FESTA 28032 Instruction manual

1

Manual for use

Item number: 28032

Please read this manual carefully before using.

2

3

Technical specification

Item

Cordless angle grinder

Max. wheel diameter

115mm

Speed without load

8000min-1

Max. battery voltage

20V

Spindle thread size

M14

Max. thickness of cut material

15mm

Weight without battery

1,6kg

Protection marking

IPX0

Sound pressure level, uncertainty K

LpA= 76,67dB(A), K= 3dB(A)

Sound power level, uncertainty K

LwA= 87,67dB(A), K= 3dB(A)

Vibration during surface grinding

ah.AG= 5,324m/s2;K= 1,5m/s2

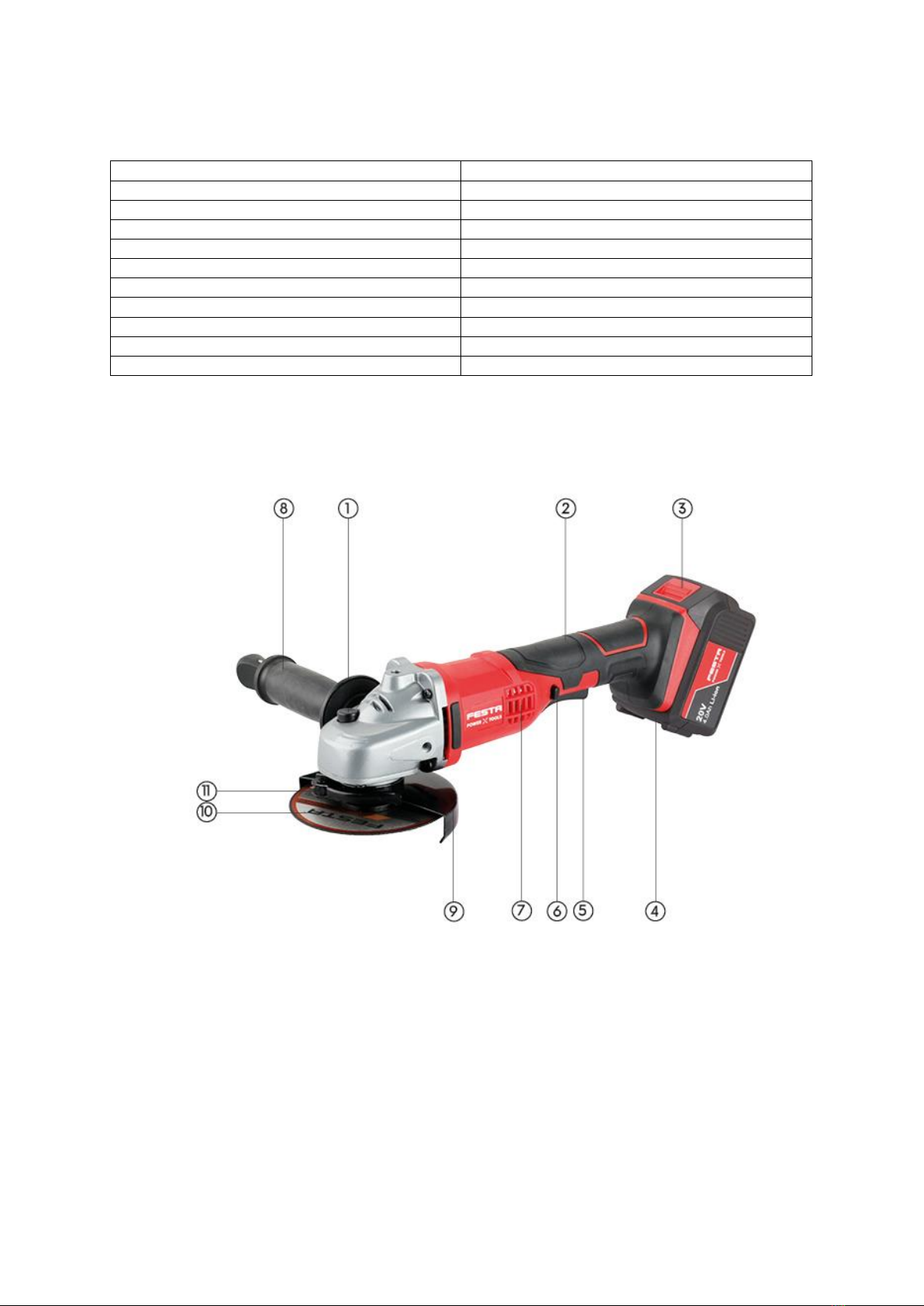

Components and controls

1) Spindle rotation lock button for tool change

2) Handle

3) Battery release button

4) Button for checking the battery charge level with leds

5) Trigger

6) Button for unlocking the operating switch

7) Engine vents

8) Front handle

9) Protective cover

10) Washer with disc clamping nut

11) Lever of the quick-release mechanism of the protective cover

4

Charging the battery

APPROXIMATE CHARGE TIMES WITH CHARGERS

4000 mAh

4 A quick charger (28086)

55 min.

2,4 A quick charger (28085)

90 min.

2000 mAh

4 A quick charger (28086)

30 min.

2,4 A quick charger (28085)

45 min.

WARNING

Before preparing and using the cordless tool for use, read the entire instruction manual and keep

it with the product so that the operator can familiarize himself with it.

If you lend or sell the product to anyone, enclose this instruction manual with it. Avoid damaging

this manual. The manufacturer is not liable for damages or injuries caused by using the device,

which is in conflict with these instructions. Before using the appliance, familiarize yourself with all

its controls and components, as well as how to switch off the appliance, so that you can switch it

off immediately in the event of a dangerous situation. Before use, check that all components are

securely fastened and that any part of the device, such as the safety guards, is not damaged,

incorrectly installed or missing in place. This also applies to the charger and its power cord. If the

cordless tool, battery or charger is damaged or incomplete, do not use it and have it repaired or

replaced with original parts.

To check the battery charge level, press the button on the battery and, if necessary, charge the

battery according to the number of LEDs and the expected operating time of the cordless tool.

When the battery is fully charged, all LEDs are lit. The battery can be charged from any charge

level without reducing its capacity.

1. Insert the battery into the slots of the supplied charger first.

2. Before connecting the charger to a power source. current, check that the voltage in

the socket corresponds to the range 220-240 ~ 50 Hz and that the charger does not

have a damaged power cable (eg insulation) or cover or other part.

If the charger is damaged, have it replaced by a faultless original one from the manufacturer. Only

the original charger provided by the manufacturer must be used to charge the battery, otherwise

the use of another charger may cause a fire or explosion due to unsuitable charging parameters.

Protect the charger's power cord from damage.

3. Connect the charger to a wall outlet. current.

For 28085/28086 chargers

•when in charging process, it is indicated by a green flashing LED next to the red LED.

•when full charging, it is indicated only by a green LED on.

•when in abnormal charging process, it is indicated by both green and red flashing LED.

•The charge level of the battery can be monitored by the number of lit LEDs on the battery

that light up when the battery is being charged. We reserve the right to change the above

signaling of the charging and recharging process.

5

4. After charging, first disconnect the charger from the power source. power, and then

slide the battery out of the charger slots by pressing and holding the button on the

battery.

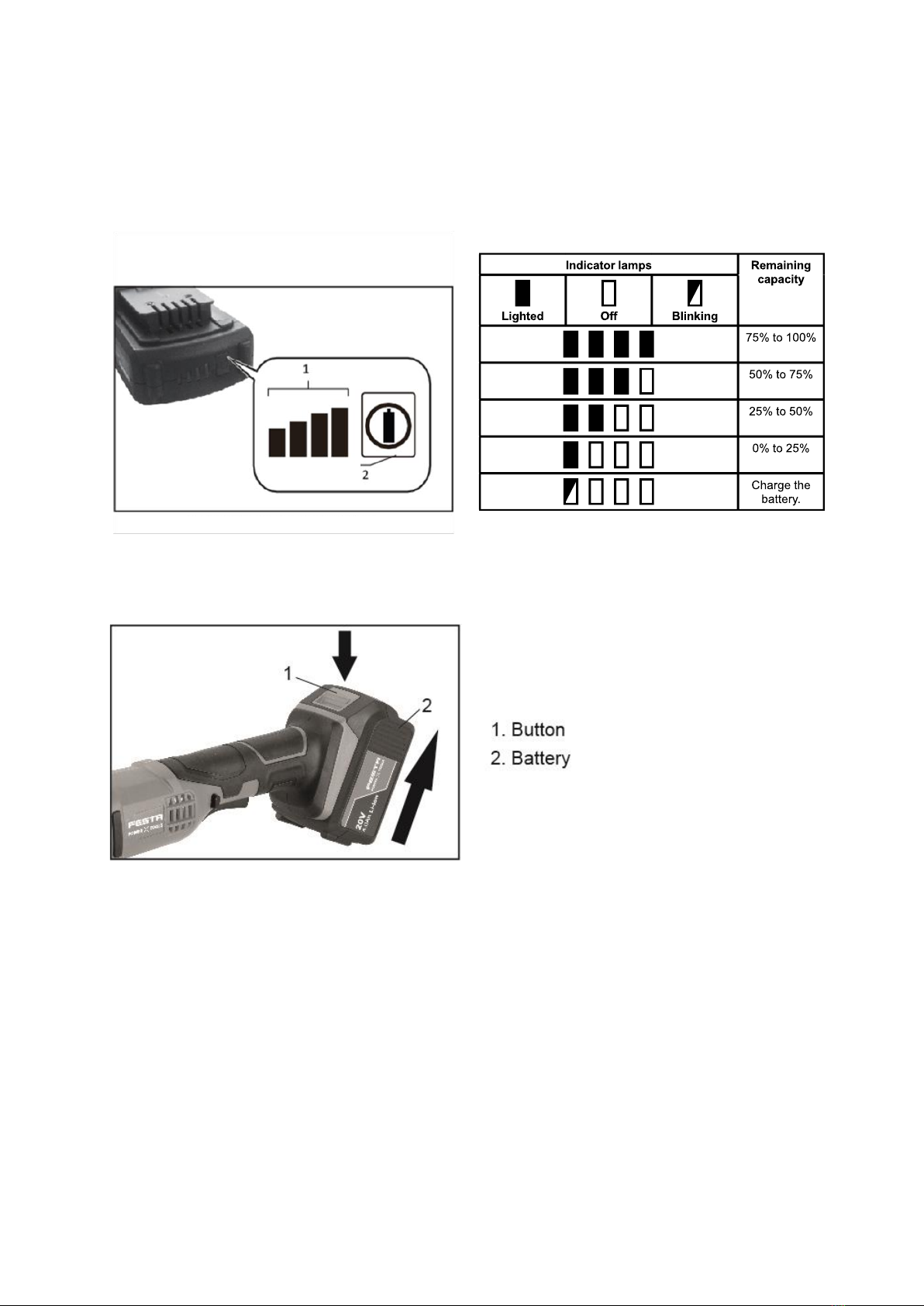

Description of battery functions

Display of remaining battery capacity

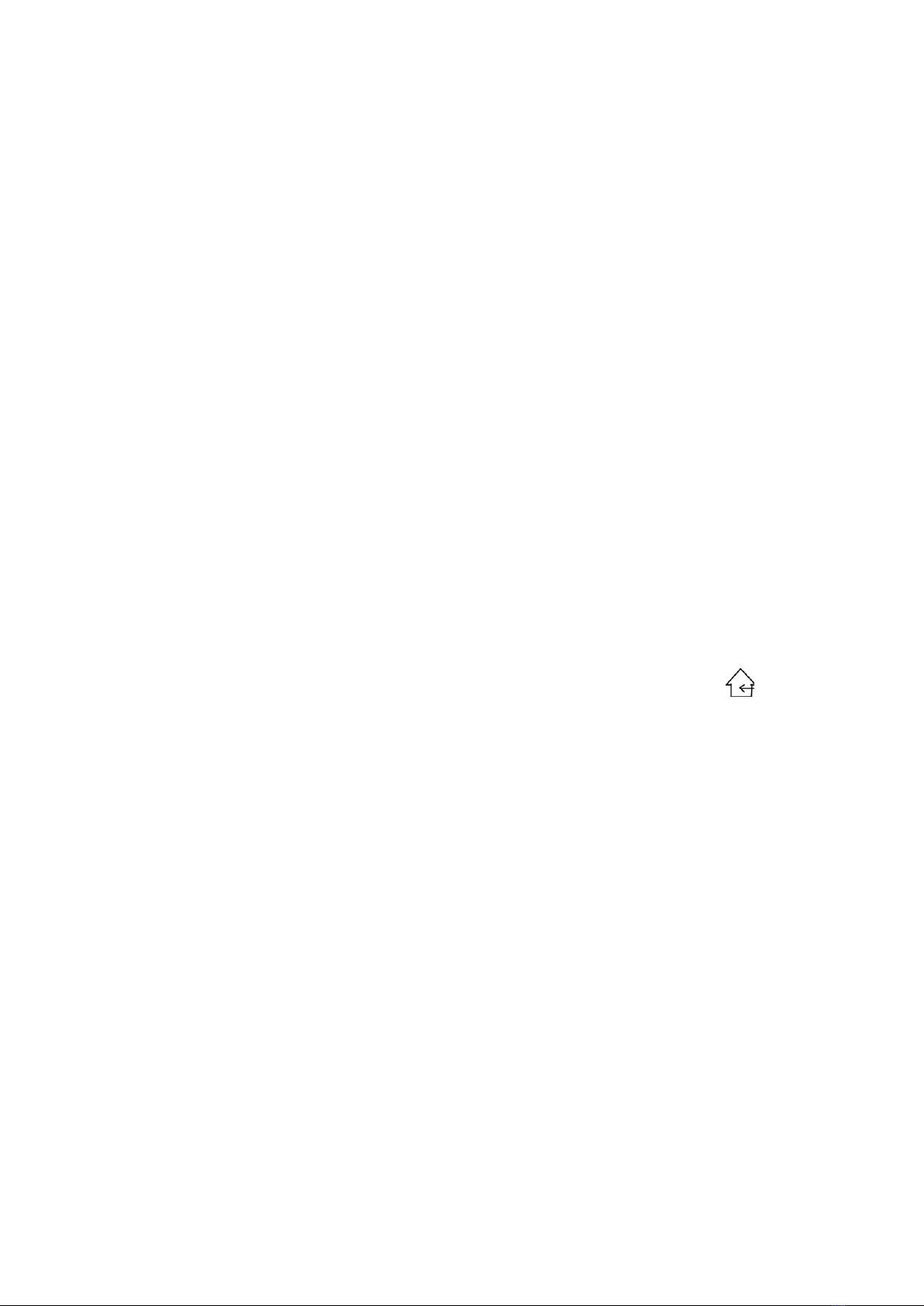

Attaching or removing the battery

6

Use

•Install the protective cover, handle and disc with the battery removed from the grinder!

INSTALLATION OF THE ADDITIONAL (FRONT) HANDLE

•The angle grinder must not be used without the front handle installed.

•Screw the frontauxiliary handle into the corresponding holes on the grinder body according

to the type of activity performed.

•To cut, screw it into the hole on the right or left side of the grinder, depending on whether

you are right-handed or left-handed.

When using a surface grinding machine, screw the handle into the hole at the top of the

grinder.

PROTECTIVE COVER INSTALLATION

•Install a protective cover on the neck of the angle grinder, which must be oriented so that

the cutting cover points towards the operator during cutting and protects the user from

possible flying fragments of material or discs and sparks. Place the metal protrusion on the

guard sleeve into the notch on the neck of the grinder so that the protrusion can be placed

in the groove on the neck, and then turn the guard with the protrusion in the groove into

position.

•Then lower the lever of the quick-release mechanism and secure the protective cover on

the neck of the grinder by screwing in the nut with a suitable mounting tool. Screw in the

nut so that the protective cover is well secured and also so that the lever of the quick-

release mechanism can be openedwithout loosening the nut if the positionof the protective

cover needs to be changed. If the quick release lever cannot be opened, loosen the nut no

more than necessary.

DISC INSTALLATION / REPLACEMENT

1. Place a washer on the grinder spindle so that it fits into the notches of the spindle and

rotates with it. Make sure it is seated correctly with your hand.

2. Place the disc on the washer.

•If the blade has a cup-shaped bend, the blade must be seated on the spindle so that the

blade bend is on the pad

3. Screw the outer clamping nut onto the grinder spindle.

4. To fasten a thicker (grinding) wheel with a maximum thickness of 6 mm, screw the outer

clamping nut to the side with the raised ring towards the wheel. To fasten the thin (cutting)

blade, screw the clamping nut towards the blade to the side without the protruding ring.

INSTALLATION OF PERMITTED ACCESSORIES ON THE GRINDING SPINDLE

•If the angle grinder is to be used with an M14 threaded accessory (eg wire brush, sanding

pad holder), first screw the lower washer from the spindle and unscrew the clamping nut

and then screw the required accessory onto the spindle by hand before screwing this

accessory onto the grinder spindle.

•The accessory must be designed for use with an angle grinder, and its maximum permitted

speed (marked on the accessory) must not be lower than the speed of the angle grinder

during no-load operation (indicated on the grinder label). The fact that the accessories can

7

be screwed onto the grinder spindle is not yet a prerequisite for safe work with the tool.

•Accessories with a larger diameter than specified in the technical data table must not be

installed on the angle grinder spindle. Under no circumstances may the protective cover be

removed in order to use accessories larger than the permitted diameter!

INSERTING THE BATTERY INTO THE ANGLE GRINDING MACHINE HANDLE

•Insert the battery into the handle of the angle grinder of the grinder so that it clicks.

USING ANGLE BATTERY

CUTTING WITH CUTTING WHEELS

1. When cutting, the grinder must be held perpendicular to the plane of the material to be cut

throughout the cut and must not be tilted to the sides. The grinder is not intended for liquid-

cooled cutting.

2. When cutting, the workpiece must be firmly secured with suitable clamping means, and

when cutting longer workpieces, the workpiece must be supported on both sides near the

cutting point so that the blade cannot be trapped inside the cut.

3. When circumferential grinding using grinding wheels (max. Thickness 6 mm) or cutting with

a cutting wheel, prevent the wheel from bouncing on the workpiece.

FLAT GRINDING

•For surface grinding, screw the additional handle into the hole on the "back" of the grinder.

•

ground plane.

•When sanding flat (using lamellar discs or sandpaper with attachment to the carrier disc),

do not apply excessive pressure to the grinder, the effect of the tool's own weight is

sufficient. Guide the grinder in a circular motion over the surface of the ground material.

BRUSHING WITH WIRE BRUSHES

•When brushing with wire brushes, do not apply pressure to the brush, as this will reduce

work efficiency, speed up brush wear and put too much strain on the grinder. When using

potted wire .

SAFETY INSTRUCTIONS FOR ANGLE BATTERY GRINDING MACHINE

SAFETY INSTRUCTIONS FOR ALL WORK ACTIVITIES

•Safety instructions common to grinding, surface grinding, wire brushing or abrasive cutting

work

1. This electromechanical tool is intended for use as a grinder, surface grinder, wire brush

grinder or cutting tool. All safety warnings, instructions, illustrationsand specifications given

for this electromechanical tool must be read. Failure to follow all instructions below may

result in electric shock, fire and / or serious injury.

2. It is not recommended to performwork activities such as polishing with this tool. Performing

work for which this tool is not intended can create a risk and cause personal injury.

3. Accessories that are not explicitly designed and recommended by the tool manufacturer

must not be used. The mere fact that an accessory can be connected to your tool does not

8

guarantee its safe operation.

4. The rated speed of the accessory must be at least equal to the maximum speed marked

on the tool. Accessories that operate at speeds higher than their rated speed may break

and fall apart.

5. The outer diameter and thickness of the accessories must be within the nominal range for

the electromechanical tool. Accessories of the wrong size cannot be adequately

protected or controlled.

6. The threaded attachment of the accessory must match the thread on the grinder spindle.

The clamping hole of the accessory, which is mounted on the flanges, must be suitable for

the defining diameter of the flange. Accessories that do not match the mountingdimensions

of the power tool will be unbalanced, may vibrate excessively, and may cause loss of

control.

7. 2. Damaged accessories must not be used. Before each use, check the accessories: for

grinding wheels, chips and cracks, for backing pads, cracks, tears or excessive wear, for

wire brushes, loose or cracked wires. If the accessory or tool has been dropped, check for

damage or install an undamaged accessory. After checking and fitting the accessory, the

operator and bystanders must stand so that they are out of the plane of the rotating

accessory and the tool must be idle at maximum speed for one minute. During this trial

period, damaged accessories will usually break or disintegrate.

8. Personal protective equipment must be used. Depending on the application, a face shield

or safety goggles must be worn. A dust mask, hearing protection, gloves and a work apron

capable of retaining small fragments of abrasive or workpiece must beused to a reasonable

extent. Eye protection must be able to contain flying debris that is generated during various

work activities. The dust mask or respirator must be able to filter out particles that are

formed during the activity. Prolonged exposure to high-intensity noise can cause hearing

loss.

9. Bystanders must remain at a safe distance from the work area. Everyone entering the work

area must use personal protective equipment. Fragments of the workpiece or damaged

accessories can fly off and cause injuries even outside the immediate work area.

10. When performing an operation where themachine toolmay touch a hidden guide or its own

supply, the power tool must only be held by insulated gripping surfaces. Contact of the

machine tool with a "live" wire can cause the non-insulated metal parts of the power tool to

become "live" and can lead to electric shock to the user.

11. 2. The flexible feed must be located out of reach of the rotating tool. If the operator loses

control, the moving lead may be cut or reground, and the operator's hand or arm may be

drawn into the rotating tool.

12. Electromechanical tools must never be setdown untilthe tool has come to a complete stop.

The rotating tool can catch on the surface and pull the tool out of the operator's control.

13. Electromechanical tools must never be started during transport on the operator's side. If

the tool is accidentally touched, it may hook on the operator's clothing and pull on the body.

14. The air vents of the tool must be cleaned regularly. The motor fan draws dust into the

housing, and excessive accumulation of metal dust can cause electrical hazards.

15. Electromechanical tools must not be used near flammable materials. These materials could

ignite from sparks.

16. Accessories that require liquid cooling must not be used. Use of water or other coolants

can cause electric shock or death.

9

ADDITIONAL SAFETY INSTRUCTIONS FOR ALL WORK ACTIVITIES

REVERSE AND RELATED WARNINGS

1. Kickback is a sudden reaction to a pinch or jam of a rotating disc, backing pad, brush, or

other accessory. Clamping or jamming will cause the rotating tool to stop abruptly, which in

turn will cause the uncontrolled tool to move in the opposite direction to the direction of

rotation of the tool at the point of jamming. For example, if a grinding wheel is pinched or

jammed in a workpiece, the edge of the wheel that enters the clamping point may penetrate

the surface of the material and cause the wheel to be pushed up or thrown. The blade can

either jump towards or away from the operator, depending on the direction of movement of

the blade at the jamming point. Grinding wheels can also break in these cases.

2. Kickbackistheresultofimproperuseofelectromechanicaltoolsand/orincorrectoperating

procedures or conditions and can be prevented by proper compliance with the safety

precautions described below.

3. The tool must be held firmly and the correct position of the body and arms must be

maintained so that it can withstand the forces of kickback. An auxiliary handle, if equipped,

must always be used for maximum control over kickback or reaction torque when starting

the machine. The operator is able to check the reaction torques and kickback forces if he

observes the correct safety precautions.

4. The hand must never come close to the rotating tool. The tool can throw the operator's

hand away.

5. It must not stand in an area where the tool can get in the event of a kickback. The kickback

throws the tool in the direction opposite to the direction of the blade movement at the

jamming point.

6. Special attention must be paid to machining corners, sharp edges, etc. It is necessary to

prevent bouncing and jamming of the tool. Corners, sharp edges or bouncing tend to jam

the rotating tool and cause loss of control or kickback.

7. The saw chain saw blade or toothed saw blade must not be attached to the tool. These

discs often cause kickback and loss of control.

ADDITIONAL SAFETY INSTRUCTIONS FOR GRINDING AND CUTTING WORK

ACTIVITIES

SAFETY WARNINGS SPECIFIC TO WORKING ACTIVITIES GRINDING AND

ABRASIVE CUTTING:

1. Use only the types of blades recommended for this electromechanical tool and the specific

guard that is designed for the selected blade. Discs for which the electromechanical tool

was not designed cannot be adequately covered and are dangerous.

2. The grinding surface of the discs, which are lowered in the middle, must be mounted below

the plane of the edge of the protective cover. An incorrectly mounted disc that protrudes

beyond the plane of the edge of the guard cannot be adequately protected.

3. The guard must be securely attached to the power tool and positioned for maximum safety

so that as little of the blade as possible is exposed in the direction of operation.

4. A protective cover helps protect the operator from blade debris, accidental contact with the

blade, and sparks that can ignite clothing.

5. The discs must only be used for their intended use. For example: grinding with the side of

the cutting disc is not permitted. Abrasive cutting discs are designed for circumferential

cutting, lateral forces acting on these discs could shatter them.

6. Undamaged disc flanges that are the correct size and shape for the selected disc must

always be used. Proper blade flanges support the blade, reducing the possibility of blade

10

breakage. Flanges for cutting wheels may differ from flanges for grinding wheels.

7. Wear discs of originally larger dimensions intended for larger electromechanical tools must

not be used. Discs designed for larger electromechanical tools are not suitable for higher

speeds of smaller tools and may break.

ADDITIONAL SAFETY INSTRUCTIONS FOR CUTTING ADDITIONAL SAFETY

WARNINGS SPECIFIC TO ABRASIVE CUTTING OPERATIONS:

1. The cutting disc must not be driven into the material or subjected to excessive pressure.

No effort should be made to achieve excessive depth of cut. Overloading the blade

increases the load and susceptibility to twisting or jamming of the blade in the cut and the

possibility of kickback or cracking of the blade.

2. Do not stand in line with or behind the rotating disc. As soon as the blade moves away from

the operator's body at the working point, a possible kickback may throw the rotating blade

and electromechanical tools directly at the operator.

3. If the blade jams or cutting is interrupted for any reason, the electromechanical tool must

be turned off and held still until the blade comes to a complete stop. The operator must

never attempt to remove the cutting blade from the cut while the blade is in motion, as

kickback may occur. It is necessary to check the situation and arrange a remedy to avoid

jamming the blade.

4. Cutting in the workpiece must not be restarted. The blade is allowed to reach full speed

and is carefully re-inserted into the cut. If the tool is restarted with the blade submerged in

the cut, it may jam, be pushed up, or kickback.

5. Panels and other large pieces of workpieces must be supported to reduce the risk of

jamming the disc and kickback. Large workpieces tend to sag under their own weight. The

supports must be placed under the workpiece near the cutting line and near the edges of

the workpiece on both sides of the blade.

6. Special care must be taken when making a "cavity cut" into existing walls or other blind

spaces. A penetrating blade can cut through gas or water pipes, electrical lines or objects

that can cause kickback.

ADDITIONAL SAFETY INSTRUCTIONS FOR FLAT GRINDING WORK ACTIVITIES

SAFETY WARNING SPECIFIC TO WORKING FLAT GRINDING WORK

ACTIVITIES:

1. Do not use oversized sandpaper for the grinding wheel. When choosing sanding paper, it

is necessary to follow the manufacturer's recommendations. Large sanding paper that

extends beyond the sanding plate poses a risk of tearing and can cause jams, wheel tears

or kickback.

ADDITIONAL SAFETY INSTRUCTIONS FOR WIRE BRUSH GRINDING WORK

ACTIVITIES SAFETY WARNINGS SPECIFIC TO WIRE BRUSH GRINDING WORK

ACTIVITIES:

1. Even during normal operation, wire bristles are thrown from the brush. The wires must not

be overloaded above the specific load of the brush. Wire bristles can easily penetrate light

clothing and / or skin.

2. If the use of a protective cover is recommended for grinding with a wire brush, ensure that

there is no contact between the wire wheel or brush and the protective cover.

•The wire disc or brush may increase in diameter when working due to loads and centrifugal

forces.

11

General safety instructions for power tools

CAUTION!

All safety instructions, operating instructions, pictures and regulations supplied with this

tool must be read. Failure to follow all of the following instructions may result in electric shock,

fire, and / or serious personal injury.

All instructions and instructions for use must be kept for future reference.

The term "power tool" in all of the following warnings refers to a mains-operated (flexible power

supply) or a battery-powered power tool (without a movable power supply).

1. SAFETY OF THE WORK ENVIRONMENT

a) Workplaces must be kept clean and well lit. Clutter and dark spaces are often the cause

of accidents.

b) Power tools must not be used in potentially explosive atmospheres where flammable

liquids, gases or dust are present. Power tools create sparks which may ignite the dust

or fumes.

c) When using a power tool, keep out of the reach of children and others. If the operator

is disturbed, he may lose control of the activity being performed.

2. ELECTRICAL SAFETY

a) The plug of the power tool's flexible lead must match the power outlet. The forks

must never be modified in any way. No socket adapters may be used with tools that

have a protective earth connection. Plugs that are not damaged by modifications and

the corresponding sockets will reduce the risk of electric shock.

b) Operators must not touch grounded objects, such as pipes, central heating units,

cookers and refrigerators. The risk of electric shock is greater if your body is connected

to the ground.

c) Power tools must not be exposed to rain, moisture or wetness. If water enters the

power tool, the risk of electric shock increases.

d) The flexible supply must not be used for other purposes. The power tool must not

be carried or pulled by the power cord, nor must the plug be unplugged from the

outlet. The inlet must be protected from heat, grease, sharp edges or moving parts.

Damaged or tangled leads increase the risk of electric shock.

e) If the power tool is used outdoors, an extension cord suitable for outdoor use must

be used. Using an extension cord for outdoor use reduces the risk of electric shock.

f) If the power tool is used in humid areas, a RCD protected power supply must be

used. Using an RCD reduces the risk of electric shock. The term "RCD" may be replaced

by "main circuit breaker (GFCI)" or "leakage circuit breaker (ELCB)".

3. PERSONAL SAFETY

a) When using a power tool, the operator must be careful, pay attention to what he is

doing, and concentrate and think soberly. Power tools must not be used if the

operator is tired or under the influence of drugs, alcohol or medication. Momentary

inattention while using a power tool can result in serious personal injury.

b) Use personal protective equipment. Always wear eye protection. Protective equipment

such as a respirator, non-slip safety shoes, hard headgear or hearing protection, used in

accordance with the working conditions, reduces the risk of personal injury.

c) Unintentional starting of the machine must be avoided. Make sure that the switch is

12

in the off position before plugging in and / or connecting the battery pack, lifting or

carrying the tool. Carrying a tool with your finger on the switch or plugging in a tool fork

with the switch on can cause accidents.

d) All adjusting tools or wrenches must be removed before turning on the tool. An

adjusting tool or wrench that remains attached to the rotating part of the power tool may

result in personal injury.

e) The operator must only work where he can reach safely. The operator must always

maintain a stable posture and balance. This will allow better control of the power tool in

unforeseen situations.

f) Dress appropriately. Do not wear loose clothing or jewelry. The operator must make

sure that hishair and clothing are far enough away from moving parts. Loose clothing,

jewelry and long hair can be caught in moving parts.

g) Where means are provided for the connection of dust extraction and collection

facilities, care shall be taken to ensure that such equipment is connected and used

correctly. The use of these devices can reduce the hazards caused by dust.

h) The operator must not allow the routine, which is based on the frequent use of the

tool, to become complacent and ignore the principles of tool safety. Careless

operation can cause serious injury in a fraction of a second.

4. USE AND MAINTENANCE OF BATTERY TOOLS

a) Power tools must not be overloaded. It is necessary to use the correct power tool

that is intended for the work performed. The right power tool will do the job it was

designed to do better and safer.

b) Power tools that cannot be turned on and off with the switch must not be used. Any

power tool that cannot be operated with the switch is dangerous and must be repaired.

c) Before making any adjustments, changing accessories or storing power tools,

unplug the power tool and / or remove the battery pack from the power tool, if

removable. These precautions reduce the risk of accidental starting of the power tool.

d) Unused power tools must be stored out of the reach of children and persons

unfamiliar with the power tool or these instructions must not be allowed to use the

power tool. Power tools are dangerous in the hands of inexperienced users.

e) Power tools and accessories must be maintained. It is necessary to check the

adjustment of moving parts and their mobility, focusing on cracks, broken parts and

any other circumstances that may jeopardize the function of the power tool. If the

tool is damaged, it must be repaired before further use. Many accidents are caused by

poorly maintained power tools.

f) Cutting tools must be kept sharp and clean. Properly maintained and sharpened cutting

tools are less likely to catch on the material or become jammed and easier to control.

g) Power tools, accessories and tool bits etc. must be used in accordance with these

instructions and in the manner intended for the particular power tool, taking into

account the working conditions and the work to be performed. Using power tools for

activities other than those for which they were designed can lead to dangerous situations.

h) Handles and grip surfaces must be kept dry, clean and free of grease. Slipperyhandles

and grip surfaces do not allow the tool to be held and inspected safely in unexpected

situations.

5. USE AND MAINTENANCE OF BATTERY TOOLS

a) Charge the tool only with the charger specified by the manufacturer. A charger that

may be suitable for one type of battery pack may present a fire hazard when used with

another battery pack.

b) Only use the tool with a battery pack that is specifically designed for the tool. Use of

13

any other battery pack may present a risk of injury or fire.

c) When the battery pack is not in use, protect it from contact with other metal objects

such as paper clips, coins, keys, nails, screws, or other small metal objects that may

cause onebattery contact to connect with another. Short-circuiting the battery terminals

may cause burns or fire.

d) If used incorrectly, liquids may leak from the battery; avoid contact with them. In

case of accidental contact with these liquids, rinse the affected area with water. In

addition, seek medical attention if fluid gets in your eyes. Liquids escaping from the

battery can cause inflammation or burns.

e) A battery pack or tool that is damaged or rebuilt must not be used. Damaged or

modified batteries can behave unpredictably, which can result in fire, explosion, or risk of

injury.

f) Battery packs or tools must not be exposed to fire or excessive heat. Exposure to fire

g) All charging instructions must be followed and the battery pack or tool must not be

charged outside the temperature range specified in the operating instructions.

Improper charging or charging at temperatures outside this range may damage the battery

and increase the risk of fire.

6. SERVICE

a) Have your cordless tool repaired by a qualified person using identical spare parts.

This will ensure the same level of tool safety as before repair.

b) Damaged battery packs must never be repaired. Repairs to battery packs should only

be performed by the manufacturer or an authorized service center.

Charger safety instructions

•Protect the charger from rain and moisture. The charger may only be used indoors.

•The charger is intended for charging only the battery supplied with this cordless tool and

no other batteries. Charging batteries other than those for which the charger is intended

may result in fire or explosion.

•Keep the charger clean.

•Before each use, check that the charger is in good condition, including the power cord.

•Do not operate the charger on highly flammable objects and substrates (eg paper) or in an

environment with an explosive and / or flammable atmosphere.

•Always provide adequate ventilation when charging, as vapors or electrolyte may leak from

the battery if the battery is damaged due to mishandling / damage.

•Do not operate the charger on highly flammable objects and substrates (eg paper) or in an

environment with an explosive and / or flammable atmosphere.

•Always provide adequate ventilation when charging, as vapors or electrolyte may leak from

the battery if the battery is damaged due to mishandling / damage.

•When charging is complete, disconnect the charger from the wall outlet. do not leave it

connected to the power supply for longer than necessary.

•Avoid using the charger by persons (including children) whose physical, sensory or mental

disability or lack of experience and knowledge prevents them from using the appliance

safely without supervision or instruction. Children must not play with the appliance. In

general, the use of the appliance by very young children (age 0-3 years inclusive) and use

14

by younger children without supervision (age over 3 years under 8 years) are not taken into

account. It is recognized that people with severe disabilities may have needs outside the

level specified in this standard (EN 60335).

Battery safety instructions

•Store and charge the battery in a dry environment and make sure that no water enters it.

•Never expose the battery to direct sunlight or temperatures above 5

•Chargethebatteryonlyforthetime requiredfor charging,see.indicatorlightonthecharger.

•Keep the battery connectors clean and free from clogging, deformation and short circuits.

•Protect the battery from shocks, moisture and never open or mechanically damage the

battery.

•Never incinerate, dispose of in water or the environment, but dispose of it in an

environmentally friendly manner.

•Avoid skin contact if the battery is damaged and electrolyte leaks due to improper handling

of the battery. If skin gets on, wash thoroughly with water. Liquids leaking from the battery

can cause inflammation, burns,or burns. In case of contact with eyes, rinse thoroughly with

clean water and consult a doctor immediately, in case of ingestion consult a doctor

immediately about the procedure.

Storage

•Store cordless tools in a dry place out of the reach of children. For safety reasons, remove

the battery before storing the cordless tool. When the battery is inserted in the cordless

tool, it discharges faster. Protect the battery and tools from frost, high temperatures,

humidity and water.

15

Meaning of symbols on labels

Read the instructions before

use.

Use certified eye and ear

protection with a sufficient

level of protection.

Use certified respiratory

protection with adequate

level of protection.

Meets relevant EU

requirements.

Second class protection

equipment. Double insulation.

The charger is intended for

indoor use only. Must be

protected from rain and

moisture.

DC current/ voltage.

The socket is designed for

charging the battery with

direct current.

Fuse with indication of

current value in A.

Caution, warning, follow

instructions.

Battery recovery, see

below.

Electrical waste, see below.

Do not expose the battery to

direct sunlight or

temperatures above 50 .

Do not dispose of the battery

in water or the environment.

Do not incinerate the

battery.

16

Serial number including year,

month of manufacture

Waste disposal

PACKAGING

•Dispose of the packaging in the appropriate waste container.

CORDLESS POWER TOOLS

According to the European Directive (EU) 2012/19, electrical and electronic equipment

may not be disposed of as mixed waste, but it is necessary to return them for ecological

disposal to the return of electrical equipment at designated collection points. Before

returning the cordless tool, remove the battery, which must be disposed of in an

environmentally friendly manner separately. You will receive information about collection points at

the municipal office.

BATTERY

The battery contains cartridges that are dangerous for the environment, so return it to the

batteries for ecological recycling / disposal. According to the European Directive on

Accumulators and Batteries 2006/66 EC, unusable batteries must not be disposed of with

mixed waste or the environment. You will receive information about collection points at

the municipal office.

Warranty period and conditions (rights from

defective performance)

•If the buyer so requests, the seller is obliged to provide the buyer with warranty conditions

(rights from defective performance) in writing in accordance with the law.

WARRANTY AND POST-WARRANTY SERVICE

To exercise the right to warranty repair of the goods, contact the dealer from whom you purchased

the goods.

EU Declaration of Conformity

-

marked devices, based on their concept and construction, as well as the designs listed on the

market, meet the requirements of the EuropeanUnion listed below. This declaration is issued under

the sole responsibility of the manufacturer.

Subjects of declaration-product identification:

Cordless angle grinder:

28032 Cordless angle grinder

comply with the following harmonized standards, including their amending annexes, if any, by

which conformity with the following harmonization provisions is declared:

17

2006/42 ES:

EN 62841-1:2015, EN 62841-2-1:2018, EN 62841-1:2015, EN 62841-2-2:2014 cordless drills; EN

62841-1:2015, EN 62841-2-2:2014 cordless impact driver; EN 60745-1:2009, EN 60745-2-6:2010

cordless hammer; EN 60745-1:2009, EN 60745-2-3:2011 cordless angle grinder; EN 62841-

1:2015, EN 62841-2-4:2014 cordless multi-function tool; EN 62841-1:2015, EN 62841-2-5:2014

cordless circular saw; EN 62841-1:2015, EN 62841-2-4:2014, cordless sander; EN 60745-

1:2009/A11:2010, EN 60745-2-16:2010 cordless stapler; EN62841-1:2015, EN 62841-2-11:2016

cordless reciprocating saw; EN 62841-1:2015, EN 62841-2-11:2016 cordless jig saw; EN 60598-

2-5:2015 used in conjunction with EN 60598-1:2015, clause 9.2 cordless led light; EN 62841-2015,

EN 62841-2-2:2014 cordless screwdriver.

(EU) 2014/35:

EN 60335-1:2012, EN 60335-2-29:2004; EN 62233:2008 chargers

(EU) 2014/30:

EN 55014-1:2006 until 28.4.2020/ thereafter EN 55014-1:2017; EN 55014-2:1997 until 25.3.2018/

thereafter pursuant to EN 55014-2:2015; for chargers furthemore: EN 61000-3-2:2014; EN 61000-

3-3:2013;

(EU) 2011/65: EN 50581:2012

EN 62133:2013 until 14.3.2020/ thereafter EN 62133:2017, UN 38.3 battery

The completion of technical documentation 2006/42 EC and 2000/14 EC was performed by

fice at the manufacturer's address.

The technical documentation (2006/42 EC, 2000/14 EC) is available at the manufacturer's

address.

Place and date of issue of the EU declaration of conformity:

Person authorized to draw up the EU declaration of conformity on behalf of the manufacturer

(signature, name, function):

Managing director Levior s.r.o.

18

Návod k použití

32

Tento

19

20

Technické údaje

115mm

8000min-1

20V

M14

15mm

Hmotnost bez baterie

1,6kg

IPX0

; nejistota K

LpA= 76,67dB(A), K= 3dB(A)

; nejistota K

LwA= 87,67dB(A), K= 3dB(A)

ah.AG= 5,324m/s2;K= 1,5m/s2

Součásti a ovládací prvky

1)

2)

3)

4)

5)

6)

7) oru

8)

9)

10)

11)

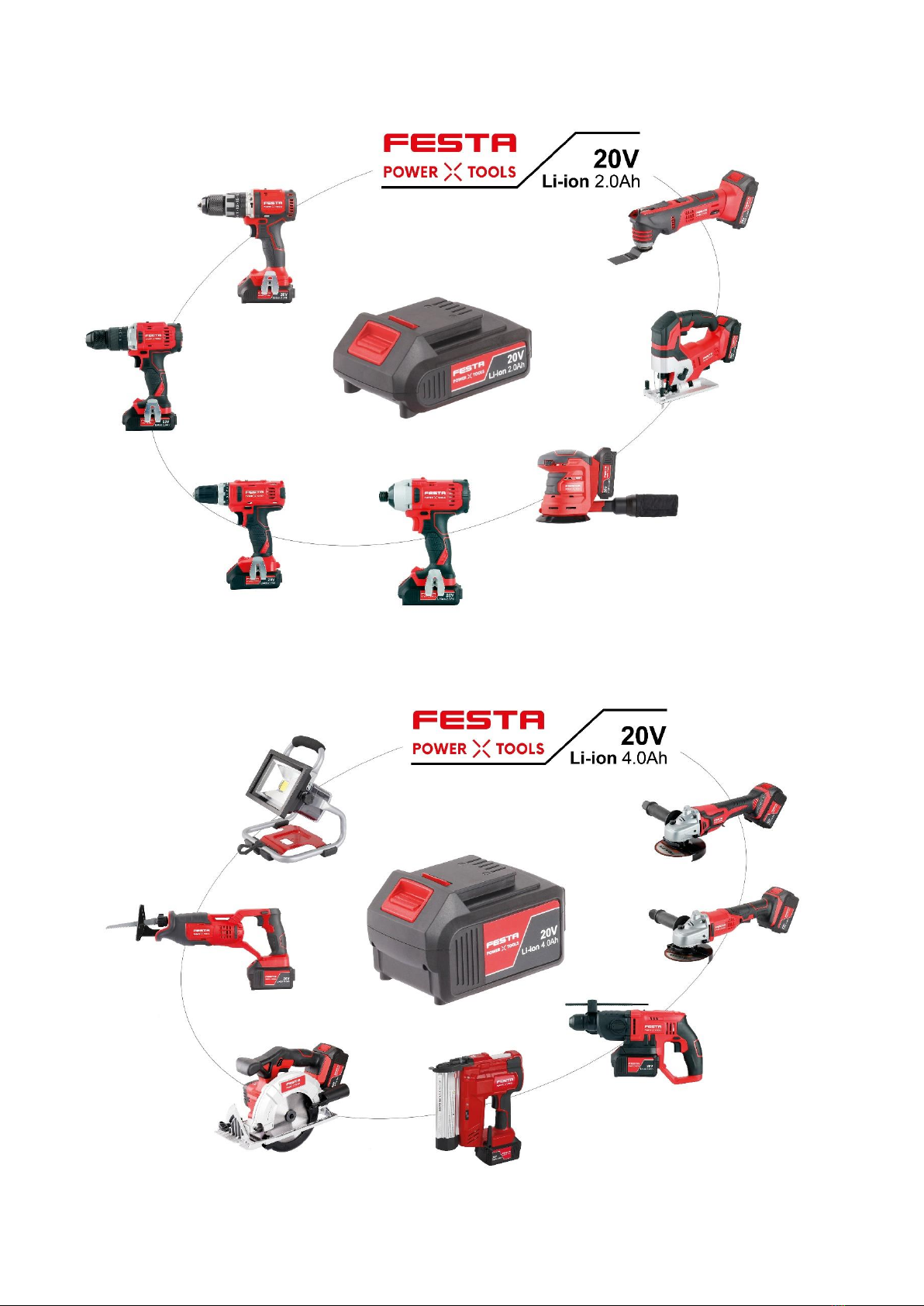

Table of contents

Other FESTA Grinder manuals