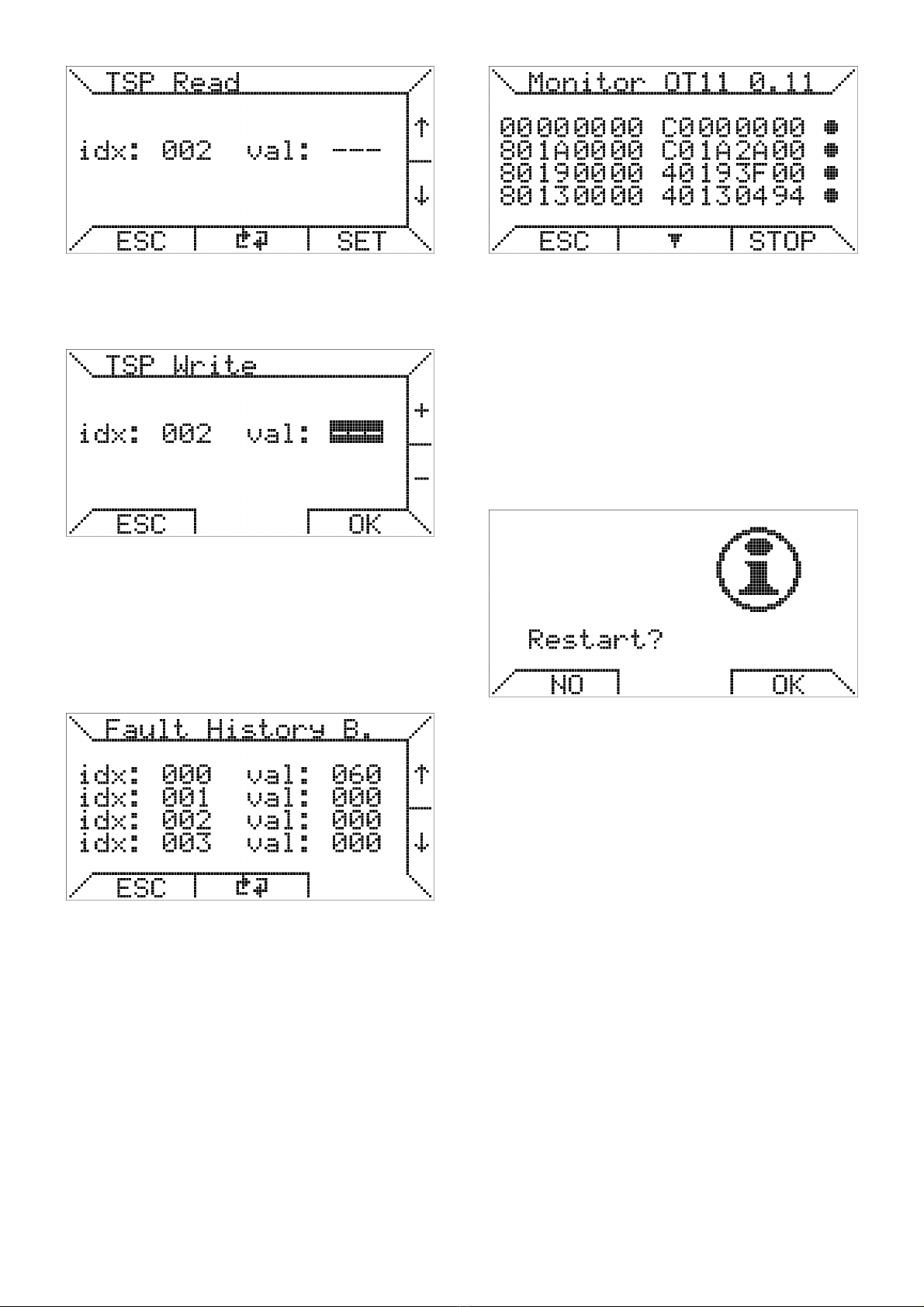

21689_r03 3/13

BASE FUNCTION

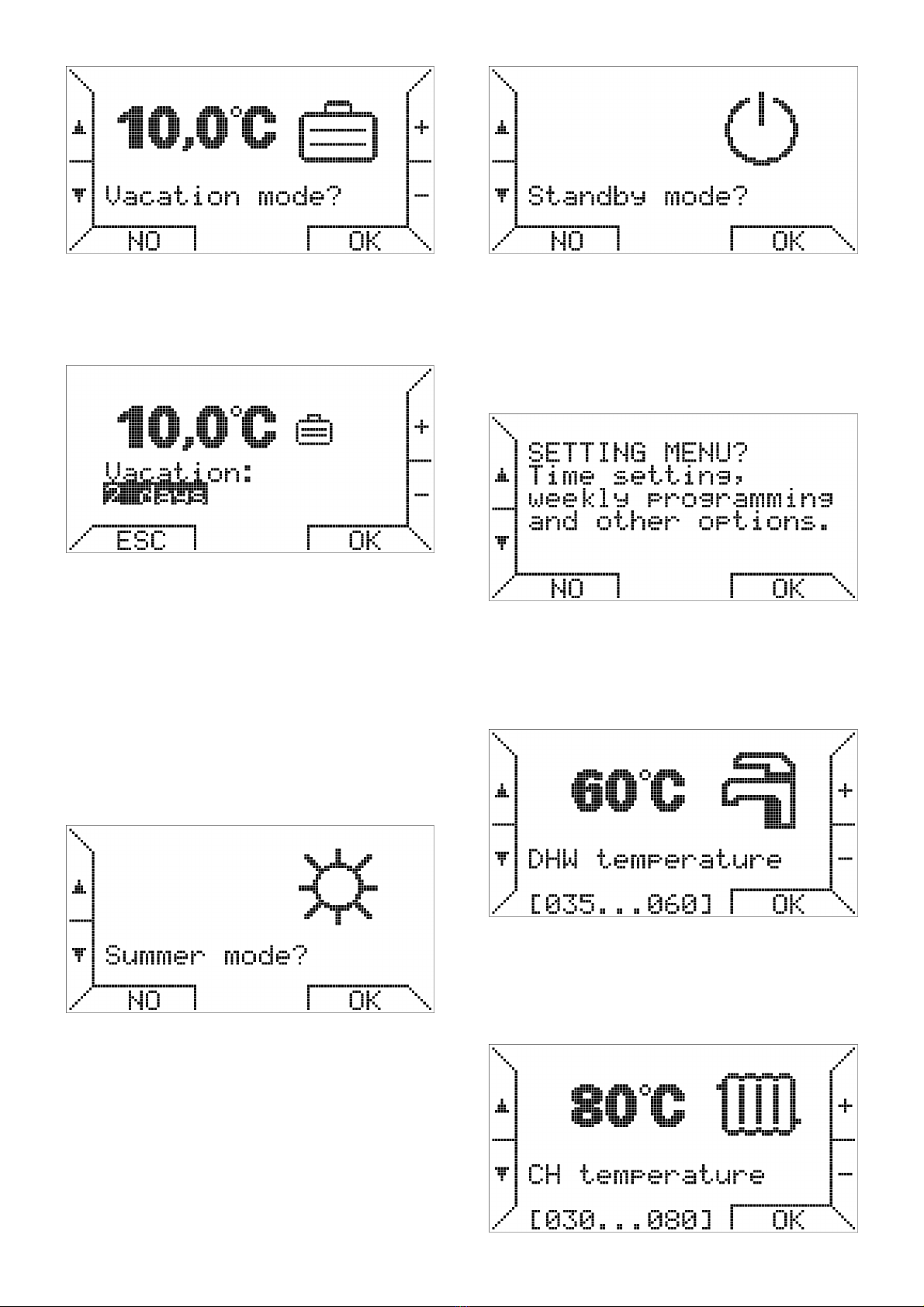

FIRST LEVEL MENU

When the chronothermostat is connected to a

thermoregulation board, the following screen appears on

the display.

If the thermoregulation board is not compatible, you will

receive an error message.

In the figure the main screen. Above are shown the day of

the week and the current time, these indications are

intermittent if they are not updated.

Below there is an indication of the temperature measured

(measurement every 10 seconds);

Beside, an icon indicates the function of thermoregulation

currently active: in this case the image of a clock indicating

the automatic operation.

Corrispondence between icons and operation modes:

Automatic

Temperature control environment

according to the weekly program

set by the user.

Program seen as a graph of the

current day.

Domestic hot water operation

enabled.

Manual

Temperature control environment

in accordance with a user-selected

temperature (thermostat function).

Domestic hot water operation

enabled.

Vacation

Temperature control at a fixed

temperature for a number of days

set by the user.

Domestic hot water operation

enabled.

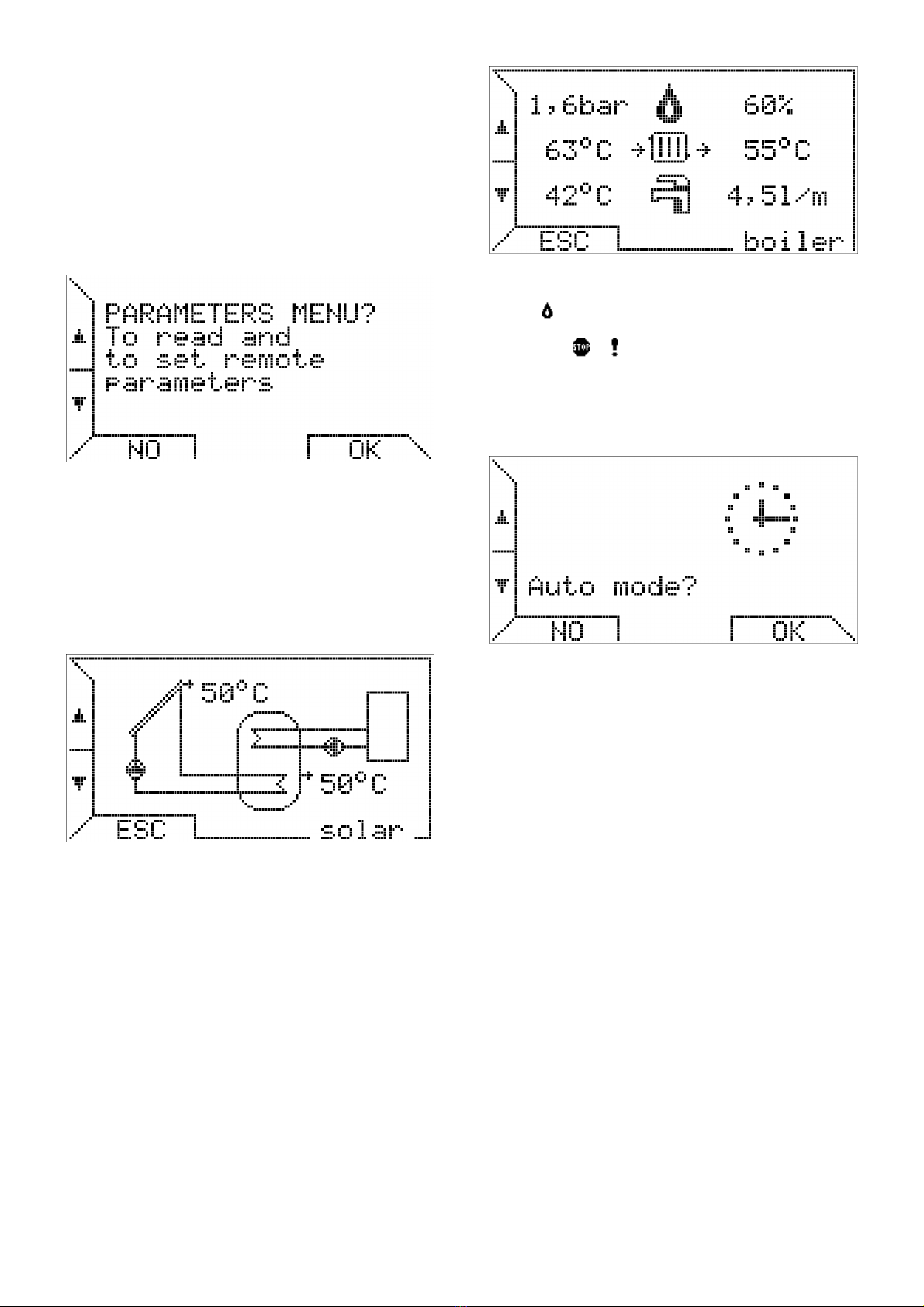

Summer

Temperature control environment

disable.

Summer ventilation can be

activated manually.

Domestic hot water operation

enabled.

Standby

Temperature control environment

disable.

Demand hot water operation

disabled.

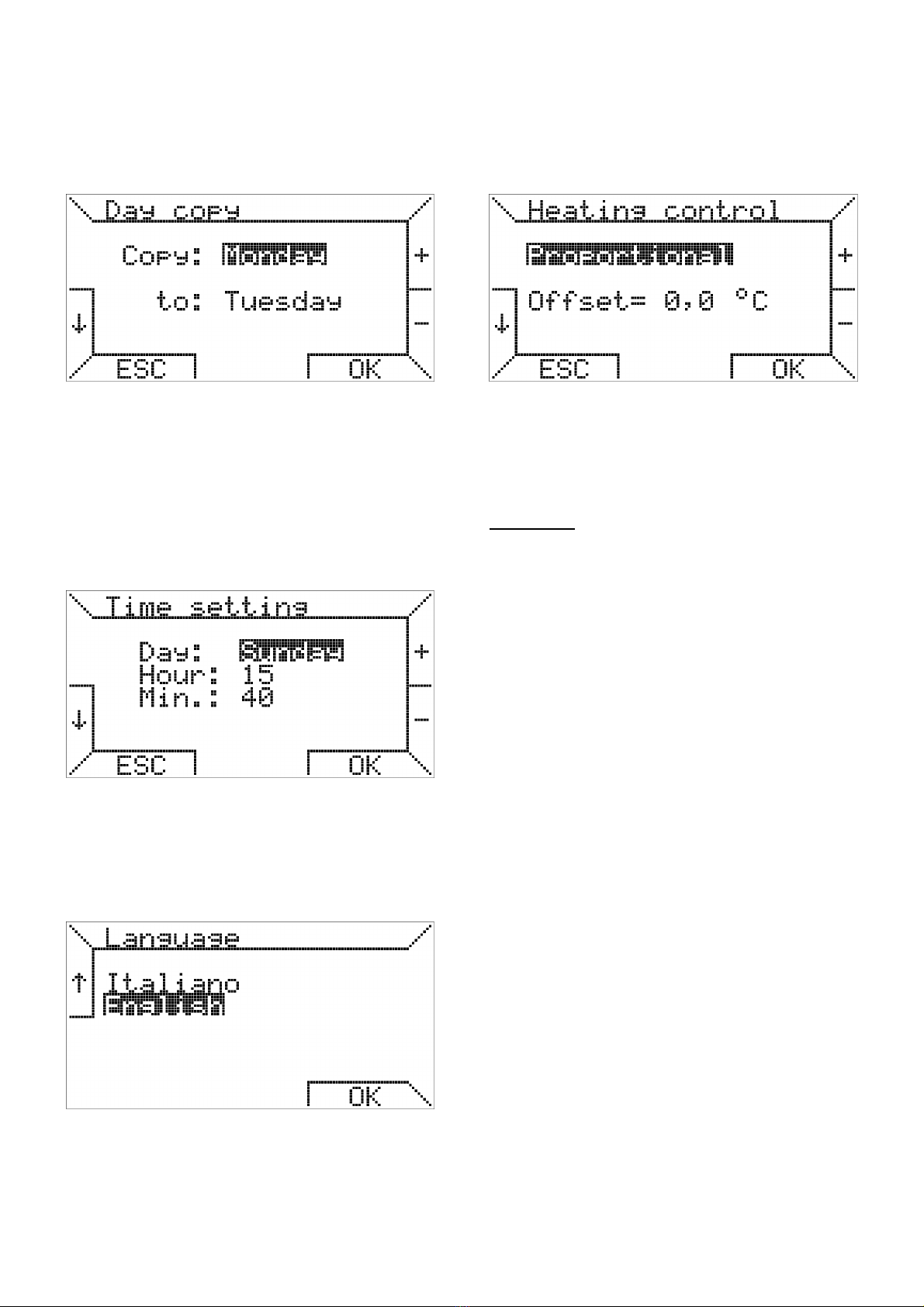

In “automatic mode”, the cronothermostat performs the

temperature control program was set for the current day,

the graph is visible at the bottom of the display.

The graph is divided into time intervals of 15 minutes,

corresponding to a pixel horizontally, and in the four

programmable temperature levels.

Near the icon of the operation mode other icons may

appear. If the boiler is turned on appears flame symbol,

different sizes depending on the modulation level of the

flame ( ). If it present a lockout or a fault appear

symbols ( , ) respectively and if it is not present the

connection icon appears symbol ( ). No icon appears in

the visualization if the boiler is in stand-by and has no

problem.

Under the indication of the ambient temperature may be

present, in addition, a line of text that provides information

to the user in special cases, such as the presence of error

or the status of additional functions such as management

of a system of solar panels integrated with the boiler and

managed by the thermoregulation board.

Here there are the messages that may appear, alongside

with their meanings:

Starting… OT11 is in the process of connection to the

boiler.

Modem connected OT11 correctly connected to the GSM modem.

Solare: standby Solar thermal system active and working correctly

in the standby state.

Solar: active Solar thermal system active and working correctly

with solar pump active.

Solar: boiler Solar thermal system active and working correctly,

integrated with the boiler.

Solar: disinf. Solar thermal system active and working correctly

with the tank disinfection procedure active.

Ambient probe error Room temperature sensor on OT11 damaged.

Solar: fault There is an anomaly in the solar thermal or part of

the boiler that manages the solar thermal system.

Modem error Communication error between OT11 and the

GSM modem

Fault code xxx There is an anomaly or a lockout on the boiler.

Code xxx .

Comm. error Communication error between OT11 and boiler.

Error ID xx The OT11 fails to correctly interpret of

information sent from the boiler.

Note: Please refer to the thermoregulation board's documentation for

detailed description of the fault codes and error codes.

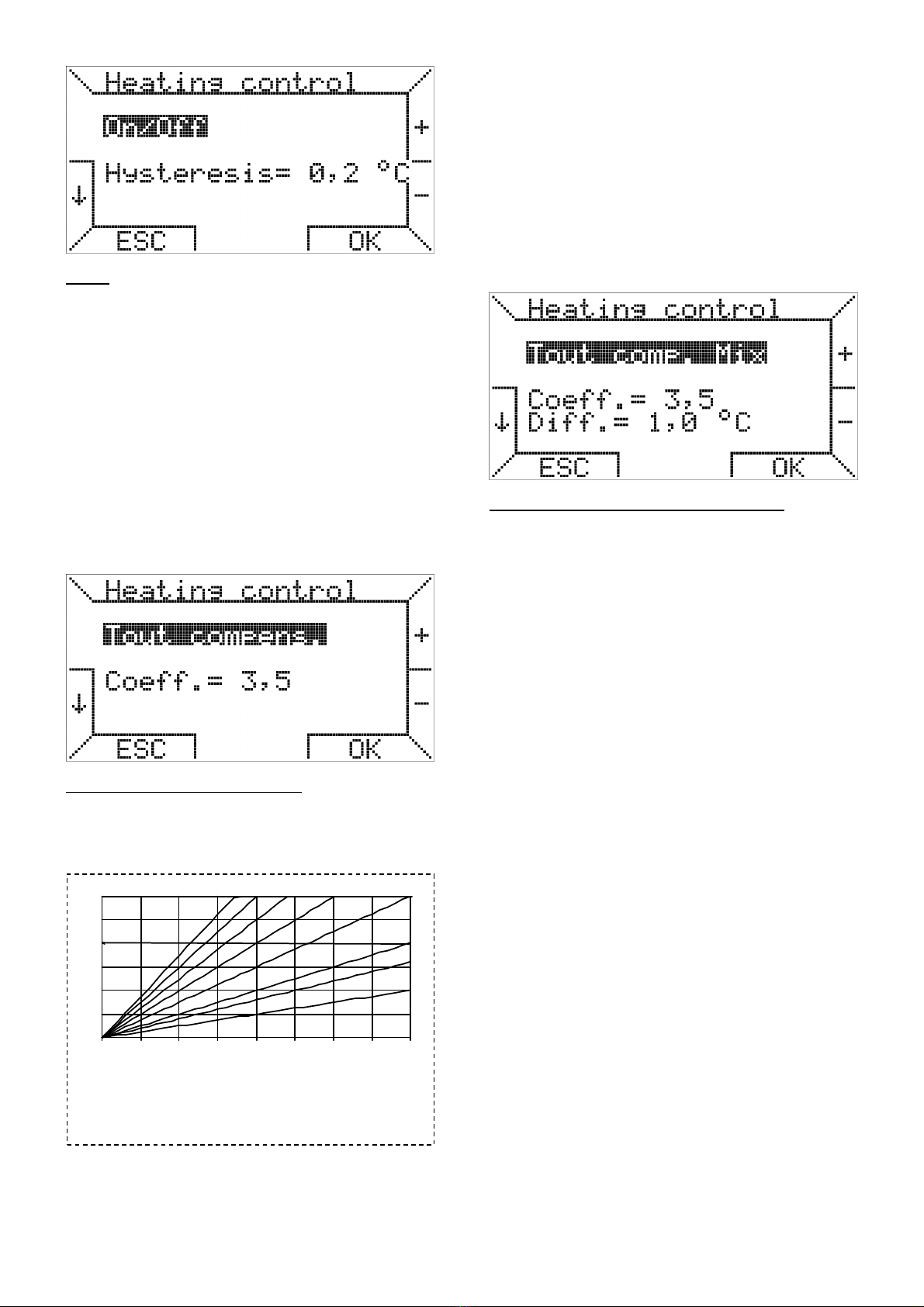

The buttons on the right, marked with + and -, allow to vary

the temperatures required for the automatic program (T0,

T1, T2, T3). Instead, in “manual mode” (icon ) allow to

vary the corresponding temperature.

Pushing the buttons on the left, marked with arrows, you

can browse the pages of first level menu.

Pushing the button ▼, the following display appears.

Pushing the buttons +/- you can vary the temperature and

pushing the button you activate the “manual mode”.

Another option selectable by the first level menu is the

“vacation mode”, which allows to maintain the desired

temperature for a configurable number of days, so as to

optimize power consumption in case of absence of the

users.