3

EN

BLUEHELIX 25K 50

'XULQJWKHILUVWVHFRQGVWKHGLVSOD\DOVRVKRZVWKHFDUGVRIWZDUHYHUVLRQ

)RUWKHIROORZLQJVHFRQGVWKHGLVSOD\VKRZV)+ZKLFKLGHQWLILHVWKHKHDWLQJ

V\VWHPDLUYHQWLQJF\FOH

2SHQWKHJDVFRFNDKHDGRIWKHERLOHU

:KHQ WKH PHVVDJH )+ GLVDSSHDUV WKH ERLOHU LV UHDG\ WR RSHUDWH DXWRPDWLFDOO\

ZKHQHYHUGRPHVWLFKRWZDWHULVGUDZQRULQFDVHRIDURRPWKHUPRVWDWGHPDQG

Switching the boiler off and on

3UHVVWKHon/offEXWWRQGHWDLOILJ IRUVHFRQGV

fig. 7 - Switching the boiler off

:KHQWKHERLOHULVVZLWFKHGRIIWKHHOHFWURQLFERDUGLVVWLOOSRZHUHG'RPHVWLFKRWZDWHU

DQGKHDWLQJDUHGLVDEOHG7KHDQWLIUHH]HV\VWHPUHPDLQVDFWLYDWHG7RVZLWFKWKHERLOHU

RQSUHVVWKHon/offEXWWRQGHWDLOILJ DJDLQIRUVHFRQGV

fig. 8

7KHERLOHUZLOOEHLPPHGLDWHO\UHDG\WRRSHUDWHZKHQHYHUGRPHVWLFKRWZDWHULVGUDZQ

RULQFDVHRIDURRPWKHUPRVWDWGHPDQG

B7KHDQWLIUHH]HV\VWHPGRHVQRWZRUNZKHQWKHSRZHUDQGRUJDVWRWKHXQLWDUH

WXUQHGRII7RDYRLGGDPDJHFDXVHGE\IUHH]LQJGXULQJORQJVKXWGRZQVLQZLQ

WHULWLVDGYLVDEOHWRGUDLQDOOZDWHUIURPWKHERLOHUWKH'+:FLUFXLWDQGWKH

KHDWLQJV\VWHPZDWHURUGUDLQMXVWWKH'+:FLUFXLWDQGDGGDVXLWDEOHDQWL

IUHH]HWRWKHKHDWLQJV\VWHPDVSUHVFULEHGLQVHF

2.4 Adjustments

Summer/Winter Switchover

3UHVVWKHsummer/winterEXWWRQGHWDLOILJ IRUVHFRQGV

7KHGLVSOD\DFWLYDWHVWKH6XPPHUV\PEROGHWDLOILJ WKHERLOHUZLOORQO\GHOLYHU

GRPHVWLFKRWZDWHU7KHDQWLIUHH]HV\VWHPUHPDLQVDFWLYDWHG

7R GHDFWLYDWH WKH6XPPHU PRGH SUHVV WKH summer/winter EXWWRQ GHWDLO ILJ

DJDLQIRUVHFRQGV

Heating temperature adjustment

8VHWKHKHDWLQJEXWWRQVGHWDLOVDQGILJ WRDGMXVWWKHWHPSHUDWXUHIURPDPLQRI

&WRDPD[RI&

fig. 9

DHW temperature adjustment

8VHWKH'+:EXWWRQVGHWDLOVDQGILJ WRDGMXVWWKHWHPSHUDWXUHIURPDPLQLPXP

RI&WRDPD[LPXPRI&

fig. 10

Room temperature adjustment (with optional room thermostat)

8VLQJWKHURRPWKHUPRVWDWVHWWKHWHPSHUDWXUHUHTXLUHGLQWKHURRPV,IWKHURRPWKHU

PRVWDWLVQRWLQVWDOOHGWKHERLOHUZLOONHHSWKHV\VWHPDWWKHVHWV\VWHPGHOLYHU\VHWSRLQW

WHPSHUDWXUH

Room temperature adjustment (with optional remote timer control)

8VLQJWKHUHPRWHWLPHUFRQWUROVHWWKHUHTXLUHGWHPSHUDWXUHLQWKHURRPV7KHERLOHUZLOO

DGMXVWWKHV\VWHPZDWHUDFFRUGLQJWRWKHUHTXLUHGURRPWHPSHUDWXUH)RURSHUDWLRQZLWK

UHPRWHWLPHUFRQWUROSOHDVHUHIHUWRWKHUHOHYDQWLQVWUXFWLRQPDQXDO

Hot water tank exclusion (economy)

+RWZDWHUWDQNWHPSHUDWXUHPDLQWDLQLQJKHDWLQJFDQEHH[FOXGHGE\WKHXVHU,IH[FOXG

HGGRPHVWLFKRWZDWHUZLOOQRWEHGHOLYHUHG

7KHKRWZDWHUWDQNFDQEHGHDFWLYDWHGE\WKHXVHU(&2PRGHE\SUHVVLQJWKH(&2

&20)257EXWWRQGHWDLOILJ ,Q(&2PRGHWKHGLVSOD\DFWLYDWHVWKH(&2V\PERO

GHWDLOILJ 7RDFWLYDWH&20)257PRGHSUHVVWKH(&2&20)257EXWWRQGH

WDLOILJ DJDLQ

Sliding Temperature

:KHQWKHRSWLRQDOH[WHUQDOSUREHLVLQVWDOOHGWKHERLOHUDGMXVWPHQWV\VWHPZRUNVZLWK

6OLGLQJ7HPSHUDWXUH´,QWKLVPRGHWKHWHPSHUDWXUHRIWKHKHDWLQJV\VWHPLVFRQWUROOHG

DFFRUGLQJWRWKHRXWVLGHZHDWKHUFRQGLWLRQVWRHQVXUHKLJKFRPIRUWDQGHQHUJ\VDYLQJ

WKURXJKRXWWKH\HDU,QSDUWLFXODUWKHV\VWHPGHOLYHU\WHPSHUDWXUHLVGHFUHDVHGDVWKH

RXWVLGHWHPSHUDWXUHLQFUHDVHVDFFRUGLQJWRDVSHFLILFFRPSHQVDWLRQFXUYH´

:LWK6OLGLQJ7HPSHUDWXUHDGMXVWPHQWWKHWHPSHUDWXUHVHWZLWKWKHKHDWLQJEXWWRQVGH

WDLOILJ EHFRPHVWKHPD[LPXPV\VWHPGHOLYHU\WHPSHUDWXUH,WLVDGYLVDEOHWRVHW

DPD[LPXPYDOXHWRDOORZV\VWHPDGMXVWPHQWWKURXJKRXWLWVXVHIXORSHUDWLQJUDQJH

7KHERLOHUPXVWEHDGMXVWHGDWWKHWLPHRILQVWDOODWLRQE\TXDOLILHGSHUVRQQHO3RVVLEOH

DGMXVWPHQWVFDQLQDQ\FDVHEHPDGHE\WKHXVHUWRLPSURYHFRPIRUW

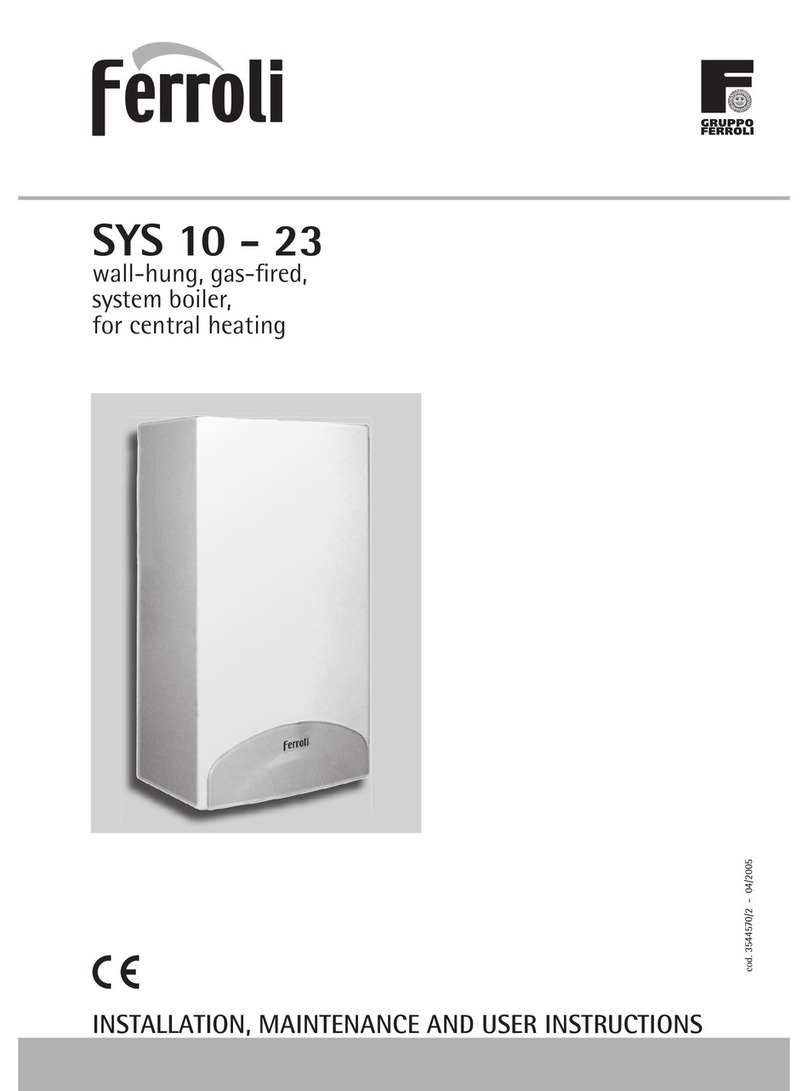

&RPSHQVDWLRQFXUYHDQGFXUYHRIIVHW

3UHVVWKHresetEXWWRQGHWDLOILJ IRUVHFRQGVWRDFFHVVWKH6OLGLQJWHPSHUDWXUH

PHQXWKHGLVSOD\VKRZV&8IODVKLQJ

8VHWKH'+:EXWWRQVGHWDLOILJ WRDGMXVWWKHFXUYHIURPWRDFFRUGLQJWRWKH

FKDUDFWHULVWLF%\VHWWLQJWKHFXUYHWRVOLGLQJWHPSHUDWXUHDGMXVWPHQWLVGLVDEOHG

3UHVVWKHKHDWLQJEXWWRQVGHWDLOILJ WRDFFHVVSDUDOOHOFXUYHRIIVHWWKHGLVSOD\

VKRZV2)IODVKLQJ8VHWKH'+:EXWWRQVGHWDLOILJ WRDGMXVWWKHSDUDOOHOFXUYH

RIIVHWDFFRUGLQJWRWKHFKDUDFWHULVWLFILJ

3UHVVWKHresetEXWWRQGHWDLOILJ DJDLQIRUVHFRQGVWRH[LWWKH6OLGLQJ7HPSHU

DWXUHPHQX

,IWKHURRPWHPSHUDWXUHLVORZHUWKDQWKHUHTXLUHGYDOXHLWLVDGYLVDEOHWRVHWDKLJKHU

RUGHUFXUYHDQGYLFHYHUVD3URFHHGE\LQFUHDVLQJRUGHFUHDVLQJLQVWHSVRIRQHDQG

FKHFNWKHUHVXOWLQWKHURRP

fig. 11 - Example of compensation parallel curve offset

Adjustments from Remote Timer Control

A,IWKH5HPRWH7LPHU&RQWURORSWLRQDOLVFRQQHFWHGWRWKHERLOHUWKHDERYHDG

MXVWPHQWVDUHPDQDJHGDFFRUGLQJWRWKDWJLYHQLQWDEOH

Table. 1

System water pressure adjustment

7KHILOOLQJSUHVVXUHUHDGRQWKHERLOHUZDWHUJDXJHZLWKWKHV\VWHPFROGPXVWEHDSSUR[

EDU,IWKHV\VWHPSUHVVXUHIDOOVWRYDOXHVEHORZPLQLPXPWKHERLOHUVWRSVDQGIDXOW

F37LVGLVSOD\HG

2QFHWKHV\VWHPSUHVVXUHLVUHVWRUHGWKHERLOHUZLOODFWLYDWHWKHVHFRQGDLUYHQWLQJ

F\FOHLQGLFDWHGRQWKHGLVSOD\E\FH.

0

1

4

2

3

0

1

4

2

3

0

1

4

2

3

0

1

4

2

3

Heating temperature setting

$GMXVWPHQWFDQEHPDGHIURPWKH5HPRWH7LPHU&RQWUROPHQX

DQGWKHERLOHUFRQWUROSDQHO

DHW temperature adjustment

$GMXVWPHQWFDQEHPDGHIURPWKH5HPRWH7LPHU&RQWUROPHQX

DQGWKHERLOHUFRQWUROSDQHO

Summer/Winter Switchover

6XPPHUPRGHKDVSULRULW\RYHUDSRVVLEOH5HPRWH7LPHU&RQWURO

KHDWLQJGHPDQG

Eco/Comfort selection

2QGLVDEOLQJ'+:IURPWKH5HPRWH7LPHU&RQWUROPHQXWKH

ERLOHUVHOHFWVWKH(FRQRP\PRGH,QWKLVFRQGLWLRQWKH

eco/com-

fort

EXWWRQGHWDLOILJ RQWKHERLOHUSDQHOLVGLVDEOHG

2QHQDEOLQJ'+:IURPWKH5HPRWH7LPHU&RQWUROPHQXWKH

ERLOHUVHOHFWVWKH&RPIRUWPRGH,QWKLVFRQGLWLRQLWLVSRVVLEOH

VHOHFWRQHRIWKHWZRPRGHVZLWKWKH

eco/comfort

EXWWRQGHWDLO

ILJ RQWKHERLOHUSDQHO

Sliding Temperature

%RWKWKH5HPRWH7LPHU&RQWURODQGWKHERLOHUFDUGPDQDJH6OLG

LQJ7HPSHUDWXUHDGMXVWPHQWWKHERLOHUFDUG6OLGLQJ7HPSHUDWXUH

KDVSULRULW\

20

30

40

50

60

70

80

90

85

20

30

40

50

60

70

80

90

85

1

2

3

4

5

6

8910 7

1

2

3

4

568910 7

OFFSET = 20 OFFSET = 40

cod. 3541F704 - Rev. 00 - 12/2018