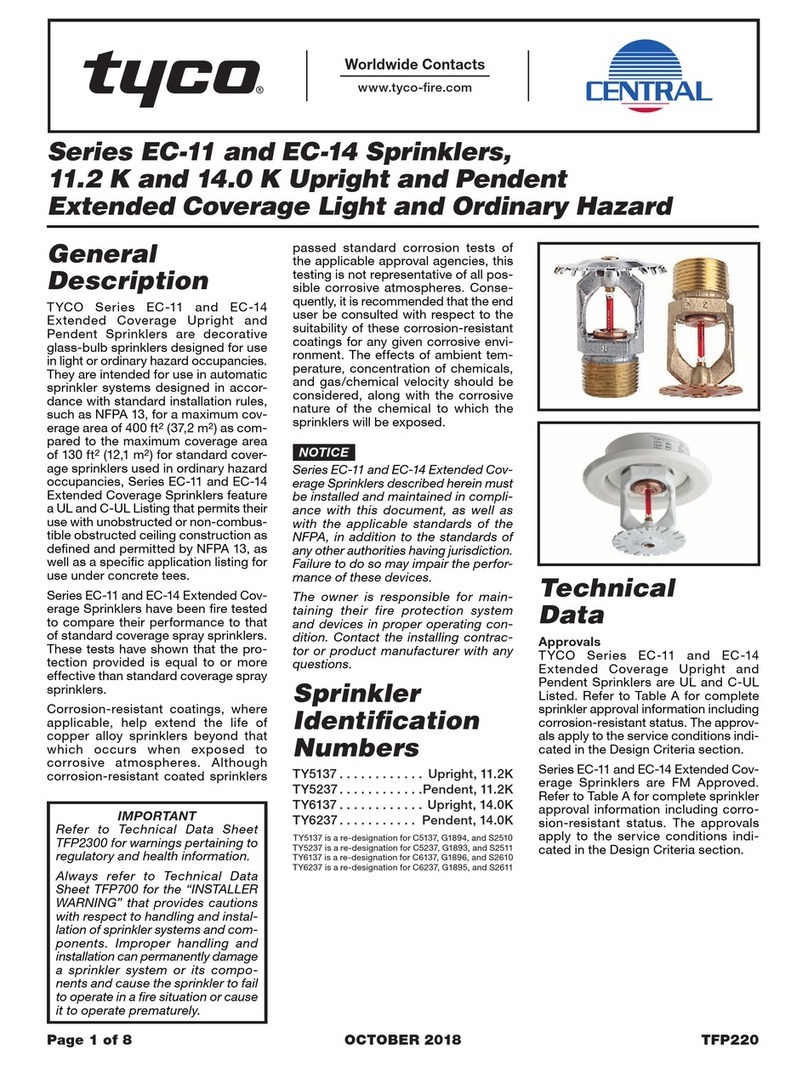

Tyco 802SB User manual

Other Tyco Firefighting Equipment manuals

Tyco

Tyco PROTECTOSPRAY EA-1 User manual

Tyco

Tyco TY-FRB Series User manual

Tyco

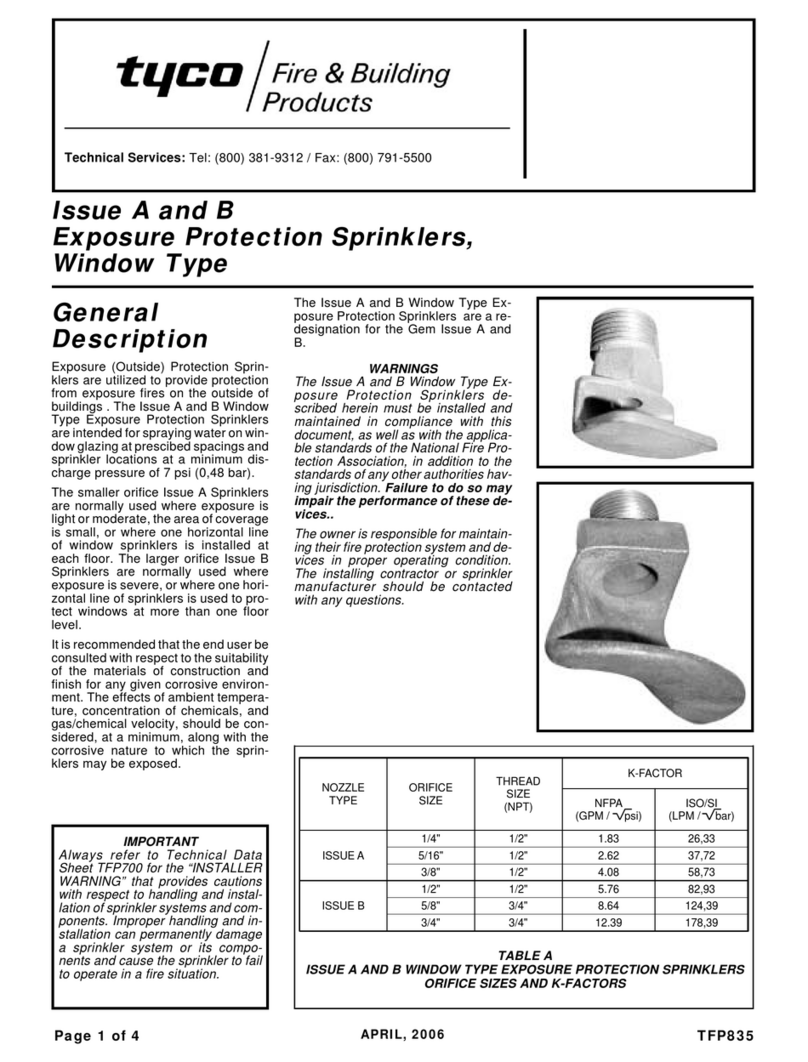

Tyco Issue A User manual

Tyco

Tyco EC-5 Series User manual

Tyco

Tyco K17-231 User manual

Tyco

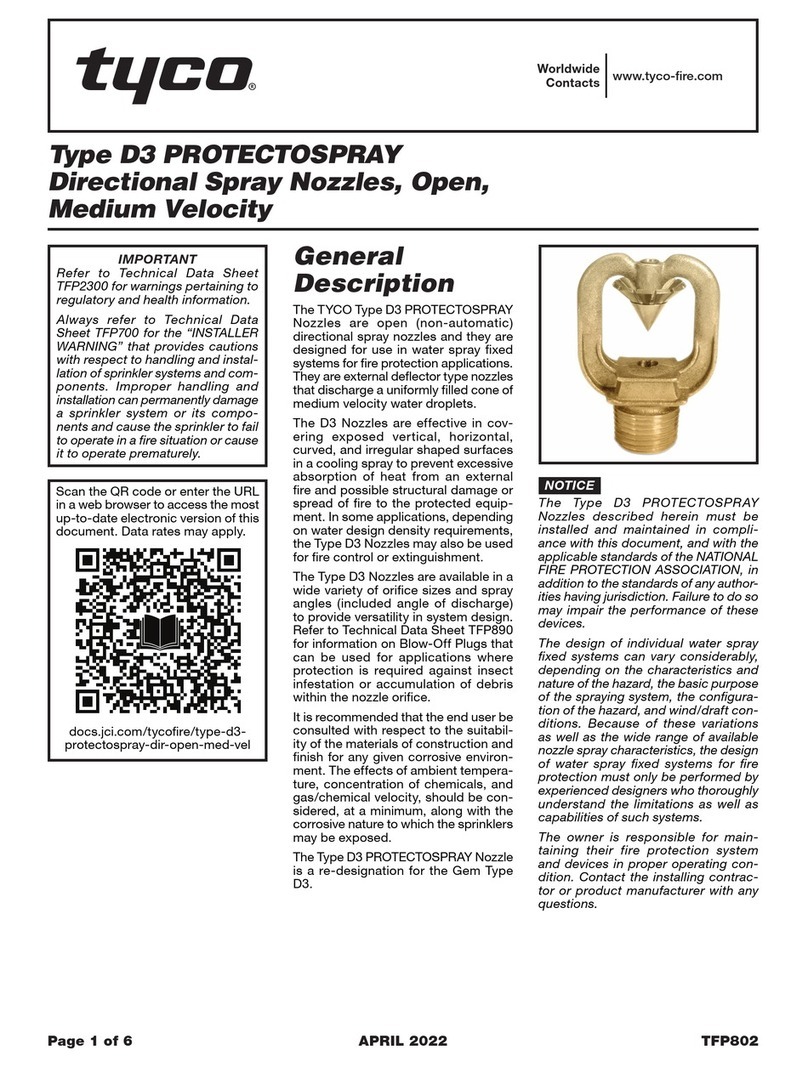

Tyco D3 PROTECTOSPRAY User manual

Tyco

Tyco AQUAMIST AM4 User manual

Tyco

Tyco FSC 80 K-factor Flush Sprinkler User manual

Tyco

Tyco EC-HS User manual

Tyco

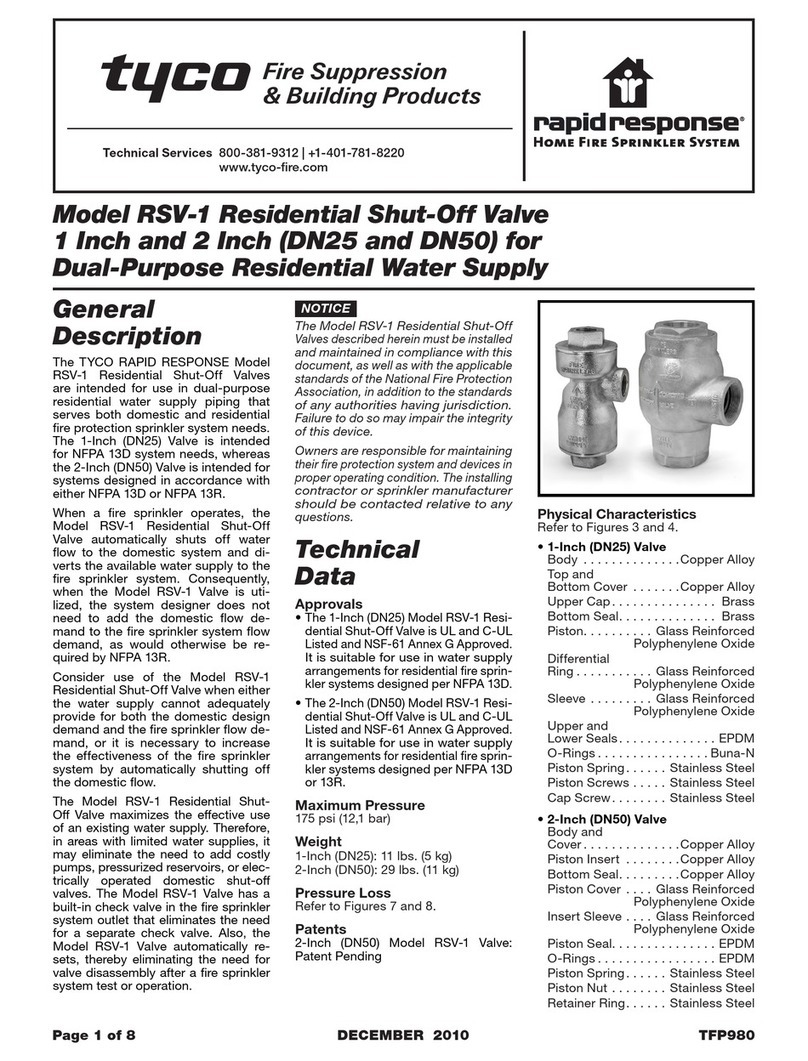

Tyco RAPID RESPONSE RSV-1 User manual

Popular Firefighting Equipment manuals by other brands

Tyco Fire Protection Products

Tyco Fire Protection Products AM31 AQUAMIST Nozzle instructions

Task Force Tips

Task Force Tips Extend-A-Gun RC3 INSTRUCTION FOR SAFE INSTALLATION, OPERATION, AND MAINTENANCE

Autronica

Autronica AutroSafe BSD-321/EX manual

POK

POK Froggy user manual

Waterous

Waterous AQUIS Series Installation, operation and maintenance instructions

CTP

CTP NPO ETERNIS GUARANT-7 Technical description and instruction manual

Projoy Electric

Projoy Electric PEFS-PL Series installation guide

klimaoprema

klimaoprema FDC25 Series product manual

Mueller

Mueller Revive M2 user manual

SEI Industries

SEI Industries BAMBI MAX BBXHL4000PF Service manual

Waterax

Waterax MARK-3 owner's manual

Apollo

Apollo Smoke Detector XP95 quick start guide