Fiore FI310 User manual

PB

1

™

COOK TOP

INSTALLATION

AND

OPERATING

INSTRUCTIONS

FI310/FI320/

FI640/FI850/FI950

2

3

BEFORE INSTALLING YOUR FIORE™ COOK TOP

PLEASE READ THE COMPLETE MANUAL CAREFULLY

INTENDED FOR DOMESTIC KITCHEN USE ONLY

IMPORTANT:

Prior to assembly please inspect your Fiore™ product. Please report any damage of the product to your local ven-

dor before installation. Any claims for damage visible or hidden must be made immediately in order for the carrier

to assume full responsibility and absorb any associated costs. If damage or defect is discovered DO NOT IN-

STALL your Fiore product. Any claimed damage or defect to the nish of the product after the product has been

installed will be excluded from any manufacturer warranty.

ATTENTION:

1. All electrical and installation work must be done by a licensed contractor who is familiar with all

applicable

building codes and standards in your

region.

2. If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or a similarly qualied

person to avoid a hazard. Any modications that may be required to the electrical system for the installation of the

range hood must only be made by qualied electricians.

3. Be sure to SHUT-OFF MAIN BREAKER PANEL before servicing the cook

top.

4. Use your Fiore cook top only for its intended purpose. The manufacturer disclaims all liability for any other

use

of the

appliance.

5. Pay close attention to existing electrical wiring and other non-visible rough utilities when cutting or drilling

into

wall or

ceiling.

6. This unit must be

grounded.

SAFETY INFORMATION

BEFORE YOU BEGIN

READ THESE INSTRUCTIONS COMPLETELY AND CAREFULLY.

IMPORTANT — Save these instructions for local inspector’s

use.

IMPORTANT — Observe all governing codes and

ordinances

Note to Installer – Be sure to leave these instructions with the Consumer

Note to Consumer – Keep these instructions for future reference.

IMPORTANT

—

Check the leakage according to the installation instruction.

Product failure

due

to improper installation is not covered under the

Warranty

2

3

FOR YOUR SAFETY:

If the information in this manual is not followed exactly, a re, explosion or gas leak may result. It may cause prop-

erty damage, personal injury or death.

Do not store or use gasoline or other ammable vapors and liquids in the vicinity of this appliance.

WHAT TO DO IF YOU SMELL

GAS

Do not try to light any appliance. Do not touch any electrical switch; do not use any phone in your

build ing.

Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s

instructions.

If you cannot reach your gas supplier, call the re department.

Installation and service must be performed by a qualied installer, service agency or the gas supplier.

WA R N I N G

Disconnect all electrical power at the main circuit breaker or fuse box before

install ing.

Installation of this cooktop must comply with local codes or in the absence of local codes with the National

Fuel

Gas Code ANSI Z223.1/NFPA54 – Latest Edition ANSI

Z223.1/NFPA

Be sure your cooktop is installed properly by a qualied installer or service technician.

To eliminate reaching over surface burners, cabinet storage above burner should be

avoided

Do not install the unit near an outside door or where a draft may affect its

use.

This product must be installed by a licensed plumber or gas tter.

When using ball-type gas shut-off valves, they shall be the T-handle

type.

If exible gas connector is being used, it must not exceed 3 feet.

Be sure the installation of this product in a mobile home must comply with the Manufactured Home Construc-

tion and Safety Standard, Title 24 CFR, Part 3280. If this standard does not apply, you must follow the standard

for

Manufactured Home Installations, ANSI A225.1 and Manufactured Home Installations, Sites and Commu-

nities, ANSI/NFPA 501A or with local codes. You can get a copy of the Federal Standard by Writing: Ofce of

Mobile Home Standards HUD, Building 451, 7th Street, S.W. Washington, D.C. 24010.

4

5

ELECTRICAL

REQUIREMENTS

This appliance must be supplied with the proper voltage, frequency and connected to an individual

properly

grounded branch circuit. The appliance must also be protected by a circuit breaker or fuse having amperage as

not-

ed on the rating

plate.

We recommend you to have the electrical wiring and hookup of your cooktop connected by a qualied electrician

After installation, have the electrician show you where your main cooktop disconnect is located. Check with

your

local utilities for electrical codes which apply in your area. Failure to wire your cooktop according to

governing

codes could result in a hazardous condition. If there are no codes, your cooktop must be wired and fused to

meet

the requirements of the National Electrical Code, ANSI/NFPA No. 70—Latest Edition. You can get a

copy

by

writing to: National Fire Protection Association Battery March Park Quincy, MA

02269

In Canada, your cooktop must be wired and fused to meet the requirements of the Canadian Electrical

Code.

4

5

COOK TOP INSTALLATION AND OPERATING INSTRUCTIONS

TABLE OF CONTENTS

INSTALLATION

PREPARATION

06

DIMENSIONS

AND

CLEARANCES

09

POWER

SUPPLY

LOCATIONS

10

INSTALLATION

INSTRUCTIONS

12

INSTALL

PRESSURE

REGULATOR

13

ASSEMBLE

BURNERS

AND

CHECK

IGNITION

14

LP

GAS

CONVERSION

16

SETTING

THE

MINIMUM

FLAME

20

6

7

INSTALATION PREPARATION

MODELS AVAILABLE

FI310 Series 11.8” Natural Gas/11.8”

LP

FI320 Series 11.8” Natural Gas/11.8”

LP

FI640 Series 22.8” Natural Gas/22.8”

LP

FI850 Series 22.8” Natural Gas/22.8”

LP

FI950 Series 30.3” Natural Gas/30.3”

LP

These models are factory set for either natural gas or LP gas operation. Be sure to order the

correct

model for

the installation

situation.

PARTS INCLUDED

2 Screws Regulator 2 Hold Down

Brackets

MATERIALS YOU MAY NEED

Joint Sealant Pipe Fittings Shut-Off Valve CSA-Approved Flexible Gas

Line

1/2″ Min. ID, 1/2″NPT Connection, 3-foot Maximum Length (Massachusetts

Only)

NOTE: Purchase new line, do not use previously used exible gas line.

TOOLS YOU WILL NEED FOR INSTALLATION

Pencil Phillips-Head Screwdriver Ruler or Straightedge Safety

Glasses

Saber Saw Pipe Wrench 1/8″ Drill Bit & Electric or Hand

Drill

6

7

INSTALATION PREPARATION

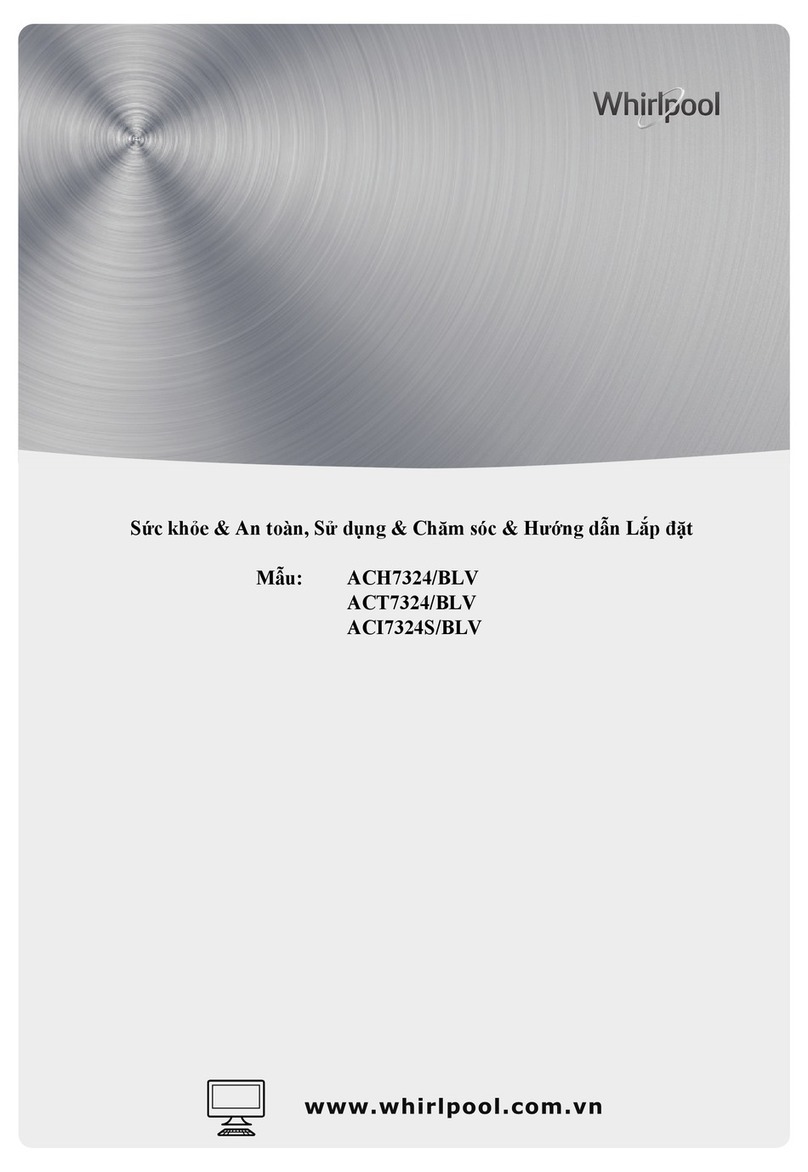

ADVANCE PLANNING

Refer to “Installation Preparation” for information on appropriate placement and necessary clearances when

plan

ning

installation.

Avoid placing cabinetry directly above cooktop when

possible.

If cabinetry is used above cooking

surface:

Use cabinets no more than 13″

deep.

Maintain 30″ minimum clearance between cooktop and unprotected cabinets directly above

cooktop.

If clearance is less than 30″, protect cabinet bottoms with ame-retardant millboard at least 1/4″ thick, or gypsum

board at least 3/16″ thick, covered with 28 gauge sheet steel or .02″ thick copper.

Clearance between cooktop and protected cabinetry must not be less than 24″.

An exhaust hood that projects at least 5″beyond front of cabinets can reduce risk of burns caused by reaching over

heated surface units.

Working areas adjacent to the cooktop should have 18″ minimum clearance between countertop and cabinet bot-

tom. A 36″or wider exhaust hood with 350 CFM or greater airow rating is recommended for use over this Mono-

gram cooktop.

Installation must complied with local codes. In the absence of local codes, the gas cooktop must complied with the

National Fuel Gas Code, ANSI Z223.1, latest edition.

Gas supply should be located near the opening for this cooktop (see Preparing the Opening and Gas Connection

sections of this manual). The supply should provide natural gas at 7″ of water column pressure (11″ of water col-

umn for LP gas) and a maximum of 14″ of water column for natural or LP gas.

The electric spark ignition feature for this model requires a 120V electrical power supply be located in the immedi-

ate vicinity of this cooktop (see Electrical Connections section of this manual).

18” min

30” min

13” max

8

9

PRE-INSTALATION CHECKLIST

1. When preparing cooktop opening, make sure the inside of the cabinet and the cooktop do not interfere with

each

other. (See section on preparing the

opening.)

2. Slide the cooktop out of the end of the box. Remove packaging materials, grate boxes, regulator and

literature

package from the cooktop before beginning

installation.

Use the shipping carton as a pad to protect customer countertops or ooring

3. Remove Installation Instructions from literature package and read them carefully before you begin. Be sure

to

place all literature, Owner’s Manual, Installations, etc. in a safe place for future

reference.

4. Make sure you have all the tools and materials you need before starting the installation of the

cooktop.

5. Your home must provide adequate electrical service tools to ensure your safety and to maintain your cooktop

as

well. (Refer to section on electrical

requirements.)

6. When installing cooktop in your home, make sure all local codes and ordinances are followed exactly as

stated.

7. Make sure the wall coverings, countertop and cabinets around the cooktop can withstand heat (up to

200°F)

generated by the

cooktop.

8

9

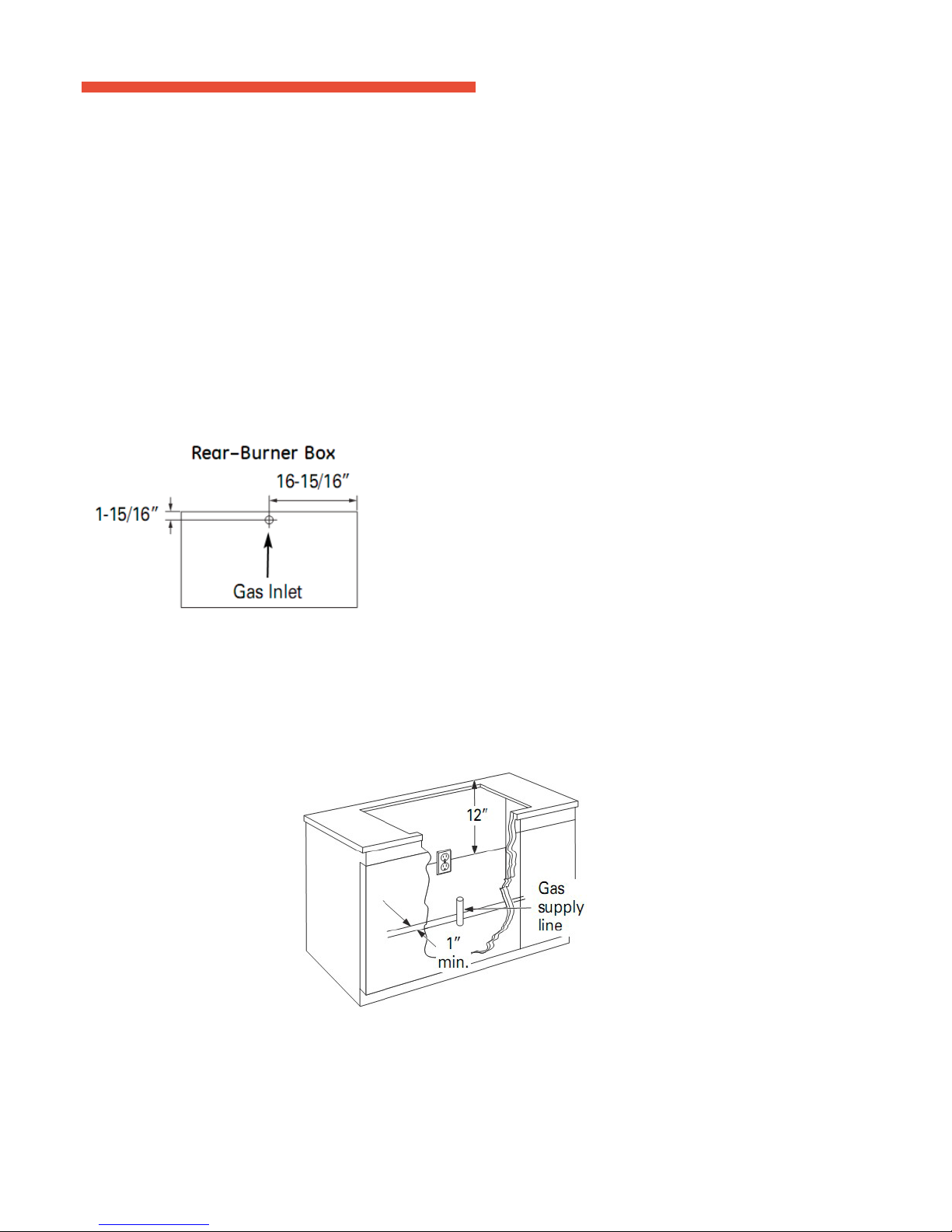

GAS SUPPLY AND PRESSURE REGULATOR

Gas supply: These cooktops are shipped from the factory set for either natural gas or LP gas. Check to be sure

you

have the correct cooktop for the type of gas being

used.

The pressure regulator must be connected in series with the manifold of the cooktop and must remain in

series

with the supply line regardless type of gas being

used.

The natural gas model is designed to operate at 5″ water column pressure. A regulator is required at the

natural

gas source to provide a minimum of 6″ water column to the cooktop

regulator

The liquid propane model is designed to operate at 10″ water column pressure. A regulator is

required

at the LP

Gas source to provide a minimum of 11″water column to the cooktop

regulator.

For ease of installation, if local codes permit the gas supply line into the cooktop should be 1/2″or 3/4″ ID exible

metal appliance connector with three to ve feet long.

NOTE:

Purchase new exible line. DO NOT USE OLD, PREVIOUSLY USED FLEXIBLE LINE

The gas inlet is located on the bottom of the burner box at the rear and

center.

Make gas connection through rear wall, or on cabinet oor at rear, as illustrated.

Install the house gas supply at least 1. from the back

wall.

Locate the electrical outlet 12. below the

countertop.

10

11

INSTALL PRESSURE REGULATOR

WARNING: Never reuse old exible connectors. The use of old exible connectors can cause gas leakage and per-

sonal injury. Always use new exible connectors when installing a gas appliance. To reduce the possibility of gas leakage,

apply Teon tape or a thread compound approved for use with LP or Natural gases to all threaded connections.

Screw the regulator onto the burner box bottom pipe connection. Make sure the top of the regulator is

facing

toward the cabinet front and the arrow on the back of the regulator points to the

cooktop.

OPTION: You can install a 90º elbow (not supplied) onto the gas inlet and route the gas connections to avoid

inter

ference when installed over an oven, with a downdraft vent, a warming drawer or other cabinetry

features.

Com-

plete the connection between the regulator and the shut-off

valve.

Before testing for leaks, make sure all burner knobs are in the OFF

position.

After connecting the cooktop to gas, check system for leakage with a manometer. If a manometer is not

available,

turn the gas supply on to the cooktop and use a liquid leak detector at all joints and connections to check for

leak

ing. Tighten all connections if necessary to prevent gas leakage in the cooktop or supply

line.

WARNING: Do not using ame to check for leaking.

Disconnect the cooktop and its individual shut-off valve from the gas supply piping system during any

pressure

testing of that system at test pressures greater than 1/2 psig (3.5

kPa).

Isolate the cooktop from the gas supply piping system by closing its individual shut-off valve during any

pressure

testing of the gas supply system at test pressures equal to or less than 1/2 psig (3.5

kPa).

CONNECT

ELECTRICAL

Check to make sure the receptacle is properly

grounded.

PLUG IN THE POWER

COR D.

10

11

Install a manual shut-off valve in the gas line in an easily accessible location outside the cooktop. Be sure you

know

how and where to shut off the gas supply to the cooktop. Install the electrical outlet 12″ below the

countertop.

ELECTRICAL CONNECTION:

This cooktop features pilotless electric ignition for energy savings and reliability. It operates on a 120 volt, 60

Hz

power supply. A separate circuit, protected by a 15 amp time delay fuse or circuit breaker, is

required.

A properly-grounded 3-prong receptacle should be located within reach of the cooktop’s four-foot power

cord.

IMPORTANT: (Please read carefully). FOR PERSON SAFETY, THIS APPLIANCE MUST BE

PROPER LY

GROUNDED.

The power cord of this appliance is equipped with a three-prong (grounding) plug which mates with a

standard

three-prong grounding wall receptacle to minimize the possibility of electric shock hazard from this

appliance.

The customer should have the wall receptacle and circuit checked by a qualified electrician to make sure

the receptacle is properly grounded and has correct polarity.

Where a standard two-prong wall receptacle is encountered, it is the personal responsibility and obligation of

the

customer to have it replaced with a properly grounded three-prong wall

receptacle.

Do Not, Under Any Circumstances, Cut Or Remove The Third (Ground) Prong From The Power

Cord.

Do not use an extension

cord.

12

13

DIMENSIONS AND CLEARANCES

Overall cooktop dimensions:

Use a 36″ or wider base cabinet.

Cut the opening in the countertop. To ensure accuracy, it is best to make a template for the opening. Make sure the

sides of the opening are parallel also rear and front cuts are exactly perpendicular to the sides.

Observe all minimum

clearances.

FI310

Series

FI640

Series

FI850/950

Series

Clearances Clearances Clearances

DIMENSIONS AND CLEARANCES

Observe all minimum clearances.

FI310 Series

Clearances

FI640 Series

Clearances

FI850/950 Series

Clearances

22"

5.9"

2.95"

19.29"

60cm cutting out

75

150

490

560

28.74"

5.9"

19.29"

2.95"

80

and

90cm cutting out

75

150 730

490

5.9" 11"

2.95"

19.29"

30cm cutting out

75

150

490

280

DIMENSIONS AND CLEARANCES

Observe all minimum clearances.

FI310 Series

Clearances

FI640 Series

Clearances

FI850/950 Series

Clearances

22"

5.9"

2.95"

19.29"

60cm cutting out

75

150

490

560

28.74"

5.9"

19.29"

2.95"

80

and

90cm cutting out

75

150 730

490

5.9" 11"

2.95"

19.29"

30cm cutting out

75

150

490

280

12

13

DIMENSIONS AND CLEARANCES

Observe all minimum clearances.

FI310 Series

Clearances

FI640 Series

Clearances

FI850/950 Series

Clearances

22"

5.9"

2.95"

19.29"

60cm cutting out

75

150

490

560

28.74"

5.9"

19.29"

2.95"

80

and

90cm cutting out

75

150 730

490

5.9" 11"

2.95"

19.29"

30cm cutting out

75

150

490

280

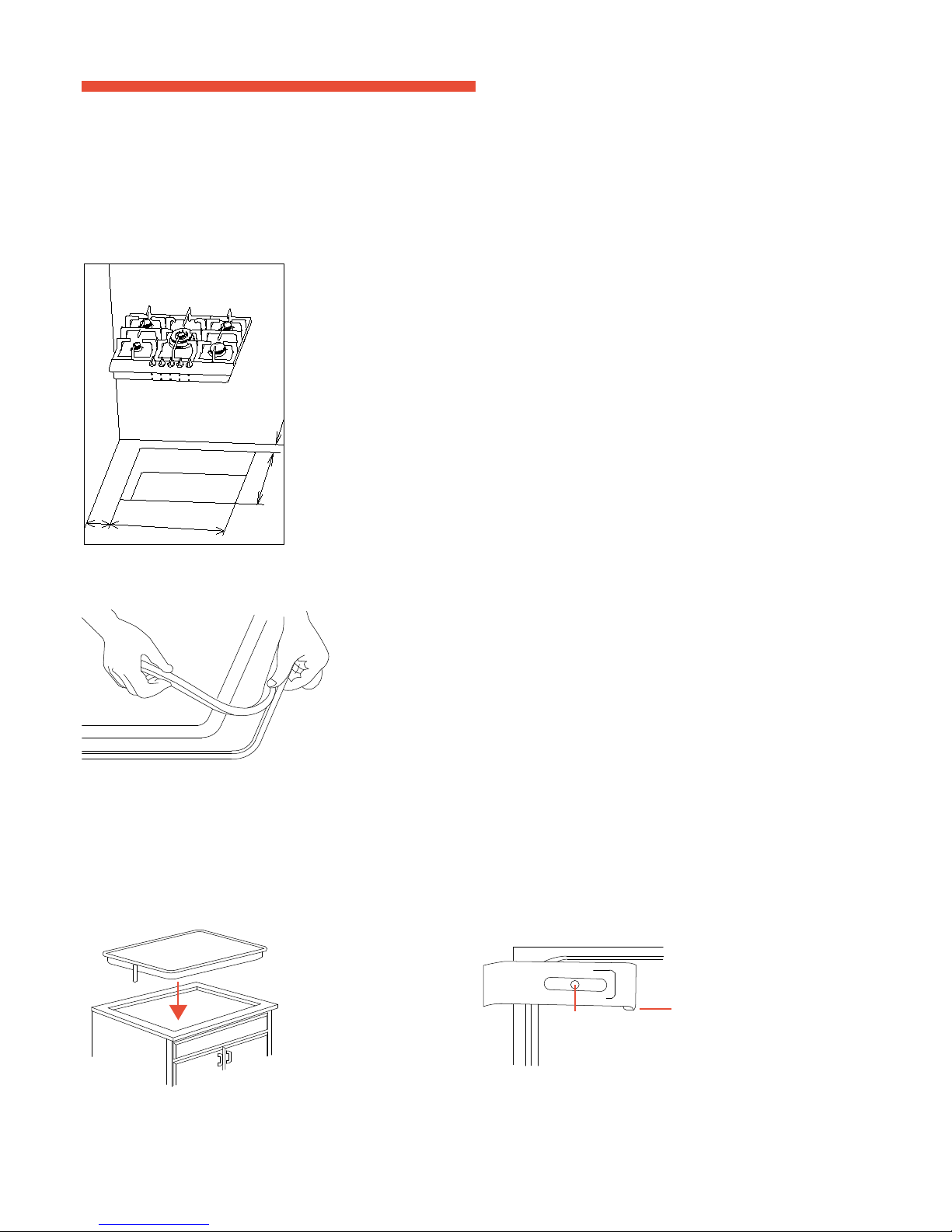

INSTALLATION INSTRUCTIONS

Remove the screws on the sides of the cooktop burner box. Use those screws to attach the side mounting

brackets.

Insert the cooktop centered into the cutout opening. Make sure the front edge of the countertop is parallel to

the

cooktop. Check clearances at the front, back and

sides.

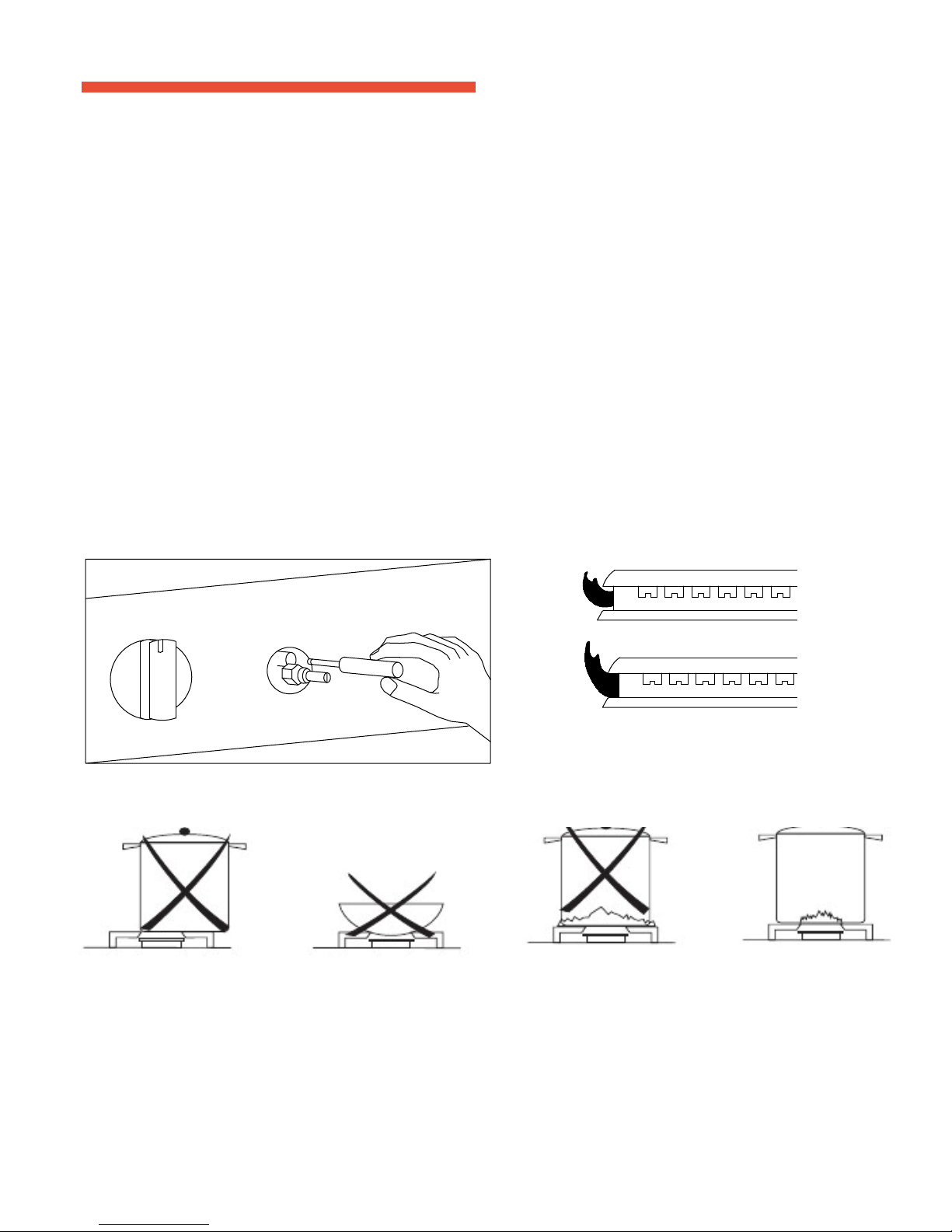

FIGURE A

Secure the hold-down bracket to the cabinet sides with

screws.

Cut the opening in the countertop. To ensure accuracy it is

best

to

make a template (see Figure A) for the

opening.

Make sure the sides are parallel also rear and front cuts are

exactly

perpendicular to the sides. Observe all minimum

clearances

Please refer to your exact model number for the

correct

cut-out

dimensions

FIGURE B

Before inserting the cooktop into the opening in

the

coun-

tertop, remove the grates and burner caps, turn

the

cook-

top upside down and place the special foam

gasket

around

the bottom edge of the cooktop (see Figure B). It

is

im-

portant to x this gasket evenly, without gaps or

overlap-

ping, to prevent liquid seeping underneath the

cooktop.

After the foam gasket has been afxed, place

the

cooktop into the countertop (see Figure

C).

FIGURE C

Secure cooktop from underneath with the

supplied

clips

and screws (see Figure

D).

FIGURE D

INSTALLATION INSTRUCTI

FIGURE B

FIGURE A

FIGURE C FIGURE D

ONS

1. INSTALL THE COOKTOP

A Remove the screws on the sides of the cooktop burner box. Use those screws to attach the side mounting brackets.

B. Insert the cooktop centered into the cutout opening. Make sure the front edge of the countertop is parallel to the

cooktop. Check clearances at the front, back and sides.

Secure the hold-down bracket to the cabinet sides with screws.

Cut the opening in the countertop. To ensure accuracy it is best

to make a template (see Figure A) for the opening.

Make sure the sides are parallel also rear and front cuts are exactly

perpendicular to the sides. Observe all minimum clearances

Before inserting the cooktop into the opening in the

countertop, remove the grates and burner caps, turn the

cooktop upside down and place the special foam gasket

around the bottom edge of the cooktop (see Figure B). It is

important to fix this gasket evenly, without gaps or overlap-

ping, to prevent liquid seeping underneath the cooktop.

After the foam gasket has been affixed, place the

cooktop into the countertop (see Figure C).

Secure cooktop from underneath with the supplied

clips and screws (see Figure D).

28.74"

5.9"

19.29"

2.95"

80

and

90cm cutting out

75

150 730

490

Please refer to your exact model number for the correct

cut-out dimensions

Clip

Screw Slot

14

15

ASSEMBLE BURNERS AND CHECK IGNITION

The electrode of the electronic ignition system is positioned above the surface of the burner base. Do not remove

a

burner cap or touch the electrode of a burner while another is turned on. Damage or electrical shock may

occur.

The electrode of the electronic ignition system is positioned above the surface of the burner base. Do not remove

a

burner cap or touch the electrode of a burner while another is turned on. Damage or electrical shock may

occur.

Place burner heads over the burner base. Make sure the hole in the burner head is properly aligned with the

elec-

trode in the burner

base.

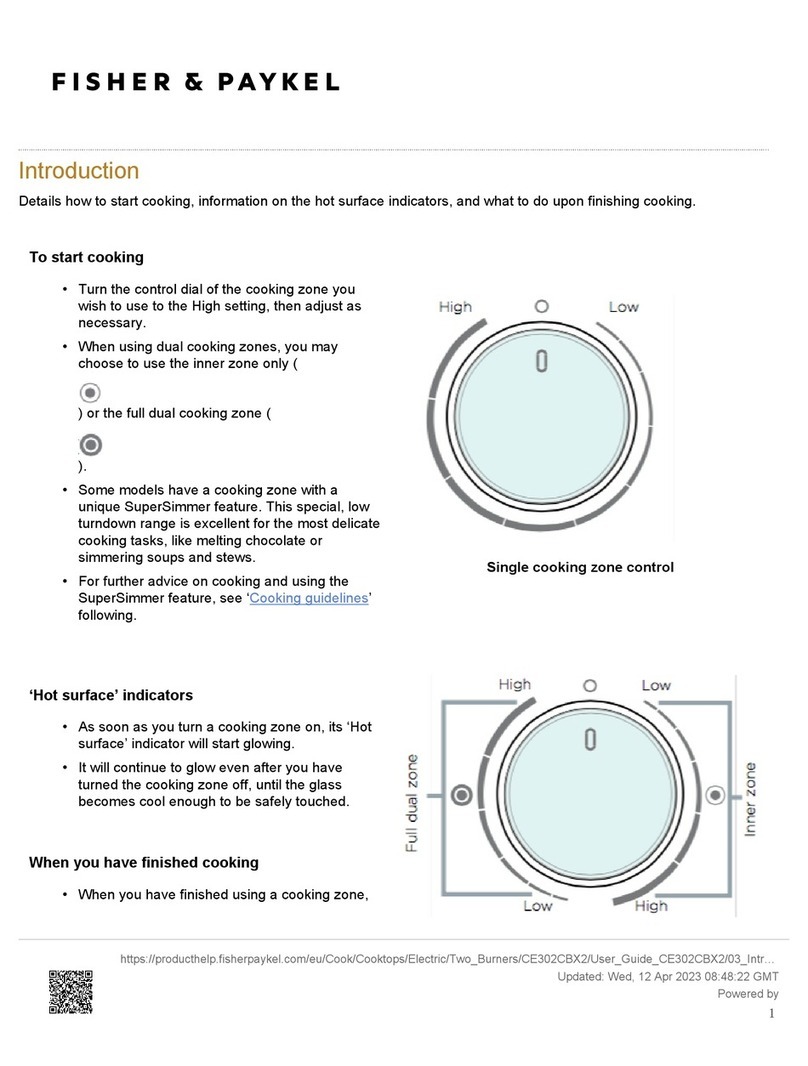

Place the burner caps on the burner heads. Make sure that the burner caps are properly seated on the burner

heads.

Burner cap properly seated Burner cap not properly

seated

Check

igniters.

Operation of the electric igniters should be tested after the cooktop and supply line have been carefully checked

for

leaks and the cooktop has been connected to the electrical

power.

Push and turn a burner valve to the LITE position. All spark igniters will make a series of sparks (ticking

sounds),

but only the burner turned to LITE will

light.

The burner should light when gas is available to the

burner.

Once the burner lights, it should be turned to another

position.

Test each valve separately until all burners have been

checked.

IMPORTANT: If the igniter electrodes continue to spark after all of the burners are lit, check that each burner

com-

ponent is assembled and properly

seated.

14

15

Burner

ignition.

Cooktop Spark Ignition—When you turn the cooktop knob to LITE, the spark igniter makes a series of

electric

sparks (ticking sounds) which light the burner. During a power failure, the burners will not light automatically. In

an

emergency, a cooktop burner may be lit with a match by following the steps

below.

WARNING: Lighting gas burners with a match is dangerous. You should match light the cooktop burners only

in

an

emergency.

Light a match and hold the ame near the burner you want to light. Wooden matches work

best.

Push in and turn the control knob slowly. Be sure you are turning the correct knob for the burner you are

lighting.

NOTE: If the burner does not light within ve seconds, turn the knob off and wait one minute before trying

again.

Turn on each burner. On LP models, ames should be blue in color but may have yellow tips. Natural gas

models

should have soft, blue ames. The burner ames should not utter or blow away from the burner. The ame

should

be no less than 1/4″ on the lowest setting and no greater than 1-1/2″ on highest

sett ing.

Burners should be checked

frequently.

WARNING: If you attempt to measure the ame, please use caution. Burns could

result.

OPER ATION

CHECKLIST

1. Make sure all controls are left in the OFF

position.

2. The serial plate for your cooktop is located on the bottom of the burner box. In addition to the model and serial

numbers,

it

tells you the ratings of the burners and the type of fuel and pressure the cooktop was adjusted for when it left the

factory.

3. When ordering parts, always include the serial number, model number and a code letter to ensure proper replacement

parts.

4. Check again to be sure all installation procedures have been

completed.

16

17

LP GAS CONVERSION

If sold outside the U.S. and

Canada:

WARNING: If you wish to use this product with Liqueed Petroleum (LP) gas containing greater than 10%

bu-

tane,

you must purchase the butane conversion

kit.

SAFTY INFORMATION

The pressure regulator and burner orices are set for natural gas

operation.

To convert this cooktop from natural gas operation to LP operation, the regulator and burner orices must be

convert-

ed.

LP burner orices are attached to the

regulator.

This appliance can be used with Natural Gas or LP/Propane Gas. It is shipped from the factory for use with Natural Gas. A

kit

for converting to LP gas is supplied with your appliance. The kit is marked “FOR LP/PROPANE GAS

CONVERSION”.

When the range is converted for Liquid Petroleum (LP) Gas, the LP gas supply is required to provide a minimum

of

10” to a maximum of 14” water column to the range

regulator.

CAUTION — The cooktop, as shipped from the factory, is set for use with its intended gas. If you wish to use

your cooktop with the alternate gas, you must rst replace the orices and convert the pressure

regulator.

WARNING — This conversion must be performed by a qualied installer or gas supplier in accordance

with

the manufacturer’s instructions and all codes and requirements of the authority having jurisdiction. Failure to

follow

instructions could result in serious injury or property damage. The qualied agency performing this work

assumes

responsibility for the

conversion.

CAUTION — The following adjustments must be made before turning on the burner. Failure to do so

could

result

in serious injury. Be sure pressure regulator has been converted as described in Step

1.

16

17

TOOLS YOU WILL NEED

1. ADJUST THE REGULATOR

A. Disconnect all electrical power at the main circuit breaker or fuse

box.

B. Shut off the gas supply to the appliance by closing the manual shut-off

valve.

C. Adjust the pressure regulator by doing the

following:

FIGURE A FIGURE

B

For Natural Gas usage the retainer pin will look like this.

(See Figure B)

FIGURE D

Unscrew the cap with a Crescent wrench.

(See Figure A)

Remove the retainer pin.

(See Figure C)

Proceed

to

reverse the retainer pin and place

it

back into the

regu-

lator cap. This

is

how the regulator pin looks for LP gas

usage.

(See Figure

D)

FIGURE E

5) Screw the regulator cap back into the regulator and

re-at-

tach the regulator to the nipple and are

union.

(See Figure

E)

FIGURE C

18

19

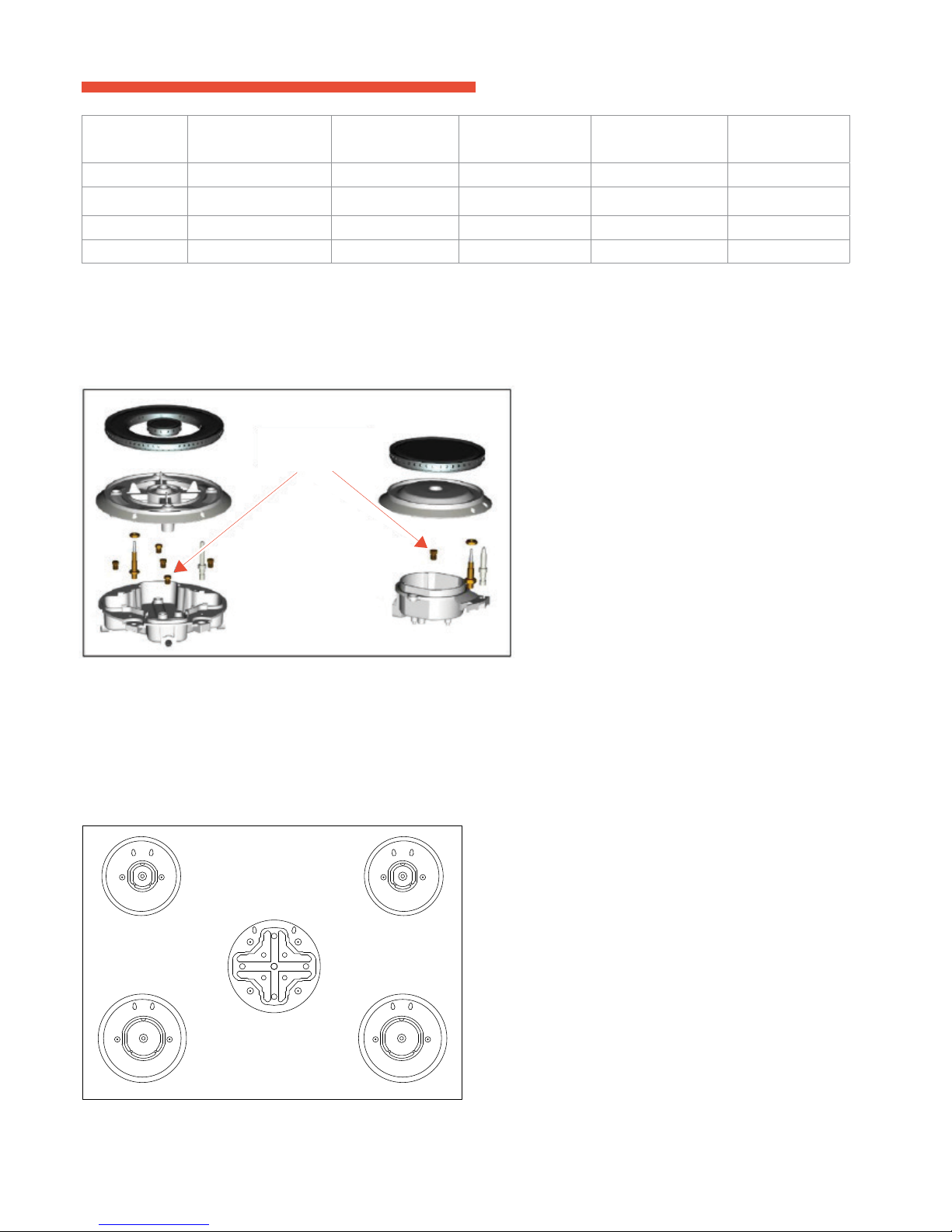

2. CHANGE BURNER NOzzLES

INSTALLATION TIP: First remove all nozzles and then start replacing them. This will help to prevent the

pos-

si-

bility that some may not be

replaced.

1. Remove the burner grates, burner caps and burner

heads.

2. Using a 7mm nut driver, remove the top burner nozzle. There are two nozzle per burner. The main orice is

locat-

ed below center of the burner, while the simmer nozzle is located higher beside the center of the

burner

Triple ring burner Rapid burner Semi-rapid burner Auxiliary

burner

IMPORTANT:

Orices must be located exactly as shown. Carefully read and observe each orice label for correct

location.

3. Install the proper nozzle in the exact locations as noted in the illustrations

above.

4. Return the natural gas nozzle to the bracket and reattach the bracket and the instruction sheet to the pressure

regu-

lator using the screw removed

previously.

5. Replace the burner bases, heads, caps and top

grates.

BURNER POSITION NOZZLE

DIAMETER

MINIMUM

PRESSURE

MAXIMUM

PRESSURE

RATE

( BT U/H )

Auxiliary Front Right 1 x 0.70 10” 14” 4,800

Semi-Rapid Rear Left & Right 1 x 0.80 10” 14” 6,500

Rapid Front Left 1 x 0.89 10” 14” 8,500

Triple Ring Center 5 x 0.56 10” 14” 15,500

ATTENTION: BE SURE TO REVIEW AND OBSERVE EACH NOZZLE FOR CORRECT LOCATION

AND POSITION - PLEASE REFER TO FIGURE F and G BELOW:

FIGURE F

TRIPLE RING BURNER AUXILARY BURNER

5 NOZZLES SEMI-RAPID BURNER

RAPID BURNER

1 NOZZLE EACH

FIGURE G

SCALE: 3" = 1'-0"

BURNER

Install the proper nozzles in the exact locations as noted in the illustrations above and the table below.

Replace the burner bases, heads, caps and top grates. Conrm burner caps are properly resting on the burner head.

LIQUID PRETROLEUM (LP) GAS NOZZLES

NOZZLES

56 5656

80

89 70

80

56

56

BURNER POSITION NOZZLE

DIAMETER

MINIMUM

PRESSURE

MAXIMUM

PRESSURE

RATE

( BT U/H )

Auxiliary Front Right 1 x 0.70 10” 14” 4,800

Semi-Rapid Rear Left & Right 1 x 0.80 10” 14” 6,500

Rapid Front Left 1 x 0.89 10” 14” 8,500

Triple Ring Center 5 x 0.56 10” 14” 15,500

ATTENTION: BE SURE TO REVIEW AND OBSERVE EACH NOZZLE FOR CORRECT LOCATION

AND POSITION - PLEASE REFER TO FIGURE F and G BELOW:

FIGURE F

TRIPLE RING BURNER AUXILARY BURNER

5 NOZZLES SEMI-RAPID BURNER

RAPID BURNER

1 NOZZLE EACH

FIGURE G

SCALE: 3" = 1'-0"

BURNER

Install the proper nozzles in the exact locations as noted in the illustrations above and the table below.

Replace the burner bases, heads, caps and top grates. Conrm burner caps are properly resting on the burner head.

LIQUID PRETROLEUM (LP) GAS NOZZLES

NOZZLES

56 5656

80

89 70

80

56

56

18 19

2. CHANGE bURNER NOZZLES

INSTA LLATION TIP: First remove all nozzles and then start replacing them. This will help to prevent the possi-

bility that some may not be replaced.

A. Remove the burner grates, burner caps and burner heads.

B. Using a 7mm nut driver, remove the top burner nozzle. There are two nozzle per burner. The main orice is locat-

ed below center of the burner, while the simmer nozzle is located higher beside the center of the burner

Triple ring burner Rapid burner Semi-rapid burner Auxiliary burner

IMPORTANT:

Orices must be located exactly as shown. Carefully read and observe each orice label for correct location.

C. Install the proper nozzle in the exact locations as noted in the illustrations above.

D. Return the natural gas nozzle to the bracket and reattach the bracket and the instruction sheet to the pressure regu-

lator using the screw removed previously.

E. Replace the burner bases, heads, caps and top grates.

18

19

LIqUID PRETROLEUM (LP) GAS NOzzLES

BURNER POSITION NOZZLE

DIAMETER

MINIMUM

PRESSURE

MAXIMUM

PRESSURE

R ATE

( BT U/H )

Auxiliary

Front

Right

1 x

0.70 10” 14” 4,800

Semi-Rapid

Rear Left &

Right

1 x

0.80 10” 14” 6,500

Rapid

Front

Left

1 x

0.89 10” 14” 8,500

Triple

Ring Center

5 x

0.56 10” 14” 15,500

ATTENTION: BE SURE TO REVIEW AND OBSERVE EACH NOZZLE FOR CORRECT

LOCATION

AND POSITION - PLEASE REFER TO FIGURE F and G

BE L OW:

FIGURE F

TRIPLE RING

BURNER

AUXILARY

BURNER

5

NOZZLES

SEMI-RAPID

BURNER

RAPID

BURNER

1 NOZZLE

EACH

FIGURE G

BURNER POSITION NOZZLE

DIAMETER

MINIMUM

PRESSURE

MAXIMUM

PRESSURE

RATE

( BT U/H )

Auxiliary Front Right 1 x 0.70 10” 14” 4,800

Semi-Rapid Rear Left & Right 1 x 0.80 10” 14” 6,500

Rapid Front Left 1 x 0.89 10” 14” 8,500

Triple Ring Center 5 x 0.56 10” 14” 15,500

ATTENTION: BE SURE TO REVIEW AND OBSERVE EACH NOZZLE FOR CORRECT LOCATION

AND POSITION - PLEASE REFER TO FIGURE F and G BELOW:

FIGURE F

TRIPLE RING BURNER AUXILARY BURNER

5 NOZZLES SEMI-RAPID BURNER

RAPID BURNER

1 NOZZLE EACH

FIGURE G

SCALE: 3" = 1'-0"

BURNER

Install the proper nozzles in the exact locations as noted in the illustrations above and the table below.

Replace the burner bases, heads, caps and top grates. Conrm burner caps are properly resting on the burner head.

LIQUID PRETROLEUM (LP) GAS NOZZLES

NOZZLES

56 5656

80

89 70

80

56

56

BURNER POSITION NOZZLE

DIAMETER

MINIMUM

PRESSURE

MAXIMUM

PRESSURE

RATE

( BT U/H )

Auxiliary Front Right 1 x 0.70 10” 14” 4,800

Semi-Rapid Rear Left & Right 1 x 0.80 10” 14” 6,500

Rapid Front Left 1 x 0.89 10” 14” 8,500

Triple Ring Center 5 x 0.56 10” 14” 15,500

ATTENTION: BE SURE TO REVIEW AND OBSERVE EACH NOZZLE FOR CORRECT LOCATION

AND POSITION - PLEASE REFER TO FIGURE F and G BELOW:

FIGURE F

TRIPLE RING BURNER AUXILARY BURNER

5 NOZZLES SEMI-RAPID BURNER

RAPID BURNER

1 NOZZLE EACH

FIGURE G

SCALE: 3" = 1'-0"

BURNER

Install the proper nozzles in the exact locations as noted in the illustrations above and the table below.

Replace the burner bases, heads, caps and top grates. Conrm burner caps are properly resting on the burner head.

LIQUID PRETROLEUM (LP) GAS NOZZLES

NOZZLES

56 5656

80

89 70

80

56

56

Install the proper nozzles in the exact locations as noted in the illustrations above and the table

below.

Replace the burner bases, heads, caps and top grates. Conrm burner caps are properly resting on the burner

head.

20

21

SETTING THE MINIMUM FLAME

The ame on the small output is regulated by the factory. When the injectors have been replaced or there are

special

mains pressure conditions, it may be necessary to regulate the minimum ame again. The operations necessary to

set

the minimum ame are as

following:

1. Light the

burner;

2. Turn the knob to the minimum

position;

3. Take out the knob (and gasket if there is

one);

Using a thin blade screwdriver to turn by-pass screw located in the brass shaft as shown right.Turn the by

pass

screw

fully clockwise then turn it anti-clockwise 1/4 turn for the Triple ring and 1/8turn for all other burndrs.

The

result should be a small,stable ame which is uniform around the entire burner ring.If not,turn the by-pass

screw

anti-clockwise until satised with the

ame

Put the knob back on and turn it quickly from the maximum position to the minimum position, checking that

the

ame does not go out

;

For burners with safety valve make sure that the regulation obtained is sufcient to maintain heating of the

ther-

mocouple. If it is not, increase the

minimum.

SETTING THE MINIMUM FLAME

The ame on the small output is regulated by the factory. When the injectors have been replaced or there are special

mains pressure conditions, it may be necessary to regulate the minimum ame again. The operations necessary to set

the minimum ame are as following:

Light the burner;

Turn the knob to the minimum position;

Take out the knob (and gasket if there is one);

Using a thin blade screwdriver to turn by-pass screw located in the brass shaft as shown right.Turn the by pass

screw fully clockwise then turn it anti-clockwise 1/4 turn for the Triple ring and 1/8turn for all other burndrs. The

result should be a small,stable ame which is uniform around the entire burner ring.If not,turn the by-pass screw

anti-clockwise until satised with the ame

Put the knob back on and turn it quickly from the maximum position to the minimum position, checking that the

ame does not go out ;

For burners with safety valve make sure that the regulation obtained is sufcient to maintain heating of the ther-

mocouple. If it is not, increase the minimum.

This manual suits for next models

4

Table of contents

Popular Cooktop manuals by other brands

Fisher & Paykel

Fisher & Paykel CE302CBX2 manual

Whirlpool

Whirlpool GJC3634RB00 parts list

Whirlpool

Whirlpool ACH7324/BLV Use, care and installation guide

Frigidaire

Frigidaire Professional FPDF4085KF Important safety instructions

Bonnet

Bonnet OPTIMUM 700 Technical instructions

Jenn-Air

Jenn-Air JGCP430 installation instructions

Bompani

Bompani BO374AA/E User instructions

Kleenmaid

Kleenmaid cooking GCTK9011 Instructions for use and warranty details

Waldorf

Waldorf RN8603E-B Technical data sheet

Whirlpool

Whirlpool SMP658CNEIXL quick guide

Electrolux

Electrolux E36IC80ISS - 36" Induction Cooktop Wiring diagram

Wolf

Wolf CI243C/B Use and care guide