FIESSLER

ELEKTRONIK

10

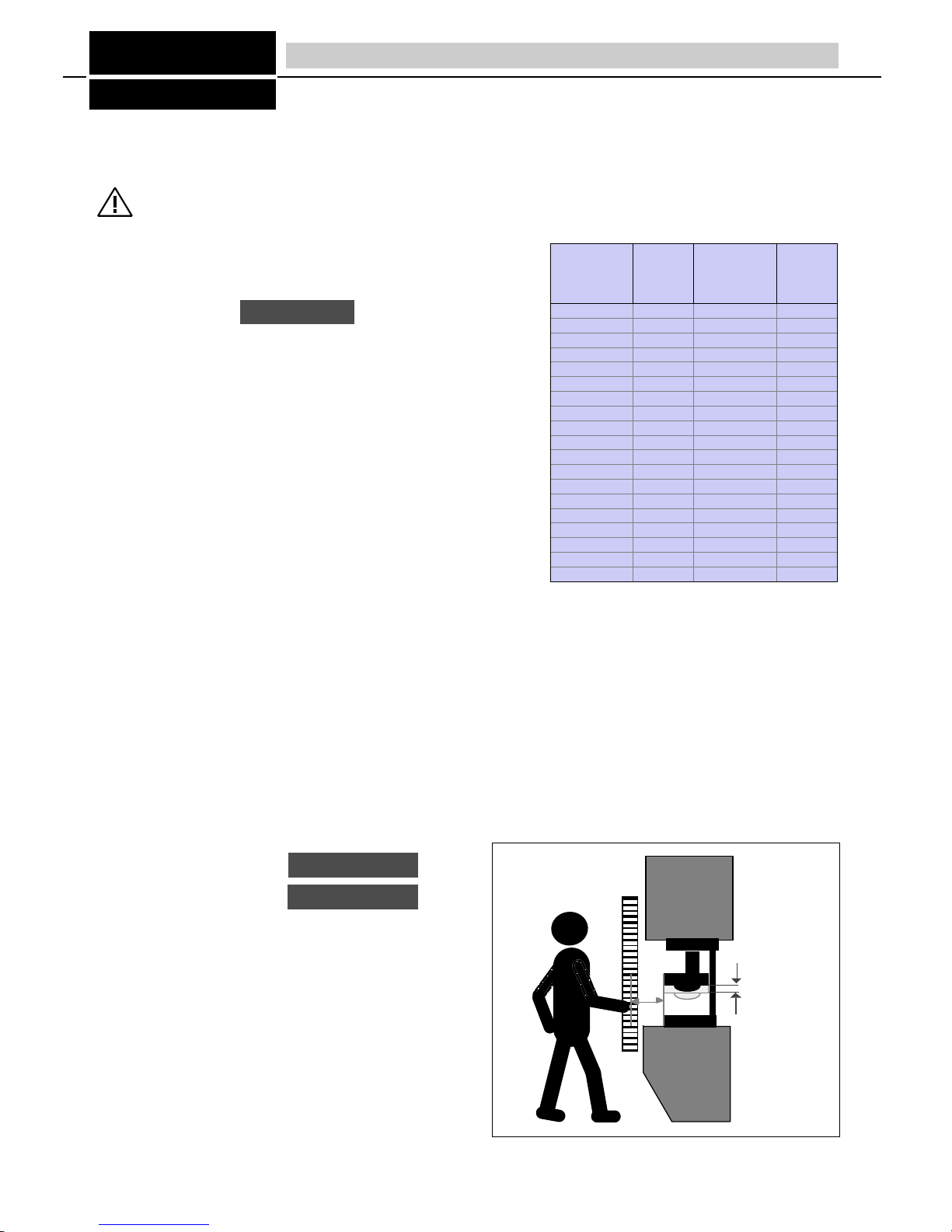

4.1 Safe distance from hazardous area

The safe distance (S) between the accident-preventing light barrier and hazardous area must be big enough to ensure that when

the protective field is penetrated, the hazardous area cannot be accessed before the hazardous movement has been

ended. In addition, it must be ensured that reaching over, under or around, or walking behind the protective field is

prevented by additional mechanical screening or further light barriers. To this end, please also refer to EN 999 and

other effective national and international safety regulations.

4.1.1 Vertical light barrier protection of hazardous areas

The safe distance S is calculated as follows:

- K = Grabbing speed or approach speed

For the grabbing speed K, a speed of 2000 mm/s is preset. If the calculation

for S produces a value greater than 500 mm, the calculation can be repeated

with 1600mm/s if this does not lead to a value lower than 500 mm (smin > 100

mm)

- T = t1 + t2 t1 = Response time of the safety device

t2 = Run-on time of the machine

With ULVT light barriers, the response time of the safety

device

t1 depends on the number of beams (refer to Table 10/1).

When using the ULVT with the optional safety

switchgears, the

response time of the switchgears is added to t1:

For LSUW N1 Muting switchgear: 20 ms

For LSUW NSR 3-1K switchgear: 25 ms

For ULSG switchgear: 6 ms

The run-on time of the machine t2 must be specified by the

machine manufacturer.

- C = 8 (d - 14 mm) d = Definition of the safety device

(minimum detectable obstacle size)

The definition capacity d ( = 14 mm or 30mm) is specified on the nameplate of the ULVT light barrier,

for d =14mm => C=0, for d= 30 0> C= 128mm

Calculation examples for the safe distance with vertical area protection using ULVT light barriers

≥

Example 1:

ULVT100/13 safety light barrier

Run-on time t2 of the machine from 75 ms

S = 2000 mm/s x (0.075s + 0.006s)

S = 162 mm

Example 2:

ULVT500/35 safety light barrier

ULSG safety switchgear

Run-on time t2 of the machine from 75 ms

S = 2000 mm/s x (0.075s + 0.007s + 0.006s) +8(30mm-14mm)

S = 304 mm

Table 10/1 Response time t1 of the ULVT light

barriers (standard form factors)

SNachlaufweg

der Maschine

4 Installation - Safe distances

S = (K x T) + C

Fig. 10/1 Vertical protection of hazardous areas

For S = 100 mm to 500 mm:

For S > 500 mm:

S = (2000 mm / s .T)

S = (1600 mm / s .T)

BA - ULVT

Run-on path

of the machine

Protective field

height / no of

smallest

obstacle

14mm

reaction

time

(ms)

14mm

Protective field

height / no of

smallest

obstacle

30mm

reaction

time

(ms)

30mm

ULVT100 /13 6 ULVT100 /7 5

ULVT200 / 26 7 ULVT200 / 14 6

ULVT300 / 39 8 ULVT300 / 21 6

ULVT400 / 52 9 ULVT400 / 28 7

ULVT500 / 65 10 ULVT500 / 35 7

ULVT600 / 78 11 ULVT600 / 42 8

ULVT700 / 91 12 ULVT700 / 47 9

ULVT800 / 104 13 ULVT800 / 56 9

ULVT900 / 117 14 ULVT900 / 63 10

ULVT1000 / 130 15 ULVT1000 / 70 10

ULVT1100 / 143 17 ULVT1100 / 77 11

ULVT1200 / 156 18 ULVT1200 /84 12

ULVT1300 / 169 19 ULVT1300 / 91 12

ULVT1400 / 182 20 ULVT1400 / 98 13

ULVT1500 / 195 21 ULVT1500 / 105 13

ULVT1600 / 208 22 ULVT1600 / 112 14

ULVT1700 / 221 23 ULVT1700 / 119 15

ULVT1800 / 234 24 ULVT1800 / 126 15

ULVT1900 / 247 25 ULVT1900 / 133 16