Fike 403-0006 User manual

This document is only intended to be a guideline and is not applicable to all

situations. Information subject to full disclaimer at www.ke.com/disclaimer

INSTALLATION AND MAINTENANCE

INSTRUCTIONS

Document No. 26-1075 Issue 6

Subject to change

http://www.ke.co.uk/

resource-downloads/addressable/

403-0006 SITA MANUAL CALL POINT

General Description

The Sita Manual Call Point allows for user activation of the re alarm system. Once

operated the device latches into the alarm position and requires manually resetting

via a special key. The MCP is an addressable unit that attaches to the loop. Digital

communication technology to the control panel is implemented allowing for accurate

data transfer at high transmission speeds.

Before Installation

The MCP must be installed in compliance with the control panel installation manual.

The installation must also meet the requirements of any local authority.

Spacing

Fike recommends spacing of call points in accordance with any local authority.

Device Installation

All wiring must be installed in compliance with the recommendations laid out by any local authority as well as any special

recommendations documented in the control panel installation manual. All wiring must be installed in compliance with

the recommendations laid out by any local authority as well as any special recommendations documented in the control

panel installation manual. The cabling used should be of a 2-core 1.5mm2 screened, re resistant type, with the

following characteristics:

Max Capacitance Core to Screen...................................................180pF / m

Max Capacitance Core to Core ......................................................100pF / m

Max Inductance ..............................................................................1.0mH / km

Max Resistance Two Core Screened 1.5mm²................................12.1Ω / km

It is to be wired in the form of a screened 2-core loop returning to the control panel. The use of spurs on this

system is not permitted. Cables may be terminated into the connectors, as shown overleaf. If the device is ush

mounted then the loop cabling must be attached to the device via a suitable connection block (not supplied). Cut o

crimp fork terminals, strip ends for desired length and twist conductor strands together neatly as shown below. Terminate

your cables directly into a ying terminal block. If using a metal back box, do not connect the screen to the back box

earth terminal or allow it to come into contact with the metal box

Document No. 26-1075 Issue 6

Subject to change

Care should be taken when terminating devices to ensure all cables are correctly sleeved and connections are secure.

Improper connections will prevent a system from responding properly in the event of a re.

The Loop +ve (positive) IN and the Loop +ve (positive) OUT connections are split within the module. For cable continuity

readings at the commissioning stage they must be temporarily removed and connected through. Please remember that

all high voltage testing must be carried out before the installation of the electronics, otherwise the electronics will be

damaged. Please also note that the E terminal should only be connected to the loop screen and NOT to the building

earth.

Once all testing has been carried out on the cabling and continuity & insulation has been proven,

the MCP can be connected, with each of the three wires from the MCP front being connected to

the corresponding terminal in the backbox according to the wire colour. The MCP front may then be

installed by locating the upper mounting hook into the receiver in the back box and then pushing the

unit gently home. The single xing screw may then be tightened as required.

NOTE: Before installing the MCP remember to note the serial number of the device (located on the rear of the unit) on

to your drawings or conguration sheets to enable you to prove its location later. The address allocation for the device is

carried out automatically by the control panel whilst in initialisation mode, so addresses do not need to be set manually.

See the system Installation and Operating Instructions for further details.

Reset and Test

The Manual Call Point contains a re-settable element, which latches in position when operated

and does not need to be replaced. Inserting the key as shown and turning it clockwise until the

element clicks back into place will reset the unit. Testing the Call Point may be carried out either

by pressing the element or by using the key in the same manner as for resetting but without

having pressed the element

Technical Data

Dimensions: Width x Height 87mm x 87mm

Depth: Standard inc base 53mm

Depth: Flush mounted 25mm

Flush Back Box Dimensions: Required Minimum Depth 47mm

Operating Temperature: -10oC to +50oC.

Voltage Range (Loop): 24 to 42V DC

LED Indication: Activated 0.3s interval

Flammability UL94-V2

IP Rating IP 21C

System Compatibility: Sita200plus V2.00 onwards.

Duonet and Quadnet V1 onwards.

CIE-A-200 V1 onwards

Terminal Description

R (RED) Loop +ve IN

Y (YELLOW) Loop +ve OUT

B (BLUE) Loop -ve IN & OUT

ELoop SCREEN IN & OUT

E

BLUE RED

YELLOW

Y

B R

Fike Safety Technology Ltd

Unit 31, Springvale Industrial Estate

Cwmbran

NP44 5BD

Tel: 01633 865 558 | Email: fstinfo@ke.com Document No. 26-1075 Issue 6

Subject to change

2831

Fike Safety Technology Ltd

Unit 31, Springvale Ind. Est.

Torfaen, NP44 5BD

11

DoP-403-0006

EN54-11: 2001 +A1: 2005, EN54-17: 2005

Isolator Technical Data: See 26-1112

403-0006

Intended for use in the re detection and re alarm

Systems in and around buildings

Essential characteristics Performance

Nominal activation conditions/Sensitivity, response delay (response time)

and performance under re conditions Pass

Operational reliability Pass

Tolerance to supply voltage Pass

Durability of operational reliability and response delay, Temperature

resistance Pass

Durability of operational reliability, Vibration resistance Pass

Durability of operational reliability, Humidity resistance Pass

Durability of operational reliability, Corrosion resistance Pass

Durability of operational reliability, Electrical stability Pass

Performance under re conditions Pass

Technical Support

Contact your supplier for technical support on this

product.

Due to the complexity and inherent importance of

a life risk type system training on this equipment is

essential, and commissioning should only be carried

out by competent persons. Fike cannot guarantee the

operation of any equipment unless all documented

instructions are complied with, without variation.

Fike’s policy is one of continual improvement and the

right to change a specication at any time without

notice is reserved. Whilst every care has been taken to

ensure that the contents of this document are correct

at time of publication, Fike shall be under no liability

whatsoever in respect of such contents. E&OE

Technical Data

PRODUCT DESCRIPTION LOOP CURRENT (mA)

Type Product Code Name Quiescent Alarm Low Medium High

MCP 403 0006 Sita Manual Call Point Mk3 0.18 2.89 - - -

BATTERY CURRENT (mA)

Type Product Code Name Quiescent Alarm Low Medium High

MCP 403 0006 Sita Manual Call Point Mk3 0.18 6.00 - - -

DLU RATING

Type Product Code Name Alarm Low Medium High

MCP 403 0006 Sita Manual Call Point Mk3 3 - - -

Other Fike Firefighting Equipment manuals

Popular Firefighting Equipment manuals by other brands

Grundfos

Grundfos Hydro EN Safety instructions and other important information

Tyco

Tyco 802SB installation instructions

Waterous

Waterous AQUIS Series Installation, operation and maintenance instructions

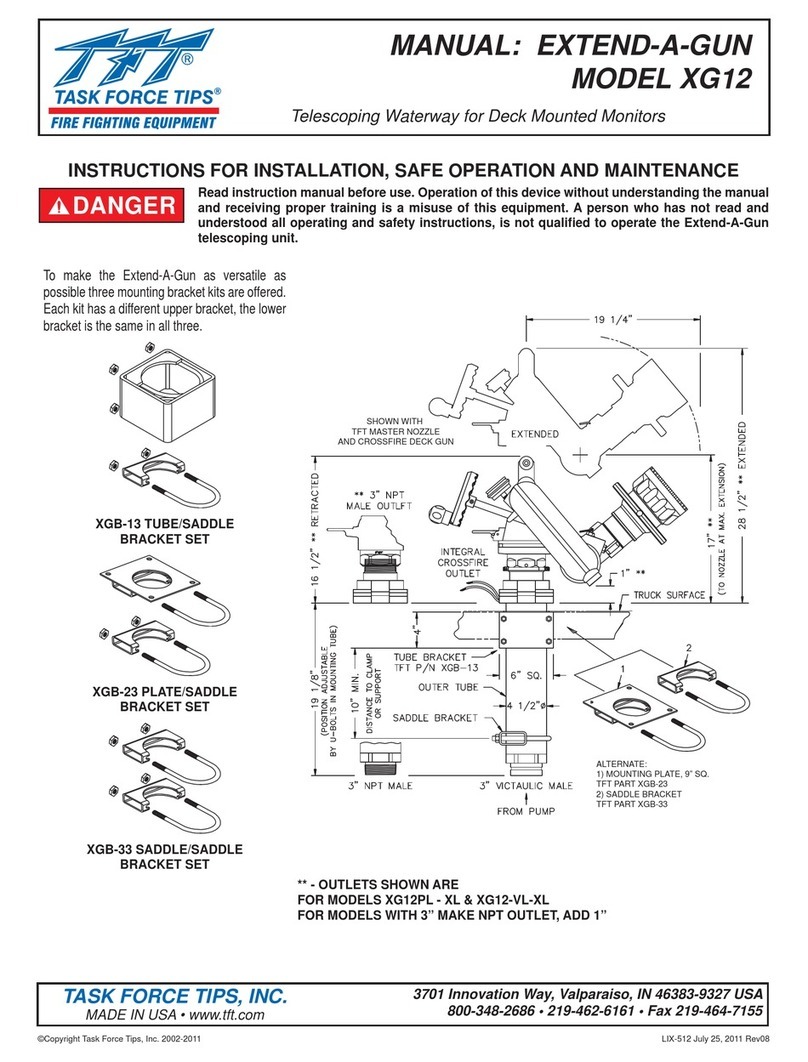

TFT

TFT EXTEND-A-GUN XG12 Instructions for installation, safe operation and maintenance

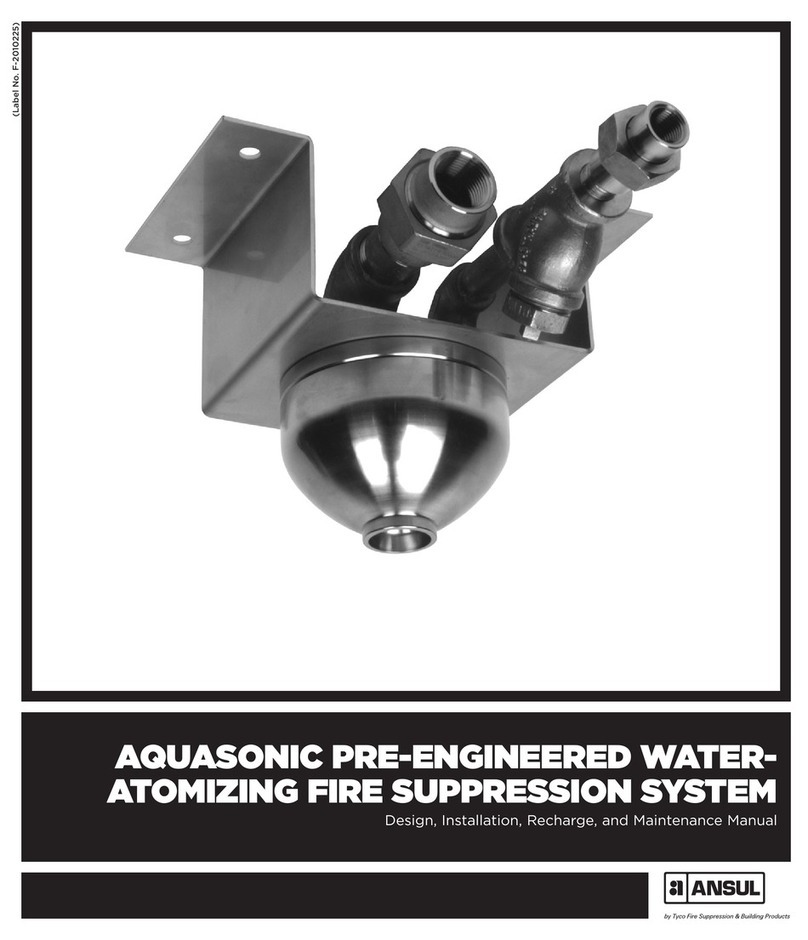

Tyco Fire Suppression & Building Products

Tyco Fire Suppression & Building Products ANSUL AQUASONIC Design, Installation, Recharge, and Maintenance Manual

Tyco

Tyco EC-11 Series quick guide