Fines HTB Series User manual

INSTRUCTIONS MANUAL

Prover HTB

ENGLISH VERSION

Date of creation: 15.05.2014

Date of change:

HTB16-M manual

HTB10-M manual

HTB16-D digital

HTB10-D digital

2

FINES – OPERATING INSTRUCTIONS – ENGLISH version

Prover HTB »HTB16,10-M in HTB16,10-D »

INDEX

1.0. DANGEROUS ZONES ............................................... 3

2.0. TECHNICAL DATA .................................................. 3

3.0. PRODUCT LABELLING .............................................. 5

4.0. SAFETY NOTES.................................................... 6

5.0. PLACEMENT OF THE PROVER ....................................... 6

6.0. INSTALLATION .................................................... 7

6.2. WATER CONNECTION .............................................. 7

7.0. DESCRIPTION ..................................................... 8

8.0. CONTROL PANEL HTB16,10-M manual ................................. 8

9.0. PROVER MANAGEMENT HTB16,10-M manual ........................... 8

10.0. CONTROL PANEL HTB16,10-D digital .................................. 9

11.0. PROVER MANAGEMENT HTB16,10-D digital ............................ 9

12.0. REGULAR CLEANING AND MINTAINANCE ............................ 10

13.0. WARRANTY CONDITIONS .......................................... 11

14.0. CONTACT DETAILS ................................................ 11

3

FINES – OPERATING INSTRUCTIONS – ENGLISH version

Prover HTB »HTB16,10-M in HTB16,10-D »

1.0. DANGEROUS ZONES

ATTENTION – RISK OF BURNS

HOT SURFACE OF THE GLASS OF THE DORS AND OF THE FRONT SIDE OF THE PROVER

HOT CHAMBER OF THE PROVER

EXTRA CAUTION REQUIRED WHEN REMOVING THE HOT TRAYS FROM THE PROVER

2.0. TECHNICAL DATA

Model HTB16-M HTB10-M

Management manual regulation manual regulation

Tray capacity 16x dim. 60 x 40 cm 10x dim. 60x 40 cm

Tray distance 70 mm 70 mm

Outside dim. AxBxC 930 x 800 x 905 mm 930 x 800 x 655 mm

Weight 75 kg 65 kg

Total electrical power 1,2 kW 1,2 kW

Fuses 10 A 10 A

Voltage 230V / 50Hz 230V / 50Hz

Water connection R 3/4” R 3/4”

Water preasure 200 – 500 kPa (2-5 bar) 200 – 500 kPa (2-5 bar)

Temperature max. 85°C max. 85°C

Model HTB16-D HTB10-D

Management digital regulation digital regulation

Tray capacity 16x dim. 60 x 40 cm 10x dim. 60x 40 cm

Tray distance 70 mm 70 mm

Outside dim. AxBxC 930 x 800 x 905 mm 930 x 800 x 655 mm

Weight 75 kg 65 kg

Total electrical power 2,7 kW 2,7 kW

Fuses 16 A 16 A

Voltage 230V / 50Hz 230V / 50Hz

Water connection R 3/4” R 3/4”

Water preasure 200 – 500 kPa (2-5 bar) 200 – 500 kPa (2-5 bar)

Temperature max. 60°C max. 60°C

4

FINES – OPERATING INSTRUCTIONS – ENGLISH version

Prover HTB »HTB16,10-M in HTB16,10-D »

5

FINES – OPERATING INSTRUCTIONS – ENGLISH version

Prover HTB »HTB16,10-M in HTB16,10-D »

3.0. PRODUCT LABELLING

TECHNICAL DATA PAD

HTB16-M manual HTB 10-M manual

HTB16-D digital HTB 10-D digital

6

FINES – OPERATING INSTRUCTIONS – ENGLISH version

Prover HTB »HTB16,10-M in HTB16,10-D »

4.0. SAFETY NOTES

The appliance is designed exclusively for reheating and raising food, such as various confectionery,

bakery, meat and vegetable dishes!

Proverisstrictlymadeonlyforrisingfoodandnotanythingelseunlessmanufacturerconrms

otherwisewithwrittenconrmation!

Itisstrictlyforbiddentoriseanyproductscontaininginammablevapours(e.g.alcohol)thatcanset

onre!

The prover can be operated only by authorized persons who are familiar with all safety instructions!

When inserting and taking out the material from the prover wear protective gloves made of non-

combustible material!

For unauthorised persons movement near to the prover is strictly forbidden.

Before each start of the prover operation certain precautions should be secured

– All the safety elements of the prover are in place;

– No part of the prover is damaged;

– All foreign bodies from the prover and its surround ings are eliminated;

If these criteria are not met the prover should be started only after eliminating all the faults!

Afternishedrisingprocedurethemainswitchshouldbealwaysswitchedoandalsothewatervalve

should be closed.

Allmaintenanceandserviceworkshouldcarriedoutonlybyanauthorizedandaqualiedperson,

fami liar with the technical characteristics of the prover and regulations for the safe operation!

Always carry out repair and service work with the a ppliance at zero voltage!

After the maintainance or servis of the prover it s i necessary to take in consideration all upper

instructions.

Alsoitisnecessarytoshurethatallproverpartsandsecurityelementsareproperlyconguredand

installed on their places.

Iftheregulationsforsafeworkarenotsatised,theprovershouldn’tbeoperated!

5.0. PLACEMENT OF THE PROVER

Prover HTB-M, D can be used as a standalone deviceor you can use it to put the HTB or FIN DEKO

proveron it.

When installing the appliance for safety reasons, their own refrigeration servicing and general for reliable

operation,necessarytotakeintoaccountthestandarddeviationofthewalls,dierentpartitions,kitchenfurn

iture, decorative coverings, etc. ... All the walls and all the objec ts that are in the immediate vicinity must be

madeof noncombustible materials (ceramic, plating, etc. ...), otherwise they shall be surrounded with non-

combus tible heat insulating material.

In the area where the device operates normally, therefore, creates a moisture is necessary to

provide ventilation.

7

FINES – OPERATING INSTRUCTIONS – ENGLISH version

Prover HTB »HTB16,10-M in HTB16,10-D »

IT IS FORBIDDEN TO INSTALL THE PROVER IN A PLACEHTWOI UT APPROPRIATE

VENTILATION SYSTEM!

The place desiganted for installation of the proverhas to be prepared in line with the manufacturer‘s

instructions prior to the installation. Accordingly the purchaser (or a designer) has to ensure the

following:

– A spacious position at appropriate distance from the walls and the ceiling

– Electrical supply of appropriate electrical power supply, appropriate fuses and nearby main switch

– Connection of the appliance to the potential equalization – separate grounding conductor

– Connection to the cool water supply with a soften ing system having a valve

– Ventilation system and steam suction above the prover

6.0. INSTALLATION

6.1. - ELECTRICAL CONNECTION

ELECTRICAL CONNECTION OF THE PROVER CAN ONLY BE DONE BY A DULY

AUTHORISED PERSON!

PLEASE FOLLOW ALL REGULATIONS FOR SAFE WORK WHEN INSTALLING THE

ELECTRICAL DEVICE!

In order to electrically connect the prover, it is necessary to use a standardized connector cable with

a rubber insulation H 05 RN–F5 G 2,5 mm2, factory already installed onto the prover. In case that the

prover is installed in countries with power supply 110 V / 60 Hz, the cable cross-section correspondingly

increases.

The cable must be physically protected by a plasticpipe or a tube, so it is not directly exposed to

outsideinuences!

The device must be grounded in accordance with the safety of electrical equipment!

Equalisation of potentials is carried out onto the screw marked with a symbol, which is located below

the feedthrough for electrical connection, on the back side of the prover!

A separate 3-core cable must be provided for the prover from the electrical cabinet of the facility,

whose cross section corresponds to the maximum electrical powerof the prover with appropriate

protection with one-phase automatic circuit breaker;

6.2. WATER CONNECTION

Watersupplyislocatedontherearleftbottomside.Connectionismadewithasuppliedexibledelivery

pipeforwaterattachedtodistributionnetworkvalveorbyathreadedpipewithaľ.Theconnectionshouldbe

made so that it cannot be removed in the event of a pressure overload.

Sand trap shall be installed before the entering of the water into the prover and due to scaling is advisable to

also install a water softener.

8

FINES – OPERATING INSTRUCTIONS – ENGLISH version

Prover HTB »HTB16,10-M in HTB16,10-D »

7.0. DESCRIPTION

A prover is intended for rising of food with a help of hot air circulating evenly in the prover chamber with

possibility of humidifying.

• When talking about M-manual version we humidify with pressing the humidify button for longer time

but no longer than 10s.

• With D-digital version we set the humidity level with controller and then it controls the level itfsel.

Food shall always be placed on standard trays EN 60/40, with which are than inserted into the provers

guides.

Depending on a model, a prover may have 5+5 or 8+8 levels.

Prover can be placed as self standing device or in most cases as additional element in combination with

HTB convection or FIN DEKO deck PROVER.

Depending on the needs of the whole set (hood + PROVER + prover) you can choose between two heights:

PROVER – HTB10-M or D – with capacity of 5+5 trays EN 60/40

Standard height H=905 mm

PROVER – HTB16-M or D – with capacity of 8+8 trays EN 60/40

Lowered height H=605 mm

8.0. CONTROL PANEL HTB16,10-M manual

MAIN SWITCH – 0/1

HUMIDITY BUTTON

SIGNAL LIGHT FOR THE HEATER

TEMPERATURE SET BUTTON

9.0. PROVER MANAGEMENT HTB16,10-M manual

Device is turned on with main switch. In it green light shines when we do it.

Temperature can bi set with knob till max. 85°C – standard set temperature for rising is cca. 40–50°C+

Open the doors of prover (risk of burns!);

Put the products in the chamber (necessary to wear gloves - risk of burns). At that you have to

provide that the hot air reaches all products.

Close the door as soon as possible, to avoid heat loss.

9

FINES – OPERATING INSTRUCTIONS – ENGLISH version

Prover HTB »HTB16,10-M in HTB16,10-D »

Between the process you should provide humidity wit h pressing the humidity button. The button

shouldn’tbepressedmorethan10satonce.

Whentherisingprocessisnishedyoutakeouttheproductsassoonaspossible.(atthatyoushould

be using the protective gloves – risk of burns)

During process it is recommended that you open thedoors as less as you can, because of the heat loss.You

can watch the rising of the products through big glass doors.

ALWAYS FOLLOW THIS PROCEDURE AT THE END OF THE PROCESS:

Turn o the device with main switch 0/1 !!!

Close the water pipe or valve!!!

10.0. CONTROL PANEL HTB16,10-D digital

BUTTON TEMPERATURE BUTTON SET

BUTTON UP

BUTTON DOWN

BUTTON TIME

BUTTON DOWN

BUTTON FUNCTION

BUTTON UP

BUTTON ON/OFF

MAIN SWITCH – 0/1

11.0. PROVER MANAGEMENT HTB16,10-D digital

Device is turned on with main switch. In it green light shines when we do it.

Temperaturecanbesetonleftcontrollerrstwithpressingthebuttontemperatureandthenwithbuttonsup

anddownwesetthetemperatureuptomax.70°C.Whenthetemperatureisset,conrmitwithbuttonset-

standard temperature for rising is cca. 40–50°C.

Time can be set on the left controller with pressing the button time following with buttons set and then with

buttonsupanddown.Weconrmitwithbuttonset.

Also the humidity can be set on the left controller with pressing the button time following with buttons set

andthenwithbuttonsupanddown.Wealsoconrmitwithbuttontime.

Open the doors of prover (risk of burns!);

Put the products in the chamber (necessary to wear gloves - risk of burns). At that you have to provide

that the hot air reaches all products.

Close the door as soon as possible, to avoid heat loss.

Whentherisingprocessisnishedyoutakeouttheproductsassoonaspossible.(atthatyoushouldbe

using the protective gloves – risk of burns)

10

FINES – OPERATING INSTRUCTIONS – ENGLISH version

Prover HTB »HTB16,10-M in HTB16,10-D »

During process it is recommended that you open the doors as less as you can, because of the heat loos.

You can watch the rising of the products through big glass doors.

ALWAYS FOLLOW THIS PROCEDURE AT THE END OF THE PROCESS:

Turn o the device with main switch 0/1!!!

Close the water pipe or valve!!!

12.0. REGULAR CLEANING AND MINTAINANCE

EXTERIOR AND INTERIOR OF THE PROVER MUST BE COOLEDOWN TO ROOM

TEMPERATURE (approximately 25 C) BEFORE CLEANING!

PROVER MUST BE DISCONNECTED FROM ELECTRICAL POWER SUPPLY BEFORE

CLEANING!

DO NOT USE AGGRESSIVE CLEANING AGENTS FOR CLEANING OF THE PROVER

CLEANING OF THE INTERIOR OF THE PROVER CAN ONLY BE DONE WITH CERTIFIED AND

ORIGINALLY PACKED CLEANSING AGENTS, WHICH ARE APPROVED FOR USE IN FOOD

INDUSTRY FOR CLEANING THE INTERIOR OF PROVERS AND ON WHICH IS THIS CLEARLY

SPECIFIED OF THE PACKAGING OF THE CLEANSING AGENT

WHEN USING ANY KIND OF CLEANSING AGENTS IS OBLIGATORY TO USE PROTECTIVE

GLOVES

STRICT COMPLIANCE WITH INSTRUCTIONS for USE and SAFE WORK WITH THE

CLEANSING

AGENT IS OBLIGATORY

IT IS FORBIDDEN TO CLEAN THE PROVER WITH RUNNING WATER or JET OF WATER

WHEN CLEANING, IT IS FORBIDDEN TO USE TOOLS, WHICH MAY MECHANICALLY

DAMAGE THE SURFACE

12.1. REGULAR CLEANING OF THE EXTERIOR OF THE PROVER

EXTERIOR OF THE PROVER is cleaned with a moistened damp cloth or with a mild detergent for

decreasing of metal surfaces.

Clean the CONTROL PANEL only with a moistened soft cloth, never use any detergent!

THE EXTERNAL GLASS OF THE DOOR from the outside shall be cleaned on regular intervals with a damp

cloth or mild cleaning agent for glass.

For all outside surfaces of the PROVER is recommended to use cleaning detergent FINES MOROTO

GX500 and GX500 S that is packed in handy packaging with spra yer for easier spraying, and multi-purpose

cleanerMX200.

12.2. REGULAR CLEANING OF THE INTERIOR OF THE PROVER

METAL PARTS OD THE INTERIOR of the device it is nec essary to clean regularly with wet cloth and

cleaning agent for degreasing surfaces that can be used in the food industry.

For cleaning stubborn grease stains on the metal parts inside, use detergent to clean the PROVER cavity,

which may be used in the food industry, this is exactly hold the manufacturer‘s instructions.

To facilitate the cleaning guides are quickly remov able without tools, if necessary, you can easily remove

and clean place behind them;

Clean the DOOR GASKET with a damp cloth at the end of each working day, never clean the gasket of

thedoor with any detergents;

Clean the INTERNAL GLASS OF THE DOOR with a damp cl oth or mild cleaning agent for glass.

For all outside surfaces of the PROVER is recommended to use cleaning detergent FINES MOROTO

GX500 and GX500 S that is packed in handy packaging with spra yer for easier spraying, and multi-purpose

cleanerMX200.

11

FINES – OPERATING INSTRUCTIONS – ENGLISH version

Prover HTB »HTB16,10-M in HTB16,10-D »

13.0. WARRANTY CONDITIONS

WARRANTY for the product is 24 months,

onlyincase,ifthebuyerpriortothepreviousperiodoftherst12months,orders,atitsownexpensea

preventive check up of the product at the authorized FINES service centre and provided that the service

centre,afterexaminingtheproduct,conrmsthathandlingofthePROVERhasbeencarriedoutwithdue

care and diligence, otherwise the WARRANTY is limited to 12 months!

STANDARD WARRANTY CONDITIONS

This warranty includes replacement of original parts found to be defective and installation free of charge by

the authorised FINES agent.

The warranty becomes efective from the date of saleor installation date of the equipment

under the following restrictive conditions:

1. The equipment is purchased under » normal » conditions;

2. Installation is made by an authorised agent;

3. The equipment is maintained and serviced only by an authorised agent!

4. Utilisation of the equipment conforming to the indications of the instructions for use and for the

purpose for which it is made;

5. The equipment is maintained daily as a good father should and with all due care;

6.Maintenancefollowed-upbytheauthorisedagentconformingtothemaintenancespecications

with at least one maintenance a year (maintenance at the user`s cost); If there is no maintenance

follow-up by an authorised servicer, the warranty is limited to 12 months!

7. Exclusive use of FINES original parts;

This warranty doesn`t cover:

1. Replacement of normally wearing parts (bulbs, seals) and door glass damage;

2. Parts found not to be defective by our dealers;

3. Problems resulting from abnormal use of the equipment;

4. Problems resulting from an installation not ins talled by an authorised agent;

5. Parts where problems result from transport damage or incorrect handling;

Repair and/or replacement of defective parts duringthe warranty period does not extend the initial warranty!

EXTENDED SPECIAL WARRANTY CONDITIONS

Extended special warranty conditions include all the terms of » standard warranty » with exception

ofwarranty period, which is extended!

The Extended warranty may include additional conditions if agreed upon in writing with the purchaser.

14.0. CONTACT DETAILS

MANUFACTURER:

FINES d.o.o.

Industrijska 5, 1290 Grosuplje, SLOVENIJA

Tel: +386 1 788 83 40

Fax: +386 1 788 83 42

Internet:www.nes.si

E-mail:info@nes.si

This manual suits for next models

4

Table of contents

Popular Convection Oven manuals by other brands

EUROPRO

EUROPRO JET JO287SP owner's manual

Southbend

Southbend Marathoner Gold ES/20SC Features & dimensions

MasterChef

MasterChef 043-1322-6 instruction manual

Southbend

Southbend TruVection TVGS/12SC Installation & operation manual

EUROPRO

EUROPRO TO285 N owner's manual

BLACK DECKER

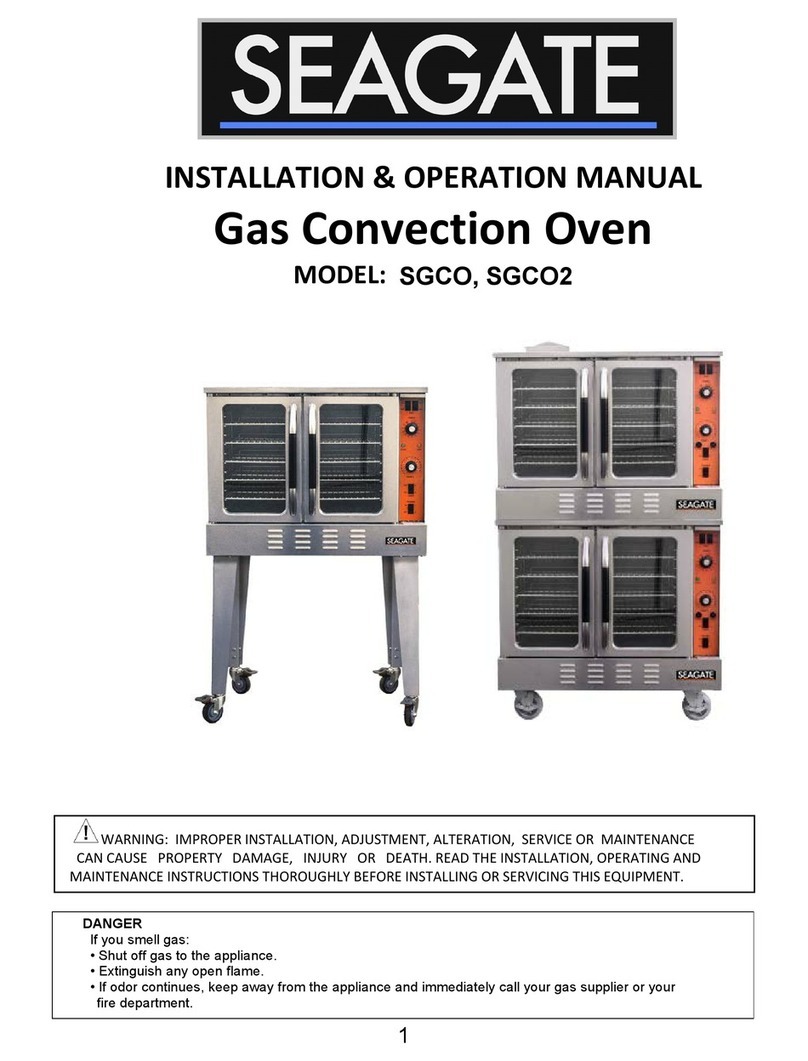

BLACK DECKER PERFECT BROIL CTO4551KT-AR manual

Alto-Shaam

Alto-Shaam PLATINUM ASC-2E Installation, operation and maintenance

Alto-Shaam

Alto-Shaam 2-ASC-2E/STK Specification sheet

KitchenAid

KitchenAid KERA205PBL1 parts list

Black & Decker

Black & Decker TRO4085 Use and care book

BEING

BEING BOF Series operating instructions

Lang

Lang EHS-AP Installation operation & maintenance