FIOCCHETTI ECT-F TOUCH Operating instructions

USER AND MAINTENANCE

Manual ECT-F TOUCH

3

INDEX

1GENERAL INFORMATION_________________________________________________________________________ 5

1.1 CERTIFICATION_______________________________________________________________________________ 5

1.2 TESTING AND WARRANTY ______________________________________________________________________ 5

1.3 AIM, CONTENT AND ADRESSEES OF THE MANUAL __________________________________________________ 5

1.4 CLIENT’S RESPONSIBILITIES _____________________________________________________________________ 6

1.5 INSTRUCTIONS FOR SERVICE REQUESTS ___________________________________________________________ 6

2DESCRIPTION OF THE PRODUCT ___________________________________________________________________ 6

2.1 TECHNICAL DESCRIPTION ______________________________________________________________________ 6

3SAFETY _______________________________________________________________________________________ 7

3.1 GENERAL SAFETY RULES _______________________________________________________________________ 7

3.2 INTENDED USE _______________________________________________________________________________ 7

3.3 CONTRAINDICATION __________________________________________________________________________ 7

3.4 SAFETY AND ACCIDENT PREVENTION _____________________________________________________________ 7

4TRANSPORT AND HANDLING _____________________________________________________________________ 8

4.1 TRANSPORT AND HANDLING____________________________________________________________________ 8

4.2 POSITIONING ________________________________________________________________________________ 9

4.3 WIRING AND ELECTRICAL HOOK UP ______________________________________________________________ 9

4.4 SETUP OPERATIONS ___________________________________________________________________________ 9

5CONTROL PANEL ECT-F TOUCH ___________________________________________________________________ 13

5.1 DESCRIPTION CONTROL BOARD ECT-F TOUCH _____________________________________________________ 13

5.2 FUNCTIONING ECT-F TOUCH CONTROL __________________________________________________________ 15

6ELECTRICAL SAFETY FUSES_______________________________________________________________________ 35

7DMLP TOUCH DIGITAL MONITOR _________________________________________________________________ 35

8ORDINARY AND PROGRAMMED MAINTENANCE ____________________________________________________ 35

8.1 PROHIBITION OF SAFETY DEVICES REMOVAL ______________________________________________________ 35

8.2 CLEANING OF THE EQUIPMENT INSIDE AND OUTSIDE_______________________________________________ 35

8.3 CONDENSER CLEANING _______________________________________________________________________ 36

8.4 CONDENSATE WATER DRAINING _______________________________________________________________ 38

8.5 BATTERIES REPLACEMENT (if present) ___________________________________________________________ 38

9EXTRAORDINARY MAINTENANCE AND REPAIRS _____________________________________________________ 39

10 DEMOLITION _________________________________________________________________________________ 39

11 ANNEXES_____________________________________________________________________________________ 40

12 DATA PLATES _________________________________________________________________________________ 40

12.1 DATA PLATES WITH EQUIPMENT CHARACTERISTICS______________________________________________ 40

12.2 WARNINGS DATA PLATES ___________________________________________________________________ 41

13 CONSUMABLES________________________________________________________________________________ 41

14 DRAWBACKS AND REMEDIES ____________________________________________________________________ 42

5

1 GENERAL INFORMATION

1.1 CERTIFICATION

All appliances are manufactured in compliance with the CE directives applicable at the

moment of their placing on the market.

All appliances are certified according to the directives 2006/42/CE, 2006/95/CE,

2004/108/CE and further amendments and they are manufactured taking into account the

safety standards of electrical appliances used in laboratories (CEI EN 61010-1). Medical

devices (for the storage of blood and blood related products) are, on the contrary, produced

in line with directive 93/42/CEE.

1.2 TESTING AND WARRANTY

The equipment is tested in our premises in compliance with the existing rules and it is ready

to be used.

The warranty is valid for 12 months from the date of delivery and covers the repair or the

replacement of defective parts, with the exception of electrical parts and electronic

components.

Manifest defects or any difference from the orders must be communicated to the

manufacturer within 5 days from the receipt of goods or they will not be covered by the

guarantee terms.

Any hidden or other defects must be communicated to the manufacturer within five days from

their discovery and in anyway within the maximum guarantee term of six months. The

purchaser shall be entitled to ask only for the repair or replacement of parts. The purchaser is

not entitled to claim compensation for direct or indirect damages of any whatsoever nature. In

any event, the entitlement for the repair or replacement of the materials must be exercised

within the maximum term of the guarantee, which is contractually stipulated to cover a shorter

period than the maximum term of the guarantee, which is contractually stipulated to cover a

shorter period than the maximum term established by law.

Repairs or replacement of defective materials will be carried out at manufacturer's premises;

the sent back materials must be shipped on ex-works basis and will be returned to the

purchaser at his expenses.

1.3 AIM, CONTENT AND ADRESSEES OF THE MANUAL

This manual has been prepared with the aim of supplying all the instructions required for the

correct use of the appliance and to maintain it in optimal working conditions. It also contains

important safety information for the user. The following professional roles are explained in

order to define the responsibilities of each person involved:

Installer: qualified technician who installs and commissions the appliance following the

instructions included in this manual.

User: the person who, after having read this manual, uses the appliance in accordance with

the intended use specified in this manual. The user is obliged to read the manual carefully

and refer constantly to the information in it contained.

Ordinary maintenance worker: qualified technician able to perform ordinary maintenance of

the appliance by following the instructions in this manual.

Extraordinary maintenance worker: qualified technician, authorized by the manufacturer,

to perform extraordinary maintenance of the appliance.

The manufacturer disclaims any liability for misuse or for not foreseen uses of the equipment

and for all operations carried out that are not in compliance with the instructions written in this

manual.

This manual must be kept in a place accessible and known to all the operators (installer,

user, ordinary maintenance worker, extraordinary maintenance worker).

This manual must not be reproduced or disclosed, in whole or in part, using any whatsoever

mean or in any whatsoever form.

6

1.4 CLIENT’S RESPONSIBILITIES

The customer is required to:

- do the electrical connection of the appliance

- prepare the place of installation

- provide cleaning products

- perform ordinary maintenance

In case of power failure or malfunctions, do not open the door in order to maintain uniform

temperature inside the cabinet. If the problem persists for many hours, we suggest moving

the stored products in a more suitable place.

1.5 INSTRUCTIONS FOR SERVICE REQUESTS

For any technical problem and service requests, refer exclusively to your local dealer (see

space in the last page) or directly to the manufacturer, specifying model and serial number of

the equipment. Please, send equipment backup data of the last period of functioning as well.

2 DESCRIPTION OF THE PRODUCT

2.1 TECHNICAL DESCRIPTION

The refrigeration of the internal cabinet is the result of low-pressure steaming of a refrigerant

liquid, type HCFC or HFC, in a thermal exchanger (evaporator). The obtained steam is

brought to the original liquid state through a mechanical compression at higher pressure

(compressor), followed by a cooling stage in another thermal exchanger (condenser).

One or more electro-mechanical fans (according to the model) grant the correct and uniform

distribution of the cold air into the chamber.

The appliance consists of a modular single structure coated with various materials and

insulated in expanded polyurethane foam, density 43 Kg/m³.

The controller is in the front panel. In some models, the user can find behind the front panel

the cooling unit represented by the condenser and the electrical loom.

The cabinet of the appliance is fitted with suitable racks for wire shelves, extractible drawers

and wire baskets. The doors are fitted with an automatic device and magnetic seal elements

easily replaceable. During the design and construction stages, the engineers have adopted

all the necessary measures to manufacture equipment compliant to specific safety

requirements such as the internal corners rounded off, the external exhaust of the

condensate liquid, lack of rough surface, fixed guards protecting moving or potentially

dangerous parts, etc. The maximum grids or drawers load for any Fiocchetti model is 30 kg,

and the weight should be uniformly distributed.

Our equipment has been developed for indoor use and it is not meant to be used

outdoors.

7

3 SAFETY

3.1 GENERAL SAFETY RULES

Read this manual carefully and follow the prescriptions contained herein.

The user assumes full responsibility in case of operations carried out without observing the

instructions in the manual. Primary general safety regulations:

- do not touch the equipment with wet hands and/or feet

- do not insert screwdrivers or other pointed objects into the guards or moving parts of the

appliance

- do not pull the power cord to disconnect the appliance from the electrical mains

- make sure that the appliance is not used by non-qualified personnel

- before performing any clearing or maintenance on the appliance disconnect it from the

electrical mains by switching it off and disconnecting the plug

- In case of failures or malfunctions, switch off the appliance and do not attempt to repair it

on your own. It is absolutely necessary to contact qualified personnel.

3.2 INTENDED USE

This appliance has been conceived to be used in hospitals, laboratories, pharmacies, etc. It

has been designed for the storage of products at a controlled temperature, within the

following temperature ranges:

MEDIKA / MEDIKA 2T +2°C +15°C

LABOR +2°C +15°C

(PLASMA) LABOR 2T C+: +2°C +15°C; C-: -10°C -24°C

EMOTECA +4°C

EMOTECA TWIN +4°C

(PLASMA) VISION -15°C -20°C

(PLASMA) VISION 2T +2°C +15°C / -15°C -20°C

(PLASMA) FREEZER -10°C -25°C

(PLASMA) SUPERARTIC -20°C -40°C

(PLASMA) SUPERARTIC 2T +2°C +10°C / -20°C -35°C

TER +15°C +30°C

SPARK-PROOF +2°C +15°C

All the above listed series of appliances are suitable for products storage; for this reason, we

suggest to store only products already cooled, or frozen, depending from the equipment type.

We declare that any use outside of those allowed of the appliance are considered as

“improper uses”, therefore the manufacturer declines all responsibility.

To assure a correct functioning of the appliance, the set temperature must be always

lower than the ambient temperature, exception made for TER series.

3.3 CONTRAINDICATION

The appliance must not be used:

- Exposing it to outdoors conditions

- With reductions or multi-way adapters

- In places subject to explosive atmosphere or with risk of fire

- Near to heat sources

In case the equipment is embedded in any type of furniture, a correct air flow of the

condensing unit (compressor and fan motors) must be always ensured. If this is not

guaranteed, the warranty will immediately expire.

3.4 SAFETY AND ACCIDENT PREVENTION

The appliance embodies various features designed to assure safety and to protect the health

of the user. The following list describes the protections adopted against mechanical risks:

8

-Stability: the appliance is designed and built in order to guarantee its stability even in case

shelves/drawers are fully extracted, without any risk of tipping, falling or sudden

movement.

-Surfaces, edges, corners: accessible parts of the appliance have no sharp corners, sharp

edges or rough surfaces that could cause injury.

-Moving parts: they are designed, built and configured to avoid risk. Moving parts are

protected by fixed guards to prevent accidental contact that could result in injuries

LIST OF MEASURES ADOPTED FOR THE PROTECTION AGAINST ADDITIONAL RISKS:

oElectrical power: the appliance is designed, built and fitted with the aim of preventing the

risks of electric shock in compliance with established safety regulations

oNoise: the appliance is designed and built to reduce risks at the minimum related to the

emission of the acoustic noise (lower than 70 dB).

It is strictly forbidden:

- to tamper with or remove the evaporator cover that protects the user from the risk of

cutting on the heat exchanger fins

- to remove the data plates fixed in the inside edge of the engine compartment showing

technical specifications and earth connection warning

- to remove the data plates placed on the evaporator unit cover and near the electrical

wiring inside of the engine compartment, which warns the user to disconnect the electrical

plug before working on appliance

The manufacturer declines any responsibility for safety of the appliance if the above

recommendations are not observed.

4 TRANSPORT AND HANDLING

4.1 TRANSPORT AND HANDLING

The appliance must be transported and handled exclusively in a vertical position paying

attention to the instructions printed on the packing.

This precaution is necessary to avoid contamination of the refrigerant circuit with compressor

lube oil which may cause the failure of the valves, of the cooling coils and problems of engine

starting. The manufacturer declines any responsibility for problems due to transport done in

condition others than those specified above.

The internal fittings (slides, wire shelves, drawers, baskets, etc.) are shipped inside the unit.

The appliance is fixed on a wooden pallet by means of screws, wrapped with polyethylene

and packaged in cardboard, wooden crate or wooden case.

The appliance must be handled using a fork lift truck with suitable forks (forks length at least

equal to 2/3 length of unit).

In case the appliance should be laid down flat in order to bring it into the installation place, it

is absolutely necessary to wait at least 6 hours before switching it on.

9

4.2 POSITIONING

Incorrect positioning can cause damage to the appliance and create dangerous conditions for

users. Therefore, the installer must observe the following general regulations:

- make sure to maintain a minimum of 10 cm distance from the walls

- the room must be well ventilated

- keep the equipment far from heat sources

- avoid direct sunlight exposure and AC flow

- remove packing material

- remove accessories from the inside of the unit and the wooden pallet

below the equipment

- Position the appliance with the help of a spirit level. If necessary,

adjust the levelling feet of the unit (in the models fitted

with adjustable feet) (fig.1)

- remove the protective PVC film from the external surfaces of the unit

- clean the inside of the chamber with a cloth and alcohol in order to eliminate the

protective oil

Freezers glass doors (model Vision and Vision 2T) internal part has compulsorily to

be cleaned with a cloth and water.

Do not use chemical products.

4.3 WIRING AND ELECTRICAL HOOK UP

The electric installation and connection must be performed by qualified personnel. For safety

reasons the user must pay attention to the following indications:

- check that the electric installation is suitably sized for the absorbed power of the unit

- If the electrical socket and the plug of the power cord are incompatible, change the plug

with a suitable component, ensuring that the replacement part is approved, according to

the laws in force.

- do not use reductions or multi-way adapters

It is important to connect the appliance correctly to an efficient earth system, in compliance

with the relevant legislation.

If the power cord is damaged, it must be replaced by the manufacturer, by an authorized after

sale service or by a trained technician in order to avoid any possible risk.

4.4 SETUP OPERATIONS

To prevent errors and accidents, a series of checks for possible damages caused during

transport, installation and hook-up operations must be performed before connecting the unit.

4.4.1 Preliminary checks:

-check the condition of the power cord (it should not have cuts or chaffing)

-check that the feet, door hinges and shelf supports are stable

-check the condition of internal and external components (pipelines, heat exchanger

elements, fans, electrical components, etc.); check also that all parts are firmly fixed into

position

-Check that the door gaskets and drawers have not been damaged (broken or

scratched) and that the doors close and seal properly.

-Check that the TFT display is not damaged

While in use the equipment must be placed far from cross talks of engines,

generators, infrared rays, radio transmitters, telephones which may have negative

effects for the device.

Figure 1

10

4.4.2 Indication for optimal use

-do not block the motor compartment air vents

-Arrange the material on the suitable provided shelves or drawers. Do not place the

products directly on the base of the chamber, against the walls, doors or fixed guards

of the unit

-make sure door is closed properly

-keep the defrost water drain outlet clear

-limit the frequency and duration of door openings; each time the door is opened, the

internal temperature will alter and there will be possible ice formations on the

evaporator

-perform regular maintenance (see “Cleaning of the condenser”Par. 9.3 )

-load gradually the material at ambient temperature to allow correct refrigeration

-The power supply must be as indicated in the technical data plate (+/- 10%)

-Appliances are designed and built to work at particular ambient temperatures (see the

climatic classes of reference Par. 13.1) and at a relative humidity of 60%. In ambient

working operations different from the specified, it will not be possible to achieve the

performances declared from the manufacturer.

4.4.3 Special warnings for Superartic and Plasma range

These appliances have been designed and built to store and maintain products at a

controlled temperature (the products should be stored when already frozen). The lowest

working temperature is -40°C and the rotation of the stored products cannot exceed 5% daily.

4.4.4 Internal fittings for new range

The system of stainless steel racks (standard fitted) allow the possibility of having an internal

fitting mixing shelves and drawers (mounted on telescopic slides) perfectly interchangeable

(For eventual orders of additional shelves or drawers, please refer always to the model and

serial number, see data plate paragraph 12.1).

SUPERARTIC and PLASMA SUPERARTIC series fit drawers mounted on extractible slides

(not telescopic).

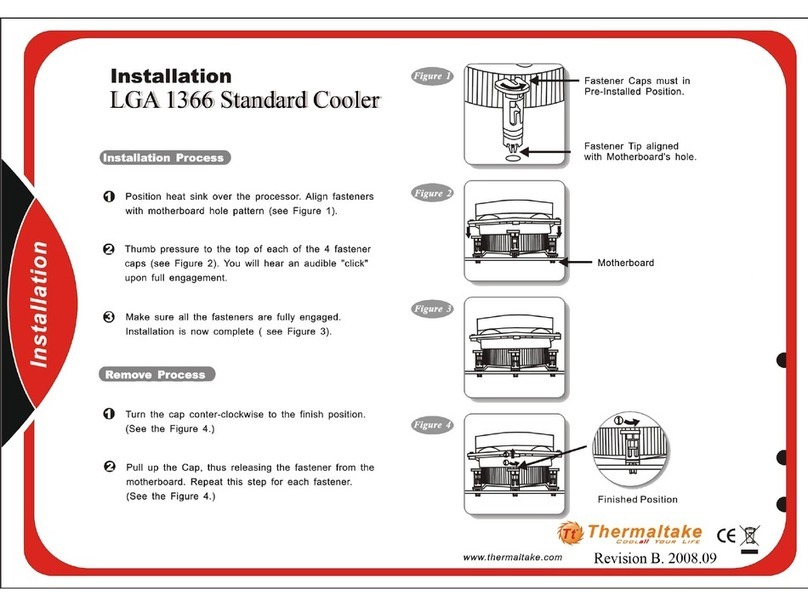

Position the shelves support in the rack at the desired position inserting them into the special

slots (fig. 4) and turning them of 90° to block them. Once positioned the 4 supports at the

same height level, it is possible to install the shelf (fig.3).

Position of drawer slides

Position of shelf bracket

Figure 2

11

In order to change the position of the drawers, extract the same, and once it is fully extracted,

unlock it from the slides through the unlocking devices (plastic lever black colour) positioned

on the side. The drawer is unlocked by pushing the right lever up and the left lever down at

the same time. (Sequence Figure 3

Figure 3

1

2

3

12

After that it is possible to remove the telescopic slides by lifting the front part of the slide up

(to extract it from the rack in the front part) and pulling the slide frontward, to extract the rear

part. Repeat the same operations, but inverting the sequence to reposition the slides and the

drawers.

Figure 4

The wall-racks are even easily removable in order to allow a better cleaning of the interior of

the appliance.

The racks mounted in the front part can be removed pushing them upward (fig.5), while the

ones mounted in the rear side can be removed by first, unscrewing safety fixing screw (using

a cross screwdriver) positioned in the top part (fig.6), and then pushing against the internal

wall the small plastic edge on the top part of the rack and simultaneously pulling the rack

itself upward (Fig 5).

Push to unblock

Figure 5

13

Graph

INFO 1 Panel

Equipment name

5 CONTROL PANEL ECT-F TOUCH

5.1 DESCRIPTION CONTROL BOARD ECT-F TOUCH

Equipment with one chamber

Equipment with two chambers

INFO Panel 1st chamber Graph 1st chamber

Graph 2nd chamber INFO Panel 2nd chamber

INFO 2 Panel

Equipment status

STATUS Panel

Date/Hour

Figure 6

Figure 7

14

Equipment with one chamber + ballasted probe

Panel INFO 1 Panel INFO 2

Product temperature Product alarm Min/Max limits

Screensaver mode: it is possible to set the screensaver page which will be automatically

activated if the screen is not in use for a certain period of time (see “Description setup system

menu” par. 6.2.13). The screensaver page will show the chamber temperature against a

black background easily readable from the distance. The screensaver page will disappear at

the touching of the screen.

5.1.1 USER HARDWARE INTERFACE

USB slot for Software update, programming and for the backup

temperature data.

SD card to register all functional data of the system, temperatures

and technical documents in digital format.

SIM Card Slot for GSM modem (optional)

Figure 8

Figure 9

Figure 10

15

5.2 FUNCTIONING ECT-F TOUCH CONTROL

Introduction

The fridge is equipped with a latest generation Electronic Controller with a TFT display of 7”

Touch screen. This screen visualizes the temperature and the functioning status of the

equipment with an accuracy of 0,1°C. This instrument guarantees maximum safety in case of

alarms and failures, signaling promptly critical conditions and recording each event in order to

help the Service engineer to speed up the analysis and the repair of faulty conditions.

Safety is at the highest level by means of alarms for High and Low temperature, power

failure, open door as well as auto test to prevent failures. Safety is also assured in case of

faulty compressor relays or faulty defrost relays in order to prevent the freezing or

overheating of products.

The instrument records every 30 Seconds the equipment temperatures with a resolution

accuracy of 0,1°C.

Data are registered in two memories: the first is a flash memory able to store 1 year

operations; the second memory is represented by Secure Digital (SD) which works as a black

box since it can store up to 5 years of data.

In the display it is possible to charge data to build graphs from both memories.

The registered information in the SD is the following:

Day of the week, date and hour

Temperature chamber A and B (Chamber –Evaporator - Condenser)

Temperature chamber A and B (Chamber A e Chamber B with DMLP TOUCH)

Product simulator temperature (only with DMLP TOUCH)

Programmed Setpoint

Status door chamber A and B (Opening –Closed)

Duration door opening chamber A and B

Relay status to remote alarms (Dry contact)

Buffer battery tension (if present)

Presence/absence of the mains

Humidity probe temperature (if present)

High and Low alarms of temperature for both chambers and alarm delays (only with

DMLP TOUCH)

Alarm and failure codes

5.2.1 SWITCHING ON

Once connected the equipment to the mains, the display will show the “STAND-BY” page

which means that power is on.

Pressing the three red squares sequentially from left to right, the equipment will turn on.

Only at the first turning on of the equipment it is automatically requested to select language,

date and hour.

Figure 11

16

5.2.2 DESCRIPTION PANEL INFO 1

Touch the temperature value to visualize all the useful information of the equipment both for

the user and for the Service.

MESSAGE

MODE IN PROGRESS

PAUSE

Compressor is OFF, waiting for next cooling cycle

COOLING

Compressor is ON to reach setpoint

DEFROST

The equipment is defrosting, i.e. warming up the evaporator

DRIPPING

Last phase of the defrost cycle to allow dripping of condensate water

RECOVERY

After a defrost cycle the compressor is ON to reach again the setpoint

HEATING

Warming up phase is ON (ONLY FOR PRESET MODELS)

Touch the green

arrows to browse

pages or touch the

“Home” symbol to go

back to homepage.

Figure 13

Figure 12

17

5.2.3 SET TEMPERATURE CHANGE

If the Control user password is enabled (Par Errore. L'origine riferimento non è

stata trovata.), user shall enter the password in order to switch off the system.

Touch in the homepage the Setpoint value in order to access to the dedicated page. Enter

the new value and press “OK”.

Together with the Setpoint, user can find also information about the compressor switching

on/off differential and of the Running setpoint (this differs from the “Current setpoint” when

the Night & Day function is active).

At every temperature change, user should always check that the set limits are

modified accordingly. If not, user should change them (see par. 5.2.4).

According to the stored products, the limits must be set some degrees higher and lower the

setpoint: the lower limit must always be 2°C or 3°C lower than the setpoint; whereas, the

upper limit must always be 2°C - 5°C more than the setpoint. For instance, for the storage of

drugs, user may set the setpoint at 8°C, lower limit at 6°C and upper limit at +11°C. For the

storage of blood at 4°C the limits must be set at +2°C and +6°C.

5.2.4 TEMPERATURE ALARM LIMITS CHANGE

If the Control user password is enabled (Par Errore. L'origine riferimento non è

stata trovata.), user shall enter the password in order to switch off the system.

Figure 14

Figure 15

18

Touch in the Homepage the Lower and Upper Limit value in order to modify limits in the

dedicated page.

Enter the new value and press “OK”. In the dedicated page the user can also modify the

delay for the signalization of the alarm and of door opening.

5.2.5 CONSUMPTION PANEL

Touch the Battery value in the homepage in order to access the dedicated page.

In the CONSUMPTION the following information is displayed:

•Snapshot equipment consumption

•Daily equipment consumption (of the last 24h)

•Current energy mains

•Minimum accepted value for the signalization of “Low mains tension”

•Battery backup voltage

•Battery backup working status

•Battery backup wear level

•Battery backup setup date

Touch the Home icon to go back to Homepage.

Figure 16

19

5.2.6 ELECTRIC DIGITAL KEY LOCK (optional)

As safety device against unauthorized door opening, the equipment can be fitted with an

electric-digital key locking, consisting in mini electronic hook placed in the upper corner of the

door (and lower in 2 doors refs.). The door is opened by means of pressure on the key icon in

the homepage.

Please look at Par. 5.2.11 and Par.5.2.12 for additional electronic locking functionalities and

for enlarging opening icon in home page.

When the equipment gets turned OFF (STAND BY status) locking opens itself

automatically. In case of power failure, it remains open if it was open. On the

contrary, it remains closed if it was closed, and you have to follow instructions given

below in order to manually unlock it.

In the event of unexpected power failure, it is possible to unlock the

electronic locking by means of the key provided.

Insert the key in the dedicated slot, placed on the frontal panel side, in

accordance with the handle position.

In order to be able to open the door, it is necessary to hold the release lever pushed.

By stopping pushing, he mechanism door will be locked again.

Figure 17

Figure 18

Figure 19

20

Double temperature (2T) models do follow the same

manual unlocking. In Figure 20, indications to find the

slot for unlocking, in accordance with the handlong

position.

For model 600 2T, manual unlocking have to be

performed from front side with the supplied key.

For model 1500 (Figure 21), manual door opening has to be

performed by accessing from top of the refrigerator to the two

lockings, as you can see in Figure 22.

Figure 22

Lockings can be opened from top of the equipment, by pulli9ng the release lever upwards.

Keeping levers individually in tractions, allows opening the related door.

Figure 20

Figure 21

Figure 23

Table of contents

Other FIOCCHETTI Freezer manuals