SECTION PAGE NO.

________ _________

COMPONENTS 1 – 17

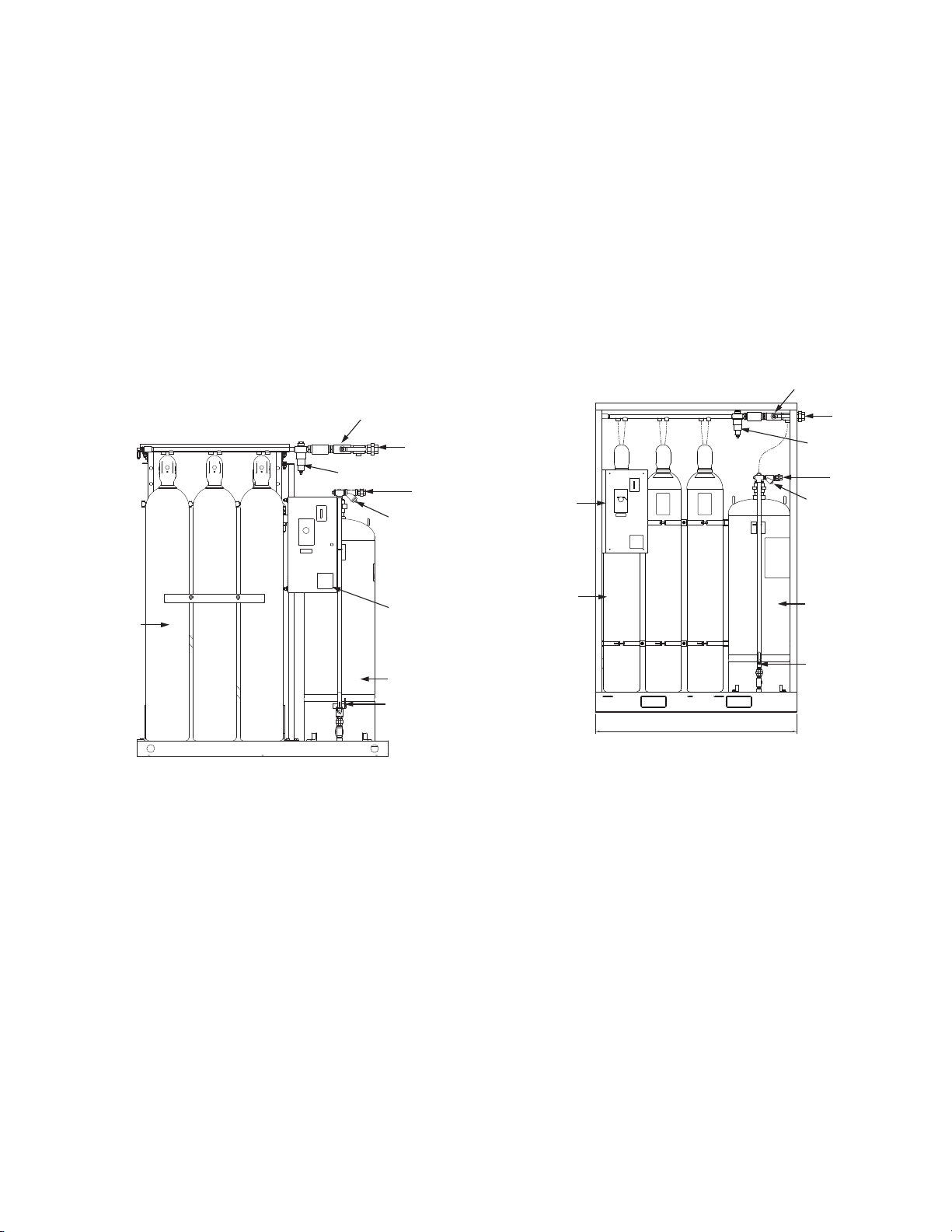

Complete ASME and DOT Approved 1

AQUASONIC Skid Assembly

Complete TPED and CE Marked 1

AQUASONIC Skid Assembly

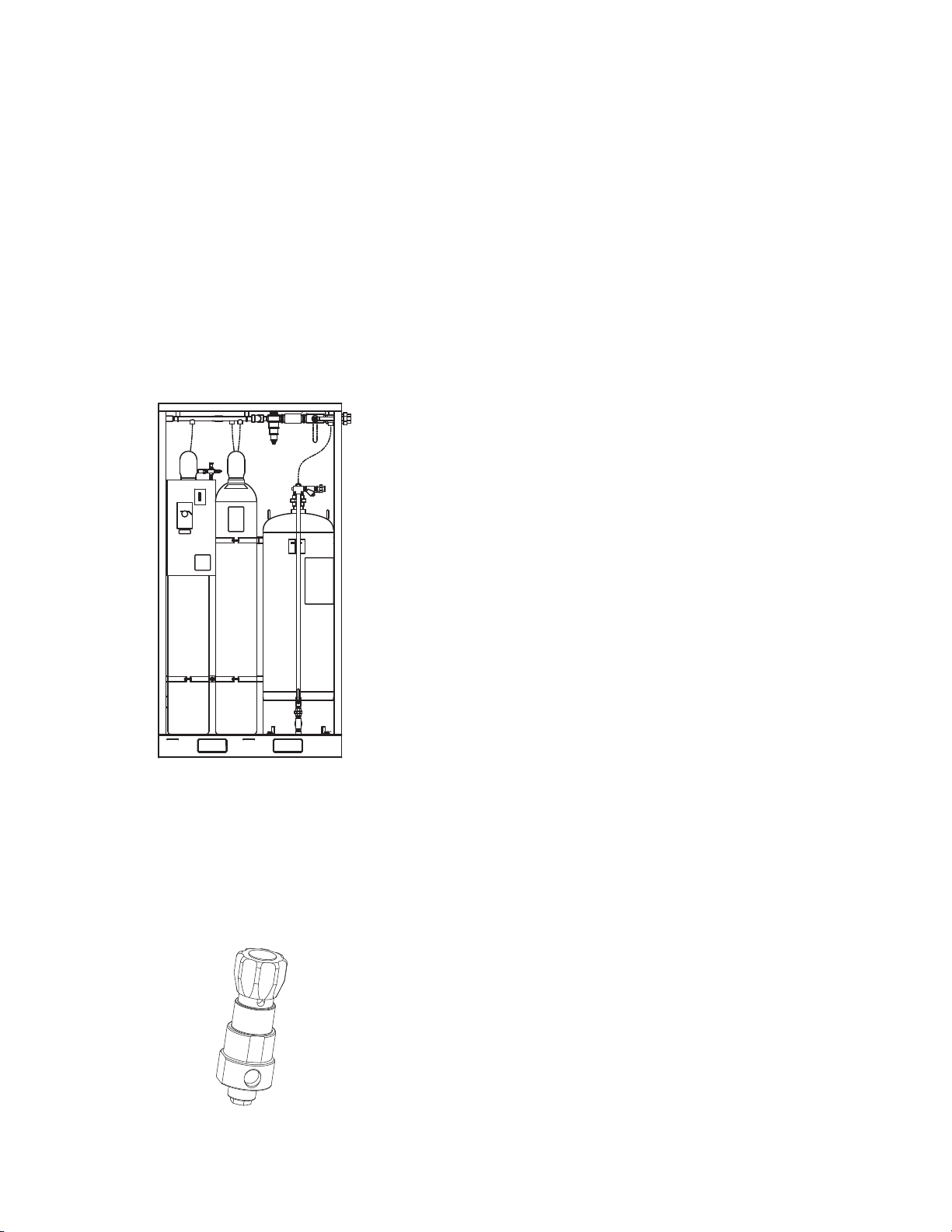

Complete TPED and CE Marked 2

AQUASONIC 130 m3Skid Assembly

Regulator 2

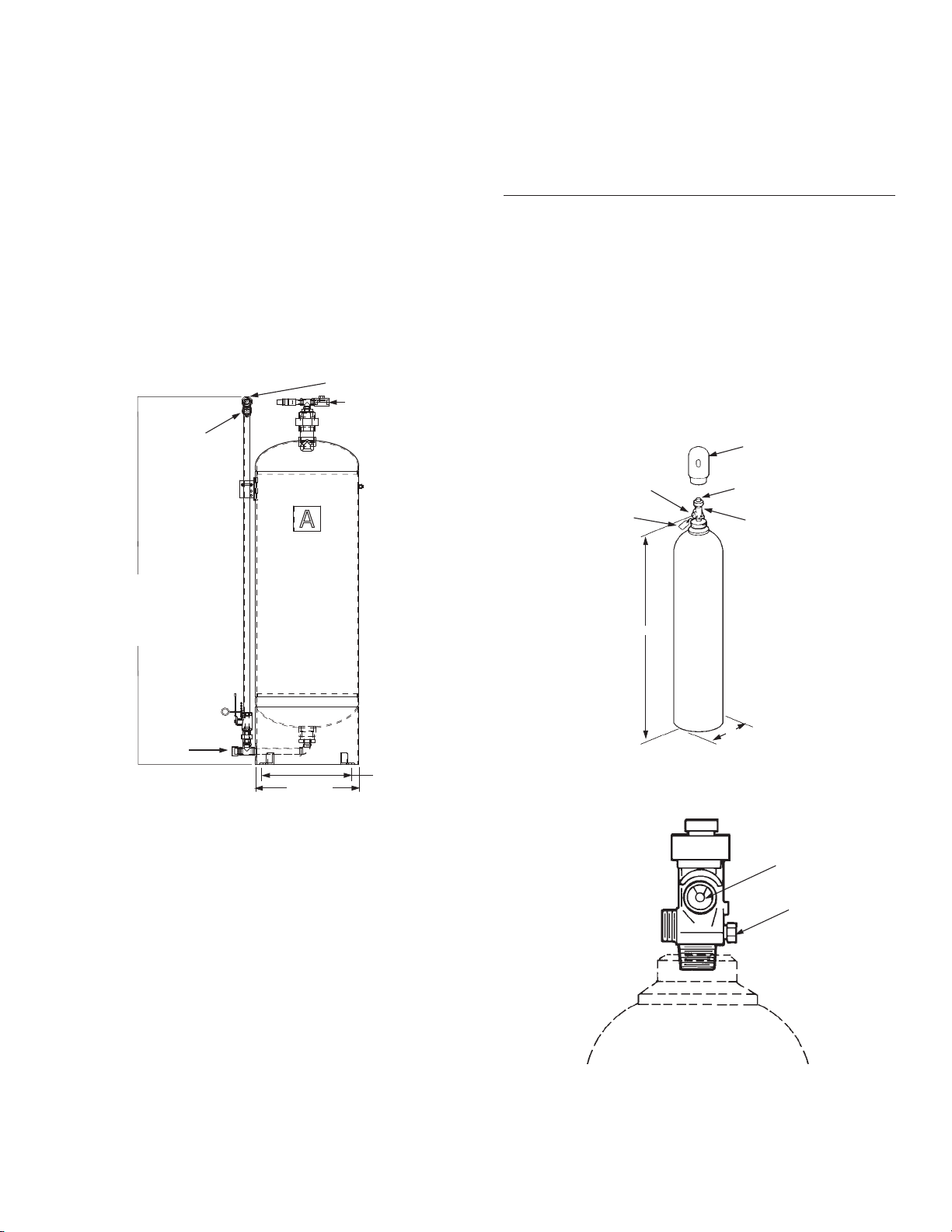

50 US Gallon (189.3 L) Water Tank Assembly 3

CV-98 Valve / Cylinder Shipping Assembly 3

CV-98 Valve 3

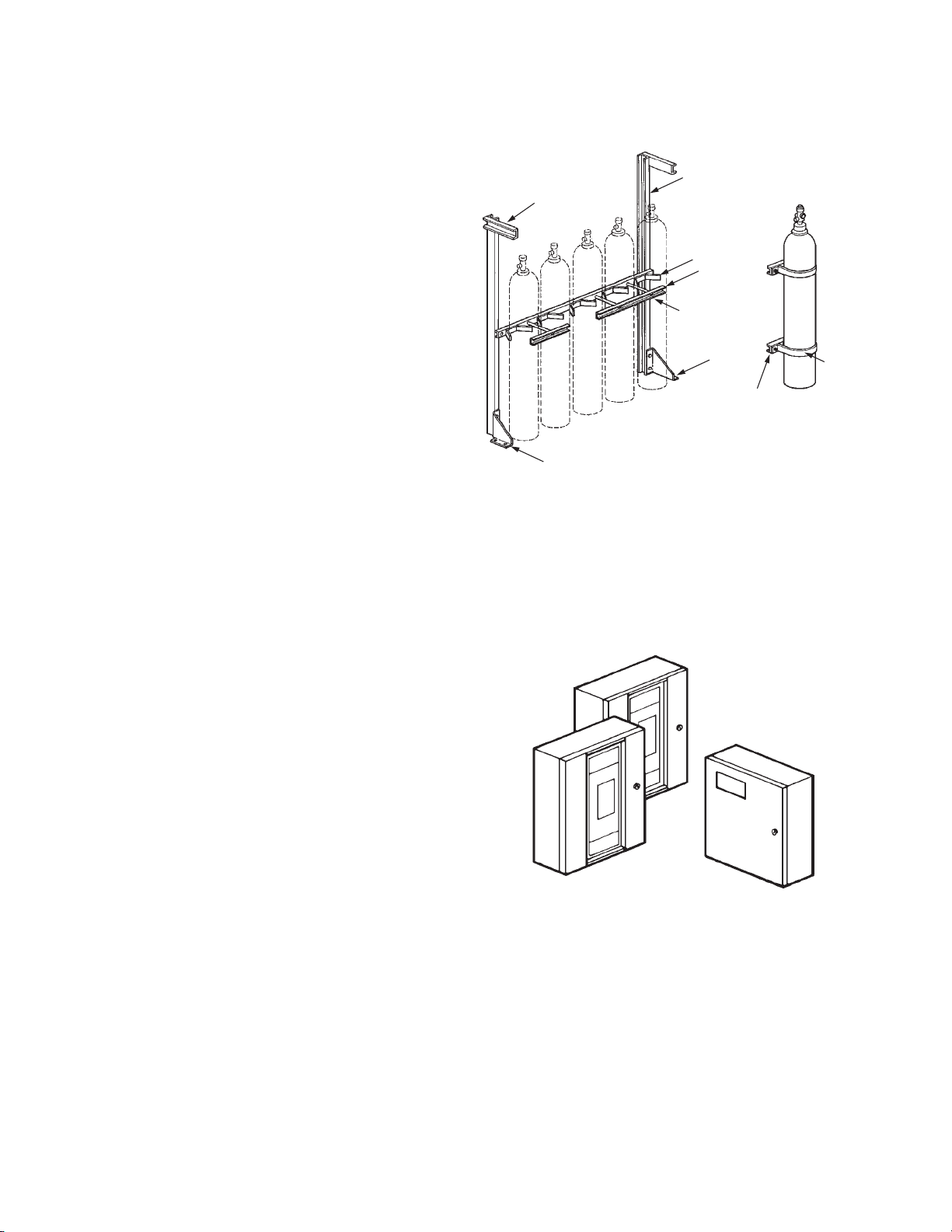

Cylinder Bracketing 4

AUTOPULSE Control System 4

ANSUL AUTOMAN II-C Releasing Device 5

Remote Actuator (Optional) 5

Booster Actuator 6

HF Electric Actuator 6

Lever Release Actuator 6 – 7

Flexible Discharge Bend 7

Water Tank Pressurization Hose and Fitting 7

Header Vent Plug 7

Header Safety Burst Disc 8

Actuation Components 8

Check Valves 8

Relief Valve 9

Vent Poppet 9

Pressure Switch – DPST 9

Pressure Switch – DPDT – Explosion-Proof 10

Pressure Switch – 3PST 10 – 11

Pressure Trip 11

Nitrogen Discharge Relief Valve 11

System Shut-Off Valves 12

Atomizer 12

Pneumatic Selector Valve 12 – 13

Electric Selector Valves 13

Nameplate – AQUASONIC System (US) 14

Nameplate – AQUASONIC System (EMEA) 14

Nameplate – MAIN 14

Nameplate – RESERVE 14

Warning Plate – Inside Room With Alarm 5

Warning Plate – Outside Room Without Alarm 15

Pressure Test Assembly 15

Check Valves 16

GENERAL INFORMATION 17 – 22

Spray Characteristics 17

Approvals 17 – 18

Typical Operation Sequence 18

Types of Actuation 18

Electrical 18

Mechanical 18

Pneumatic 18

Types of Detection 18

Electronic Control Panel 18

Electric Releasing Device 18

SECTION PAGE NO.

________ _________

System Limitations 18 – 21

AQUASONIC Atomizer 19

Pendent (Downward) Position Parameters 19

Sidewall Position Parameters 19

Application of Pendent Constraints 20

Application of Sidewall Constraints 21

Control of Run-Off 22

Ventilation and Leakage 22

Relief Venting 22

PLANNING 23 – 24

Initial General Information 23

Hazard Information 23

Supply Requirements 23

Atomizer Placement Requirements 23

Actuation and Alarm Requirements 23

DESIGN 25 – 30

Step No. 1 – Determine the Floor Area and 25

Gross Volume of the Room

Step No. 2 – Determine the Minimum Number 25

of Atomizers Required

Step No. 3 – Verify Atomizer Array Placement 25

Step No. 4 – Determine Location of System Supply 25

Step No. 5 – Sketch Pipe Routing 26

Water Calculation Procedure 26 – 28

Step No. 6 – Determine Volume of Water 27

Supply Required

Step No. 7 – Determine Number of Water 27

Tanks Required

Step No. 8 – Determine Total Atomizer Pressure 27 – 28

(TAP)

Step No. 9 – Select Appropriate 28

Atomizer Assembly

Nitrogen Calculation Procedure 29 – 30

Step No. 10 – Determine Atomizer Pressure Loss 30

Step No. 11 – Determine the Number of 30

Nitrogen Cylinders

Step No. 12 – Complete Layout of the System 30

Step No. 13 – Create a Bill of Materials 30

Step No. 14 – Create Installation Drawings 30

INSTALLATION 31 – 40

General Information 31

Pre-Assembled Supply Skid Installation 31

Nitrogen Cylinder Installation 31 – 34

Bracketing without Uprights – Double Row 32

Bracketing with Uprights – Back-to-Back 32

Bracketing with Uprights – 33

Double Row Back-to Back

Water Tank Installation 34

Atomizer Installation 34

Releasing Devices 35

General Piping Requirements 35

Pipe Assembly 35

Hanger Requirements 35

TABLE OF CONTENTS

7-19-10 Page 1

REV. 3