points are

accessible. Superior plates, supporting the rolling axis, have to be fixed on a good reinforced

concrete or soldered on a steel support.

You can add more fixing plates if necessary, correctly shared on the total length.

You have to measure the opening dimensions (width and height) and to verify them with

the delivery documents.

The high-speed door has to be assembled by qualified and authorised staff following

assembly instructions manuals.

The area has to be securitised and the circulation has to be completely forbidden.

· 4.3. To assemble

Check there is no obstacle to install the frame and check the are where the door will be

installed is correctly levelled, otherwise you must suitably level it.

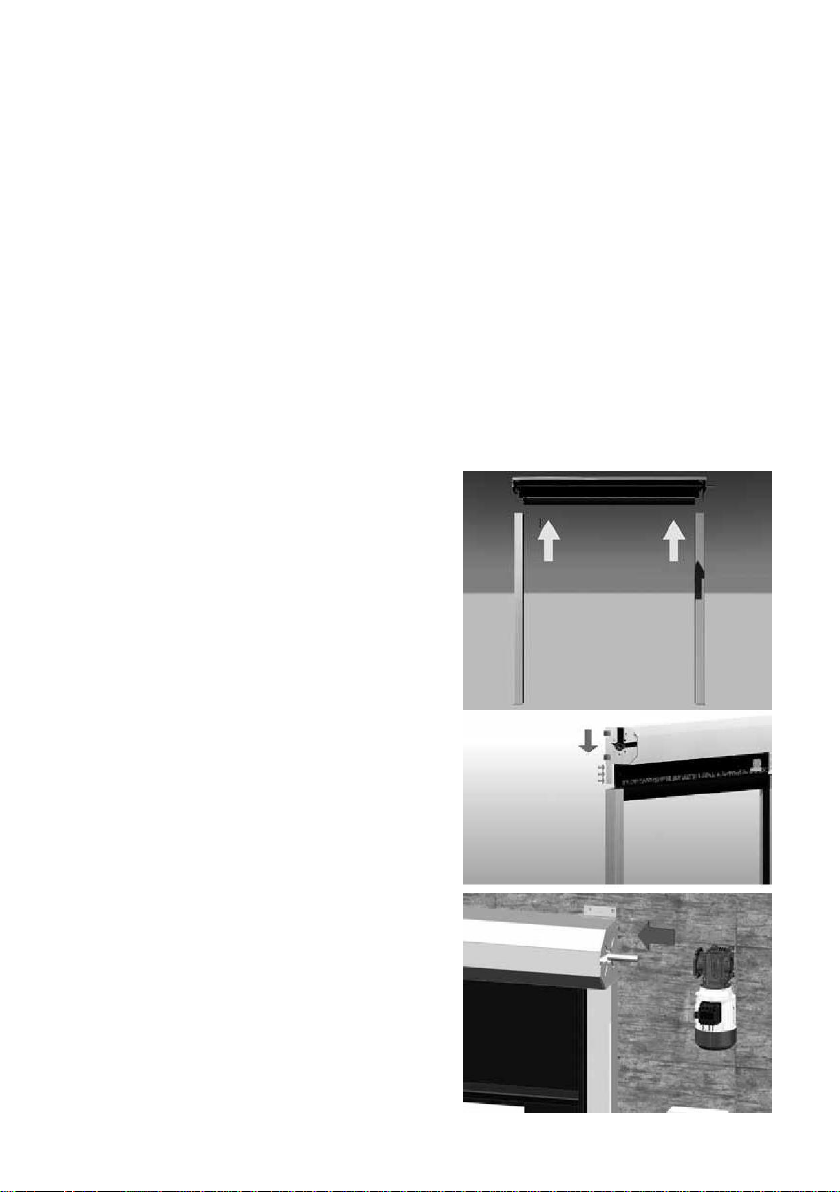

· 4.3.1. To start the assembly, you must

completely unpack lateral guides and superior

protection cover. You only have to remove the

packing corresponding to the necessary parts

(extremities) to fix lateral guides with superior

frame. The rest of packing must to be maintained

to avoid damaging the door during the assembly,

or the blade fall.

Place the upper roll-up drum on the floor and

insert the two lateral guides into the lateral plates

placed on the upper tray. Fix the different parts

using the 6 hexagonal Allen screws of size 8 x 10

and their corresponding washers.

· 4.3.2. Once lateral guides fixed, you

have to place the motoreductor on the door’s

axis, using the 2 screws of size 10 x 30 and their

corresponding washers.

15

· 4.3.3. Then, trough small carriage or lift-truck, you have to raise the assembly

inside the opening and support it on the wall. Level the door and fix the inferior part with

two screws on each guide as well as superior and lateral parts according to the wall. The

door is supplied with separate superior and lateral squares soldered on the door for its fixing.

We recommend you to fix the door on the wall using plastic plug or metallic plug for

concrete, or to solder it.

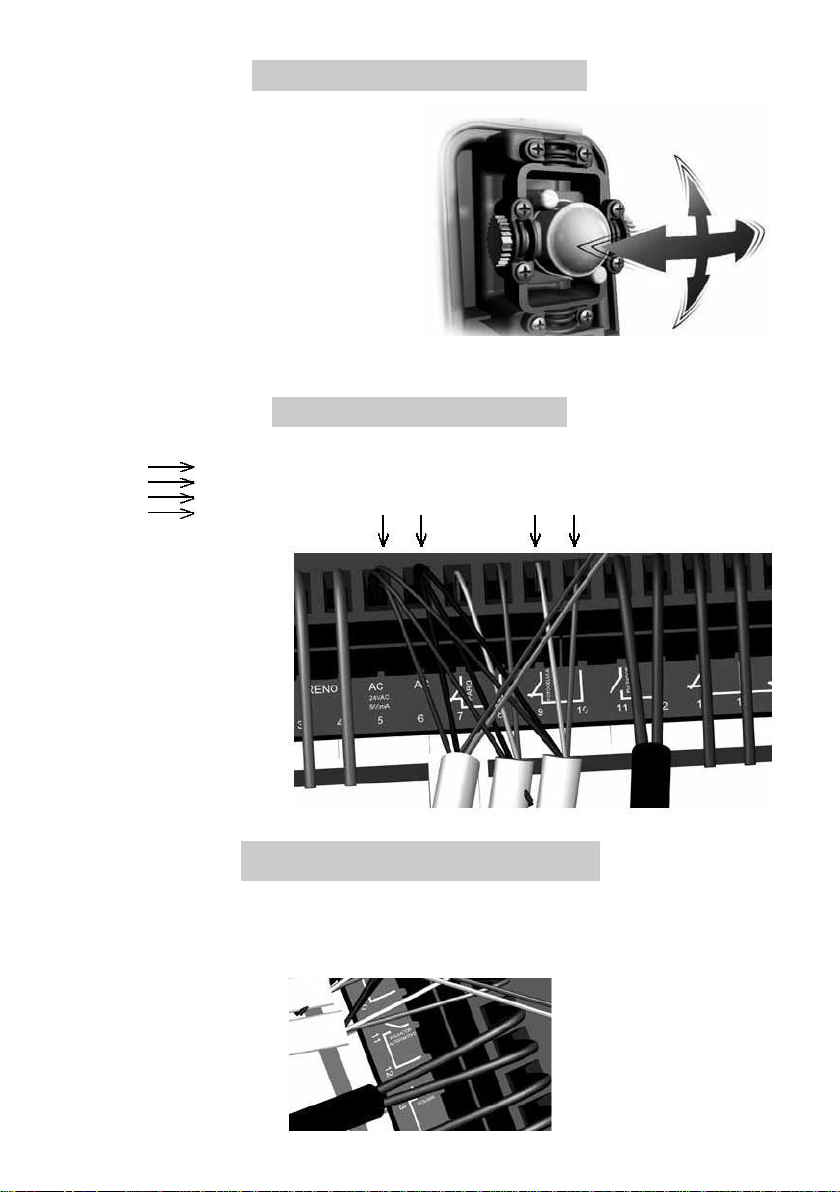

·4.3.4. Install the blade door into the

lateral guides. Roll-down the blade door to half

height to posteriorly check the motor rotation

way. Install the electrical control box in the guide

closest to the motoreductor at approximately

1300 or 1500 mm height from the ground, using

4,8 x 38mm screws and M6 plug and place cables

through supplied gutter for their correct

installation and protection.

We suggest you to install the control box close

to the door to activate the emergency stop if

necessary.

Install inferior photocells onto the inferior part

of the lateral guide at minimum 200 mm height from the floor and connect photocells,

following corresponding instructions manual.

·4.3.5. Fix the external push button using 4,8x38mm screw on the wished place.

We suggest you to place it close to the door in the opposite side regarding the control box.

external push button using M6 plugs and 4,8x38mm screws.

·4.3.6. To connect the electrical control box, you must carefully read and follow

the following instructions:

·Check the motor rotating and operating mode.

·Connect all security elements on the door.

·Adjust the maximum opening and closure door.

·Check the operating and programming modes as well as go down timing

16

· 4.4. Electrical Control Box

Matrix 6 control box

·4.4.1. Characteristics

·The MATRIX 6 Control box with 3 KW at 400V / 3~

as maximum with Mechanical limit Switch.

·Status indication through LEDs through a two digits

digital indicator:

·Mains voltage

-400V / 3~

-230V / 3~

-230V / 1~ (for single phase motors with frequency

inverter)

· Industrial door operating mode.

-Opening and closure by present man.

-Automatic opening and closure by present man (without safety edge protector).

-Automatic opening and closure (automatic closure combining with safety edge protector)

· Automatic detection and handling of three different safety edges types.

-8K2 Normally active contact.

· Automatic closure.

-After a waiting time (adjustable) from 1 up to 90 seconds as maximum.

-The time can be reduced interrupting the photocell light beam.

-it can be interrupted with auxiliary switch.

·Connection to supply external devices.

·Terminal block with indication to connect all necessary devices.

·Push button with 3 buttons on the cover OPENING / STOP / CLOSURE.

·Additional connections for control devices.

·4.4.2. First steps

-The control box is composed by a box with a

removing front cover.

-Open the front panel and insert cables through

inferior holes on the box.

17

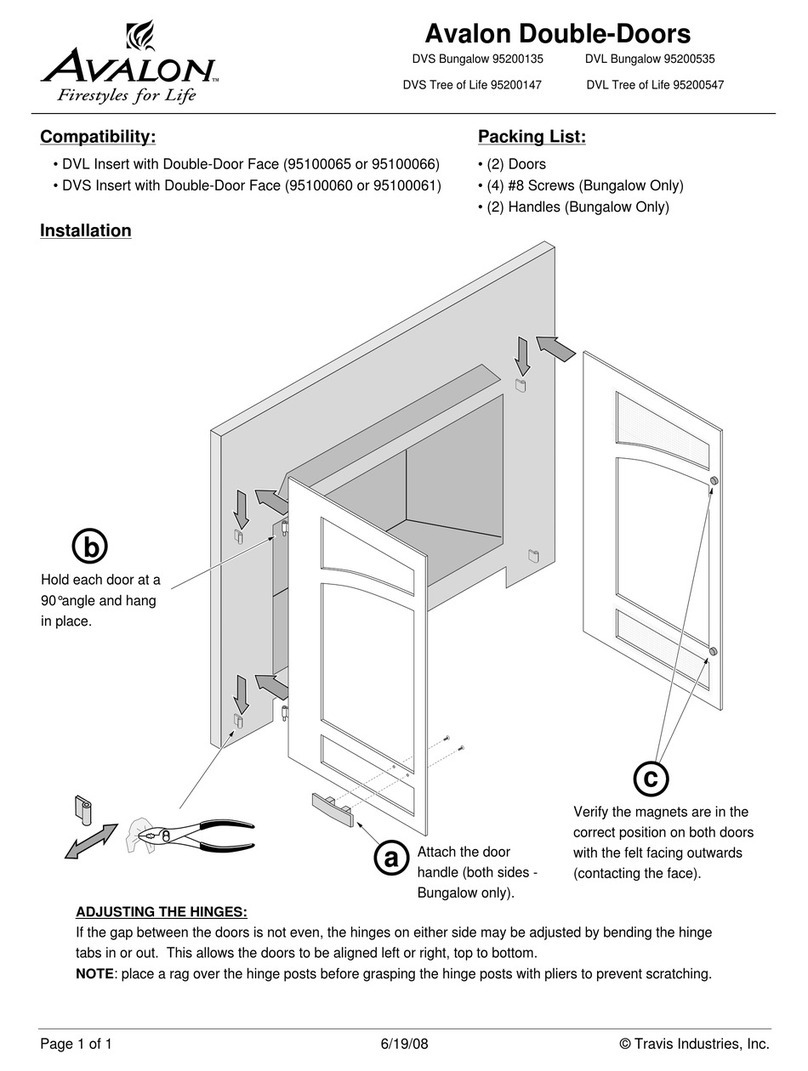

· 4.4.3. Standard connections for power supply

The MATRIX 6 control box can be supplied according to the available voltage:

· 400V III + PE

You have to connect the 3 phases on L1, L2, L3

terminals and the ground cable to the corres-

ponding terminal. Check on the central part of

the motherboard that operating power supply

cables are in 400V and 0V terminals.

· 230V III + PE

You have to connect the 3 phases on L1, L2,

L3 terminals and the ground cable to the

corresponding terminal. Check on the

central part of themotherboard that

operating power supply cables are in 230V

and 0V terminals

Motor and break

To connect the motor to the motherboard, you

have to connect the 3 phases of the motor to U, V

and W terminals and the ground cable to the

corresponding terminal. Cables of the motor

break’s rectifier must to be connected to the

terminal indicated as “FRENO” on terminal block.

· 4.4.4. Inferior security photocell

Connect cables to the corresponding terminals according to the following drawing.

Transmitter Power supply through batteries

(included).

Receiver Terminal 1 -24V

Terminal 2 - GND

Terminal 3 - OUTPUT CONTACT

Terminal 4 - OUTPUT CONTACT

18

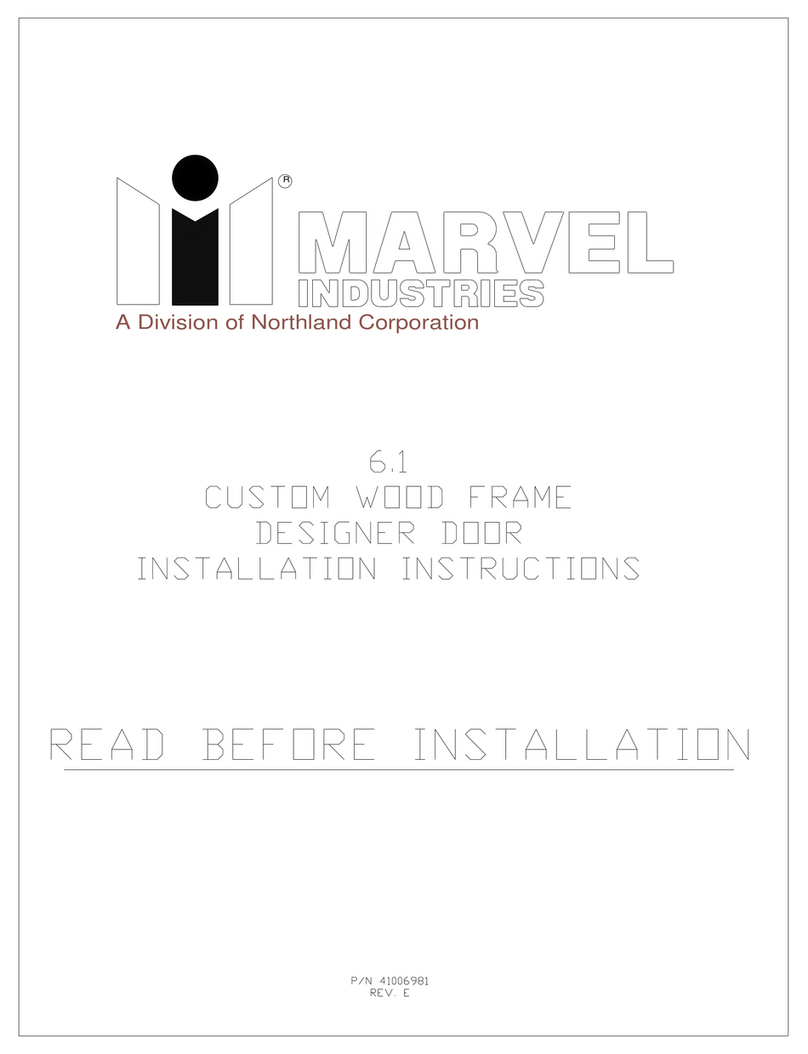

Inferior photocells adjustment

In order to correctly orientate photocells, you

have to use support for the fixing screw

available in the photocell support, vertically

leaning up to the light beam is reflected in the

mirror and sent back to the photocell. When

this happens, the 2 LED placed on photocell

electronic board will light on.

In order to verify that it operates correctly,

you have to pass the hand to cut the light

beam and the signal LED will be immediately

lighted and you could heard a small click from the contact change status.

CONNECTION ON CONTROL BOX

RED Cable

5(AC) Terminal

BLACK Cable

6(AC) Terminal

GREEN Cable

10(Photocell)

Terminal

YELLOWCable

9(Photocell) Terminal

GREEN

YELLOW

BLACK

RED

Additional external push button

Connection on 11 and 12 terminals. (Alternative push button)

19

· 4.4.5. Wireless-band

Wireless-band tramsitter: Connect the output rubber band electrical cable to terminals 1

and 2 on the Transmitter and activate the switch Nº1 to start the test.

Wireless-band receiver: Connect the receiver supply, terminals +0 and 12/24v to terminals

5 and 6. Connect terminals C and S from receiver to “Banda palpadora” terminals on the

control box.

TRANSMITTER

CONTROL BOX

RECEIVER

C and S from the receiver

To connect transmitter and receiver

1- Connect the receiver feed. (Be careful to respect the polarity when you use a DC power

supply) 2- Check transmitter and receiver options.

3- Match emitter and receiver following the programming

steps. 4- Install the transmitter on the door.

5- Wire the resistive safety edge to the transmitter and connect

it. 6- Install the receiver in the suitable place.

7- Wire the power supply, the test input and the receiver output to the control

box 8- Activate the power supply.

9- Make a test with the connected safety edge with door in different positions, mainly

close to the opening and closure position.

10- We recommend to follow step 1 to 4 before to install the device. Respect a minimum

distance of 1m between transmitter and receiver to have the optimal operating mode. 11-

Once assembled and matched transmitter and receiver , you have to maintain the

transmitter’s microswitch in position Nº1.

The transmitter and the receiver are supplied already

configured to operate in couple.

If the programming is not correct, you can reprogram them

proceeding as following:

A- All switches of transmitter and receiver must be to in down position (OFF), except the

Nº1 on transmitter.

B- Press the program button on the receiver and you will hear a “Beep” as validation. C-

Then, you will be in programming mode and the “program” LED will light to indicate it.

20

Table of contents

Popular Door manuals by other brands

Avalon

Avalon DVS Bungalow 95200135 installation guide

Marvel

Marvel 6SWCE-BB-G installation instructions

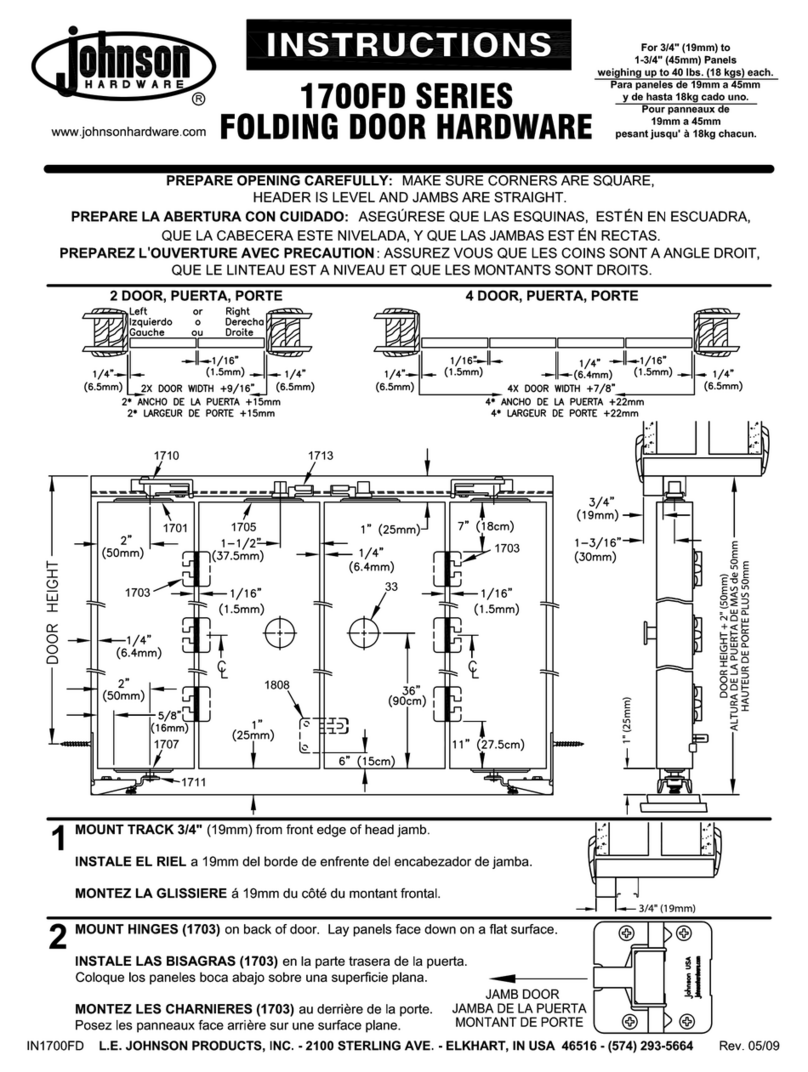

Johnson Hardware

Johnson Hardware 1700 instructions

B&D

B&D Roll-A-Door R1D installation instructions

Pella

Pella 818L0100 installation instructions

JR Home

JR Home RetractAway Installation instructions / warranty