DGP 2 User manual

Document: DGP-M2 User Manual Rev: B

0

2/03

/2022

DGP-M2

AND DGP-M2-V2

MODEL 2

TUNGSTEN GRINDER

(Formerly

known as DGP-2)

USER MANUAL

Document: DGP-M2 User Manual Rev: B

0

2

/

03

/2022

TABLE OF CONTENTS

General Page

General Description 3

Vacuum System Overview 3

Specifications 3

Unpacking 4

Warranty Information 4

Safety and Operating Guidelines 4

Maintenance 5

Troubleshooting Chart 5

Mounting the DGP-M2 6

Using the Equipment

Electrode Grinding Assembly 6

The Basics 6

Operating Instructions 6

Recommended grinding times 7

Electrode Cutting Assembly 7

The Basics 7

Operating Instructions 8

Other Information

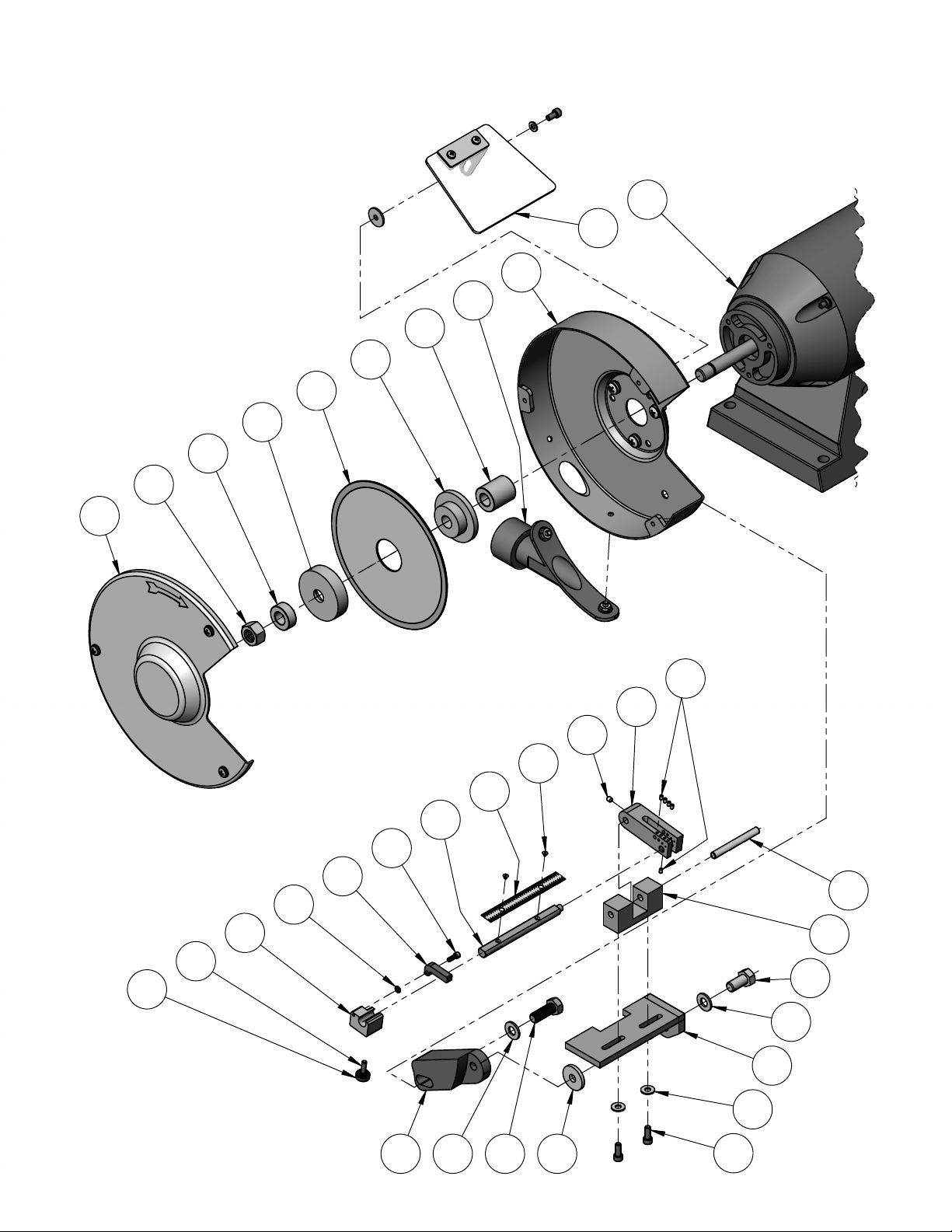

Exploded Views - Left & Right Sides 9,11

Parts Lists - Left & Right Sides 10,12

Accessories and Consumable Parts List 13

DGP-M2

& DGP-M2-V2

MODEL 2

TUNGSTEN GRINDER

(Formerly known as DGP-2)

USER MANUAL

Page 2

Document: DGP-M2 User Manual Rev: B

0

2/03

/2022

Models DGP-M2

and DGP-M2-V2

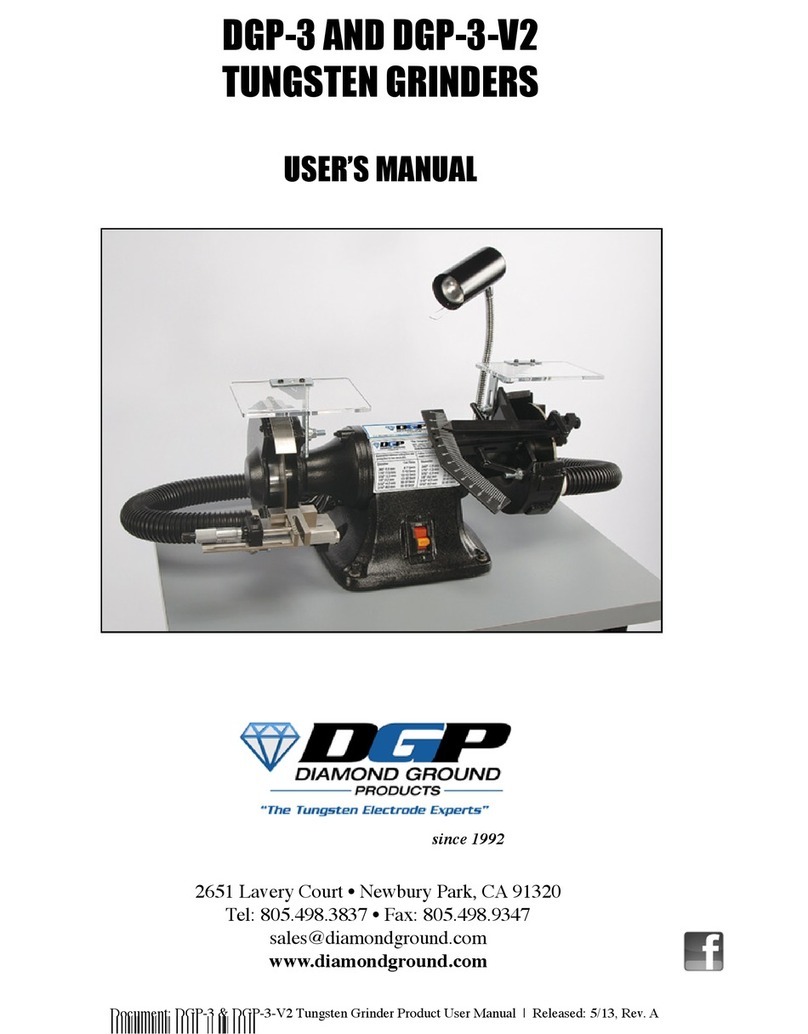

1. GENERAL DESCRIPTION

DGP-M2

Tungsten Welding Electrode Grinder is designed specifically for the longitudinal grinding of the conical or

tapered points on tungsten welding electrodes from .040’’ (1.0mm) to 3/16’’ (4.8mm) in diameter.

This model also cuts

these electrodes to

precise lengths using a

precision scale

and

an adjustable indexer block. The grinder is equipped with

a completely enclosed ball bearing motor and a rotor and shaft assembly that is dynamically balanced for vibration-free

rotation.

The

motor

housing

is

compact

and

the

unit

has

ample

side

clearance

on

the

grinding

and

cutting

wheels.

Wheel guards are secured to the shaft by threaded nuts and safety eyeshields are also included.

DGP-M2

and DGP-M2-V2 Tungsten Electrode Grinders offer precise grinding for your precision welding needs. The

DGP-M2

consists of a horizontal axis grinder that can be pedestal mounted, a diamond grinding wheel and assembly on

the

right

side,

and

a

diamond cutting

wheel

for

cutting

an

electrode

to

a

precision

length

on the left side.

The

DGP-M2-V2 adds

a

foam-insulated cabinet,

vacuum system for dust collection,

and a flexible spotlight in addition to

the

DGP-M2

features.

The DGP-M2

can be upgraded later to a DGP-M2-V2.

The

diamond

grinding

wheel

on

both

grinders

is

on

the

right

side

of

the

machine

and

the

surface

rotates

toward

the

electrode

which

provides

consistent

and

repeatable

points

from

each

grind.

The

grinding

surface

faces

right

and

the

right wheel enclosure housing supports the electrode grinding assembly in addition to a Point Flat Dresser

Block. The

location of the area of contact between the diamond grinding wheel and the tungsten electrode is

visible to the operator

at all times, which allows for excellent control of the grinding operation. After repeated use,

a groove will eventually

be

worn

into

the

wheel

at

the

contact

point.

The

contact

point

should

then

be

adjusted

downward

slightly

to

the

next

unused spot on the diamond grinding wheel. The

cutting

assembly on the left

side also provides excellent visibility and

is easy to operate.

Wheel rotation, viewed from the left end of the grinder, is

clockwise.

VACUUM SYSTEM OVERVIEW

The

DGP-M2-V2

comes

with

a

tool

cabinet

and

integrated

vacuum

system

for

the

collection

of

tungsten

dust.

This

feature

has

become

very

popular

due

to

notifications

in

the

past

few

years

about

the

danger

of

inhaling

dust

from

the

commonly

used

2%

Thoriated

tungsten,

which

is

a

known

radioactive

cancer-causing

element.

Please

contact

your

local

OSHA

office

if

you

would

like

more

information

about

this

issue.

In

addition,

we

offer

free

samples

of

non-radioactive

alternative

tungsten,

which

performs

better

in

most

applications.

Users

of

the

DGP-M2

can

later upgrade their systems to add the vacuum system if

c

hosen

later

.

It

is

impossible

to

contain

all

of

the

lightweight

dust

particles

that

deflect

quickly

off

the

wheels

from

grinding.

The vacuum system offers

a

way

of

collecting

the

majority

of

the

dust

that

is

produced

while

grinding

tungsten

electrodes.

Each

side

of the grinder

has

vacuum

holes

and

hoses

to

collect

dust.

To

maximize

the

suction

power,

use

the

valves

at

the

back

of

the

grinder

motor

to

direct

the

suction

to

the

side

you

are

using.

If

you

are

using

both

sides

at

the

same

time,

leave

both

sides

open.

However,

if

you

are

only

using

one

side,

close

the

valve

on

the

opposite

side

and

you will increase the suction power to the side you are using.

Replacement vacuum filters are in

stock

at the factory for immediate shipment.

2. SPECIFICATIONS

Motor:

1 HP 110/120 Volt, 60 Hz Standard OR 220/240 Volt, 50 Hz Optional

Wheels:

Right side:

Nickel Plated Diamond Wheel, 6’’ diameter

Left side:

Diamond Cutting Wheel, 6’’ diameter

Weight: DGP-M2:

42 lbs. / 19.05 kg in box

DGP-M2-V2:

152 lbs. / 68.9 kg on pallet

Page 3

Document: DGP-M2 User Manual Rev: B

0

2/03

/2022

3. UNPACKING

Check for shipping damage. Diamond Ground Products takes great pride in producing quality equipment. If for

some reason you find anything to be defective, please call us at: (805) 498-3837 and we will work with you to

solve the problem. The following accessories are shipped with the DGP-M2

and DGP-M2-V2 grinders:

1.

Pin Vise used to hold tungsten while grinding.

2.

Six different Hex Keys, used to make various adjustments, and one Hex Screwdriver, used to secure the

tungsten in the cutting apparatus.

3.

Collets (four of your choice)

-

used to guide the tungsten and hold it at the proper angle while grinding.

4. WARRANTY

The DGP-M2

& DGP-M2-V2 comes with a one-year warranty on parts and labor, excluding wheels that are a

consumable part that naturally wears over time. This warranty excludes abuse to the machine, dropping of the unit or

improper handling by the operator.

5. SAFETY AND OPERATING GUIDELINES

Before any work is done, read the caution below carefully. Working safely prevents accidents.

• When not in use, turn the grinder off for safety purposes and to decrease wear on the machine.

• Wear proper apparel. Do not wear loose clothing, including gloves, neckties, rings, bracelets, or other

jewelry, which

may get caught, in moving parts of the machine.

• Wear protective hair covering to contain long hair.

• Wear safety glasses and a facemask.

• Never operate power tools when tired, intoxicated, or when taking medication that may cause drowsiness.

• Work area should have sufficient lighting.

• A proper electrical outlet should be available for the tools. A three-prong plug should be plugged directly into

a three-

prong outlet. Extension cord should be the correct gauge.

• Keep visitors at a safe distance from work area.

• Always unplug grinder prior to inspection.

• Read this manual thoroughly for specific adjustments and operating procedures.

• Do not perform “make-shift” repairs. Any part that is damaged should be promptly replaced.

• Only use the

grinder for its intended purpose. Do not use it for a job it was not designed for.

• Make sure that the grinder is off before plugging it in.

• Do not apply extreme force on the tungsten while grinding. This may cause your grinder to jam or cause premature

grinding wheel wear.

• Never leave the grinder unattended. Turn the grinder off first and do not leave it until it comes to a complete stop.

• Know your grinder; learn its operation, applications, and specific limitations.

• Always unplug grinder prior to inspection.

• Read this manual thoroughly for specific adjustments and operating procedures.

• Grinding parts other than tungsten will severely decrease wheel and equipment life.

• Unplug the grinder when changing accessories, such as collets, wheel, or other replacement parts.

• Avoid accidental start-up. Make sure that the grinder is in the off position before plugging it in.

• Do not force the grinder. It will work most efficiently at the rate for which it was designed. Consult the

“Recommended

Minimum Cutting and Grinding Time for New Electrodes” sticker on the grinder to determine

optimum rate of speed.

• Use recommended accessories. Use of improper accessories may cause risk of injury of persons or accelerated wear

on

the grinder.

• Handle the tungsten and grinder correctly. Consult grinder operation procedures in this manual and handle tungsten

with pin vise whenever possible to protect hands from possible injury.

• Feed tungsten into grinding wheel against the direction of rotation of the wheel.

Page 4

Document: DGP-M2 User Manual Rev: B

0

2/03

/2022

SAFETY AND OPERATING GUIDELINES

(continued)

• Turn the wheel off if it jams. A wheel jams when it digs too deeply into the tungsten (the motor force keeps it stuck in

the tungsten).

• Never stand or lean on the grinder. Serious injury could occur if the grinder is tipped or if the cutting tool is

unintentionally contacted.

• Keep hands away from moving parts and cutting surfaces.

6.

MAINTENANCE

• Always unplug grinder before inspection.

• Keep the grinder clean for safest operation

• Remove adjusting keys and wrenches. Form a habit of checking that keys and adjusting wrenches are removed

before the grinder is turned on.

• Keep all safety guards in place and in good working order.

• Keep all parts in working

order. Check to determine that the guard or other parts will operate properly and

perform their intended functions.

• Check for damaged parts and alignment of moving parts, binding of moving parts, breakage of mounting parts

and any other condition that may affect the grinders operation. Consult DGP factory for replacement parts

at: (805) 498-3837

• Do not use power tools in dangerous environments, such as damp or wet locations. Do not expose power tools

to rain.

• Work area should be properly lighted.

• The proper electrical outlet should be available for the tool. For 110V, a three prong plug should be plugged

directly into a three prong outlet and /or extension cord.

• Keep visitors a safe distance from work area and keep children out of work place. Use padlocks or master switches to

prevent any unintentional use of power tools.

TROUBLESHOOTING CHART

SYMPTOMS POSSIBLE CAUSES(S) CORRECTIVE ACTION

Grinder won’t start 1. Blown line or tripped circuit

breaker

1. If fuse is blown, replace with fuse of proper

size. If breaker is tripped, reset it.

2. Low line voltage

2. If voltage is less than rated, check size of

wiring from main switch on property. If OK,

contact power company.

3. Material wedged between

wheel and guard

3. Remove material wedged between wheel

and guard

Excessive vibration 1. Improper mounting of grinder 1. Remount

or accessories

2. Improper wheel mounting

2. Remove both wheels then remount wheels

but rotate one wheel 1/4 turn with respect to its

previous position. The other wheel would

retain its original position.

Grooved wheel 1. Electrode pushed with 1. Use recommended grinding times table

excessive force

2. On steep angled tungsten,

collet touching wheel

2. Use short collets available from Diamond

Ground Products

Motor is overheating 1. Motor not turning freely

(without power)

1. Clean around wheels & shaft. Then replace

bearings.

Page 5

Document: DGP-M2 User Manual Rev: B

0

2/03

/2022

MOUNTING THE DGP-M2

The DGP-M2 stand alone grinder (without vacuum system and cabinet) should be mounted to a solid horizontal surface

(mounting hardware is not provided).

If mounted to a metal cabinet or pedestal, align the mounting holes with the corresponding holes in the cabinet or

pedestal. Insert a 1/4”-20 X 1 1/4’’ hex head bolt with flat washer beneath the head of the grinder. From the bottom of

the cabinet or pedestal, place a 1/4’’ flat washer and 1/4”-20 hex nut onto the bolt extension. Tighten only until the

space between the grinder base and the cabinet or pedestal is 1/8’’. Using a second nut on each bolt, tighten against the

first to prevent loosening by vibration.

If mounted to a wooden bench top, use 1/4’’ wood screws that are 1-1/4’’ long with flat washer beneath the heads.

Tighten screws until the space between the grinder base and the bench is 1/8’’.

Electrode Grinding Assembly

The Basics

The Electrode Grinding Assembly is attached to the right wheel housing (refer to Figure 1 on the next page for the

general arrangement of the assembly). It provides the means to support an electrode in a fixed position relative to the

diamond-grinding surface through an electrode guide collet that matches the electrode diameter. The electrode is

brought into gentle contact with the diamond-grinding surface and at the same time is rotated slowly in one direction

between the operator’s thumb and forefinger. As an alternative, pin vises are also provided to hold the tungsten during

rotation.

Operating Instructions

Note: all positioning and adjustment should be made before turning on the grinder.

Refer to Figure 2 on the next page for use with the following operation instructions:

1. If the tungsten you are using is already flat at the end, like new tungsten straight out of the box, proceed to Step 4.

2. Locate the Point Flat Dresser Block (DGP-PG1477) attached at the 6 o’clock position of the right side wheel cover.

Find the hole that matches the diameter of your tungsten and turn on the grinder. Slowly push the tip against the wheel

until the point is removed. Once again, be patient and do not gouge the wheel. A burr can form if too much pressure is

exerted on the tungsten.

3. Select the electrode guide collet with the hole diameter closest to the tungsten electrode diameter and position it in

the electrode guide collet tube. Notice that the collet has been beveled on a 15° angle at the front or exit end of the

collet. With this surface parallel to the grinding wheel surface, tighten the set screw to hold it in place. The back, or

entrance, end of this collet has been milled down to its center line to make it easy to insert the electrode for grinding.

4. Adjust the angular position of the electrode grinder assembly to the desired included angle of grind for the electrode

point using the angle adjustment handle (Handle A).

5. Left to right positioning: Adjust the position of the electrode grinder assembly using the horizontal adjustment knob

(Handle B) to place beveled surface of the electrode guide collet approximately 1/64” from the grinding surface.

6. Slip a tungsten electrode into and through the electrode guide collet to determine where it will contact the grinding

disk surface.

7. Up and down positioning: Adjust the electrode grinder assembly using the vertical adjustment knob (Knob C) so that

the tungsten electrode will contact the actual grinding surface.

Page 6

Document: DGP-M2 User Manual Rev: B

0

2/03

/2022

ELECTRODE GRINDING ASSEMBLY (continued)

8. Remove the tungsten electrode from the electrode

guide collet.

9. Put the eyeshield in place and start the grinder.

Slide the tungsten electrode into and through the

electrode guide collet and twirl the electrode (or the

pin vise holding the electrode) slowly in one direction

between thumb and forefinger as it approaches and

makes contact with the grinding surface. To retain

maximum symmetry of the point, try to keep from

moving the electrode side to side within the collet. The

best technique for this is to constantly lean the

electrode against the inside surface of the collet while

turning. Continue grinding until the desired sharpness

is obtained. Make sure to continue rotation as the

electrode is backed off from the wheel or a flat spot

may occur along the point. Contamination of the

wheels can occur by using the diamond grinding and

cutting wheels as all-purpose shop wheels. If you

grind tools or other metal items, other than electrodes,

there is always the risk of contaminating the wheels.

Table 1: Recommended grinding times for each diameter.

Electrode Cutting Assembly

The Basics

The left side of the DGP-M2 is an Electrode Cutting Assembly which includes a Diamond Cutting Wheel and cutting

apparatus consisting of a

measuring ruler on a cut-off arm

, a cut-off fork, and an adjustable indexer for cutting the

electrodes to various lengths quickly and accurately. Holes are provided for several different diameters of electrodes in

the cut-off fork. The cutting assembly rotates from a level position up towards and past the edge of the cutting wheel to

accomplish the cut. Please refer to Figures 3 and 4 on Page 8 in conjunction with the following instructions.

Electrode Diameter

(in.)

Electrode Diameter

(mm)

Grinding Time

(sec)

.040” 1.0mm 5-8 sec

1/16” 1.6mm 11-15 sec

3/32” 2.4mm 15-20 sec

1/8” 3.2mm 25-35 sec

5/32” 4.0mm 30-40 sec

3/16” 4.8mm 55-65 sec

Page 7

Document: DGP-M2 User Manual Rev: B

02/03

/2022

ELECTRODE CUTTING ASSEMBLY (continued)

Operating Instructions

1. Locate the adjustable Cutoff Indexer Block (A), which is the black anodized block mounted on the Ruler Support

Bar (C). Make sure the Cutoff Indexer Handle (F) is positioned so that it is in contact with the steel Ruler (G).

2. The exciting feature of the Cutoff Indexer System is the ability to change between different lengths quickly and

accurately. To locate the Cutoff Indexer Block (A), loosen Thumb Screw (B) and position the Cutoff Indexer Block

(A) to achieve the required length then finger tighten the Thumb Screw (B).

3. With your length chosen and the power off, insert the electrode tip first, into and through (right to left) the

appropriate sized hole on the Cut-Off Fork (D) until tip gently touches the right side of the Cutoff Indexer Handle (F).

4. Tighten the associated setscrew (E) on the Cut-Off Fork (D) with the provided hex screwdriver to hold the electrode

securely. Then turn on the power.

5. Pivot the cutting assembly up and towards the diamond cutting wheel and gently push the electrode shaft into the

cutting wheel. For larger electrode sizes, please be especially patient.

6. Return the cutting assembly to the level position before removing the electrode.

Figure 3: Electrode Cutting Assembly Figure 4: Electrode Cutting Assembly

Viewed from the left Viewed from the right

Consult Illustrated Parts Lists on the following pages

and

See Page 13 for optional Accessories and Consumables Parts List

Page 8

23 26

28

27

12

14

15

16

17

18

19

20

21

24 25

30

31

32

33

29

7

6

5

3

8

5

9

10

4

2

11

13

1

22

DGP

-

M

2 PRECISION TUNGSTEN GRINDER

LEFT SIDE

Page 9

Document: DGP-

M2

User Manual Rev: B

02/03

/202

2

DG

M

GGD

D

02/03/

2

Pe

e

Document DGP-

M

e nu

P DSP

DGP-P-

DGP-P-

GD- P - SDD

GD- P - P

DGP-P- SD PGSS D

DGP-

-A

SD D

DGP-P GD D

DGP-P

-A

SP S

DGP-

F

-

-

DGP-P DD G

DGP-- -

DGP- D

DGP- SD D

DGP-PG S SSS - P

DGP-- SS SD

DGP-P S SSS SS - P P

DGP-P S S

DGP-P

DGP-P

S- SDD

SS P

DGP-- SPP

DGP-PG S

-

SS

3/8"

DGP- D D

DGP-P S SP SS

DGP- D

DGP-P S S - -

DGP-P S D -

DGP-

-A

SPP

DGP-P S

DGP-P S D

DGP-P S - S

DGP-P S S - P -

DGP-P S D SS

DGP-- S D

DGP-P S

3/8"

DGP-P S

-

S D

1

DGP- P

DGP- P S

1

2

3 4 6 8 9 10 11 1275

13

5

14

15

16

17

19

18

20

21

30

28

26

32

33

31

34

35

36

37

24

33

44

33

39

38

32

40

25

23

22

41

42

43

29

27

32

DGP-

M2

PRECISION TUNGSTEN GRINDER

RIGHT SIDE

Page 11

Document: DGP-

M2

User Manual

Rev: B

02/03/2022

DGP-

M2

PRECISION TUNGSTEN GRINDER

RIGHT SIDE

Document: DGP-

M2

User Manual Rev: B

02/03/2022

ITEM PART NUMBER DESCRIPTION QTY

DGP-P400-A BENCH GRINDER-MOTOR 7” 1HP 120V - STANDARD

1

DGP-P400-B BENCH GRINDER-MOTOR 7” 1 HP 220V - OPTIONAL 1

2

DGP-P605-A

DGP-P609-A

ON-OFF SWITCH

(STANDARD)

110V

ON-OFF SWITCH

(OPTIONAL)

220V

1

3 DGP-F277-A RIGHT WHEEL INSIDE COVER W/HARDWARE 1

4 DGP-P602-A WHEEL GUARD W/HARDWARE 1

5 DGP-P67

3

-A ARBOR SPACER W/WASHER 1

6 DGP-PG1439 SCREW – SHSS ¼”- 20 x 3/8” CUP PT BLK 1

7 DGP-F155-A ARBOR 1

DGP-PG1425 WHEEL – DIAMOND 300 GRIT (STANDARD)

8

DGP-PG1426 WHEEL – DIAMOND 600 GRIT (OPTIONAL) 1

9 DGP-PG1442 SCREW – BHSCS #10-32 x ½” BLK 4

10 DGP-PG1349 SCREW – BHSCS #6-32 x ¼” BLK 4

11 DGP-F278-A RIGHT WHEEL OUTSIDE COVER W/HARDWA

R

E 1

12 DGP-PG1477 BLOCK - FLATTING 1

13 DGP-F231 NUT – ½” 12 HEX-RH THREAD 1

14 DGP-P660 SCREW – BHSCS #10-32 x1 ¼” BLK 2

15 DGP-P730 WASHER – BLK FLAT #10 x ½” OD x 3/32” THK 5

16 DGP-F220-A INSIDE DUST SHIELD 1

17 DGP-PG1458 PLUG FINISHING ½” SNAP BLK 1

18 DGP-P672 SCREW – SHC #10-32 x 5/8” BLK 1

19 DGP-F230-A SUPPORT BRACKET 1

20 DGP-P725 WASHER - FLAT 3/8” 1

21 DGP-P310 BOLT – HEX HEAD 3/8” 16 x 1 1

22 DGP-F255-A Y AXIS CLAMP BLOCK 1

23 DGP-P660 SCREW – BHSCS #10-32 x 1 ¼” BLK 2

24 DGP-P661 SCREW – BHSCS #10-32 x 1 BLK 2

25 DGP-F049 COLLET - .020”

DGP-F060 COLLET - .040”

RIGHT DGP-F070 COLLET – 1/16”

HAND DGP-F080 COLLET – 3/32”

DGP-F090 COLLET – 1/8”

DGP-F100 COLLET – 5/32” ID ¼” OD

DGP-F110 COLLET – 3/16”

CHOICE

OF 4

TOTAL

26 DGP-P440 KNOB - #6 BLK 1

27 DGP-PG1320 SCREW

–

BHSCS #6-32 x 3/8” BLK 1

28 DGP-P460 KNOB - #10 BLK 1

29 DGP-PG1363 SCREW – SHCS #10-32 x 1” BLK 1

30 DGP-F260 Z AXIS CLAMP BLOCK 1

31 DGP-F007-A ANGLE POINTER 1

32 DGP-P730 WASHER

–

FLAT #

1

0 x ½” OD x 3/32” 4

33 DGP-P410 HANDLE – ADJUSTABLE THREADED HOLE - BLK 3

34 DGP-P541 SCREW – BHSCS #6-32 x 3/8” BLK 1

35 DGP-F025-A ANGLE SCALE – RT HAND 1

36 DGP-P571 SCREW – BHC #8-32 x ½” BLK 2

37 DGP-F225-A SCALE SUPPORT BAR 1

38 DGP-

F

242-A X AXIS CLAMP BLOCK 1

39 DGP-F245-A X AXIS GUIDE BAR 1

40 DGP-P542 SCREW – BHSCH #8-32 x ½” BLK 2

41 DGP-P177 BOLT – HEX 3/8” 16 x ¾” ZINC 1

42 DGP-P604 WASHER – FLAT 5/16” x 1/8” - STEEL 1

43 DGP-P733 WASHER – LOCK 5/16” 1

44 DGP-P663-R EYE SHIELD – PLEXIGLASS W/HARDWARE 1

Page 12

Document: DGP-M2 User Manual Rev: B

0

2/03

/2022

ACCESSORIES AND CONSUMABLES PARTS LIST

Description Part No.

300 Grit Grinding Wheel - For grinding .040” to 3/32” (1.0mm to 2.4mm) DGP-PG1425

600 Grit Grinding Wheel - For grinding 3/32” to 3/16” (2.4mm to 4.8mm) DGP-PG1426

Cutting Wheel DGP-P735

Vacuum Filters (Cartridge type for vacuum units only) DGP-M968

Upgrade to Vacuum System (Includes cabinet, vacuum system and flexible spotlight) DGP-UPG

Flexible Spotlight (No bulb) DGP-P490

Replacement Bulb for Flexible Spotlight (110V / 220V version) DGP-P480

Tip/Flat Gauge (For measuring the diameter of the tip/flat) DGP-F145

Replacement Collets .040” (1.0mm) DGP-F060

1/16” (1.6mm) DGP-F070

3/32” (2.4mm) DGP-F080

1/8” (3.2mm) DGP-F090

5/32” (4.0mm) DGP-F100

3/16” (4.8mm) DGP-F110

Cabinet Only (no vacuum or flexible spotlight) DGP-P685

110 V (Standard) DGP-P605-A

Replacement Grinder Switch

220 V (Optional) DGP-P609-A

Small .040”-1/16” (1.0mm to 1.6mm) DGP-P513

Medium 1/16” to 1/8” (1.6mm to 3.2mm) DGP-P514

Pin Vises

Large 1/8” to 3/16” (3.2mm to 4.8mm) DGP-P515

To order your replacement parts, or if we may assist you, please call us:

2651 Lavery Court • Newbury Park, CA 91320

Tel: 805.498.3837 • Fax: 805.498.9347

www.diamondground.com

Page 13

2651 Lavery Court Newbury Park, CA 91320

Phone: (805) 498-3837 Fax: (805) 498-9347

E-mail: [email protected] Website: www.diamondground.com

TRI-MIX- WS2

Non-Radioactive – Color Code: Cream / Turquoise

Tri-Mix™ tungsten is non-radioactive tungsten with the similar performance to 2% Thoriated

tungsten. Three Oxides scientifically balanced promote migration and evaporation rates that

result in extended tungsten life. This tungsten offers stability and consistency not seen on most

other tungsten. Results commonly received in some applications include an increase in the

quality of welds, a dramatic increase in service life as well as, an increase in arc starts before

resharpening and fewer misfires saving the customer money and time.

CRYO-T

Radioactive – Color Code: Pink

Cryogenically treated thoriated tungsten which provides a more dense structure of the thoriated

blend. Easier starting as compared to 2% Thoriated. Performance includes easier arc starts as

well as extended tungsten life.

2% THORIATED & 4% THORIATED

Radioactive element – Color Code: Red / Orange

2% Thoriated material is the primary tungsten used in the United States. Used primarily for

DC Welding, it has a low work function and provides high load and amperage capability.

Vapors, grinding dust and disposal of thorium dioxide raise health, safety and environmental

concerns.

1.5% LANTHANATED & 2% LANTHANATED

Non-Radioactive – Color Code: Gold / Blue

The most commonly used, non-radioactive tungsten used as an alternative to 2% Thoriated

tungsten. 2% Lanthanated offers a long electrode life under heavy or pulsing amperage loads.

Common results include, improved and stable arc starts at any amperage level, good resistance

to contamination and long service life. Because of its high ability to resist thermal shock, the

user receives excellent ignition with a lower burn-off rate.

2% CERIATED

Non-Radioactive – Color Code: Grey / Formerly Orange

Recommended for short welding cycles on low-amp, DC orbital tube, pipe, thin sheet, and

small part applications. Provides low current capacity and arc ignition with good arc stability.

Ceriated tungsten is not recommended for higher applications, because the oxides contained in

ceriated material tend to migrate very quickly to the heat at the tip of the electrode.

ZIRCONIATED

Non-Radioactive – Color Code: Brown / White

Recommended for use in radiographic-quality welding, where tungsten contamination must be

minimized. Zirconiated material tends to ball-up easily in AC applications. Performance

includes good arc starting and current capacity. Not recommended for DC Welding.

PURE TUNGSTEN

Non-Radioactive – Color Code: Green

Non-Radioactive with a low current capacity. Recommended for use in AC welding of

aluminum.

This manual suits for next models

2

Table of contents

Other DGP Grinder manuals