FIEDLER H531 User manual

+

Level measurement in

wells, boreholes,

tanks and sumps

Level gauge H531

user manual version 1.03

H531 level gauge assembly

User manual

2

electronics for ecology

FIEDLE R

H531 level gauge assembly

User manual

FIEDLE R electronics for ecology

3

1. SAFETY INSTRUCTIONS 4

2. USING THE LEVEL GAUGE 5

3. QUICK INSTALLATION OF THE LEVEL GAUGE 6

3.1.1. INSTALLING THE LEVEL SENSOR 6

3.1.2. INSTALLATION OF THE DISPLAY UNIT 7

4. BASIC DESCRIPTION 8

4.1. LEVEL SENSORS 8

4.1.1. ABSOLUTE LEVEL SENSOR 9

4.1.2. PRESSURE COMPENSATED LEVEL SENSORS 10

4.2. H531 IMAGING UNIT 12

4.2.1. DESCRIPTION OF H531 CONTROLS AND CONNECTIONS 12

4.2.2. POWER SUPPLY FOR THE LEVEL GAUGE 13

4.2.3. DESCRIPTION OF TERMINALS AND CONFIGURATION JUMPERS OF THE H531 UNIT 14

5. INSTALLATION 15

5.1. MECHANICAL INSTALLATION 15

5.1.1. INSTALLATION OF THE TSH27 ABSOLUTE LEVEL SENSOR 15

5.1.2. INSTALLATION OF A PRESSURE COMPENSATED LEVEL SENSOR 16

5.1.3. EXTENSION OF THE CONNECTING CABLE 16

5.1.4. INSTALLATION OF THE H531 DISPLAY UNIT 17

5.2. ELECTRICAL WIRING 18

5.2.1. CONNECTING THE LEVEL SENSOR TO THE H531 UNIT 18

5.2.2. CONNECTING AN EXTERNAL POWER SUPPLY TO THE H531 19

5.2.3. CONNECTING A RELAY OR OTHER POWER ELEMENT TO H531 20

6. PARAMETERS 21

6.1. H531 LEVEL GAUGE PARAMETERS 21

6.1.1. PARAMETER DISPLAY 21

6.1.2. STRUCTURE OF THE H531 MENU 22

6.2. PARAMETER EDITING PROCEDURE 23

6.3. BASIC FACTORY SETTINGS OF THE H531 LEVEL GAUGE 25

6.4. DESCRIPTION OF INDIVIDUAL H531 PARAMETERS 26

7. REMOTE ACCESS 40

7.1. ARCHITECTURE OF THE DATA ACQUISITION SYSTEM 41

7.1.1. ACTIVE STATION SYSTEM 41

7.1.2. DATA SERVICES 41

7.1.3. CLOUD SERVICES 41

7.1.4. DATAHOSTING AGGREGATE SERVICE 41

7.2. LEVEL GAUGE H531-G 42

7.2.1. GSM/GPRS TECHNOLOGIES 42

7.2.2. ANTENNA 42

7.2.3. PARAMETERS OF THE H531-G LEVEL GAUGE 43

8. TECHNICAL PARAMETERS 44

CONTE

NTS

H531 level gauge assembly

User manual

4

electronics for ecology

FIEDLE R

1. Safety instructions

•The installation of a level gauge with external power supply must be carried

out by a person with the necessary qualifications for the installation of elec-

trical equipment. The installer must carry out the installation in accordance

with all instructions, regulations and standards relating to safety and electro-

magnetic compatibility.

•If a malfunction of the level gauge could result in a risk to the safety or health

of persons or serious damage to property, independent measures must be

taken or additional equipment installed to eliminate this risk.

•All connected downstream equipment must comply with the relevant stand-

ards and safety regulations and be equipped with suitable anti-interference

filters and surge protection.

•Do not use in explosion hazardous areas!

•Do not use in areas of excessive vibration.

•The manufacturer is not liable for damages resulting from improper instal-

lation, improper maintenance or use contrary to the recommendations in

the operating instructions.

!

If an external power supply is used, it must meet all safety standards and be

appropriate for the environment in which it will be operated.

!

Connect the binary transistor output for switching a relay, solenoid valve or

light or sound signal only when the supply voltage is disconnected.

!

When installing a submersible level sensor, make sure that the maximum

measuring range of the sensor is not exceeded even at the maximum possi-

ble water level.

1

H531 level gauge assembly

User manual

FIEDLE R electronics for ecology

5

2. Using the level gauge H531

The battery-powered H531 level gauge assembly consists of the H531 display

unit itself and a submersible level sensor. The assembly is designed for level

measurement in rainwater tanks, cisterns and tanks, wells or boreholes.

The assembly can be used wherever the measuring range and accuracy of the

type of sensor used is suitable and where long-term archiving of the measured

values is not required (the H531 unit does not provide a datalogger function).

The H531 level gauge also includes a binary output controlled by the actual

measured level and therefore the level gauge assembly can be used, in addition

to displaying the level, for simple control of a pump or solenoid valve based on

user adjustable parameters.

The measured level height can be transmitted via the internal communication

module to the database on the server via GSM/GPRS or NB-IoT network (H531-

G or H531-N level gauges). The user can then monitor the level remotely via a

web browser. A special server service can also ensure that a warning SMS is sent

when a preset level is reached.

The mechanical design of the H531 display unit with IP66 protection allows the

unit to be placed outdoors directly at a well or rainwater sump. In this case, it is

advisable to avoid direct sunlight on the H531 display unit to prolong the life of

the unit, as UV radiation can cause the plastic materials used to become brittle.

TYPICAL APPLICATIONS

•Monitoring water levels in wells and boreholes

•Monitoring the level in stormwater sumps

•Automatic water supply to the tank

•Blocking the pump in the well from running on empty

•Indication of reaching limit levels

2

B i n a r y o ut pu t

R e m o te a c c e s s

L o c a t i o n

H531 level gauge assembly

User manual

6

electronics for ecology

FIEDLE R

3. Quick installation of the H531

3.1.1. Installing the level sensor

From the factory, the level gauge is assembled and set so that when the sensor

is lowered into the measured sump/mud/tank, the H531 display shows the

measured water level above the sensor. The measuring range of the level gauge

is determined by the type of sensor used (0 to 10 m, 0 to 25 m).

For a sensor with a measuring range of 0 to 10 mH2O, without further adjust-

ment of the H531 parameters, the display will also show a level height in the

range of 0 to 10 m, depending on the depth of immersion of the sensor below

the measured water level.

If the level gauge is to indicate the level from the bottom of the measured

sump/cold and the measuring range of the sensor used is greater than or equal

to the maximum possible level in the measured sump/cold, then it is sufficient

to lower the level gauge to the bottom.

In these first two cases, the user does not need to make any changes to the

parameter settings when installing the level gauge.

Measurement by immersion depth Level measurement from the bottom

Param. Delta

3

L e v e l

m e a s u r e m e n t b y

i m m er s i o n d e p t h

L e v e l

m e a s u r e m e n t f r o m

t h e b ot t o m

H531 level gauge assembly

User manual

FIEDLE R electronics for ecology

7

If the level gauge is to display the level from the bottom even if the measuring

range of the sensor used is less than the maximum possible level in the meas-

ured sump/well (third case in the previous figure), then it is necessary to correct

the measured level with the Delta parameter. The numerical value of this pa-

rameter will be permanently added to the measured level height in the H531

unit. It is clear from the principle that the displayed level height will never fall

below the value of the Delta parameter in this case.

The approach to the Delta parameter is given in chap. 3-4-3 Delta on p. 31.

3.1.2. Installing the display unit

The H531 display unit is usually placed close to the measured level. The maxi-

mum possible distance between the submerged transducer and the display unit

is determined by the length of the connection cable between the transducer

and the unit.

If it is necessary to place the display unit

at a greater distance from the measured

sump/cell, then the connection cable can

be extended (see chap. 5.1.3 Extension of

the connection cable on p. 16), or order

an extra length of jumper cable from the

level meter manufacturer.

The mechanical design of the imaging unit

allows it to be placed outdoors, it is only

necessary to protect the unit with a suita-

ble cover from direct sunlight to prevent

gradual degradation of the plastic imag-

ing panel due to UV radiation.

The display unit is factory set to a power

saving display mode, in which the unit's

display wakes up only for a short time af-

ter pressing one of the unit's control but-

tons. The unit is powered by an internal

lithium battery in this mode.

If the level gauge is to be operated in the

mode with permanently switched on dis-

play of the measured level, then it is nec-

essary to connect to the H531 display unit

a source of external power supply voltage of 5 to 28 VDC (see chap. 5.2.2 on p.

19).

The installation of the level gauge is covered in more detail in the chapter 5.

Installation on p. 15.

The installation and commissioning of the level gauges with the H531-G

or H531-N communication module is described in chapter 7-Remote access on

p. 40.

L e v e l co r r e c t i o n

b y D E LTA

p a r a m e t e r

C o v e r ag e f r o m

s u n l i g h t

P ow er s u p p l y a n d

o p e r at i n g m o d e

H531 level gauge assembly

User manual

8

electronics for ecology

FIEDLE R

4. Basic description

4.1. Level sensors

The submersible transducer converts the pressure applied to the

diaphragm by the transducer into an electrical signal measurable

by the H531 using a strain gauge sensor.

According to the type of measuring sensor used, strain gauge

sensors are divided into:

-absolute sensors

-pressure compensated sensors

The principle of measuring both types of sensors is explained in the following

two chapters.

Absolute sensors do not require a special cable with a compensation capillary

and therefore usually have a lower purchase price. On the other hand, they re-

quire more complex processing of their output signal in the connected display

unit.

The H531 can work with both types of sensors.

The level sensor is usually suspended by a cable above the bottom of the sump,

well or borehole being monitored. However, in some cases, instead of submerg-

ing the sensor in the monitored environment, it may be advantageous to screw

the sensor into a ½" sleeve located at the bottom of the vessel or sump being

measured.

Each level sensor includes a cable that suspends the sensor and connects it to

the H531 display unit. Since the cable is an integral part of the sensor, the length

of the cable along with the measurement range of the sensor must be specified

when ordering the sensor.

The connection cable is used both for powering the sensor's own electronics

and for transmitting the measured signal from the sensor to the H531 unit.

Pressure compensated sensors require a special cable with a compensation ca-

pillary. Therefore, the purchase price of such a sensor is usually higher than that

of an absolute sensor. This is especially true for sensors installed in deep bore-

holes, which require a long connection cable.

4

S e n s o r di v i s i o n

S e n s o r l oc a t i o n

S e n s o r ca b l e

C a bl e p r i c e b y

s e n s o r t yp e

TSH27 ab-

solute le-

vel sensor

H531 level gauge assembly

User manual

FIEDLE R electronics for ecology

9

TSH27 absolute sensor

(without sensor cap)

4.1.1. Absolute level sensor

These sensors use an absolute pressure sensor to measure the water level,

which measures the hydrostatic pressure of the water above the sensor (h) in-

cluding the atmospheric air pressure (atm) and converts the resulting total pres-

sure to an output voltage signal in the range of 0 to 5 V.

The principle of level measurement with an absolute level sensor

In the H531 evaluation and display unit, the atmospheric air pressure separately

measured by the H531 is automatically subtracted from the sensor output sig-

nal. The resulting value, corresponding to the height of the water level above

the sensor, is converted to a numerical value displayed on the H531 LCD.

The absolute pressure measurement principle used allows the sensor to be con-

nected to the H531 level gauge via a standard 3-core cable without the usual

atmospheric pressure compensation capillary. A standard cable without a com-

pensation capillary is easier to handle, can be easily extended if necessary and

is also significantly cheaper than a cable containing a compensation capillary.

ABSOLUTE LEVEL SENSOR TSH27-X/Y (0-5 V output)

The TSH27 is an inexpensive absolute level sensor that does not require a special

cable with compensating capillary. The sensor has a stainless steel body with a

diameter of 27 mm and is 115 mm high including the sensor cap. By unscrewing

this cap, the sensor can also be installed in a ½" sleeve.

TSH27 sensors are available in two measuring ranges:

•TSH27-10/10 or TSH27-10/25

(measuring range 0 .. 10 mH2O, PUR cable 10 m or 25 m)

•TSH27-25/30

(measuring range 0 .. 25 mH2O, PUR cable 30 m)

The TSH27 can be supplied with a different cable length for an additional charge.

The sensors have a measurement accuracy of 2.5% of the range and an output

signal of 0..5 V DC. The H531 unit is factory set to connect this type of absolute

encoder.

TSH27-10/25 sensor with measuring range 0..10 mH2O, cable 25 m.

S e n s o r si g n a l

p r o c e s si n g

U s i n g a c h e a p

c a b l e

E xa m pl e 1 .

TSH27 absolute

sensor (without

sensor cap)

H531 level gauge assembly

User manual

10

electronics for ecology

FIEDLE R

TSH35 sensor

4.1.2. Pressure compensated level sensors

For sensors with automatic compensation of atmospheric air pressure, a special

cable containing a compensation capillary (tube) is used to supply air pressure

(atm) to the back of the strain gauge diaphragm of the sensor. The sensor then

measures only the pressure of the water itself above the sensor (h) acting on

the front side of the measuring diaphragm, since the air pressure above the wa-

ter level is compensated by the air pressure supplied by the compensation ca-

pillary to the back of the sensor diaphragm.

The principle of level measurement using a pressure compensated level sensor

The deflection of the strain gauge diaphragm caused by the water pressure is

converted into a corresponding electrical signal in the sensor. The output signal

from the pressure-compensated sensor therefore does not contain an air pres-

sure component, as in an absolute level sensor, and is proportional only to the

measured height of the water level (h) above the sensor.

There are many pressure compensated sensors on the market and most of them

can be easily connected to the H531. The following overview lists the 2 basic

types of recommended pressure compensated sensors suitable for connection

to the H531 display unit.

TSH35-10/Y LEVEL SENSORS (4-20 mA output)

Cost-effective pressure compensated level sensor with stainless steel body and

measuring diaphragm. These sensors are suitable for routine level measure-

ments of both domestic and waste water.

The sensor has a current output of 4-20 mA and typical measurement accuracy

is better than 0.5% of the measurement range. The sensor body has a diameter

of 24 mm and a height of 70 mm.

TSH35-10/Y sensors are available in only one measuring range:

0 .. 10 mH2O

The Y symbol indicates the required length of the PUR compensation cable in

metres (10 m and 100 m cables are offered as standard).

TSH35-10/10 sensor with measuring range 0..10 mH2O, cable 10 m.

E xa m pl e 2 .

H531 level gauge assembly

User manual

FIEDLE R electronics for ecology

11

LMK809 sensor

(4-20 mA)

LMK809-X/Y LEVEL SENSORS (4-20 MA OUTPUT)

Pressure compensated level sensor with plastic body and ceramic diaphragm.

These sensors are suitable for level measurement even in heavily polluted

wastewater.

The sensor has a current output of 4-20 mA and typical measurement accuracy

is better than 1% of the measurement range. The sensor body has a diameter

of 45 mm and a height of 126 mm.

The LMK809-X/Y sensors are available in measuring ranges from 0 .. 0.4 mH2O

to 0 .. 100 mH2O (X in the sensor ordering code):

0.4 m; 0.6 m; 1 m; 2.5 m; 4 m; 6 m; 10 m; 25 m; 40 m; 60 m; 100 mH2O

The Y symbol represents the required length of the PUR compensation cable in

metres.

LMK809-4/6 sensor with measuring range 0..4 mH2O, cable 6 m.

E xa m pl e 3 .

H531 level gauge assembly

User manual

12

electronics for ecology

FIEDLE R

4.2. H5 display unit 31

4.2.1. Description of H531 controls and connections

The H531 level gauge display unit is housed in a 120 x 80 x 55 mm plastic box

with IP66 protection. The top of the box contains a control panel with display

and three knobs. The bottom part contains the power battery and the control

electronics board with terminals for connecting the cable from the level sensor,

power supply and relay. Two M12 pins [9, 10] are provided on the underside of

the level gauge for cable connection. Access to the terminals is possible by loos-

ening the four M4 screws in the corners of the upper part.

In addition to the cable glands, the bottom part of the unit contains a semi-

permeable filter [5], which on the one hand allows the atmospheric air pressure

to be equalized between the external environment and the inside of the box,

and on the other hand prevents the penetration of air moisture to the electron-

ics of the H531 unit. When using a pressure-compensated level sensor with a

cable containing a compensation capillary, the filter also prevents the penetra-

tion of moisture through the capillary into the body of the sensor itself.

1

Graphic LCD display with backlight.

2

SET knob to turn on the display, enter MENU and confirm the MENU selec-

tion and confirm the parameter set value.

3

Knob to turn on display, move down in MENU, change parameter - de-

crease parameter value.

4

Knob to turn on display, move up in MENU, change parameter - increase

parameter value.

5

Filter to equalize atmospheric air pressure inside and outside the H531 unit.

6

Display of the measured level value adjusted by the additive coefficient [m].

7

Displays the percentage value of the measured level adjusted by an addi-

tive coefficient relative to the set maximum level.

8

Coaxial FME connector for connecting the antenna of a GSM/GPRS or NB-

IoT communication module with standard 1 dB antenna. Only H531-G and

H531-NB units include the communication module.

9

Cable gland for external power supply and binary output cable.

10

Cable gland for connection of the immersion level sensor.

M e c h a n i c al

a r r a n g e m en t

F i l t er D A 2 8 4

H531 level gauge assembly

User manual

FIEDLE R electronics for ecology

13

The control panel of the level gauge contains a graphic LCD display, supple-

mented for better readability by a switchable orange backlight. The display in

basic operating mode shows the measured level [m] with a resolution of 0.1 m

[6], accompanied by a graph of the last 72 measured level values [1]. The display

also shows the percentage of the currently measured level relative to the set

maximum possible level [7].

When the binary transistor output of the H531 unit is switched on, an icon indi-

cating this condition appears in the upper left window of the graph.

The battery-powered level gauge switches on the graphic display and its back-

light for a preset time only after pressing one of the control buttons. The time

the display turns on after the knob is pressed is an adjustable parameter, and

this feature is implemented in the unit to save power on the power supply bat-

tery.

However, the device parameters can be set to an operating mode that keeps

the display, and possibly its backlight, permanently on in the presence of an ex-

ternal power supply (parameter 3-2-2 Working mode on p. 26).

Three control knobs [2, 3, 4] are used to wake up the unit from the power saving

mode to turn on the graphic LCD display (touch any of the knobs), as well as to

set and change the parameters of the device. The knobs react to the touch of a

finger and therefore have no mechanical switching response.

The description of individual parameters and the method of their change and

setting is given in chap. 6.4 Description of individual H531 parameters on p. 26.

4.2.2. Power supply for the level gauge

The H531 is powered by a replaceable 3.6 V lithium battery with a capacity of

19 Ah (Li-SOCl2 battery type ER34615). This battery powers both the H531 dis-

play unit itself and the TSH22 submersible level sensor.

If the level gauge includes a built-in GSM communication module, which re-

quires higher current consumption for data transmission, then the level gauge

must be powered by a spiral type lithium battery 3.6 V / 13 Ah, which provides

a short-term peak current of up to 1.8 A (battery type ER34615M).

The battery used is sufficient for up to 10 years of operation of the unit without

the communication module and up to 5 years of operation of the unit with the

built-in GSM or NB-IoT communication module. The battery lifetime is affected

by both the frequency of measurements and the frequency of data sessions to

the server. Both parameters are user adjustable (see parameter 3-2-3 Measure-

ment interval on p. 27 and parameter 3-6-2 Transmission Interval [hr] on p. 35).

A suitable type of replacement power supply battery can be ordered from the

supplier of the level gauge.

If you need to operate the H531 unit with the LCD display permanently on or

use the communication module for frequent data transfers to the server, then

it is advisable to power the H531 unit from an external power supply in addition

to the replaceable battery. This should have a DC output voltage in the range of

5 to 28 V DC (typically 12 V DC / 200 mA).

The internal battery is disconnected while external voltage is present, thus sav-

ing battery capacity. The battery is automatically connected to the unit only dur-

ing any external power failure.

G r a ph i c di s p l a y

A u t o m a t i c d i s p l a y

s h u t d o w n

C o nt ro l k n o b s

P ow er b a t t e r y

E x t e r n al p o w e r

s u p p l y f o r l ev e l

g a u g e

H531 level gauge assembly

User manual

14

electronics for ecology

FIEDLE R

4.2.3. Description of terminals and configuration jumpers of the H531

The circuit board inside the H531 unit contains connection terminals and jump-

ers for selecting the level sensor to be used.

Note: When using level sensors with RS485 digital output, the position of jump-

ers 6 and 7 does not matter.

1

Replaceable power supply battery type ER34615 (ER34615M for H531-G)

2

Removable terminal block for connecting the cable from the level sensor

1 - GND negative supply voltage of the level sensor, cable shielding

2 - PIN spare input - leave free

3 - AIN input of the sensor signal wire 0..5 V or 4(0)-20 mA

4 - RS485-A sensor connection via RS485 interface

5 - RS485-B sensor connection via RS485 interface

6 - UNAP positive supply voltage of the level sensor +12 V DC

3

Removable terminal block for connecting external power cable and binary

output

7 - OK binary output-open collector; Umax: 28 V DC, Imax: 300 mA

8 - GND connection of the negative pole of the external supply voltage

9 - EXT connection of the positive pole of the external supply voltage

5..28 V DC

4

Connector for connection of GSM/GPRS or NB-IoT plug-in communication

module

5

Flat cable terminated with a connector to connect the display electronics

located in the cap of the H531 unit

6

Mounting cable for sensors with 0-5 V output (= TSH27)

(position 7 must remain unconnected)

7

Mounting jumpers for sensors with 4-20 mA output (= LMK809)

(position 6 must remain unconnected)

H531 level gauge assembly

User manual

FIEDLE R electronics for ecology

15

5. Installation

5.1. Mechanical installation

5.1.1. Installation of the TSH27 absolute level sensor

The submersible level sensor can be simply lowered by cable

into the measured object (well, sump, etc.) to such a position

that even at the expected minimum level the sensor is still sub-

merged and the maximum level in the measured object does not

exceed the measuring range of the sensor (10 mH2O for the

TSH27-10 sensor or 25 mH2O for the TSH27-25 sensor).

The TSH27-10 can be ordered with a 10 m and 25 m intercon-

necting cable. The TSH27-25 is available with a 30 m intercon-

necting cable.

As the TSH27 sensor cable does not contain a capillary to com-

pensate for atmospheric air pressure (atm), the cable can be

clamped tightly into the supplied cable gland to fix the sensor in the desired

position - immersion depth. A cable gland on the cable, supported by the tank

or well lid, prevents the sensor from dropping below the desired position.

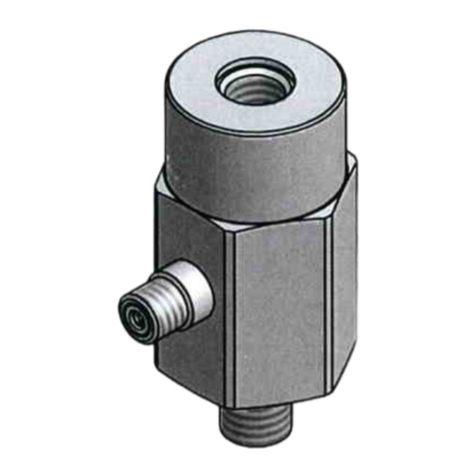

The TSH27 level sensor can also be installed outside the tank in a ½" sleeve lo-

cated at the bottom of the measured vessel. For this type of installation, the

black plastic cap of the measuring

diaphragm must first be removed

(unscrewed) from the sensor.

When installing the sensor, it is rec-

ommended to place a shut-off valve

between the sensor and the meas-

ured vessel, which will allow the

sensor to be replaced without emp-

tying the measured vessel. In this case, however, it is necessary to use a suitable

type of valve that does not increase the pressure on the measuring diaphragm

of the sensor when closing, which could lead to overloading and subsequent

destruction of the sensor.

5

I n s t al la t i o n by

i m m er s i o n

f o r t h e c a b l e

I n s t al la t i o n i n t h e

t r a i l e r

H531 level gauge assembly

User manual

16

electronics for ecology

FIEDLE R

5.1.2. Installing a pressure compensated level sensor

The connection cable of each pressure compensated level sensor contains a compensation

capillary which must remain permeable after the sensor is installed to equalize the atmos-

pheric air pressure between the sensor body and the surrounding environment.

Therefore, the cable cannot be bent to a radius of less than 15 cm during installation, nor

can it be clamped by the cable grommet when hanging the sensor in the desired position

as with the TSH27 sensor. For hanging the sensor by the cable with the compensating ca-

pillary, a stainless steel Hinge-U is provided, which can be ordered together with the level

gauge.

Hanger-U designed to lower the pressure compensated transducer by the cable to the de-

sired depth of the tank/sump/well to be measured.

5.1.3. Extension of the connection cable

If necessary, the connection cable between the sensor and the H531 display unit

can be extended.

However, for reliability of operation, we recommend that the H531 unit be

placed close to the sensor itself to prevent inducing surges in the interconnecting

cable or equalizing ground potential differences between the sensor and the

H531 unit during storms.

Instead of extending the connecting cable, it is preferable to order the H531

level gauge assembly with the required length of connecting cable for a small

extra charge.

ABSOLUTE SENSOR CABLE EXTENSION

The TSH27 absolute sensor is connected to the unit with a standard three-core

cable without a compensating capillary and therefore the extension of the con-

necting cable can easily be realized with, for example, JYTY cables or some other

type of control or communication shielded cable.

PRESSURE COMPENSATED SENSOR CABLE EXTENSION

It is also possible to extend the connection cable of a pressure compensated

sensor with some type of communication or control cable, but it is necessary to

ensure that the connection between the original cable from the sensor with the

compensation capillary and the extension cable is permanently above the level

of the measured water. The compensation capillary must continue to supply at-

mospheric air pressure behind the measuring diaphragm of the transducer and

therefore the cable connections cannot be underwater or hermetically sealed

as with the absolute transducer extension cable.

In order to prevent water vapour from penetrating through the compensation

capillary into the sensor body itself to its measuring electronics, it is necessary

to treat the end of the compensation capillary with a suitable type of filter. Such

a filter, type DA284, is located next to the cable glands on the bottom edge of

the H531 display unit, or can be ordered from the level gauge manufacturer.

The mechanical design of the cable connection can thus be implemented, for

example, in a small installation box fitted with the above-mentioned DA284 fil-

ter on the side.

H i n g e - U

N o t e

O r d er c a b l e f r o m

t h e m a n uf a c t u r e r

F i l t er D A 2 8 4

H531 level gauge assembly

User manual

FIEDLE R electronics for ecology

17

5.1.4. Installing the H531 display unit

The H531 unit is usually placed

in the immediate vicinity of

the measurement. The me-

chanical design of the unit al-

lows it to be placed directly

outdoors. In this case, it is

only necessary to protect the

unit with a suitable cover from

rain and direct sunlight to pre-

vent the UV radiation from

gradually degrading the plastic

display panel of the unit.

For the actual mounting of the

H531 unit, there are 4 mount-

ing holes in the bottom of the level gauge box that are accessible by removing

the top of the display box. When installing the level gauge, the flat cable con-

necting the bottom and top of the H531 display unit can be disconnected for

ease of installation.

The following figure shows four mounting holes with a diameter of 4.1 mm and

a spacing of 50 x 108 mm.

Since the H531 unit includes a display and knobs for controlling the unit, it is

advisable to install the unit in an easily accessible location and preferably at eye

level.

M e c h a n i c al

d i m e n si o n s H5 3 1

H531 level gauge assembly

User manual

18

electronics for ecology

FIEDLE R

5.2. Electrical wiring

5.2.1. Connecting the level sensor to the H531 unit

The detachable series terminal block with terminals 1 to 6 is designed for con-

necting a level sensor. The colour coding of the individual cores and their con-

nection can be seen in the following figures. The cable shield is always con-

nected to terminal GND [1].

The TSH27 and TSH35 or LMK809 sensors have interchanged power and signal

wire colours. Therefore, pay due attention to the sensor connection!

C o n n e c t i n g t h e

T S H 2 7 l ev e l

s e n s o r

R e m a r k :

C o n n e c t i n g t h e

L M K 8 0 9 o r T S H 3 5

l e v e l s e n s o r

H531 level gauge assembly

User manual

FIEDLE R electronics for ecology

19

The two previous sensors also have different type of analog output signal (0..5

V for TSH27, 4-20 mA for LMK809 and TSH35) and therefore it is necessary to

set the correct position of jumpers 6 and 7 from the picture on page 6. 14.

The correct jumper position for each type of sensor is also shown in the previous

two figures by the red highlighted rectangle to the right of terminals 3 and 4.

5.2.2. Connecting an external power supply to the H531

Terminals 8 and 9 are used to connect an external supply voltage in the range

of 5 to 28 V DC (typically 12 V DC) from a safe voltage source designed for the

environment of the level gauge installation site. The positive terminal of the

power supply is connected to terminal 9 [EXT] and the negative terminal to ter-

minal 8 [GND].

An external power supply is only required when operating the H531 unit with

the backlit display permanently on or in the case of frequent data transmissions

to the server for level gauges equipped with a communication module (H531-G

or H531-N). For other normal operation of the level gauge, no external power

supply is required and the H531 level gauge can be operated permanently from

the internal power supply battery.

A suitable power supply can be ordered together with the level gauge:

DELTA-12V/10W

DIN rail power supply; 12 V DC / 10 W

ESPE-0312-W2E

Socket adapter, 12 V DC / 300 mA

!

The external power supply must meet all safety standards and be appro-

priate for the environment in which it will be operated.

S e t t i ng j u m p e r s

H531 level gauge assembly

User manual

20

electronics for ecology

FIEDLE R

5.2.3. Connecting a relay or other power element to the H531

The H531 includes an open-collector binary output that can directly switch an

alarm siren or auxiliary power relay. The binary output switching transistor con-

nected between terminals 7 [OK] and GND [8] can handle a continuous maxi-

mum current of 0.5 A and is rated to switch loads connected to supply voltages

up to 28 VDC.

A pump supplied with 230 VAC mains voltage must be connected to the H531

level gauge via an external auxiliary relay as shown in the following figure.

Example of connecting an external relay or audible siren to the terminals of a

level gauge.

In the picture, the coil of the power relay and the warning siren are connected

to an external supply voltage of 24 V DC and 12 V DC respectively. However, the

external supply voltage of the H531 level gauge can range from 5 V to 28 V DC.

INSTALLATION NOTE H531 FOR PUMP CONTROL OR EL. VALVE

If the H531 level gauge is to directly control a

pump or other power element via an auxiliary

relay, then it is usually advisable to use a suit-

able power cabinet for the placement of the

power elements and the source of external

supply voltage. The H531 level gauge display

unit can then usually be placed on the front

panel of the power cabinet.

Since the H531 level gauge contains only 2 ca-

ble glands and one of these glands is perma-

nently occupied by the connected level sensor,

the external supply voltage wires (terminals 8,

9) and the relay coil control signal (terminal 7)

need to be combined into one 3-core cable and

the cable needs to be pulled through the free

cable gland of the H531 unit.

P ow er d i s t r i b u t i o n

box

Table of contents

Popular Measuring Instrument manuals by other brands

Extech Instruments

Extech Instruments EN510 user manual

ICP DAS USA

ICP DAS USA iWSN-9601 Series quick start

Dwyer Instruments

Dwyer Instruments RPME Series Specifications-installation and operating instructions

Hoymiles

Hoymiles DTU-W100 user manual

FRER

FRER Q52A3H Series operating manual

PRESIDIUM

PRESIDIUM Multi-Tester III User handbook