FIPA GS01.004 User manual

Operang instrucons

Sensor-relay-switchboxes

GS01.004

GS01.006

GS01.008

GS01.012

EC Declaraon of Conformity

In accordance with the EC Machinery Direcve 2006/42/EC of May 17, 2006, Annex II B

We

FIPA GmbH

Freisinger Str. 30

85737 Ismaning

hereby conrm that the products:

GS01.004

GS01.006

GS01.008

GS01.012

do not contain any toxic substances that are specied in the RoHS Direcve 2011/65/EU.

Conformity with RoHS Direcve 2011/65/EU is conrmed!

Ismaning, January 2018

Place and date

Rainer Mehrer,

CEO

Table of Contents

1. INTRODUCTION 4

2. SAFETY 5

3. TRANSPORT INSTRUCTIONS 5

4. STORAGE 6

5. INSTALLATION 6-11

6. TECHNICAL DATA 12

7. MAINTENANCE INSTRUCTIONS 13

8. OTHER DOCUMENTS 14

SYMBOLS

Aenon! Please observe without fail!

Failure to comply can cause damage to the component, damage to the connected

system/machine or personal injury.

Sensor-relay-switchboxes

4

1. INTRODUCTION

The GS01.004, GS01.006, GS01.008 and GS01.012 sensor switchboxes are used for AND-operaon of

sensor signals to save on digital inputs for robot control systems, for example. They dier only in the

number of sensor inputs; the basic structure is idencal for all sensor switchboxes.

The connected sensors may be of PNP or NPN type, or they may be potenal-free; reversed sensor

logic can also be corrected. In addion, various sensor types can

be mixed in one AND-operaon group. The connected output signals can also be of PNP or NPN type.

The sensor switchbox is supplied pre-assembled and safely packaged.

The operang instrucons include a descripon of the safety regulaons, installaon and mainte-

nance, together with the technical data. If you have further quesons about the sensor switchbox,

please contact our Technical Sales department (+49 89 962489-0).

FIPA consistently strives to develop and improve the design and construcon of its vacuum compo-

nents. We therefore reserve the right to make changes to the design and technical features without

noce.

All of the informaon in these operang instrucons corresponds to the features at the me of pub-

licaon. Prinng errors are excepted.

Rainer Mehrer,

Managing Director

The design and construcon of the sensor switchbox may not be altered under any

circumstances without the consent of FIPA GmbH. Only original

FIPA accessories and spare parts may be used.

5

Sensor-relay-switchboxes

2. SAFETY

Read these operang instrucons carefully before inial commissioning and observe the following

safety regulaons. The sensor switchbox may be operated and maintained only by personnel who

have read these operang instrucons and fully understood their content. Append these operang

instrucons to your general operang instrucons for the system/machine as a whole.

A visual inspecon must be carried out before commissioning. The sensor switchbox must not show

any obvious signs of damage. It must be free from moisture, dust and dirt.

2.1. SOURCES OF DANGER

> The device must not be operated or maintained by personnel who are under the inuence of

alcohol, medicaon that impairs percepon such as sleeping tablets or strong painkillers, or

other drugs. Other condions such as circulaon problems and dizziness are also criteria for

prohibing personnel from operang this system.

> The device must not be operated or maintained by personnel who have not been trained or

have not read and understood this introducon.

> The operator is responsible for ensuring that no personal injuries can be caused when working

with the device.

> The sensor switchbox must never be tampered with.

3. TRANSPORT INSTRUCTIONS

During transport it must be ensured that the sensor switchbox is protected against temperature and

moisture.

3.1. PACKAGING

The sensor switchbox is packed in a cardboard box.

3.2. UNPACKING

Open the cardboard box carefully (do not use sharp objects!). Take the switchbox out of the card-

board box and ensure than none of the small parts that are included in the box is lost.

4. STORAGE

Sensor-relay-switchboxes

6

Storage condions for the sensor switchbox:

> Room temperature of 0 - 40°C

> Humidity of 40 - 60%

> Undamaged packaging

5. DESCRIPTION OF ASSEMBLY

The sensor switchbox must be correctly wired and assembled under de-energized condions. It must

not be assembled underwater or at temperatures above 60°C.

The sensor switchbox is used for AND-connecon of sensor signals, to save on inputs for robot con-

trol systems, for example. The basic structure is idencal for all sensor switchboxes; they dier only

in the number of sensor inputs.

Unlike a series circuit, a separate signal is fed through several miniature relays, each of which is ac-

vated by a sensor. Each sensor must therefore feed the (small) relay coil, but not all of the following

sensors. There are no voltage drops at PN transion points.

> Addional tool: Screwdriver

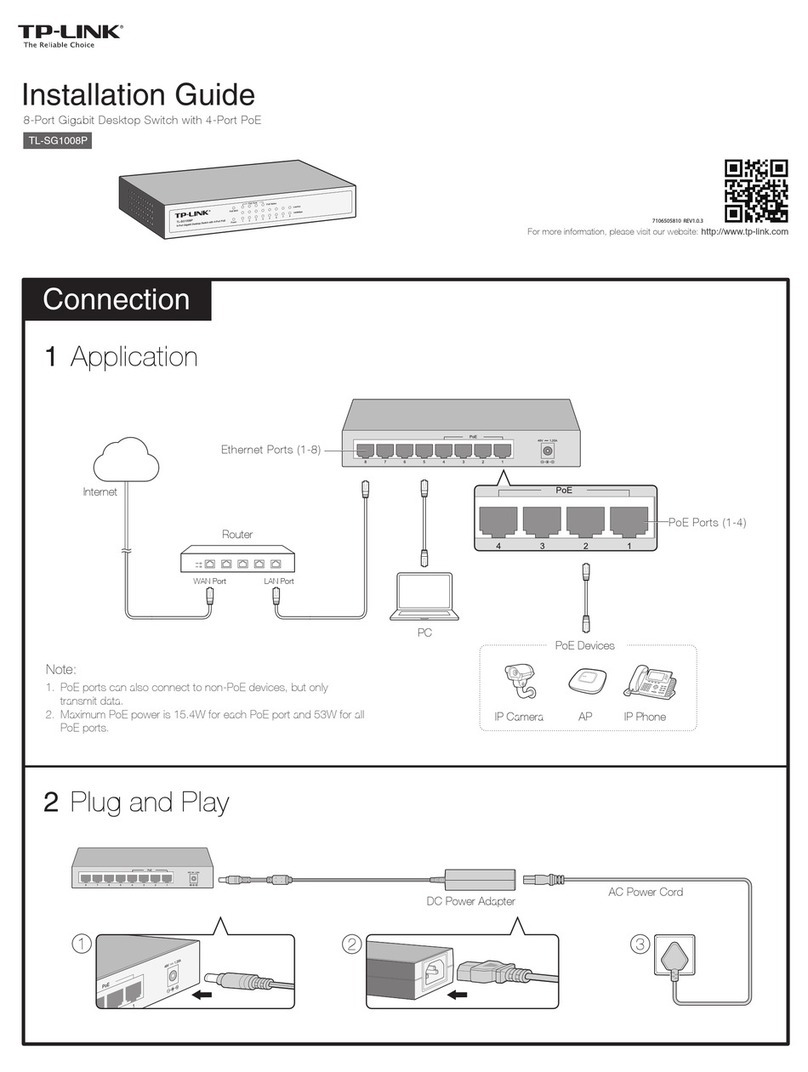

5.1. FITTING CABLE GLANDS

With the small GS01.004 switchbox, cable glands can only be ed on the top and boom. With the

larger GS01.006/GS01.008/GS01.012 switchboxes, all four sides can be connected.

94

65

56,7

R7,5

79

50

Kopf- /Fußseite Anschluss

mit M16 oder M20

Linke und rechte Seite Anschluss

mit M16 oder M20

(GS01.006; GS01.008; GS01.012)

5.2. ATTACHING THE SENSOR CABLES

Note: In the following illustraons, only the circuit board of the sensor switchbox is shown in the

7

Sensor-relay-switchboxes

interests of clarity.

First, t the sensor cables. Each sensor input consists of a terminal

for +24 VDC (brown), sensor signal IN (black) and earth (blue).

Important: The circuit board terminals do not require soldering, screwing or insulaon stripping.

Remove the outer insulaon of the sensor cable only!

The colored insulaon on the individual wires must not be removed, but the uninsulated wires are

inserted into the upper, extended part of the slot once the corresponding push-buon actuator has

been pulled up. Pushing down the orange push-buon actuator causes two contact pieces to cut

through the wire insulaon, creang a conducve connecon between the wire and the terminal.

5.3. SETTING THE SENSOR TYPE

Next, set the type of the sensors used by connecng two of the three contact pins behind the con-

necon terminal with a jumper.

Sensor-relay-switchboxes

8

The following illustraon shows the labelling on the circuit board(s), in parcular the labelling on the

jumper contacts.

In the following example, six sensors have been connected. The rst sensor and the third to the sixth

sensor are PNP type, while the second is an NPN sensor:

The jumpers are inserted in such a way that the center contact pin is connected with the le (NPN)

or the right (PNP) contact pin in each case.

5.4. CREATING GROUPS

The connected sensors can be combined to form one or more groups connected by an AND-opera-

on. The sensor switchboxes allow any group formaon.

9

Sensor-relay-switchboxes

In the example, the rst four and the last two sensors are to be connected by an AND-operaon.

Groups I and II are formed.

First the type of output signal must be established. This is determined by the design of the digital

inputs on the control system to which the switchbox is connected.

If there are PNP inputs (as with most European manufacturers), the output signal on the

sensor switchbox must be PNP type, in other words it must make a conducve connecon

between +24 VDC and the input.

If there are NPN inputs (as with most Asian manufacturers), the output signal on the sen-

sor switchbox must be NPN type, in other words it must make a conducve connecon

between the input and earth.

The type must be set for each sensor group, although usually the same sensor type is set, as the

same control system is involved.

Sensor-relay-switchboxes

10

To do this, a jumper is connected to the rst relay of the group:

The other contact pins above the relay remain free!

(In the example, the sensor switchbox is connected to a control system with PNP inputs. For a control

with NPN inputs, the le and center contact pins would have to be connected.)

The next step is to make the connecon for the AND-operaon itself. Either the normally closed

contact or the normally open contact of a relay must be connected to the common switching contact

of the next relay, with the excepon of the last relay in a group.

In the example, all of the sensors in group I are normally open contacts.

The two sensors in group II, on the other hand, are normally closed contacts, i.e. they should detect

if the two signals are not present. (This is oen the case with through-beam light barriers, for ex-

ample.)

The jumpers are inserted as follows:

11

Sensor-relay-switchboxes

Please note that no jumper is inserted on the 4th and 6th relays. While a jumper on the

6th relay would not have any eect, a jumper on the 4th relay would connect

group I to group II! This is not what is required.

5.5. CONNECTION TO THE CONTROL SYSTEM

Finally, the sensor switchbox must be connected to the control system. To do so, the linked signals

must be connected to the digital inputs, and the power supply must be connected.

It should be noted that group I is connected via the terminal OUT4-NO, as even the last sensor of this

group (4) is a normally open contact, while group II is connected via the OUT6-NC terminal, as the

last sensor in group II is a normally closed contact (NC).

The supply voltage is connected to the 24VDC + and – terminals.

Sensor-relay-switchboxes

12

6. GENERAL TECHNICAL DATA

Nominal supply voltage: 24 VDC ± 10%

Output current (max.): 1A per group

Load current per sensor: 6.25 mA, corresponds to 150 mW

Cable cross-secon: 0.22..0.34 mm² (AWG 22..26), wire Ø ≤1.8 mm

Dimensions

F

D

A

E

B

C

Item no. A [mm] B [mm] C [mm] D [mm] E [mm] F [mm]

GS01.004 94 65 57 79 50 25

GS01.006 94 94 57 79 79 25

GS01.008 130 94 57 115 79 25

GS01.012 180 94 57 165 79 25

Technical data

Item no. Weight [kg] Protecon category Protecon method

GS01.004 0.177 II – Protecve insulaon in accor-

dance with VDE 0106

IP66 – in accordance with EN 60529 / DIN

VDE 0470-1

GS01.006 0.237 II – Protecve insulaon in accor-

dance with VDE 0106

IP66 – in accordance with EN 60529 / DIN

VDE 0470-1

GS01.008 0.309 II – Protecve insulaon in accor-

dance with VDE 0106

IP66 – in accordance with EN 60529 / DIN

VDE 0470-1

GS01.012 0.422 II – Protecve insulaon in accor-

dance with VDE 0106

IP66 – in accordance with EN 60529 / DIN

VDE 0470-1

13

Sensor-relay-switchboxes

7. MAINTENANCE INSTRUCTIONS

The maintenance instrucons must be followed precisely to ensure that the system funcons safely.

If faults are detected in the system, they must be reced immediately, before the sensor switchbox

is put into operaon.

> During service work, the switchbox must be disconnected from the voltage supply and

secured to prevent reconnecon.

7.1 SCHEDULE (MONTHLY TO ANNUALLY)

The sensor switchbox should undergo a visual inspecon once a month to once a year. It must be

ensured that the sensor switchbox is free from moisture, dust and dirt and has no obvious signs of

damage, such as breaks or cracks in the housing.

7.2. QUALIFICATIONS REQUIRED OF MAINTENANCE PERSONNEL

The maintenance personnel must be instructed and suitably qualied to carry out the maintenance

work. They must also have read and understood these instrucons. It must be ensured that the

maintenance personnel have access to these instrucons at all mes.

7.3. INSTRUCTIONS FOR DECOMMISSIONING

The sensor switchbox must be disconnected from the mains power supply before disassembly.

7.4. DISPOSAL

As this sensor switchbox contains electronic components, it must be disposed of properly.

Sensor-relay-switchboxes

14

8. OTHER DOCUMENTS

Circuit diagram:

29

RE L1A

G5V-1 24V

51

10 6

RE L1B

G5V-1 24V

ye

D4

LED ye

ye

D5

LED ye

rd

D1

LED rt

gn

D2

LED gn

+24

GND

29

RE L2A

G5V-1 24V

ye

D6

LED ye

ye

D7

LED ye

+24

GND

29

RE L3A

G5V-1 24V

ye

D8

LED ye

ye

D9

LED ye

+24

GND

29

RE L4A

G5V-1 24V

ye

D10

LED ye

ye

D11

LED ye

+24

GND

51

10 6

RE L2B

G5V-1 24V

51

10 6

RE L3B

G5V-1 24V

51

10 6

RE L4B

G5V-1 24V

GND

D3

MBR1 40SFT 1G

+24

GND

GND

GND

GND

+24

+24

+24

+24

1

2

X2

ID C 0,3/2-3,81

1

2

X1

ID C 0,3/2-3,81

1

2

3

4

5

6

X6

ID C 0,3/6-3,81

1

2

3

4

5

6

X16

ID C 0,3/6-3,81

1

2

3

4

5

6

X7

ID C 0,3/6-3,81

1

2

3

4

5

6

X17

ID C 0,3/6-3,81

GNDGND

GND

GND

GND

GND

+24

+24

+24

+24

GND

+24

X3

X8

X9

X12

X13

X18

X19

X22

X5

AMP-8 26629-3

X11

AMP-8 26629-3

X15

AMP-8 26629-3

X21

AMP-8 26629-3

X20

AMP-8 26629-3

X14

AMP-8 26629-3

X10

AMP-8 26629-3

X4

AMP-8 26629-3

R3

3k3

R4

3k3

R2

3k3

1

2

3

X23Brück e 3p.

CH N3

q

R1

PT C

Bohrung 4,1 mm

4,1 mm

V+

29

RE L5A

G5V-1 24V

ye

D12

LED ye

ye

D13

LED ye

+24

GND

29

RE L6A

G5V-1 24V

ye

D14

LED ye

ye

D15

LED ye

+24

GND

51

10 6

RE L5B

G5V-1 24V

51

10 6

RE L6B

G5V-1 24V

GND

GND

+24

+24

1

2

3

4

5

6

X28

ID C 0,3/6-3,81

1

2

3

4

5

6

X29

ID C 0,3/6-3,81

GND

GND

+24

+24

GND

+24

X25

X30

X31

X34

X27

AMP-826629-3

X33

AMP-826629-3

X32

AMP-826629-3

X26

AMP-826629-3

1

2

3

X24

Brücke 3p.

CH N3

15

Sensor-relay-switchboxes

Notes

Headquarters:

FIPA GmbH

Freisinger Straße 30

85737 Ismaning / Germany

Phone +49 89 962489-0

Fax +49 89 962489-11

info@pa.com | www.pa.com

FIPA Inc.

1855 Evans Road

Cary, NC 27513 / USA

Phone +1 919 651 9888

Fax +1 919 573 0871

sales.us@pa.com | www.pa.com

FIPA Ltd.

1338/939 Supalai Prima Riva Building

Rama 3 Road

Chong Non Si Sub-District, Yannawa District

10120 Bangkok / Thailand

Phone +66 2 294 4166

Fax +66 2 294 4149

sales.th@pa.com | www.pa.com

This manual suits for next models

3

Table of contents