FFS Brands VIHD2 User manual

Hot Dog Grill 2

VIHD2

Hot Dog Grill 4

VIHD4

HOT DOG GRILL 2 SPECIFICATION PAGE

MODEL VIHD2

Dimensions

Height

Width

Depth

Machine

188mm

526mm

480mm

Weight 15kg

Electrical

Running Amps

Connection Type

International Option

1kw, 1 phase, 50HZ AC, 230v

4.4 Amps

2m BESCHUKO Euro cable with,

MFEUROCONVERT Euro to UK converter plug

N/A

HOT DOG GRILL 4 SPECIFICAION PAGE

MODEL VIHD4

Dimensions

Height

Width

Depth

Machine

188mm

811mm

480mm

Weight 21kg

Electrical

Running Amps

Connection Type

International Option

2kw, 1 phase, 50HZ AC, 230v

9 Amps

2m BESCHUKO Euro cable with,

MFEUROCONVERT Euro to UK converter plug

N/A

Assembly Instructions

1. Remove protective plastic covering from all surfaces.

2. Remove grid and wash in hot soapy water, rinse and dry.

3. Clean all surfaces with a clean, hot, damp cloth.

4. Replace grid on drive studs.

Installation

Position the

Hot Dog Grill

near a suitable electrical supply; ensure that the electrical cable

cannot cause a tripping hazard etc.

Operating Instructions

Turn RED switch 'ON', the digital control will display a temperature and then the grid will

travel up and down, heating will commence.

Allow 20 minutes for grill plate to pre-heat.

Temperature control is factory pre-set at 90°C.

Using tongs, place hot dogs/frankfurters between roller bars. Product will be ready to

serve in 10-15 minutes, depending on size and thickness. Recommended internal

temperature of product should be 68°C - 70°C.

NEVER LEAVE TONGS ON OR BELOW A MOVING GRID.

Note:

All HOT DOG GRILLS operate on a "heat n' hold" principle. The pre-set grill plate

temperature will heat the hot dogs in a matter of minutes and hold them for several hours

with little or no deterioration in appearance or taste. If there are any early signs of

deterioration, the grill plate temperature should be lowered, see "GRILL PLATE

TEMPERATURE" instructions.

Grill plate temperature

The grill plate temperature has been factory pre-set at 100°C. This operating temperature

can be adjusted between 90°C and 110°C. To change the temperatures proceed as follows:

To set an operating temperature between the factory set parameters. Push and

hold “SET” button

and with the -and the - button set the required temperature.

Setting and changing controller parameters

Press and hold, in sequence, the + SET +keys

After 3 seconds SCL will be displayed

The key will allow you to step through the parameters

Use the key t step back if required

To read the current setting of a display parameter press the SET key

To change the current set parameter, when displayed press and hold the SET

key and with the or

keys enter the required parameter settings.

To exit from the set-up press the key

Note: - When the controller is ON the ISP (set working temperature) can be

adjusted between the

SPL and SPH (min and max temp) by pressing and holding the SET key and

resetting the temperature with the keys.

Cleaning daily

Switch power OFF, and remove electrical cord from wall supply.

Allow unit to cool.

Remove the Grid and wash thoroughly in hot soapy water, using a soft brush.

Whilst Grill Plate is warm, clean with a soft, clean cloth wrapped around a small quantity

of ice chips (try it! it works!). Dry thoroughly.

The Grill Plate has an anodised coat. Do NOT use any abrasive materials, scouring pads or

sharp implements to remove food residue, these will damage the plate's surface and

invalidate the warranty.

Do NOT use bleach

Clean all stainless steel surfaces and control panel with proprietary stainless steel cleaner

and a soft, damp cloth. Dry thoroughly. Replace GRID on drive studs.

Note: Do not use abrasive cleaners or pads.

Do NOT use bleach

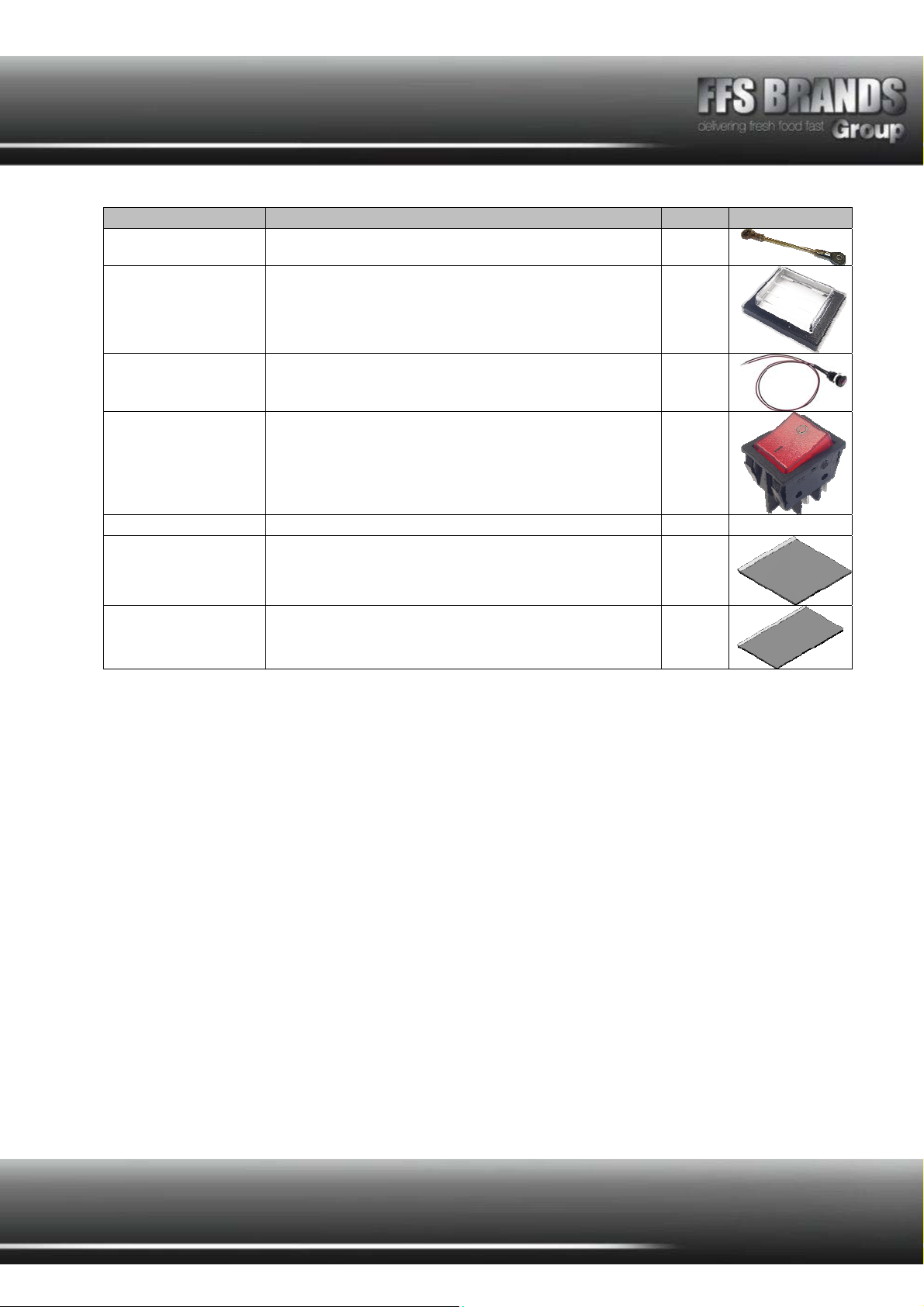

Spare Parts Listing

PART NO. DESCRIPTION QTY. IMAGE

BESCHUKO H05Rr-F 2Mtr. Rubber C032 1

MF13701NAT Natural Polyoxymethelyne Push-In Rivets

137001000005 8

MF817-8877 Black Nylon 66, strain relief cable bush 1

MF354Z 2 Pole 5amp term block TB06 1

MF464-9845 3 Way Ceramic Block TB08 1

MF543-204 9.5mm Grommet 1

MF605-649 Grommet 1

MFCOMMON2 Label 9 280 x 60 1

MFEUROCONVERT Euro to UK converter plug In black 19-1032 1

MFFF-001 Richco Round Fixed Height Feet, 24mm, 14mm,

TPE 4

PART NO. DESCRIPTION QTY. IMAGE

MFINSHD2 Hot Dog 2 Insulation 1 Oos

MFMOTOR/GEARB

OX Motor/Gearbox 80 547 019 1

MFMTR11TIRES Ltr-5Tsre-A(P) Digit Therm. With Probe 1

MFV05-09T Drive bush with thread 2

MFV05-18 Drive link 1 (Cmp) V05-18 1

MFV05-24 Reciprocator wheel Vc-01 2

MFVC-07 Drive Pin VC-07 2 Z63b4

MFV12-25 Ali drive link large 2

MFVC-13 Sneeze screen location 4

MFVC-14 Socket drive Sh/MSM4GY1011SS0100 4

MFVC-25 HD2 / HD4 element 1Gikin363001 1

PART NO. DESCRIPTION QTY. IMAGE

MFVC-27 Drive shaft assy with 2 rod ends & thread 1

VILE14 Switch cover / bezel HD2/HD4 MFF1025 / MF1026 1

MF374-1029 10mm low profile lens indicator 230VAC 1

VISW17 Rocker switch HD2 Revolva HD4 MFC1553ALR 1

MFSTEGCAP Capacitors (204-4939) 1 Y3shelf3

MF05-

01ANODISED Reference - Cooking platen for HD2 1

MF07-

01ANODISED

Reference - Cooking platen for HD4 1

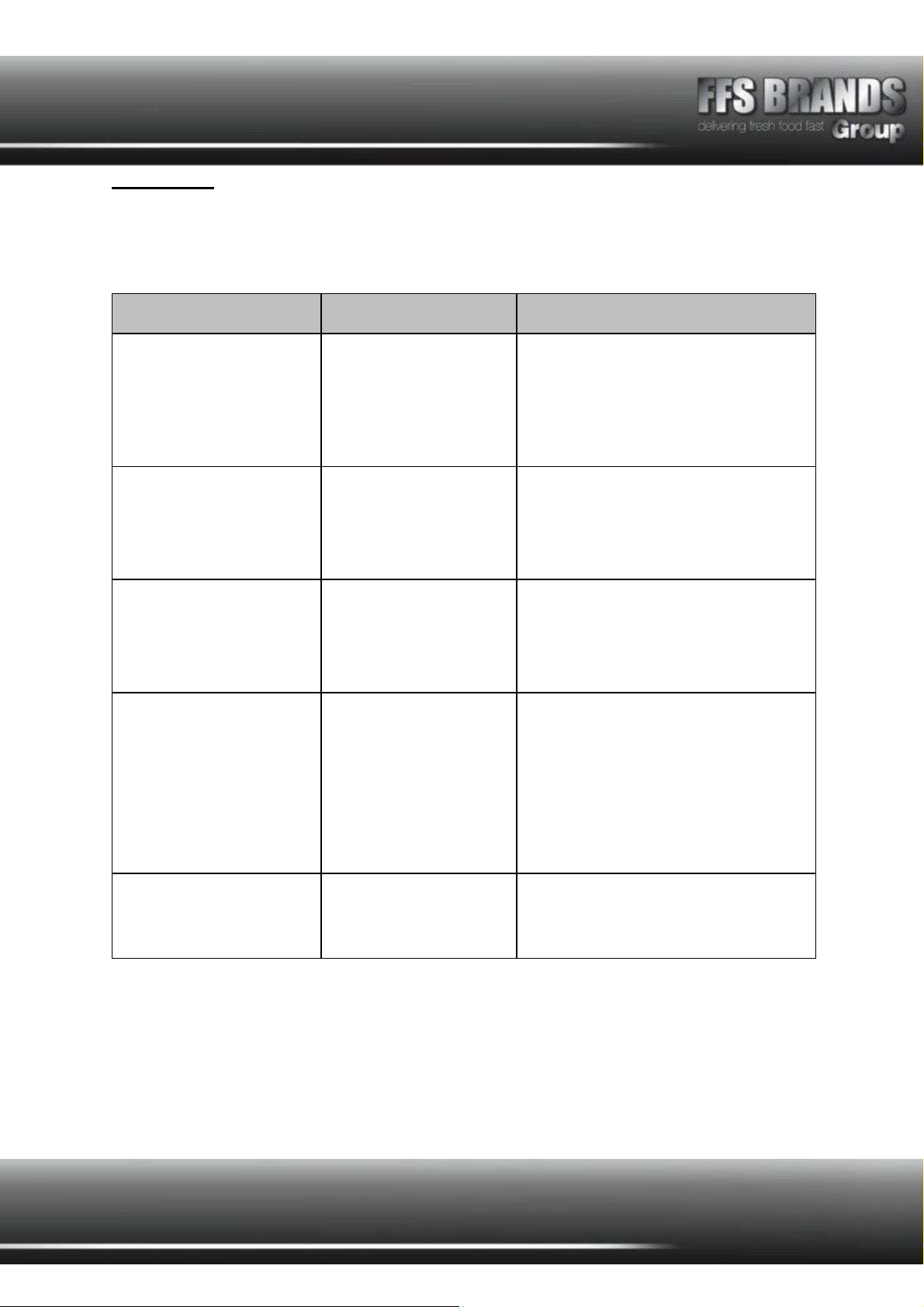

Faultfinder

Any servicing must be carried out by qualified personnel.

Disconnect from power before servicing.

Problem Possible Cause Solution

1. Rocker switch is not

illuminated.

No power to machine.

Rocker switch faulty.

Fuse faulty.

Check machine is plugged in & switched

ON.

Check supply trip/fuse. Reset/replace as

required.

Replace switch.

Check and replace if faulty.

2. Di

g

ital thermostat does not

illuminate

Rocker switch OFF.

Machine has over-

heated.

Digital controller

incorrectly set.

Digital controller faulty.

Switch ON. (See section1).

Allow to cool down.

Set correct temperature setting.

Replace digital controller.

3. Grid does not move. No power to machine.

Grid out of alignment

due to drive coupling

damage.

Drive motor capacitor

faulty.

Drive motor faulty.

See sections 1 and 2.

Realign or repair coupling (contact Fast

Food Systems.)

Replace drive motor capacitor.

Replace drive motor.

4. Grill does not heat up. No power to machine.

(HD4 only switching

relay faulty)

Thermocouple (probe)

faulty.

Digital controller faulty.

Element faulty

See sections 1&2.

Replace relay.

Replace thermocouple.

Replace controller (check parameters have

been correctly programmed.)

See section 1 and 2.

Replace element.

5. Grid does not move smoothly Drive component out of

alignment or damaged.

Drive motor/gearbox

damaged (1 part).

Have system corrected and realigned

(contact Fast Food Systems).

Have motor/gearbox replaced contact Fast

Food Systems.

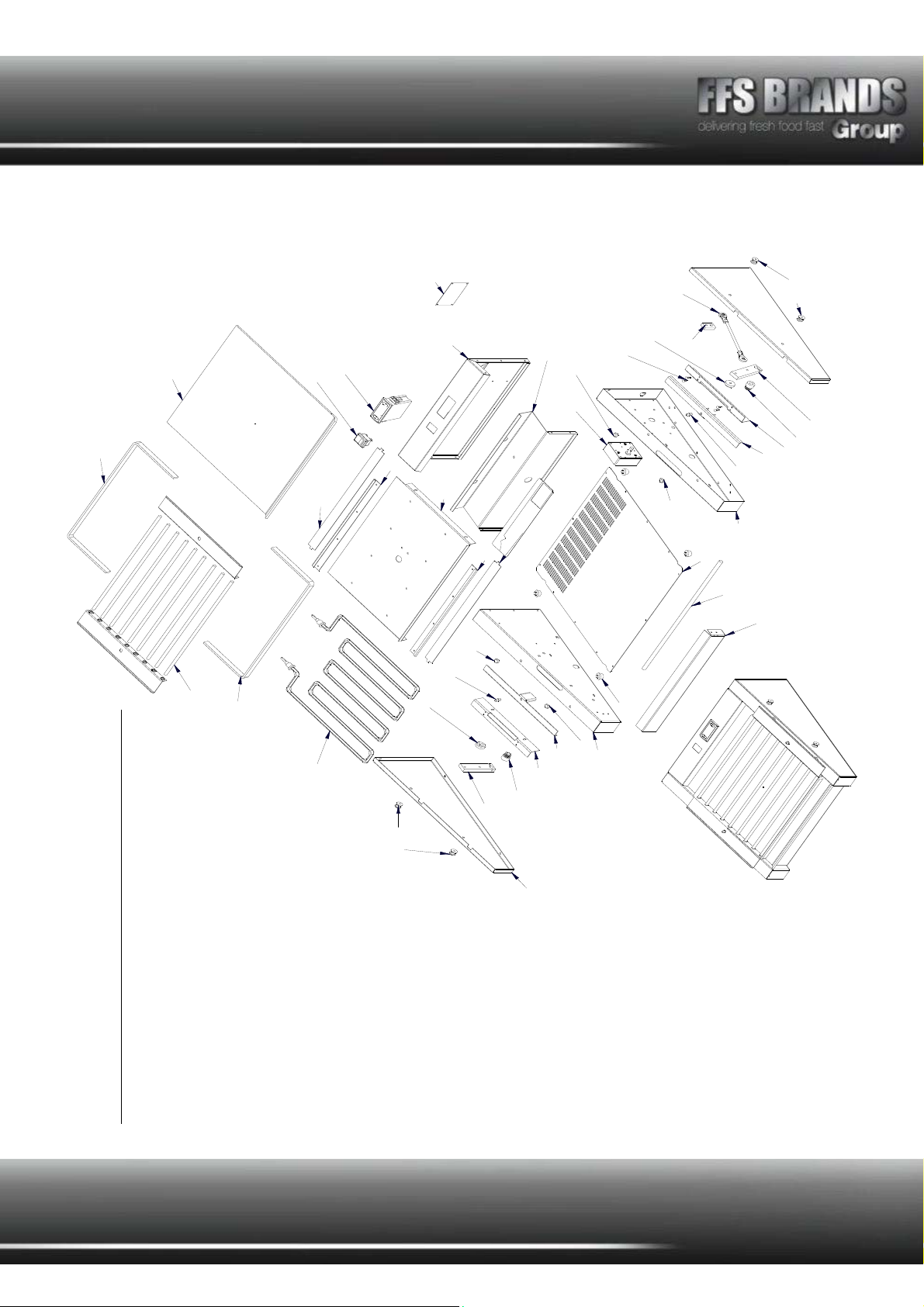

ASSEMBLED

05-07

05-07

EQVIHD2 HOT DOG GRILL 2

EXPLODED VIEW

05-01 COOKING PLATE

05-02 FRONT

05-03 REAR

05-04 BASE COVER

05-05 ELEMENT COVER

MFVC-14 RUNNER DOME

MFVO5-09T DRIVE BUSH

MFPLUGLEAD PLUG AND LEAD

MFVC-13 SNEEZE GUARD LOCATIONS

MFVC-25 ELEMENT

MFVC-07 DRIVE PIN

05-08

MFVC-14

MFVC-14

05-16

05-15

MFVC- 07

MFV05-24

MFV05-09T

MFV05-18

05-13

MFVC- 13

MFV12-25

MFV05- 09T MFVC-13

05-10

05-02

05-06

05-04

05-12

05-11

05-11

05-08

05-09

05-01

MFPLATE

05-03

MFVC- 14

MFVC- 14

05-12MFVC- 07

MF13701NAT

MFV05-24

05-16

05-15

MFVC-25

MFFF01

05-05

MFSTG61

LAELTR15 TIREAG

VISW17

MFVC-27MF05- 18

05-06 DRIVE BAR

05-07 ROLLER UNIT SURROUND BAR

05-08 INSULATOR STRIPS

05-09 ROLLER UNIT BAR

05-10 ELEMENT HOLDER

05-11 ELEMENT RETAINER

05-12 INTERNAL SIDE PANEL

05-13 SIDE PANEL

05-14 ROLLER GRID SIDE

05-15 RESIPRICATOR HOLDER

05-16 RESIPRICATOR

LAE LTR15TIREAG

DIGITAL THERMOSTAT

VISW17 SWITCH (RED)

MFV05-18 DRIVE LINK 1 (SMALL)

MFV12-25 DRIVE LINK 2 (LARGE)

MFV05-24 RESIPROCATOR WHEEL

MFFF01 FAST FOOT

MFVC-27 DRIVE SHAFT ASSEMBLY

MFSTG61 GEARBOX AND MOTOR

MF13701NAT SKIFFY PINS

MF PLATE SERIAL PLATE

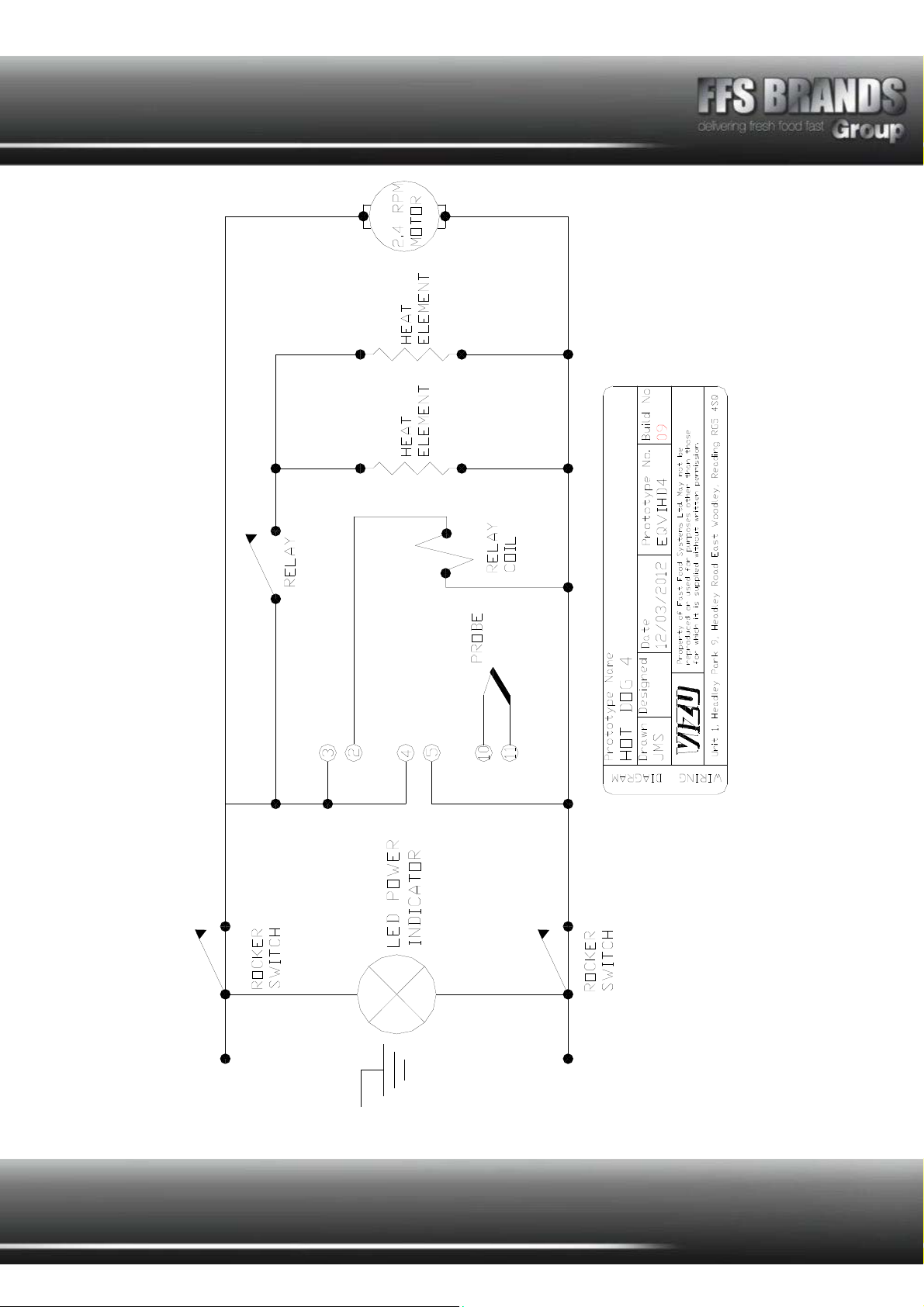

Wiring diagram HD2

Wiring diagram HD4

MFFF01

MFFF01 MFVC-07

MF13701NAT

MFV05-24

07-16

07-15

MFV05-09T MFVC-13

07-10

07-02

07-06

ASSEMBLED

07-07

07-01

EXPLODED VIEW

07-01 COOKING PLATE

07-02 FRONT

07-03 REAR

07-04 BASE COVER

07-05 ELEMENT COVER

07-06 DRIVE BAR

MFVC-07 DRIVE PIN

LAE LTR15 TIRE AG

VISW17 RED SWITCH

07-08 07-03

MFSTG61 MFVC- 14

MFVC-14

07-12

07-04

MFFF01

MFFF01

07-12

MFVC-14

MFVC-14

07-16

07-15

MFVC-07

MFV05-24

MFV05-09T

MFV12-25

07-13

MFVC- 13

MFVC- 25

MFVC- 25

07-07

07-09

07-08

07-11

07-11

MFPLATE

07-05

07-14

EQVIHD4 HOT DOG GRILL 4

LAELTR15 TIREAG

VISW17

MFVC-27

MF05- 25

MFV12-25

07-07 ROLLER UNIT SURROUND BAR

07-08 INSULATOR STRIPS

07-09 ROLLER UNIT BAR

07-10 ELEMENT HOLDER

07-11 ELEMENT RETAINER

07-12 INTERNAL SIDE PANEL

07-13 SIDE PANEL

07-14 ROLLER GRID SIDE

07-15 RESIPRICATOR HOLDER

07-16 RESIPRICATOR

MFV05-25 DRIVE LINK 1 (SMALL)

MFV12-25 DRIVE LINK 2 (LARGE)

MFV05-24 RESIPROCATOR WHEEL

MFFF01 FAST FOOT

MFVC-27 DRIVE SHAFT ASSEMBLY

MFSTG61 GEARBOX AND MOTOR

MF13701NAT SKIFFY PINS

MF PLATE SERIAL PLATE

MFVC-14 RUNNER DOME

MFVO5-09T DRIVE BUSH

MFPLUGLEAD PLUG AND LEAD

MFVC-13 SNEEZE GUARD LOCATIONS

MFVC-25 ELEMENT

Terms and Conditions

Claims

No claim shall be entertained by the Company unless made in writing. Claims arising from

damage or partial loss in transit must reach the Company within 7 days from the date of

delivery. Claims for non-delivery must reach the Company within 10 days from the date of

dispatch. All other claims must reach the Company within 7 days. Damaged goods must be

retained for inspection/collection.

Returns

The Company does not operate a returns policy unless the goods are defective:

In circumstances where the Company agrees to accept return of goods, a charge of 25% of

the invoice value will be made.

Damage claim form

Machine: HD2 VIHD2 / HD4 VIHD4

Product code: HD2 / HD4

Customer name……………………………………………………………

Date of delivery……………………………………………………………

Machine serial number…………………………………………………

Damage comments………………………………………………………

……………………………………………………………………………………………………………………………………

……………………………………………………………………………………………………………………………………

……………………………………………………………………………………………………………………………………

……………………………………………………………

Please indicate on the picture where the unit is damaged

Courier name…………………………………………………………………

Please cut this page out and post to

Fast Food Systems

(The address is on the back of this manual)

HD4

HD2

Warranty

UNITED KINGDOM AND REPUBLIC OF IRELAND

Excepting where otherwise specified all products are subject to 12 months parts and

labour warranty Goods found defective will be repaired, credited or replaced without

charge according to the terms of the Company’s standard warranty, provided written

notice is given within the guarantee period. In no case will the company be liable

for repairs made without its knowledge or sanction, or for indirect damage, or any

consequential loss or expense incurred by purchasers.

Fast Food Systems Ltd, warrants to the original purchaser that the equipment

supplied to be free from defective materials or workmanship for a period of 12

(twelve) months.

The following are NOT covered by warranty:

1. Failure or breakdown caused by incorrect installation.

2. Glass parts, electric lamps or door seals.

3. Adjustment or calibration of controls - this is a routine maintenance function.

4. Abuse or misuse, including cleaning.

5. Warranty labour is only carried out during normal working hours; calls

attended to out of hours may be subject to surcharges.

6. The warranty will commence either on installation or 1 (one) month from date

of dispatch - whichever is the sooner.

7. Warranty on spare parts purchased for equipment outside of the warranty

period is 3 (three) months from date of sale.

8. Any faulty spare parts replaced under warranty must be returned with 7 days

of supply.

9. Warranty is non-transferable.

Fast-Food-Systems Ltd

will not be held responsible, financially or otherwise, for

any loss of business as a result of equipment breakdown.

Fast Food Systems Limited

Manufacturer & Distributor of Catering Equipment

Unit 1 Headley Park 9 Headley Road East

Woodley Reading Berkshire RG5 4SQ

Tel: 0118 944 1100 Fax: 0118 944 0350

Email: service@fast-food-systems.co.uk

Website: www.fast-food-systems.com

ISSUE 22: 28th June 2017

Model Number………………………………

Order ID/Job No……………………………

Machine serial number……………………

Date of Manufacture ……/………/………

Date of delivery……/………/……

Date of Commissioning……/………/……

This manual suits for next models

1

Table of contents

Popular Grill manuals by other brands

Weber

Weber Skyline 3200 owner's manual

Vermont Castings

Vermont Castings Signature VCS3006 Assembly procedures

Renkforce

Renkforce IO-40TB ELA operating instructions

AMERICANA grill

AMERICANA grill 2010 user manual

Alice's Garden

Alice's Garden D'ARTAGNAN instruction manual

Blaze Outdoor Products

Blaze Outdoor Products BLZ-3NG Use & care guide