Fike Epaco RC80 Owner's manual

Manual P/N E06-054

Rev. No: 1, 07/04

E10-0069

Installation and Operation

Instructions

FIKE CORPORATION

FM 3020541 Fike Explosion Protection System Page i

P/N E06-054 Rev. 1 07/04

Introduction

Fike is pleased to present a new Installation,

Operation and Maintenance Manual for our

Explosion Protection System. This document

has been created to incorporate the most up-to-

date information available for this Fike product

and to make it easy to use.

Who should read this manual?

This manual is intended for those individuals

who are custodians of the Fike EPACO

System. Others such as architects, engineers,

sales and marketing personnel, etc. will find the

information useful as well.

Warranty Information

Fike provides a one-year limited manufacturer’s

warranty on the product identified in this manual.

Copies of the warranty can be obtained from an

authorized Fike sales outlet. An authorized Fike

sales outlet, using the MRA procedure, must

return warranty items. See Section 11 of this

manual for details of returning product to Fike.

Limitation of Liability

Fike Corporation cannot be held liable for any

damages resulting from the use or misuse of this

product.

Copyright, Trademark and Licensing

Notice

All Fike documentation and hardware are

copyright with all rights reserved. No part of this

product may be copied, reproduced or

transmitted by any mechanical, photographic,

electronic or other method without Fike’s prior

written consent. Fike product names are

trademarked; other product names, as

applicable, are trademarks of their respective

holders.

Disclaimer

The information contained in this manual is as

accurate as possible. This manual is intended

to be an aid to Fike authorized sales outlets or

engineers charged with the installation and

maintenance of the Fike Explosion Protection

System. Fike does not warrant that this manual

is technically correct, complete or the product

referenced herein is free from minor flaws. Fike

reserves the right to change the information

contained in this manual without notice.

Quality Notice

Fike Corporation has maintained ISO 9001

certification since 1996. Prior to shipment, we

thoroughly test our products and review our

documentation to assure the highest quality in

all respects. In a spirit of continuous

improvement, Fike welcomes your suggestions.

Please direct all suggestions or comments to

Fike Blue Springs Product Support

Phone: +1-816-229-3405

Fax: +1-816-229-0314

or

Fike Europe Product Support

Phone: +32-14-21-00-31

Fax: +32-14-21-07-43

Any suggestions or comments become the

property of Fike Corporation.

FIKE CORPORATION

Page ii Fike Explosion Protection System FM 3020541

07/04 P/N E06-054 Rev. 1

This page intentionally left blank.

FIKE CORPORATION

FM 3020541 Fike Explosion Protection System Page iii

P/N E06-054 Rev. 1 07/04

Table of Contents

1.0 Terms and Symbols Used In This Manual............................................................................................1

2.0 EPACO System Overview.......................................................................................................................2

3.0 System Components...............................................................................................................................3

4.0 Installation ...............................................................................................................................................4

4.1 Installation Overview .............................................................................................................................4

4.2 Power Specifications .............................................................................................................................4

4.3 Relay Card (RC8) ..................................................................................................................................5

4.4 Circuit Connections ...............................................................................................................................6

4.4.1 24VDC Power (P4)........................................................................................................................ 6

4.4.2 Relay (P2 & P3)............................................................................................................................. 6

4.4.3 Status Bus (P1) ............................................................................................................................. 7

5.0 Operation .................................................................................................................................................8

5.1 Configuration .........................................................................................................................................8

5.1.1 Dip Switch Configuration ............................................................................................................... 8

5.1.2 PC Configurations ......................................................................................................................... 8

5.2 RC8 Status ............................................................................................................................................9

5.2.1 RC8 Normal State ......................................................................................................................... 9

5.2.2 RC8 Trouble or Alarm State .......................................................................................................... 9

5.3 Relay Events .......................................................................................................................................10

6.0 Periodic Maintenance ...........................................................................................................................14

6.1 General................................................................................................................................................14

6.2 Inspection Procedure...........................................................................................................................14

6.3 Routine Inspections.............................................................................................................................14

6.4 Three-Year Replacement ....................................................................................................................14

6.5 Ten-Year Replacement .......................................................................................................................14

7.0 Decommissioning Procedure / Check-List.........................................................................................15

8.0 RC8 Spare Parts....................................................................................................................................16

9.0 LED Diagnostics....................................................................................................................................16

10.0 Specifications........................................................................................................................................17

11.0 Repair and Return Authorization.........................................................................................................18

FIKE CORPORATION

Page iv Fike Explosion Protection System FM 3020541

07/04 P/N E06-054 Rev. 1

List of Exhibits

Exhibit 2-1 EPACO System Block Diagram ....................................................................................................... 2

Exhibit 3-1 RC8 Photo ........................................................................................................................................ 3

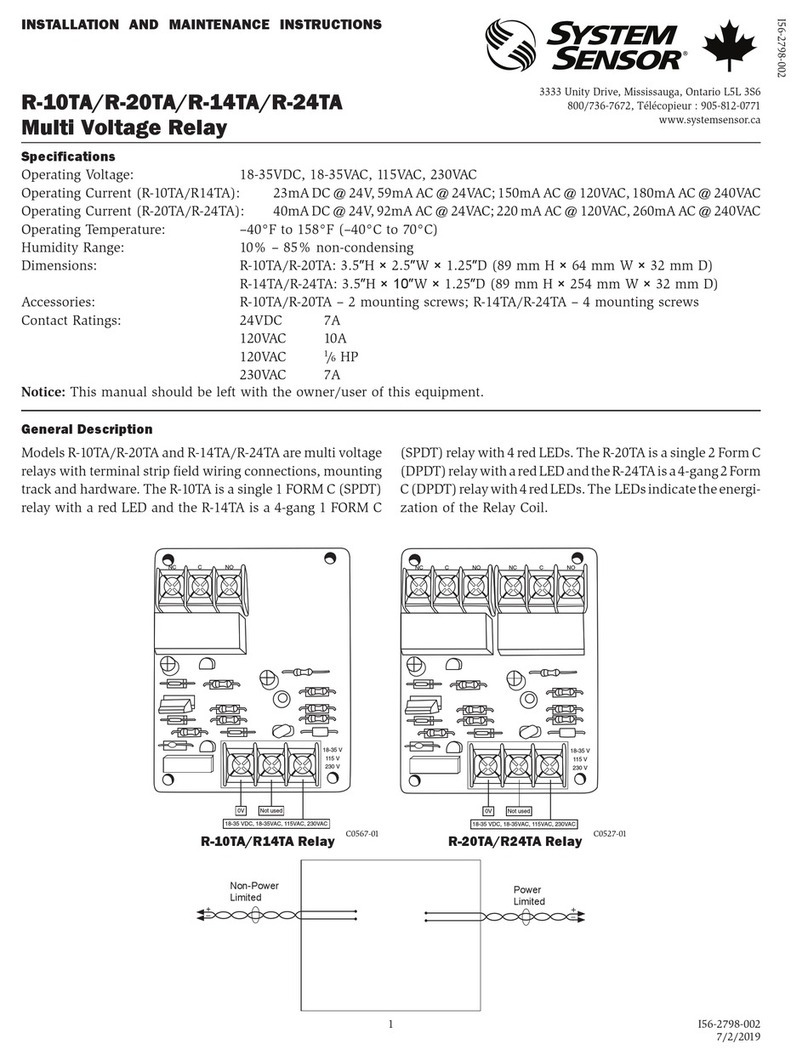

Exhibit 4-1 RC8 Block Diagram .......................................................................................................................... 5

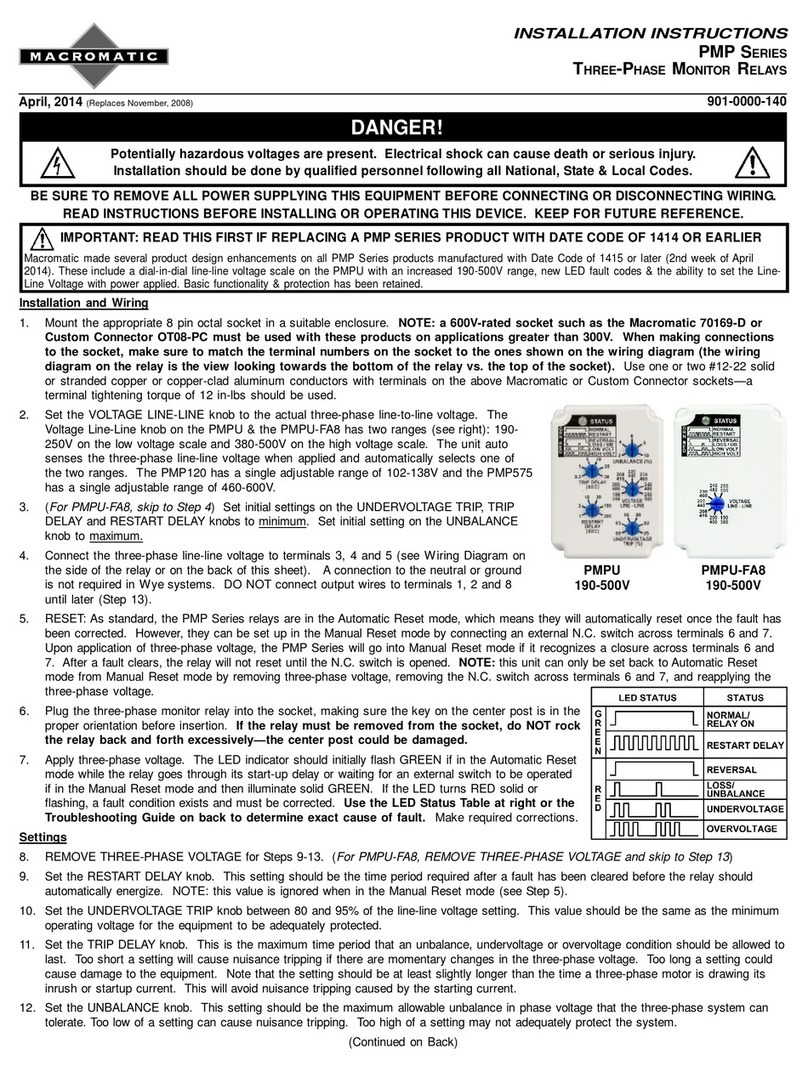

Exhibit 4-2 RC8 Bottom View – P3-P4 Wiring Connections............................................................................... 6

Exhibit 4-3 RC8 Power Input Wiring ................................................................................................................... 6

Exhibit 4-4 RC8 Relay Wiring ............................................................................................................................. 6

Exhibit 4-5 RC8 Top View – P1-P2 Wiring Connections .................................................................................... 6

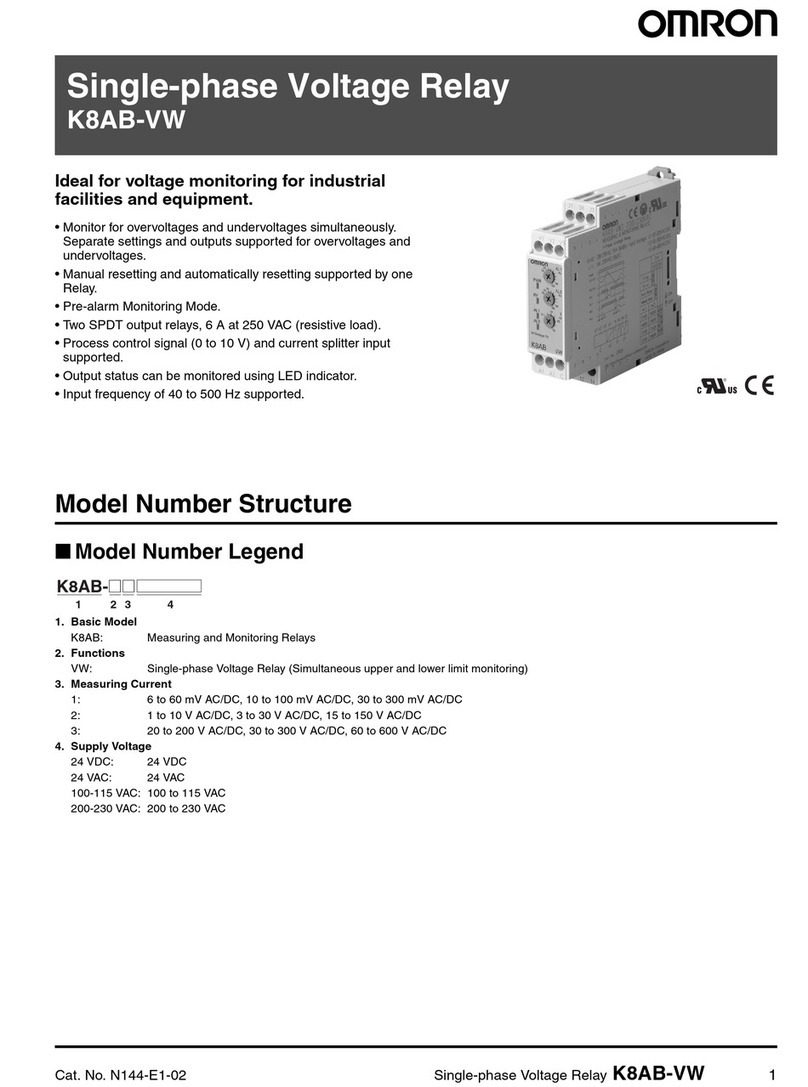

Exhibit 4-6 Status Bus Wiring ............................................................................................................................. 7

Exhibit 5-1 Serial Port......................................................................................................................................... 8

Exhibit 5-2 DIP Switches .................................................................................................................................... 8

Exhibit 5-3 Power LED ....................................................................................................................................... 9

Exhibit 5-4 Status Bus LED ................................................................................................................................ 9

Exhibit 5-5 Trouble LED ..................................................................................................................................... 9

Exhibit 5-6 Relay Events Table ........................................................................................................................ 10

Exhibit 5-7 DIP Switch Configuration Table for RC8 ........................................................................................ 11

Exhibit 5-8 EPWorks™ Configurations 1 - 6 .................................................................................................... 12

Exhibit 5-9 EPWorks™ Configurations 7 - 12 .................................................................................................. 13

Exhibit 7-1 Decommissioning Steps ................................................................................................................. 15

Exhibit 8-1 Spare Parts List .............................................................................................................................. 16

Exhibit 9-1 LED Diagnostics ............................................................................................................................. 16

Annex A EPACO Wiring Diagram..................................................................................................................... 19

FIKE CORPORATION

FM 3020541 Fike Explosion Protection System Page 1 of 20

P/N E06-054 Rev. 1 07/04

1.0 TERMS AND SYMBOLS USED IN THIS MANUAL

Term/Symbol Description

Fuse symbol. This designation represents a circuit protection fuse. The

fuse is rated at the amperage noted next to this marking.

DB9

Computer Connection symbol. This designation represents the location

for the computer connection. Using a straight-through serial cable, the RC8

can be connected from this DB9 connection to a computer serial port. The

EP Works software can be installed on the computer and provide

operational information.

Status Bus symbol. The Status Bus circuit is a low speed network

connection that sends and receives status information to Annunciator

Module.

DC Power symbol. This symbol is located on the RC8 P3 terminal. It

designates the 24VDC input terminals and the 24VDC output terminals to

the next RC8 in the system.

NCNO C

Relay symbol. This symbol located on the top and bottom of the RC8 P2

and P3 terminal outputs. It designates the relay output wiring connections.

FIKE CORPORATION

Page 2 of 20 Fike Explosion Protection System FM 3020541

07/04 P/N E06-054 Rev. 1

2.0 EPACO SYSTEM OVERVIEW

The EPACOSystem is a modular detection

and control system combining the latest in

addressable technology with simplicity of

installation and maintenance. All system

modules are DIN rail mounted to allow for a

variety of installation options. Three (3) bus type

communication circuits tie the various system

modules into one easy to operate protection

system. A non-volatile history buffer allows for

enhanced diagnostic ability to troubleshoot

process situations. With the optional

Annunciator Module (AM), the customer has the

ability to step through a menu format to retrieve

process history without having to wait for a

service agency to arrive on site.

This manual will provide the necessary

information to properly install and monitor the

Relay Card (RC8) for the EPACOSystem.

The commissioning and service should be

performed by certified service engineers and

outlets specifically trained on this system.

Exhibit 2-1 EPACO System Block Diagram

POWER

SUPPLY

UNIT

ANNUNCIATOR

MODULE EXPLOSION

PROTECTION

CONTROLLER

RELAY

CONTROL 8

(8 RELAYS)

UP TO 6

RELEASING

DEVICES

FIKE CORPORATION

FM 3020541 Fike Explosion Protection System Page 3 of 20

P/N E06-054 Rev. 1 07/04

3.0 SYSTEM COMPONENTS

The cornerstone of the system is the Explosion

Protection Controller (EPC). Three colored LEDs

provide instant visual indication of system

status. The DIN rail mounting allows for

flexibility when choosing an enclosure. The EPC

is an addressable panel that has the ability to

retain an event history for enhanced system

diagnostics. The EPC is a component that

allows mounting in close proximity to the

protected environment, thereby minimizing field

wiring. Shorter wire runs greatly reduce the

interference from electrical and radio frequency

sources, allowing for a much more reliable

protection system. The EPC’s detection inputs

can be programmed for pressure warning,

threshold detection, and rate of rise detection. It

also has a contact closure detection circuit to

support thermal, infrared, or other switch-closure

type detection devices1. A supervisory input

circuit is provided to monitor suppression

container pressure or other similar system status

safeguards. The EPC has a remote disable

input contact to allow for disabling the EPC from

a customer PLC or other remote device during

product loading, cleaning, or maintenance. DIP

switches allow for basic system programming.

An RS232 connection is available at each

module for connection to a PC. Using the EP

WorksTM software, an authorized user can

access system diagnostics and more complex

programming by PC.

The EPC is powered by the other key

component in the EPACOsystem, the Power

Supply Unit (PSU). The PSU has six separate

24 VDC, 1 amp power output circuits capable of

powering up to four EPCs in addition to other

components of the EPACOsystem. The PSU

has the flexibility of containing its own battery

backup supply or the customer has the option of

supplying a backup power source. The PSU

has an imbedded power shutdown procedure in

the event of AC power failure, which prevents

the backup batteries from being completely

depleted. In addition to powering EPCs, the PSU

can power an Annunciator Module (AM) and

Relay Card Modules (RC8). The power circuit

dedicated for the Annunciator Module can not be

shut off. All other power output circuits can be

shut off for service on the various system

components. The PSU may be eliminated if

1FM Approved switch closure for use with Fike threshold

detector (E61-042-x) and Rate of Rise detector (E61-056-x).

Other switch closure, thermal, or infrared devices are not

approved by FM.

battery backed, uninterrupted 24VDC, 0.500

Amps power per module can be provided by

others. For an FM approved installation without

the PSU, the uninterruptible power must be U.L.

1778 “Uninterruptible Power Systems” listed,

and conform to NFPA 72 “National Fire Alarm

Code”, NFPA 70 “National Electrical Code”

(Articles 700 and 701), NFPA 110 “Standard for

Emergency and Standby Power Systems”, and

NFPA 111 “Standard on Stored Electrical

Energy Emergency and Standby Power

Systems”.

The Annunciator Module (AM) provides a central

communication point for diagnostics. This

module will typically be installed in an area

removed from the process environment such as

a control room. The AM has two push buttons to

access the various menus and three numbered

LEDs for identification of the system statuses

within the menus.

The Relay Card Module (RC8) provides the user

with a block of eight Form “C” relays for

equipment shutdowns and remote notification of

system trouble and alarm conditions. On-board

LEDs display status for instant visual verification

of each relay. DIP switches are provided for

configuring the relay’s operation.

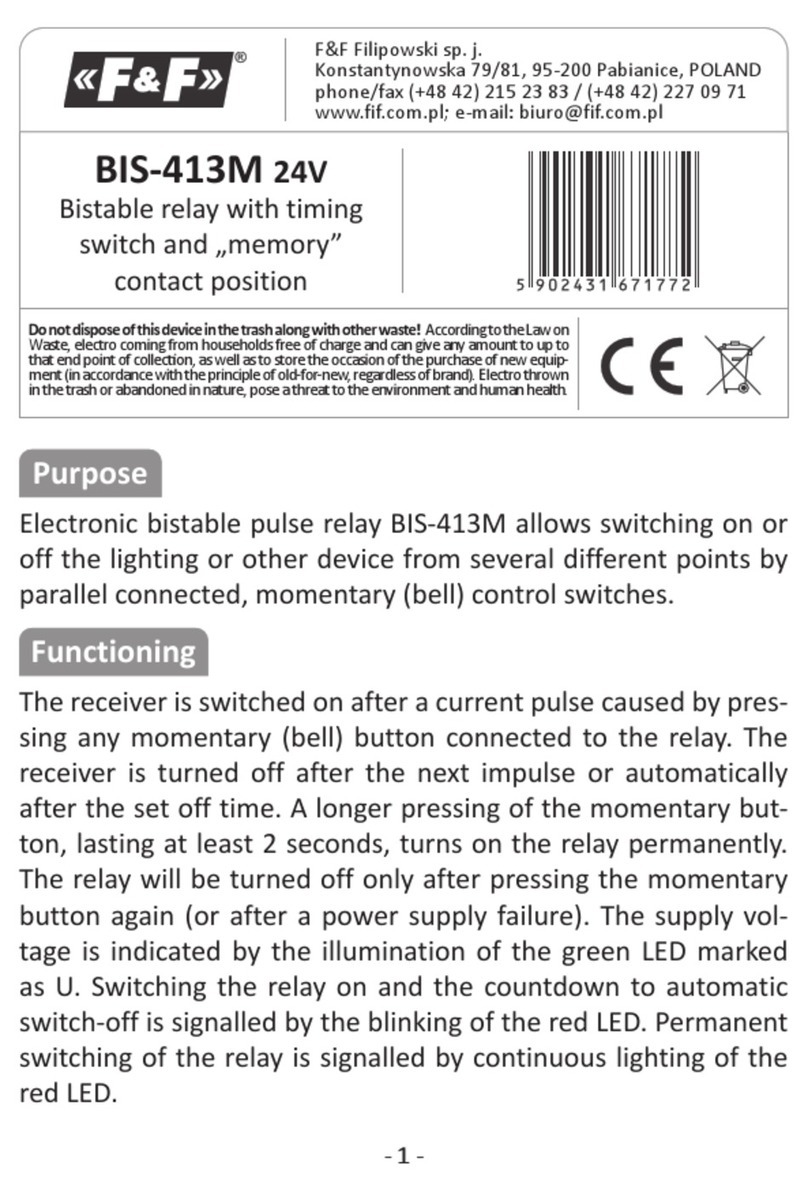

Exhibit 3-1 RC8 Photo

FIKE CORPORATION

Page 4 of 20 Fike Explosion Protection System FM 3020541

07/04 P/N E06-054 Rev. 1

4.0 INSTALLATION

4.1 INSTALLATION OVERVIEW

The effectiveness of active explosion protection

systems, such as explosion suppression and

explosion isolation, depends upon the

instantaneous reaction of the protection system

and is a direct function of its speed of response.

It is therefore, critical that all possible measures

are taken to reduce the individual system

components’ response times to an absolute

minimum.

An active explosion protection system basically

consists of three components: One or more

explosion detectors, an electronic system

controller, and one or more protective devices

such as explosion suppressors or isolation

valves. Instrumentation wiring interconnects

these components.

The system controller is microprocessor-based

and shall be installed in a location that maintains

the EPC’s temperature rating of -18°C to 43°C

(0°F to 110°F) when it is installed in an auxiliary

housing. For FM Approved installations the

housing shall be a lockable enclosure

conforming to the installed area requirements as

defined by NEMA 250 “Enclosures for Electrical

Equipment (1000 Volts Maximum).”

Besides its function as a fire controller it also

incorporates an event table and a self-checking

feature to continuously monitor the complete

system-loop for errors or system defects.

Electronic devices, microprocessors,

pyrotechnic initiators, and field wiring are

influenced by the electromagnetic “environment”

surrounding these components. The use of

cellular telephones, transmitters, induction

motors, welding equipment or the presence of

power cables and transformers can create

environments with high levels of electromagnetic

radiation, resulting in induced electrical “noise”

or voltage peaks.

Such effects are known to designers and

manufacturers of instrumentation and control

systems (PLC’s), used in industrial

environments and are handled through the use

of specially designed electronic filters. These

filters neutralize the unwanted noise and offer a

“clean” signal for further processing. The filters,

however, result in a delay in the processing of

signals, and can therefore only be applied with

great care in explosion protection systems

where the effectiveness depends on the overall

response time.

In active explosion protection systems, a

balance must be maintained: The system must

be extremely fast to achieve the required

effectiveness, but at the same time must be

stable and insensitive to surrounding sources of

noise.

The system controller will detect and report

major system troubles (such as ground faults,

wire disconnection, and unstable input or output

signals) and indicates the need for appropriate

action.

The system controller will also detect

unacceptable levels of electromagnetically

induced noise. If the magnitude of the noise is

such that this may result in a risk for

spontaneous system activation or affect the

system’s performance, the controller will revert

to its default error-mode.

It is essential to practice extreme caution when

selecting component location, cable

specifications, cable routes, and the

“cleanliness” of the offered power source. In

order to reduce the electromagnetic induced

noise to a level that will not affect the required

performance of the explosion protection system,

verify all earth connections. It is preferred to

have the enclosure and conduits connected to

Protective Earth (similar with other building

grounds) while the drain wires from the field

wiring and each module ground connected to a

separate Instrument Earth. This Instrument

Earth connection shall not have inductive or

capacitive loading such as motors, welders, or

other industrial equipment. Where a separate

earth connection is not available, the drain wires

and module ground connections should be

made to battery common. Complying with the

following recommendations will help minimize

the induced noise to acceptable levels.

4.2 POWER SPECIFICATIONS

The AC supply (commonly supplied to the

EPACO Power Supply Unit, PSU) shall be wired

through a dedicated circuit to a

1002/120/240VAC 15 or 16 Amp circuit breaker.

High voltage circuits may NOT be run in the

same conduit as low voltage circuits.

Cabling from transformer to PSU shall be

1.3 mm2(16AWG) minimum not to exceed

3 meters (10 feet).

2Not FM Approved for 100 VAC.

FIKE CORPORATION

FM 3020541 Fike Explosion Protection System Page 5 of 20

P/N E06-054 Rev. 1 07/04

Cabling from PSU to RC8 shall be 0.8 mm2

(18AWG) minimum not to exceed 10 Ω

resistance.

A keyed selector switch is recommended in the

PSU to RC8 power supply cabling to facilitate

reset of the RC8. This shall have a 30V, 1A

rating.

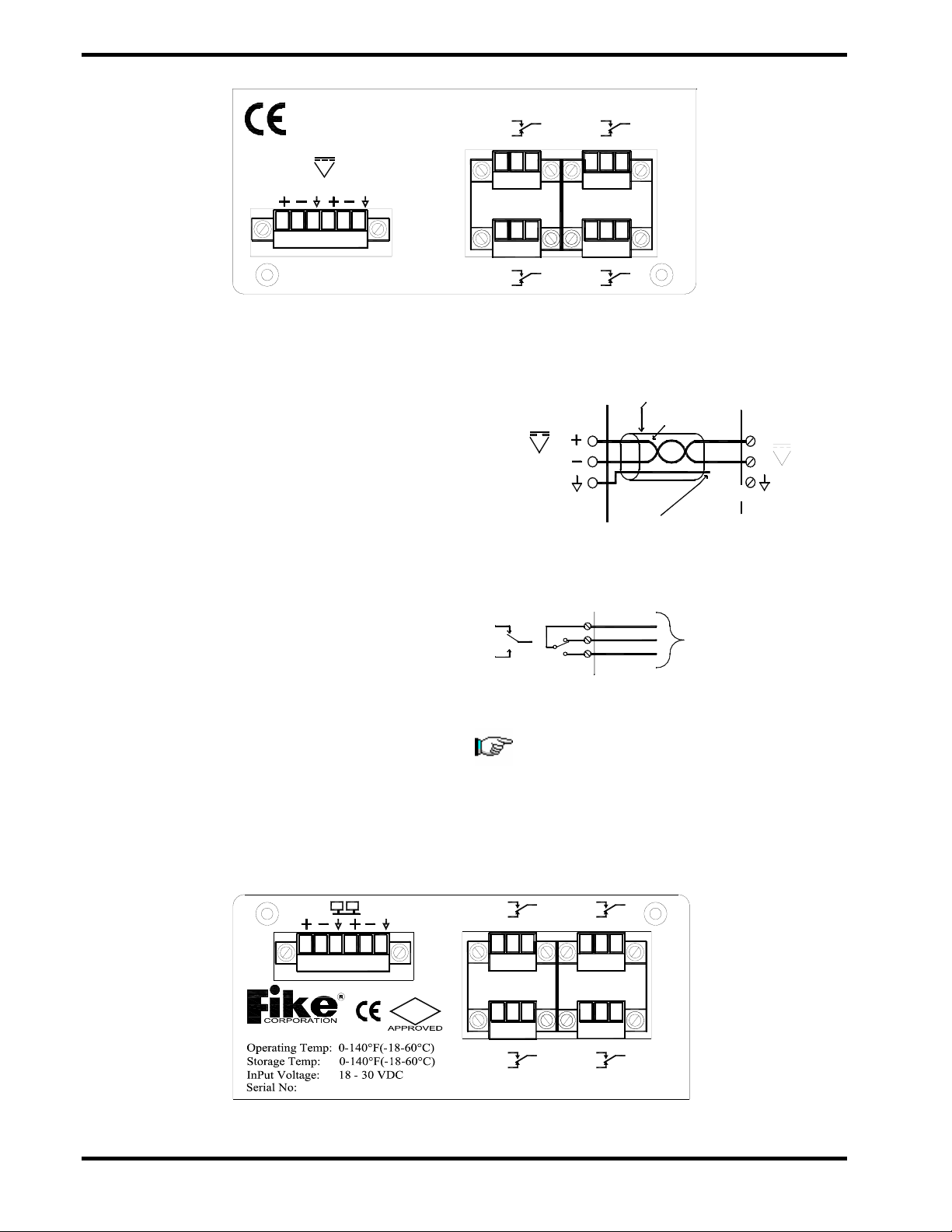

4.3 RELAY CARD (RC8)

The Relay Card (RC8) is a DIN rail mounted,

fully programmable module containing eight (8)

Form “C” relays. Each relay is equipped with a

green LED to provide a visual indication of the

relay state. These relays facilitate process

shutdowns or other actions in response to

conditions recognized by the EPACOsystem.

The RC8 is powered with 24VDC from the PSU.

Up to four (4) RC8s can be connected in parallel

to the power supply. The RC8 is capable of

communicating on the Status Bus for

exchanging status information and remote

control of the outputs. A history of the relay

states is captured in the Annunciator Module.

Exhibit 4-1 RC8 Block Diagram

OUTPUTS

POWER-24 VDC (18-30 VDC)

2 WIRE, TWISTED SHIELDED CABLE

INPUTS RC 8 MODULE

E10-0069

PSU, AM, EPC(S)

BELDEN 9841 OR EQUIVALENT

NETWORKS

P3-4

P3-3

P3-2

P3-1

P2-4

P2-3

P2-2

P4

P1

P2-1 CONTACT TERMINAL 1

CONTACT TERMINAL 2

CONTACT TERMINAL 3

CONTACT TERMINAL 4

CONTACT TERMINAL 5

CONTACT TERMINAL 6

CONTACT TERMINAL 7

CONTACT TERMINAL 8

STATUS BUS RC8(S) - STATUS BUS,

FIKE CORPORATION

Page 6 of 20 Fike Explosion Protection System FM 3020541

07/04 P/N E06-054 Rev. 1

Exhibit 4-2 RC8 Bottom View – P3-P4 Wiring Connections

4.4 CIRCUIT CONNECTIONS

4.4.1 24VDC Power (P4)

Power Input requires between 18 to 30 Vdc, at

500mA. For the Relay Card, power needs to be

from the EPACO PSU or an approved power

source for proper operation of the status bus.

4.4.2 Relay (P2 & P3)

Relays 1 through 8 are available to provide

EPACO system status to monitoring equipment.

The relays are a “fail-safe” relay that will transfer

upon any system upon the programmed

condition. This can be used for equipment

shutdown, visual, audible, or other type

annunciation. Trouble conditions may or may

not affect the protection system’s ability to

respond to a deflagration, but must be

acknowledged and identified prior to continuing

to run the process.

Exhibit 4-3 RC8 Power Input Wiring

Exhibit 4-4 RC8 Relay Wiring

Note: The relay designations (NO, NC, and

C) are shown in the de-energized state

with no power applied. When the RC8 is

powered and the system is in the NORMAL

state, the relay is energized. (The relay

marking is opposite of what is expected).

Exhibit 4-5 RC8 Top View – P1-P2 Wiring Connections

CNCNO

6

P3

CNCNO

8

E10-0069

NCNO

5

24VDC

NC

7

NO

P4

C

C

Process Monitoring

NO

C

NC

Equipment (*See Note*)

24VDC

-

+

Shield

Twisted Pair

No

Connection

P2

24VDC

of Drain Wir

e

No termination

[

insulate

]

EPC, AM or RC8

PSU

Contact: www.fike.com

FM

CNCNO

P2

NC CNO

4

2

NCNO

P1

NC

3

NO

A B 1

C

C

FIKE CORPORATION

FM 3020541 Fike Explosion Protection System Page 7 of 20

P/N E06-054 Rev. 1 07/04

4.4.3 Status Bus (P1)

The Status Bus is a low speed communication

bus that transmits control information between

the EPC, Power Supply, Annunciator Module

and Relay Modules. Belden 9841 or RE-Y2Y

cabling is recommended for this circuit.

Maximum resistance R=50 Ω, inductance

L=100uH, and capacitance C=0.02uF with a

maximum length of 300m (1,000 ft).

Note: The B+ connects to the A+ on the next

device; similarly the B– connects to the A– of

the next device. Install the 140 Ω, 1/2 watt

resistor at each end as shown.

Note: The drain wire should only be con-

nected on one end of each wire run. Make

sure that the drain wire, which is not

connected to a terminal, is cut and insulated

from making contact to metal or other wiring

connections.

Exhibit 4-6 Status Bus Wiring

Additional RC8

Twisted Pair

Shield Wire

-

+-+

Relay Module

BA

(RC8) #1

P1 Shield -

+-+

BA

RC8 #2

P1 -

+-+

Last RC8(Up to 4)

BA

P1

of Drain Wire [ insulate ]

-

+-+

-

++

-

Twisted Pair

Shield Wire

Controller (EPC) #1

Explosion Protection

-++

-

BA

P1 Shield

Annunciator

Module (AM)

BA

++

--

BA

P1

EPC #2 Last EPC (Up to 4)

B

-+-

P1

A

+

Additional EPC

Unit (PSU)

Power Supply

BA

No termination

Shield Wire

Twisted Pair

P2 Shield P1

140 ohm

140 ohm

FIKE CORPORATION

Page 8 of 20 Fike Explosion Protection System FM 3020541

07/04 P/N E06-054 Rev. 1

ADD

12

MODE

1234

5.0 OPERATION

5.1 CONFIGURATION

The RC8 is a fully programmable module.

System configuration can be performed with

DIPswitches on these modules or by way of a

DB9 serial port connection to a PC using

EPWorks™ Software. RC8 addressing is done

using the two ADD (address) DIPswitches. The

four MODE DIP switches are used for

programming specific relay configurations.

Expanded programming may be created via PC

with Fike's EPWorks™ Software.

Exhibit 5-1 Serial Port

5.1.1 Dip Switch Configuration

The EPACO system can have multiple RC8’s

connected to a single system. The ADD

switches enable the system to distinguish

between multiple RC8’s. The RC8 is configured

to one of six (6) configurations using the MODE

DIP switches on the face of the unit. The

configuration of the DIP switches set the relay

operation parameters of the RC8. The DIP

switches incorporate a safety feature that

prevents a programming change should one of

the DIP switches inadvertently get changed.

5.1.2 PC Configurations

There are twelve (12) relay configurations that

can be selected using a PC with EPWorks™

software. These relay configurations are more

elaborate than are available with the DIP switch

configurations.

NOTE: Address and configuration changes

are to be made by Fike authorized

engineers or technicians only.

Exhibit 5-2 DIP Switches

DB9

2A

- 2A -

21

65

MODEADD

4

3

DB9

24VDC

8

7

FIKE CORPORATION

FM 3020541 Fike Explosion Protection System Page 9 of 20

P/N E06-054 Rev. 1 07/04

24VDC

Green

Green

1

Green

5.2 RC8 STATUS

The RC8 is a process interface for the EPACO

system. The following tasks are accomplished

by the RC8:

•Communicates system status via relays for

user interface

•Direct shut downs, slow downs, and remote

notifications of system trouble and alarm

conditions

•Remote location of interface, separate from

the hazard zone

The RC8 operation can be classified into two main states of operation: Normal and Trouble / Alarm. Each

of these states is described in sections 5.2.1 and 5.2.2. Exhibit 5-6 further describes other conditions within

these states in a handy spreadsheet for quick reference.

5.2.1 RC8 Normal State

When power is applied to the RC8, it performs a 15 second

initialization. At the end of the initialization, the Status Bus LED will

turn on and the appropriate relays and relay LEDs will be energized to

indicate the current status of the EPACO system.

5.2.2 RC8 Trouble or Alarm State

A trouble or alarm occurs on the EPACO system if any one of the

supervised circuits experiences a wiring fault open or short condition, if

a configuration is invalid, if the system is disabled, if a process

pressure warning level is exceeded, if the input voltage drops below

18VDC or the activation criteria on the detector inputs have been met.

In the Trouble or Alarm State the green LED programmed to respond

to the fault or alarm condition will turn off, and the corresponding relay

is de-energized. Depending on the cause of the trouble, the system

may or may NOT be completely functional. Each trouble should be

investigated to determine the cause and promptly fixed. Each trouble,

except for remote disable, will latch at the EPC. If the trouble is

resolved, the EPC trouble can be cleared by disabling and re-enabling

via the remote disable input, by cycling of the power input to the EPC,

or by disabling and re-enabling the EPC via the Annunciator Module

(see Annunciator Module Installation and Operation Instructions E06-

053). If the remote disable is active, the EPC will enter the trouble

state. When the remote disable is returned to normal, the EPC will

automatically clear to the normal state, if no other troubles are present,

without cycling the power.

Note: The alarm state will activate the system. If the system is

reset after an alarm, it is typical to have an open wiring fault on

the Series Firing circuit, since the actuator(s) have activated.

Exhibit 5-3 Power LED

Exhibit 5-4 Status Bus LED

Exhibit 5-5 Trouble LED

FIKE CORPORATION

Page 10 of 20 Fike Explosion Protection System FM 3020541

07/04 P/N E06-054 Rev. 1

5.3 RELAY EVENTS

The RC8 relays can be configured for 55 different EPACO system events as shown in the table below. The

relay functionality can be selected through one of the six DIP switch configurations listed below in Exhibit 5-

7 or one of the twelve EPWorksconfigurations shown in Exhibit 5-8 or 5-9.

Module Description Module Description

EPC x No EPC or EPC Shutdown PSU No PSU/External Power Supply used

or No Communications

EPC x Normal Operation Mode PSU Normal Operation Mode

EPC x Trouble on one of the Input Circuits PSU Fan Trouble

EPC x Pressure Warning Level Exceeded PSU Ground Fault Trouble

EPC x Trouble on one of the Output Circuits PSU Battery or Charge Trouble

EPC x Trouble on the Fire Bus PSU AC Trouble

EPC x PreDischarge Condition Satisfied PSU Battery Backup being Utilized

EPC x Supervisory Input Active PSU Output Trouble

EPC x EPC has Activated Releasing Outputs PSU Outputs Disabled

EPC x EPC has been Disabled PSU Auto Shutdown Mode

EPC x Failure during Arming System Status Bus Communication Failure

“x” = EPC 1 through 4

Exhibit 5-6 Relay Events Table

FIKE CORPORATION

FM 3020541 Fike Explosion Protection System Page 11 of 20

P/N E06-054 Rev. 1 07/04

Exhibit 5-7 DIP Switch Configuration Table for RC8

8

EPC 4

Alarm

EPC 1

Arming Trouble

EPC 2

Arming Trouble

EPC 3

Arming Trouble

EPC 4

Alarm

RC8

Bus Failure

N/A

7

EPC 4

Trouble

EPC 1

Supervisory

EPC 2

Supervisory

EPC 3

Supervisory

EPC 4

Trouble

N/A

N/A

6

EPC 3

Alarm

EPC 1

PreDischarge

EPC 2

PreDischarge

EPC 3

Alarm

EPC 4

PreDischarge

PSU

Output Failure

N/A

5

EPC 3

Trouble

EPC 1

Shutdown

EPC 2

Shutdown

EPC 3

Trouble

EPC 4

Shutdown

PSU

Fan Failure

N/A

4

EPC 2

Alarm

EPC 1

Disable

EPC 2

Alarm

EPC 3

Disable

EPC 4

Disable

Ground

Fault

N/A

3

EPC 2

Trouble

EPC 1

Pres. Warning

EPC 2

Trouble

EPC 3

Pres. Warning

EPC 4

Pres. Warning

Batt. Power

Failure

N/A

2

EPC 1

Alarm

EPC 1

Alarm

EPC 2

Disable

EPC 3

PreDischarge

EPC 4

Arming Trouble

AC Power

Failure

N/A

Relay Number

1

---- User Selectable with Software ----

EPC 1

Trouble

EPC 1

Trouble

EPC 2

Pres. Warning

EPC 3

Shutdown

EPC 4

Supervisory

PSU

Trouble

N/A

4

Off

Off

Off

Off

Off

Off

Off

On

Configure Clear - Used to change the configuration settings in the Relay Card.

PC Configure - Used to provide expanded programming options.

3

Off

Off

Off

Off

On

On

On

On

2

Off

Off

On

On

Off

Off

On

On

Mode Switch Position

1

Off

On

Off

On

Off

On

Off

On

Config Clear

PC Config

Config #

PC Config

1

2

3

4

5

6

Config Clear

EPC Trouble = No EPC or EPC Shutdown, Trouble on Input Circuit, Pressure Warning, Trouble on Output Circuit, Trouble on Fire Bus, PreDischarge, Supervisory

Input Active, EPC Disabled, or Failure During Arming.

EPC Alarm = Releasing Outputs Activated, or No EPC or EPC Shutdown.

Definitions

FIKE CORPORATION

Page 12 of 20 Fike Explosion Protection System FM 3020541

07/04 P/N E06-054 Rev. 1

Configuration 6

EPC 4 - Shutdown

EPC 4 - Input Trouble

EPC 4 - Pressure Warning

EPC 4 - Output Trouble

EPC 4 - Fire Bus Trouble

EPC 4 - PreDischarge

EPC 4 - Supervisory

EPC 4 - Disabled

EPC 4 - Activation

EPC 4 - Pressure Warning

EPC 4 - Disabled

EPC 4 - Shutdown

EPC 4 - Pressure Warning

EPC 4 - PreDischarge

EPC 4 - Supervisory

RC8 - Status Bus Failure

Configuration 5

EPC 3 - Shutdown

EPC 3 - Input Trouble

EPC 3 - Pressure Warning

EPC 3 - Output Trouble

EPC 3 - Fire Bus Trouble

EPC 3 - PreDischarge

EPC 3 - Supervisory

EPC 3 - Disabled

EPC 3 - Activation

EPC 3 - Pressure Warning

EPC 3 - Disabled

EPC 3 - Shutdown

EPC 3 - Pressure Warning

EPC 3 - PreDischarge

EPC 3 - Supervisory

RC8 - Status Bus Failure

Configuration 4

EPC 2 - Shutdown

EPC 2 - Input Trouble

EPC 2 - Pressure Warning

EPC 2 - Output Trouble

EPC 2 - Fire Bus Trouble

EPC 2 - PreDischarge

EPC 2 - Supervisory

EPC 2 - Disabled

EPC 2 - Activation

EPC 2 - Pressure Warning

EPC 2 - Disabled

EPC 2 - Shutdown

EPC 2 - Pressure Warning

EPC 2 - PreDischarge

EPC 2 - Supervisory

RC8 - Status Bus Failure

Configuration 3

EPC 1 - Shutdown

EPC 1 - Input Trouble

EPC 1 - Pressure Warning

EPC 1 - Output Trouble

EPC 1 - Fire Bus Trouble

EPC 1 - PreDischarge

EPC 1 - Supervisory

EPC 1 - Disabled

EPC 1 - Activation

EPC 1 - Pressure Warning

EPC 1 - Disabled

EPC 1 - Shutdown

EPC 1 - Pressure Warning

EPC 1 - PreDischarge

EPC 1 - Supervisory

RC8 - Status Bus Failure

Configuration 2

EPC 3 - Pressure Warning

EPC 3 - PreDischarge

EPC 3 - Supervisory

EPC 3 - Arming Trouble

EPC 3 - Shutdown

EPC 3 - Input Trouble

EPC 3 - Output Trouble

EPC 3 - Fire Bus Trouble

EPC 3 - Disabled

EPC 3 - Activation

EPC 3 - Shutdown

EPC 3 - Disabled

EPC 4 - Pressure Warning

EPC 4 - PreDischarge

EPC 4 - Supervisory

EPC 4 - Arming Trouble

EPC 4 - Shutdown

EPC 4 - Input Trouble

EPC 4 - Output Trouble

EPC 4 - Fire Bus Trouble

EPC 4 - Disabled

EPC 4 - Activation

EPC 4 - Shutdown

EPC 4 - Disabled

PSU - Battery Trouble

PSU - AC Trouble

Configuration 1

EPC 1 – Pressure Warning

EPC 1 - PreDischarge

EPC 1 - Supervisory

EPC 1 - Arming Trouble

EPC 1 - Shutdown

EPC 1 - Input Trouble

EPC 1 - Output Trouble

EPC 1 - Fire Bus Trouble

EPC 1 - Disabled

EPC 1 - Activation

EPC 1 - Shutdown

EPC 1 - Disabled

EPC 2 - Pressure Warning

EPC 2 - PreDischarge

EPC 2 - Supervisory

EPC 2 - Arming Trouble

EPC 2 - Shutdown

EPC 2 - Input Trouble

EPC 2 - Output Trouble

EPC 2 - Fire Bus Trouble

EPC 2 - Disabled

EPC 2 - Activation

EPC 2 - Shutdown

EPC 2 - Disabled

PSU - Fan Trouble

PSU - Ground Fault Trouble

PSU - Batt./Charge Trouble

PSU - AC Trouble

PSU - Battery Backup

RC8 - Status Bus Failure

Relay 1

Relay 2

Relay 3

Relay 4

Relay 5

Relay 6

Relay 7

Relay 8

Exhibit 5-8 EPWorks™ Configurations 1 - 6

FIKE CORPORATION

FM 3020541 Fike Explosion Protection System Page 13 of 20

P/N E06-054 Rev. 1 07/04

Configuration 12

PSU - AC Trouble

PSU – Batt./Charge Trouble

PSU - Fan Trouble

PSU - Ground Fault Trouble

PSU - Battery Backup

PSU - Output Trouble

PSU - Output Disabled

PSU - Shutdown

Configuration 11

EPC 1 - Supervisory

EPC 2 - Supervisory

EPC 3 - Supervisory

EPC 4 - Supervisory

RC8 - Status Bus Failure

PSU - Fan Trouble

PSU - Ground Fault Trouble

PSU - Batt./Charge Trouble

PSU - AC Trouble

PSU - Battery Backup

EPC 1-4 - Shutdown

EPC 1-4 - Input Trouble

EPC 1-4 - Pressure Warning

EPC 1-4 - Output Trouble

EPC 1-4 - Fire Bus Trouble

EPC 1-4 - PreDischarge

EPC 1-4 - Supervisory

EPC 1-4 - Disabled

EPC 1-4 - Activation

Configuration 10

EPC 1 - Disabled

EPC 1 - Shutdown

EPC 2 - Disabled

EPC 2 - Shutdown

EPC 3 - Disabled

EPC 3 - Shutdown

EPC 4 - Disabled

EPC 4 - Shutdown

Configuration 9

EPC 1 - Supervisory

EPC 1 - Pressure Warning

EPC 1 - PreDischarge

EPC 2 - Supervisory

EPC 2 - Pressure Warning

EPC 2 - PreDischarge

EPC 3 - Supervisory

EPC 3 - Pressure Warning

EPC 3 - PreDischarge

EPC 4 - Supervisory

EPC 4 - Pressure Warning

EPC 4 - PreDischarge

Configuration 8

EPC 1 - Pressure Warning

EPC 1 - Disabled

EPC 2 - Pressure Warning

EPC 2 - Disabled

EPC 3 - Pressure Warning

EPC 3 - Disabled

EPC 4 - Pressure Warning

EPC 4 - Disabled

Configuration 7

EPC 1 - Supervisory

EPC 1 - Shutdown

EPC 1 - Input Trouble

EPC 1 - Output Trouble

EPC 1 - Fire Bus Trouble

EPC 1 - Disabled

EPC 2 - Supervisory

EPC 2 - Shutdown

EPC 2 - Input Trouble

EPC 2 - Output Trouble

EPC 2 - Fire Bus Trouble

EPC 2 - Disabled

EPC 3 - Supervisory

EPC 3 - Shutdown

EPC 3 - Input Trouble

EPC 3 - Output Trouble

EPC 3 - Fire Bus Trouble

EPC 3 - Disabled

EPC 4 - Supervisory

EPC 4 - Shutdown

EPC 4 - Input Trouble

EPC 4 - Output Trouble

EPC 4 - Fire Bus Trouble

EPC 4 - Disabled

Relay 1

Relay 2

Relay 3

Relay 4

Relay 5

Relay 6

Relay 7

Relay 8

Exhibit 5-9 EPWorks™ Configurations 7 - 12

FIKE CORPORATION

Page 14 of 20 Fike Explosion Protection System FM 3020541

07/04 P/N E06-054 Rev. 1

6.0 PERIODIC MAINTENANCE

CAUTION: If assistance is needed before performing any maintenance or service work on the Fike

Explosion Protection equipment and/or systems, contact Fike for instructions. See

section 11.0 Repair and Return Authorization for contact information.

6.1 GENERAL

Routine system inspections shall be conducted

in accordance with the requirements of the

appropriate local authority having jurisdiction

and National Fire Protection Association

Standard Number 69, Explosion Prevention

System, current edition.

The inspection schedule and procedure set forth

below are provided as a minimum requirement

for Fike Explosion Protection System

Controllers, which operate in moderate

environments. These control panel instructions

are to be implemented in conjunction with

complete system inspection instructions.

During initial system checkout or start-up, the

Fike Factory Field Personnel, due to process

operational characteristics and/or historical

inspection data on the specific process, may

determine that an additional inspection is

required. If this occurs, it will be in addition to

the following maintenance schedule.

It is extremely important to closely monitor the

operational characteristics of your system during

the first few days and weeks after the initial

start-up.

6.2 INSPECTION PROCEDURE

The following is the recommended procedure to

follow when conducting an inspection.

Step 1: Disable the Control Panel

Step 2: Shunt the GCA’s and install jumpers

Step 3: Re-Arm the Control Panel and Disable

Step 4: Calibrate the pressure detectors

Step 5: Cycle the Explosion Isolation Valves – if

present

Step 6: Checkout the panel

Step 7: Reconnect the GCA’s and log the

container pressures and serial numbers

Step 8: Re-arm the system

6.3 ROUTINE INSPECTIONS

These inspections are to be performed by Fike

Field Personnel or personnel trained and

certified by Fike.

To perform an inspection, it is important to first

obtain all pertinent data that relates to the

specific system being inspected. The required

information includes:

!System Engineered Drawings

Component Location Drawing No._________

Field Wiring Drawing No.____________

!Copy of Manuals, Specifications or

Documents Referenced on Fike System

Engineered Drawings

!Inspection Equipment

!Operating Specifications on Each Component

Being Inspected

6.4 THREE-YEAR REPLACEMENT

Replace all system batteries.

6.5 TEN-YEAR REPLACEMENT

Replace all GCA actuators, following all safe

handling practices and recommendations.

Note: The ten-year replacement is based

upon a 70°F to 80°F (20°C to 30°C)

actuator temperature. The replacement

frequency may be more frequent when

exposure to higher temperature or harsh

environments is experienced.

This manual suits for next models

1

Table of contents

Other Fike Relay manuals