FHM Value Leader EFGCH Series Application guide

Farmer-Helper EFGCH Flail Mower 1 Revision 10-14-17

Specificationssubjecttochangewithoutnotice.

Rugged Labor Saving Equipment Since 1995

www.Betstco.com

Toll Free: 877-876-7895, E-mail: [email protected]

83371 Melton Rd, Creswell OR 97426

Please read these instructions carefully before using!

You must fill with oil before operating!

Uses Approximately 3 quarts 80-90 gear lube

GREASE ALL FITTINGS BEFORE OPERATING!

FLAIL MOWER EFGCH

OPERATION & PARTS MANUAL

Save This Manual for Future Reference

Farmer-Helper EFGCH Flail Mower 2 Revision 10-14-17

Table of Contents

1. Introduction 3

2. Setup and Assembly Instructions 3

3. PTO Driveshaft Safety Tips 4

4. Protective Guards and Shields 5

5. Safety Instructions 5

6. Operator Protective Gear 6

7. Operation Checklist 6

8. Flail Mower Connection and Operation 6

9. Cutting Height Adjustment 8

10. Blade Replacement 9

11. Belt Tension and Adjustment 9

12. Lubrication Frequencies and Locations 9

13. Preventive Maintenance 10

14. Troubleshooting 10

15. Parts and Fasteners 11

16. Torque Values 12

17. Basic Parts Breakdown 13

18. Pictures 14

19. Flail Mower Specification 16

20. Parts Diagrams and Numbers 18

21. Warranty Registration 26

Farmer-Helper EFGCH Flail Mower 3 Revision 10-14-17

1. INTRODUCTION

Before using your flail mower, read and understand this operation manual and the

accompanying maintenance instructions. It contains important information which will

help you observe proper safety precautions, get the most work from your flail mower and

help prolong the life of your flail mower.

2. SETUP and ASSEMBLY INSTRUCTIONS

Your flail mower will arrive in a metal shipping frame. This frame can be dismantled to allow

access to all parts of your mower.

See torque value chart at end of manual for all specific bolts being used.

Remove parts box, PTO driveline, side cover shield, hydraulic side shift control

frame, and then mower from crate. See picture and verify parts, see picture at end of

manual.

Attach storage stand and PTO shield as shown in picture at end of manual.

Attach hydraulic offset control frame as shown in picture at end of manual. Metal

plates go on the underside of mower deck frame. Hint-Do not tighten nuts & bolts until

all have been loosely assembled in their proper location.

Attach upper 3pt bracket as shown in picture at end of manual. Hint-Do not tighten nuts

& bolts until all have been loosely assembled in their proper location. Tighten from top-

down.

Attach 3Pt. lift pins as shown in picture at end of manual.

Lube grease points on mower and driveline (4 total points, use lithium base general

purpose grease) see picture at end of manual

Before attaching side cover, check all axle bolts and pulley screws for tightness (see

picture at end of manual). Verify belt deflection is ¼ ” to ½ ” Attach side safety cover. 1

connecting bolt (see picture at end of manual).

Fill gear box with 80-90 gear oil (Approx. 1 Qt.) Fill to full plug level in gear box to the

left side of PTO shaft. See picture at end of manual for more info.

Attach hydraulic lines to a source for actuating a hydraulic cylinder.

Completely read the rest of manual before attaching PTO driveline and operating the

mower.

Before Operation check all bolts, nuts, and zerks for tightness. Verify the

tightness of all blade retaining bolts and nuts. Check all blades for free swinging action.

Farmer-Helper EFGCH Flail Mower 4 Revision 10-14-17

3. PTO DRIVESHAFT SAFETY TIPS

Your flail mower is shipped with a PTO driveshaft.

Always ensure that the PTO shaft is no more than 15 degrees of horizontal when

operating.

-The following steps are recommended for safe operation of the driveshaft under field

conditions.

-Test hitch angle to prevent the driveshaft from:

�

Extending beyond the recommended maximum length.

�

Bottoming out

�

Reaching a position that allows joints to lock

�

Exceeding the maximum allowable angle for constant velocity (CV) joints.

-Specify and test telescoping members to allow the lowest possible thrust loads,

considering the expected working conditions.

-Specify and test torque limiters to control excessive shock.

-Where necessary, specify and test overrun clutches to prevent inertial loads from

overpowering the tractor.

-Provide a means to support the drive shaft when it is disconnected from the tractor, to

prevent damage during storage or transportation.

-Provided drive shaft is of shear design using a grade 5 bolt, if replacing this bolt do not

use higher grade as this may cause damage to the PTO driveshaft, Implement, or your

tractor.

-On drive shafts with torque-limiting or overrun devices, be sure to connect the device on

the end of the drive shaft nearest the chipper.

-Provide a proper clearance zone for the operation of the driveshaft, to avoid damage to

the shielding components.

-It is not recommended to use PTO adaptors which may defeat the purpose of the

tractor’s master shield and/or adversely affect the performance of the driveshaft.

Farmer-Helper EFGCH Flail Mower 5 Revision 10-14-17

4. PROTECTIVE GUARDS AND SHIELDS

Do not allow the flail mower to be operated without the side cover or fender deflector’s

properly in place.

PTO driveshaft should consist of a PTO master shield, integral driveshaft shield, and a

mower input connection shield.

1. Follow all flail mower and tractor instruction labels and manuals. The flail mower

should be used only with the tractor’s PTO master shield in place.

2. Specify and test an integral driveshaft shield with end cones which will overlap, but

not interfere with the PTO master shield or flail mower input connection shield.

3. A flail mower input connection shield should be used in addition to the integral

driveshaft shield, in order to guard the shaft coupling and any torque limiting device

installed on the driveshaft.

4. Check that all routine maintenance of the driveshaft can be done without removal of

the shields.

5. SAFETY INSTRUCTIONS

Do not attempt to operate the flail mower until you have read and understood this manual.

Always keep guards and flail mower shields properly installed while operating the flail

mower.

Keep the decals in place and verify they are understandable. New labels can be ordered

from Betst Power Equipment upon request. If your flail mower is repainted, be sure the

labels and decals remain visible.

Never leave the flail mower running unattended.

Do not attempt alterations, repairs or adjustments while blade rotor is turning. Always

disconnect the PTO and stop the tractor motor, then put keys in your pocket.

Only use tractor of specified HP for your model flail mower as defined in the

specifications.

Keep hands, feet and other extremities out of and away from the blade rotor

area. When checking blades, EXERCISE EXTREME CAUTION! If

accidentally rotated, the blade rotor can contain enough residual energy to

cause serious injury.

Never allow anyone to stand beside or behind mower while operating.

Keep everyone,

especially children and animals, away from the operation area.

Anyone who has not read and understood this manual should not be in the area.

Farmer-Helper EFGCH Flail Mower 6 Revision 10-14-17

6. OPERATOR PROTECTIVE GEAR

The following protective clothing and gear is recommended when using your flail mower.

EYES -- Wraparound Safety Glasses or Goggles

EARS -- Ear Plugs

HANDS -- Leather Gloves

FEET -- Steel-Toed Boots

LEGS -- Heavy Pants

ARMS -- Long-Sleeved Shirt

NO LOOSE CLOTHING SHOULD BE WORN AROUND THE FLAIL MOWER

7. OPERATION CHECKLIST

CAUTION : Look under flail mower before operating to be sure the blade area is clear.

Make sure that:

�

You have completed all steps of the assembly instructions

�

The PTO shaft doesn’t come apart or bottom out during the normal lifting range.

�

There in no person around mower.

�

Remove Tractor Drawbar

During and after operation, check the grass clippings or mulched limbs for size and

quality of cut. It may be necessary to adjust the cutting height. See adjusting cutting

height.

8. Flail Mower Connection and Operation

Remember that if flail mower blades are blunted they will not cut properly. Dirt, rocks,

nails, or other foreign material will shorten blade life.

Always review the manual before operating the flail mower.

Operate mower in a safe well known area with the rear pointed away from doorways,

sidewalks, or any areas where your view is obstructed or people may approach.

Only use 540 RPM PTO Selection, any other use will void the warranty and may cause

severe damage to the gear box or mower.

Farmer-Helper EFGCH Flail Mower 7 Revision 10-14-17

Connecting to Tractor

Make sure there are no obstructions under the flail mower

Align lower link arms of tractor to hitch clevises on mower, Insert lower hitch pins into

lower ball swivels and attach linch pins.

Attach tractor top link to upper floating hitch on mower with pin supplied. Secure with

lock pin.

Slide driveline end with shear system over the tractor’s splined PTO shaft and secure it

with locking device of driveline

Slide driveline end with twist system over the mower’s splined PTO shaft and secure it

with locking device of driveline.

Driveline should now be moved back and forth to ensure that it is secure on the PTO shaft

of the tractor and mower gearbox.

When raising the mower to the transport position, be sure that driveline does not contact

tractor or mower. Adjust and set the tractor’s 3-point hitch lift height so that the driveline

does not contact mower deck in the fully raised position.

When moving over paved or rock road way be sure mower is lifted off the surface.

To Begin Mowing

Clear the area to be mowed of objects and debris that might be picked up and thrown by

the mower blades.

Grass is best cut when dry. Mowing wet grass can cause plugging resulting in grass

clumps behind the mower.

Grass should be cut frequently as smaller clippings deteriorate faster.

If cutting extremely tall grass, it is best to raise the cutting height and mow the area, then

lower the cutting height and mow a second time at the desired height.

To begin cutting, observe all safety guidelines in the manual.

Always check Gear Oil Level before mowing

.

Farmer-Helper EFGCH Flail Mower 8 Revision 10-14-17

At low engine rpm’s you may experience jerking in the mower, increase the engine rpm until there

is no jerking.

Most cutting is preformed with the 3pt lift system in the float position.

If the blades are touching the surface while in float position, either adjust cutting height or raise

mower with 3pt lift into fixed height position. See cutting height adjustment.

At first begin mowing at a slow forward speed. Mower knives will cut better at a faster blades speed

and slower travel speed.

After mowing 50 feet, stop and check to see that the mower is adjusted properly for the cutting

conditions.

Do Not make sharp turns or attempt to back up while the mower is on the ground.

Do Not engage PTO with mower fully raised off the ground.

Normal mowing speed will be between 2-5 mph and you will need to maintain tractor PTO speed to

produce a clean cut so select a tractor gear and range that will maintain this combination. The

quality of cut or degree of debris pulverization will be better at lower ground speeds and cutting

denser ground cover or heavier brush may create the need to slow down. Remember to look back

often.

7. CUTTING HEIGHT ADJUSTMENT

The flail mower cutting height depends upon the height of roller, height of adjustable skids, and

length of top center link. See pictures at end of manual.

On uneven terrain the roller and skids should both be touching the surface of cutting area.

On even terrain the roller only needs to be touching the cutting surface.

On rough and rocky terrain it is recommend that you cut high with all parts of the mower 3” above

the ground. To achieve lowest cutting height in this type of terrain, raise roller and skids so mower

can be operated with 3 pt in fixed position, remember change in elevation may require you to adjust

cutting height to ensure blades do not make contact with the surface.

To adjust height of roller or skids, remove bolts and nuts that affix them, lift or lower both sides in

equal measurements, replace bolts and re-tighten. See picture at end of manual.

The top center link can also be used to adjust cutting height and aggressiveness of blades. In level

grass areas the top link should be adjust so the mower sits on a slightly lifted horizontal plane. In

dense or rough terrain the mower should sit in a slightly higher horizontal plane.

Farmer-Helper EFGCH Flail Mower 9 Revision 10-14-17

8. BLADE REPLACEMENT

The best way to tell if the blades need replacing is to watch the results of your mowing.

Dull blades cause many problems, including:

�

Loss of cutting power

�

Jamming or Plugging

�

Rough cutting with more vibration than usual

�

Rowing left in cut

To remove the blades, take the PTO shaft out of gear. Shut off the tractor and keep the

keys in your pocket.

The blades are accessed underneath the mower.

Prop up mower with suitable devise to hold the weight of the mower.

Inspect and remove/replace dull or missing blades.

9. BELT TENSION ADJUSTMENT

To adjust belt tension, take the PTO shaft out of gear. Shut off the tractor and keep the

keys in your pocket.

The belts are accessed behind black side cover.

Prop up mower with suitable devise to hold the weight of the mower.

Check the deflection of belts, should be between ¼ ”and ½ ”

To adjust tension, loosen bolts and nuts as shown in picture at end of manual.

Then using support move gearbox and shaft horizontally to adjust tension, then adjust

support bolt and lock nut to the adjusted height, see picture at end of manual.

Tighten all bolts and nuts that were loosed to adjust the tension.

10. LUBRICATION FREQUENCIES AND LOCATIONS

PTO SHAFT – 2 zerks on universal once a day with lithium based multipurpose grease.

ROTOR DRIVESHAFT – There is a zerk on each end of rotor shaft. Add multipurpose

grease before each use. (2-3 Pumps)

GEAR BOX – Check level each time before operating, drain/fill as needed.

HYDRAULIC OFFSET ROD – Apply lithium grease to sliding shafts.

Farmer-Helper EFGCH Flail Mower 10 Revision 10-14-17

11. PREVENTIVE MAITNANCE

Check all bolts & nuts after initial 4 hours of operation, and once per day thereafter

before beginning operation.

Check belt tension 4 hours after initial operation, and every 24 hours of operation

thereafter before beginning operation.

12.TROUBLESHOOTING

PROBLEM:

Belt Slipping

Possible Causes Solution

Rotor Shaft Area Clogged Unplug and clean mower deck.

Pulley Sheaves Clogged/Dirty Remove shield and clean sheaves

Belt Tension insufficient Check and adjust belt tension

Travelling to fast Reduce Travel Speed

Belt Worn Replace Belt

Blades Dull

Deck too flat Reverse/Replace

PROBLEM:

Patches of Uncut Grass

Possible Causes Solution

Low Throttle Increase Engine RPM

Travelling to fast Reduce Travel Speed

Blades Dull Reverse/Replace

PROBLEM:

Excessive Vibration

Possible Causes Solution

Missing Blades Replace missing blades

Worn Drive Belt Replace worn belt

Pulley Miss-Aligned/Damaged Re-Align/Replace

Debris in Belt Area Remove cover and clean area

PTO Driveline Bent Replace Bent/Broken Parts

Engine Speed Increase Engine Speed

PROBLEM:

Gear Box Noisy

Possible Causes Solution

Low Oil Level Check and Fill with Oil

Farmer-Helper EFGCH Flail Mower 11 Revision 10-14-17

PROBLEM:

Knives Scalping Grass

Possible Causes Solution

Incorrect Cutting Height Adjust Cutting height

Mowing Pattern Change Mowing Pattern

Turning to Quickly Reduce Speed during turns

PROBLEM:

Uneven Cut

Possible Causes Solution

Missing/Dull Blades Remove/Replace Blades

Travelling to Fast Reduce Travel Speed

Mower Not Level Adjust 3Pt Linkage

PROBLEM:

Tractor Loaded Down by Mower

Possible Causes Solution

Low Engine Speed Increase Engine Throttle

Travelling to Fast Reduce Travel Speed

Blade Area Clogged Clean Blade Area

13. PARTS AND FASTENERS

Your flail mower is designed for ease of maintenance. Replacement parts are available

from Betst Power Equipment at 1-877-876-7895 or Support@Betstco.com Check the

parts list for specification.

See Parts Diagrams at end of manual

Farmer-Helper EFGCH Flail Mower 12 Revision 10-14-17

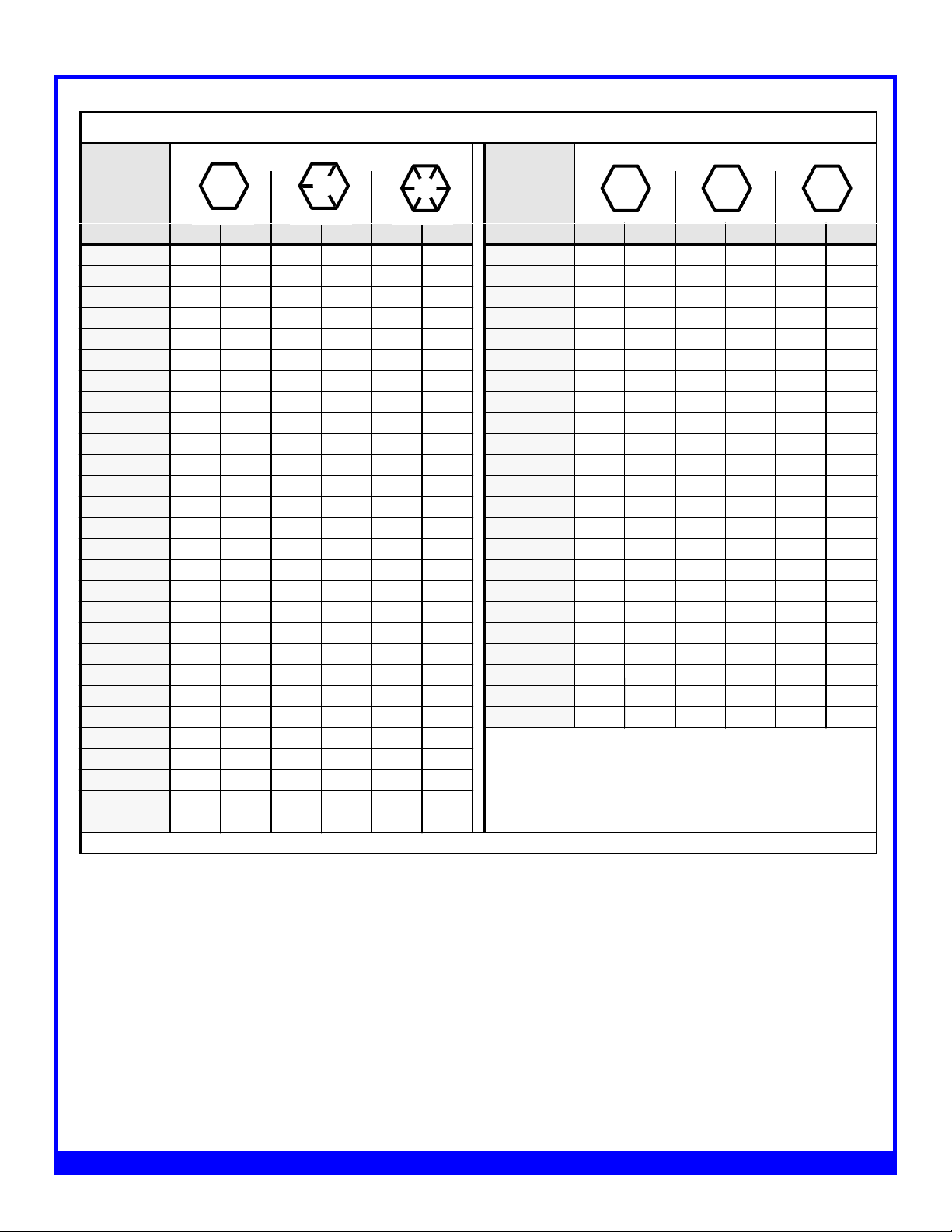

Torque Values Chart

Bolt Head Identification Bolt Head Identification

5.8 8.8 10.9

Grade 2 Grade 5 Grade 8 Class 5.8 Class 8.8 Class 10.9

in-tpi 1 N · m ft-lb 3N · m ft-lb N · m ft-lb mm x pitch N · m ft-lb N · m ft-lb N · m ft-lb

1/4" - 20 7.4 5.6 11 8 16 12 M 5 X 0.8 4 3 6 5 9 7

1/4" - 28 8.5 6 13 10 18 14 M 6 X 1 7 5 11 8 15 11

5/16" - 18 15 11 24 17 33 25 M 8 X 1.25 17 12 26 19 36 27

5/16" - 24 17 13 26 19 37 27 M 8 X 1 18 13 28 21 39 29

3/8" - 16 27 20 42 31 59 44 M10 X 1.5 33 24 52 39 72 53

3/8" - 24 31 22 47 35 67 49 M10 X 0.75 39 29 61 45 85 62

7/16" - 14 43 32 67 49 95 70 M12 X 1.75 58 42 91 67 125 93

7/16" - 20 49 36 75 55 105 78 M12 X 1.5 60 44 95 70 130 97

1/2" - 13 66 49 105 76 145 105 M12 X 1 90 66 105 77 145 105

1/2" - 20 75 55 115 85 165 120 M14 X 2 92 68 145 105 200 150

9/16" - 12 95 70 150 110 210 155 M14 X 1.5 99 73 155 115 l215 160

9/16" - 18 105 79 165 120 235 170 M16 X 2 145 105 225 165 315 230

5/8" - 11 130 97 205 150 285 210 M16 X 1.5 155 115 240 180 335 245

5/8" - 18 150 110 230 170 325 240 M18 X 2.5 195 145 310 230 405 300

3/4" - 10 235 170 360 265 510 375 M18 X 1.5 220 165 350 260 485 355

3/4" - 16 260 190 405 295 570 420 M20 X 2.5 280 205 440 325 610 450

7/8" - 9 225 165 585 430 820 605 M20 X 1.5 310 230 650 480 900 665

7/8" - 14 250 185 640 475 905 670 M24 X 3 480 355 760 560 1050 780

1" - 8 340 250 875 645 1230 910 M24 X 2 525 390 830 610 1150 845

1" - 12 370 275 955 705 1350 995 M30 X 3.5 960 705 1510 1120 2100 1550

1-1/8" - 7 480 355 1080 795 1750 1290 M30 X 2 1060 785 1680 1240 2320 1710

1 1/8" - 12 540 395 1210 890 1960 1440 M36 X 3.5 1730 1270 2650 1950 3660 2700

1 1/4" - 7 680 500 1520 1120 2460 1820 M36 X 2 1880 1380 2960 2190 4100 3220

1 1/4" - 12 750 555 1680 1240 2730 2010

1

in-tpi = nominal thread diameter in inches-threads per in.

1 3/8" - 6 890 655 1990 1470 3230 2380

2

N· m = newton-meters

1 3/8" - 12 1010 745 2270 1670 3680 2710

3

ft-lb= foot pounds

1 1/2" - 6 1180 870 2640 1950 4290 3160

4

mm x pitch = nominal thread diameter in millimeters x thread

1 1/2" - 12 1330 980 2970 2190 4820 3560 pitch

Farmer-Helper EFGCH Flail Mower 13 Revision 10-14-17

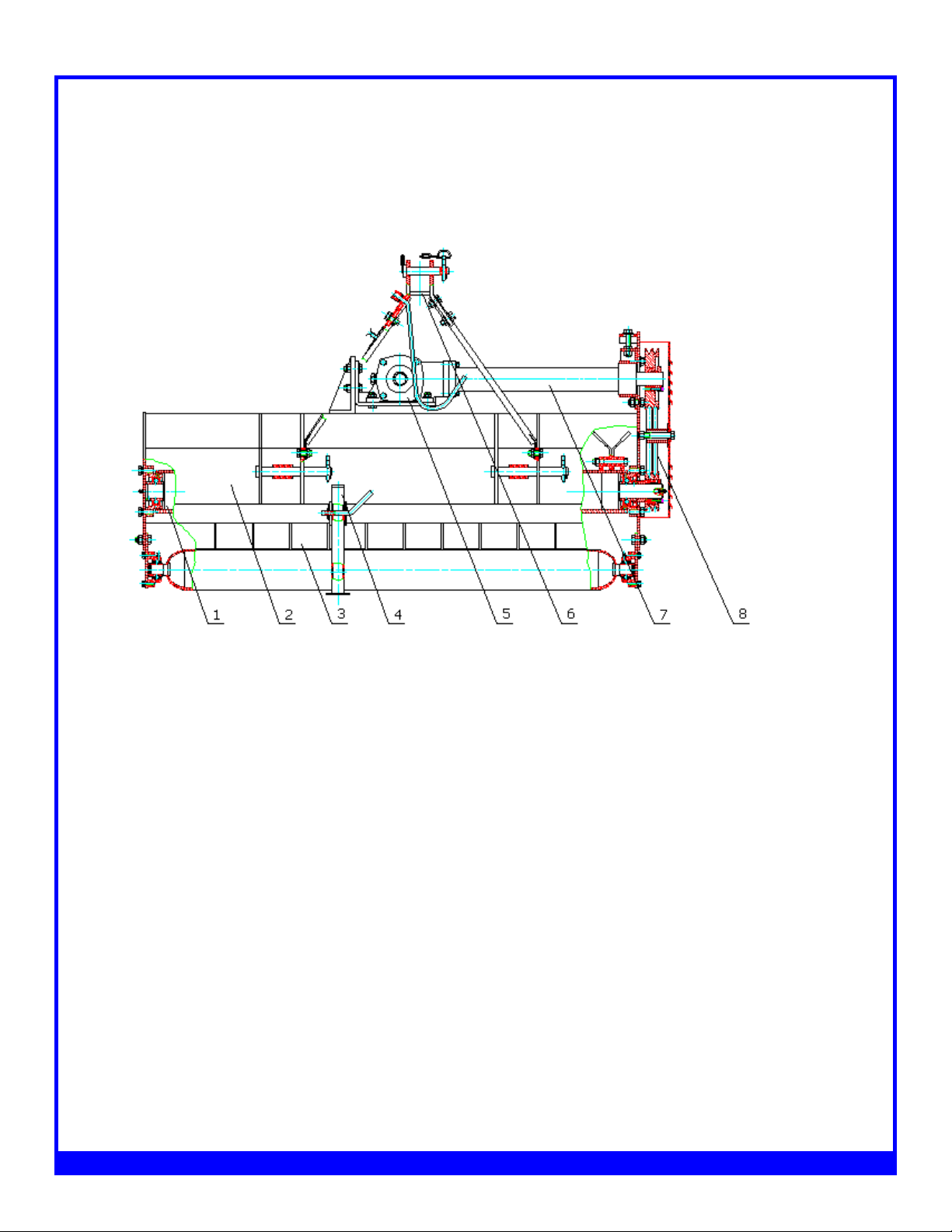

1. Blade axle 2. Mower Housing 3. Combined Safety Fender

4. Support Leg 5. Gearbox Assembly 6. 3Pt Bracket

7. Transmission shaft 8. Pulleys and Belts

Farmer-Helper EFGCH Flail Mower 14 Revision 10-14-17

Parts Box Includes the following show

in picture, you may receive extra parts

that are not shown in the picture.

Attach Hydraulic

Offset Frame, 3Pt

Bracket, Storage

Stand, and PTO

Shield shown in

picture

Lubrication Point on Lower Axle and Pulley Detail Picture

Farmer-Helper EFGCH Flail Mower 15 Revision 10-14-17

15

Fill Gear Box until oil comes out

plug on left side of PTO shaft

Next Fill Tube from Gear

Box to Belt Cover

Or

Grease Bearing at end of

Tube.

Bearings can take a lot of

Grease.

Roller and Skid Height Adjustment

Belt Tension Adjusting Points

Farmer-Helper EFGCH Flail Mower 16 Revision 10-14-17

Farmer-Helper EFGCH Flail Mower 17 Revision 10-14-17

SafetyLabels

Your Flail Mower comes equipped with all safety labels in place. They were designed

to help you safely operate your implement. Read and follow their directions.

r

1. Keep all safety labels clean and legible.

2. Replace all damaged or missing labels. To order new labels contact Betst Products.

r

3. Some new equipment installed during repair requires safety labels to be affixed to the

Replaced component assembly

4. Refer to this section for proper label placement.

To install new labels:

A. Clean the area where the label is to be placed.

B. Spray soapy water on the surface where the label is to be placed.

C. Peel backing from label. Press firmly onto the surface.

D. Squeeze out air bubbles with the edge of a credit card.

A

Farmer-Helper EFGCH Flail Mower 18 Revision 10-14-17

B

C

Farmer-Helper EFGCH Flail Mower 19 Revision 10-14-17

D

E

Farmer-Helper EFGCH Flail Mower 20 Revision 10-14-17

This manual suits for next models

5

Table of contents