IDEC SA1E-L Series User manual

SA1E-L

Miniature Photoelectric Switches

(Built-in Amplifier) Laser

Visible red laser beam and fast response speed.

High precision sensing.

Through-beamBackground

Suppression (BGS)

Polarized

Retroreective

2

Selectable modes

Light ON/Dark ON

Visible red laser, easy-to-align optical axis,

Detectable object size: ø0.2 mm

(Background Suppression)

Positioning made easy

Because the optical axis can be positioned

quickly, the photoelectric switch can be

installed on a machine or system easily, even in

applications requiring a long sensing range or

detection of small objects.

IDEC’s Unique Optical Lens Mechanism

Parallel beam to the housing axis makes

installation of the photoelectric switch easy.

Housing

Beam is parallel

to the housing axis

Optical Lens

(positioned to make the

beam parallel to the

housing axis)

Optical Lens

(fixed in the housing)

Laser Diode

(fixed in the housing)

Top View

Easy

Installation

m max.

Narrow space for the

beams to pass through

Closely-spaced objects

on a fast-moving

conveyor

Long sensing

distance

APPLICATION EXAMPLES

2

3

Through-beam

Polarized Retroreective

Background Suppression (BGS)

fast response speed, and high precision sensing.

Detects fast-moving

objects

The 250 µs response speed is the fastest in its

class. Closely-spaced objects on a fast-moving

conveyor can be detected reliably.

IP67 structure can be used in environments

exposed to dust or water vapor.

Dust and water resistant

Because the visible red laser

is easy to see in both short (20

mm) and long (30 m) distances,

the detecting position and

optical axis can be found

quickly. The small beam can

detect small objects, and it also

enables easy positioning of the

sensor in applications where

the beam has to pass through

narrow spaces.

All models are Class 1 laser

compliant (JIS, IEC, FDA).

Small red laser beam

Fast

250 µs

Red

Laser

IP67

Exposure to dust or water vapor

3

Small objects

4

Class 1 laser.

Fastest response in its class. Reliably detects fast-moving objects.

•Light source is a red laser (Class 1 by IEC 60825-1, 2007).

•Laser beams with high degree of straightness achieve a long sensing

range (30 m maximum).

•Response speed of 250 μs is the fastest in its class. Reliably detects fast-

moving small objects.

•The visible beam ensures easy and reliable positioning.

•IP67 structure can be used in environments exposed to dust or water.

Operating temperature: 55°C maximum.

•Aligning the optical axis is easy because the lens unit is xed on the

housing (through-beam/polarized retroreective).

•Light ON/Dark ON mode is selectable.

•Cable (1m, 2m, 5m cable) or M8 connector.

•CE marked.

•Compliant with Class 1 of FDA regulations

(according to Laser Notice No. 50).

Package Quantity: 1

Sensing Method Sensing Range

Connection

Cable

Length

Part No.

NPN Output PNP Output

Through-beam

30m

Cable

1 m SA1E-LTN3 SA1E-LTP3

2 m SA1E-LTN3-2M SA1E-LTP3-2M

5 m SA1E-LTN3-5M SA1E-LTP3-5M

Connector — SA1E-LTN3C SA1E-LTP3C

See the characteristics on page 11.

Polarized Retroreective

(Note)

See the characteristics on page 11.

Cable

1 m SA1E-LPN3 SA1E-LPP3

2 m SA1E-LPN3-2M SA1E-LPP3-2M

5 m SA1E-LPN3-5M SA1E-LPP3-5M

Connector — SA1E-LPN3C SA1E-LPP3C

Background Suppression

20 to 300 mm

40 to 300 mm

Adjustable Sensing Range

Cable

1 m SA1E-LBN3 SA1E-LBP3

2 m SA1E-LBN3-2M SA1E-LBP3-2M

5 m SA1E-LBN3-5M SA1E-LBP3-5M

Connector — SA1E-LBN3C SA1E-LBP3C

See the characteristics on page 12.

Note: Maintain at least the distance shown in the ( ) between the SA1E-L photoelectric switch and reector. Reectors are not supplied

and must be ordered separately. See page 5.

Through-beam

Background

Suppression (BGS)

Polarized Retroreective

With right-angle

connector cable

10m (300 mm

)

When using IAC-R5/R8

10m (300 mm)

When using IAC-R9

SA1E-L

Miniature Laser Photoelectric Switches (Built-in Amplifier)

5

SA1E-L Miniature Laser Photoelectric Switches (Built-in Amplifier)

Accessories (optional)

Sensor Mounting Brackets

Item Part No. Package

Quantity

Sensor

Mounting

Brackets

Vertical Mounting SA9Z-K01

1

Horizontal Mounting SA9Z-K02

Cover Type SA9Z-K03

Back Mounting SA9Z-K04

•See page 8 for dimensions.

•Two mounting screws (M3 × 12 mm sems screws) are supplied

with the SA9Z-K01 and SA9Z-K02.

•Two mounting screws (M3 × 14 mm sems screws) are supplied

with the SA9Z-K03.

•The through-beam type requires two mounting brackets, one

each for the projector and the receiver.

•The SA9Z-K02 cannot be used for the connector models.

•Contact IDEC about mounting brackets for the connector models.

Slits (for through-beam)

Item Slit Size Part No. Ordering No. Package

Quantity

Round Slit

ø0.5 mm SA9Z-S12 SA9Z-S12PN02

2ø1.0 mm SA9Z-S13 SA9Z-S13PN02

ø2.0 mm SA9Z-S14 SA9Z-S14PN02

•See page 6 for dimensions.

Reectors

Item Part No. Package

Quantity

Reector

IAC-R5

1IAC-R8

IAC-R9

•See page 9 for dimensions.

Reector Mounting Brackets

Item Part No.

Package

Quantity

Reector

Mounting

Bracket

For IAC-R5 IAC-L2 (Note 1)

1For IAC-R9 IAC-L3 (Note 2)

For IAC-R8 IAC-L5 (Note 3)

•See page 10 for dimensions.

Note 1: The IAC-L2 is not supplied with M4 mounting screws and

nuts.

Note 2: The IAC-L3 is supplied with two M3 mounting screws

(M3 × 8 mm sems screws).

Note 3: The IAC-L5 is supplied with two M4 mounting screws

(M4 × 10 mm sems screws).

Air Blower Mounting Block

Item Part No. Package

Quantity

Air Blower Mounting Block SA9Z–A02 1

•See page 10 for dimensions.

•Two mounting screws (M3 × 20 mm sems screws), one M5 × 6

mm screw for plugging the air supply port, and one gasket (0.5

mm thick) are supplied.

•The air tube tting and mounting bracket are not supplied and

must be ordered separately (recommended mounting bracket:

SA9Z-K01).

•Material: Anodized aluminum surface

Connector Cable (for connector models)

Number of

Core Wires Style & Length Part No. Package

Quantity

4

Straight, 2m SA9Z-CM8K-4S2

1

Straight, 5m SA9Z-CM8K-4S5

Right angle, 2m SA9Z-CM8K-4L2

Right angle, 5m SA9Z-CM8K-4L5

•See page 10 for dimensions.

•Contact IDEC for UL approved cables.

Sensitivity Control Screwdriver

Item Part No. Package

Quantity

Sensitivity Control Screwdriver

SA9Z-AD01 1

6

SA1E-L Miniature Laser Photoelectric Switches (Built-in Amplifier)

Specifications

Through-beam Polarized Retroreective Background Suppression (BGS)

Part No. SA1E-LT SA1E-LP SA1E-LB

Power Voltage 12 to 24V DC (Operating range: 10 to 30V DC)

Equipped with reverse-polarity protection

Current Draw Projector:15 mA maximum

Receiver: 30 mA maximum 35 mA maximum

Sensing Range 30m 0.3 to 10m (IAC-R5/R8/R9)

20 to 300 mm

(using 100 × 100 mm white matte

paper)

Adjustable Sensing Range — 40 to 300 mm

Detectable Object Size (typical) ø6 mm minimum (opaque, at 3 m) ø0.2 mm minimum (copper wire)

(at 170 mm)

Detectable Object Opaque

Hysteresis — 10% maximum

Response Time 250 μs maximum

Sensitivity Adjustment Adjustable using a potentiometer —

Sensing Range Adjustment — 6-turn control knob

Light Source Element Red laser diode (emission wavelength: 650 nm) (IEC/JIS/FDA Class 1) (Note)

Operation Mode Light ON/Dark ON (selectable)

Control Output

NPN open collector or PNP open collector

(30V DC, 100 mA maximum, short-circuit protection)

Voltage drop: 1.5V maximum

LED Indicators

Operation LED: Yellow

Stable LED: Green

Power LED: Green (Through-beam type projector)

Interference Prevention — Two units can be mounted in close proximity.

Degree of Protection IP67 (IEC 60529)

Extraneous Light Immunity Sunlight: 10,000 lux maximum, Incandescent lamp: 5,000 lux maximum (at receiver)

Operating Temperature –10 to +55°C (no freezing)

Operating Humidity 35 to 85% RH (no condensation)

Storage Temperature –25 to +70°C (no freezing)

Storage Humidity 35 to 85% RH (no condensation)

Insulation Resistance Between live part and mounting bracket: 20 MΩ minimum (500V DC megger)

Dielectric Strength

Cable models: 1,000V AC, 50/60 Hz, 1 minute (between live part and mounting bracket)

Connector models when connected with connector cable: 500V AC, 50/60 Hz, 1 minute (between live part and

clamp ring)

Vibration Resistance 10 to 55 Hz, amplitude 1.5 mm, 20 cycles in each of 3 axes

Shock Resistance 500 m/s2, 3 shocks in each of 3 axes

Material Housing: PBT, Lens: PMMA, Indicator cover: PC, knob; POM

Weight

(approx.)

Cable Model 35g (1 m cable), 55g (2 m cable), 120g (5 m cable)

Connector Model 20g

Connection

Method

Cable Model ø3.5 mm, 3-core, 0.2 mm2, vinyl cabtyre cable

Connector Model M8 connector (4-pin)

Note: Compliant with Class 1 of FDA regulations (21 CFR 1040.10 and 21 CFR 1040.11 according to Laser Notice No. 50).

Slit and Sensing Range (typical) [Through-beam SA1E-LT]

Slit Sensing Range (m) Minimum Detectable

Object Width (mm)

Part No. Slit Width: A Used on receiver

SA9Z-S12 0.5 mm 6 11

SA9Z-S13 1.0 mm 10 1.6

SA9Z-S14 2.0 mm 22 2.5

•Minimum detectable object width (mm): when the object is at the

intermediate point between the projector and receiver.

Slit

(stainless steel)

The slit can be pressed to

snap onto the front easily.

The slits have an orientation.

Make sure that the TOP marking

is on top of the sensor (LED side).

Dimensions

Material: Stainless Steel

All dimensions in mm.

8.2

32.1

6.1

0.3

4.4

øA

7

SA1E-L Miniature Laser Photoelectric Switches (Built-in Amplifier)

31.5

4.5 2-M3

M8×1

Operation LED (yellow) (Note 2)

Operation Mode Switch (Note 1)

Operation LED (green) (Note 1)

Sensitivity Control (except BGS) (Note 1)

Sensing Range Control (BGS)

Projector

Receiver

(Polarized Retroreflective)

Projector

or

Receiver

15.3

8.2

7.2

17.1

10.81.2

6.3

19.5

25.4

11.8

3.4

8.0

7.8

19.8

3.2

In the photo, the right-angle

connector cable is attached.

Operation LED (yellow) (Note 2)

Operation Mode Switch (Note 1)

Operation LED (green) (Note 1)

Sensing Range Control (BGS)

Sensitivity Control (except BGS) (Note 1)

Receiver

(Polarized Retroreflective)

Projector

or

Receiver

7.2

17.1

10.8

11.8

15.3

8.2

8.0

7.8

19.8

31.5

ø3.5

19.5

(Note 3)

25.4

1.2

3.4

2-M3

Projector

3.2

•Through-beam

•Through-beam

•Polarized Retroreective

•Background Suppression (BGS)

•Polarized Retroreective

•Background Suppression (BGS)

Connector Model

Note 1: No stable LED, sensitivity control, and operation mode switch are attached on the through-beam projector.

Note 2: Power ON LED (green) for through-beam projector.

Note 3: Cable length depends on models.

Note 4: The connector length is 18 mm when a right-angle connector cable (SA9Z-CM8K-4L∗) is attached.

+V

Black (4)

OUT 12 to 24V

DC

0V

Blue (3)

Main Circuit

Load

Brown (1)

Black (4)

OUT

12 to 24V

DC

0V

Blue (3)

Main Circuit

Load

Brown (1)

Main Circuit

Brown (1)

Blue (3)

+V

0V

12 to 24V DC

Output Circuit & Wiring Diagram

NPN Output PNP Output Through-beam Type Projector

(Connector Pin Assignment)

OUT

NC

0V

+V

(Connector Pin Assignment)

OUT

NC

0V

+V

(NC)

(NC)

(0V)

(+V)

(Connector Pin Assignment)

Dimensions

Cable Model

8

SA1E-L Miniature Laser Photoelectric Switches (Built-in Amplifier)

SA9Z-K01

Material: Stainless Steel

1.2

42.5

3.4

14.0

21.5

14°

3.4

8.0

13.7

3.2

12.3 25.4

9.04.5 3.0

7°

1.2

24.8

13.4

19.5

21.5

9.3 31.5

13.7

6.0

0.5

7.2

17.1

25.0

8.0

10.8

(3.2)

(Note 1)

(Note 3)

(Note 2)

25.4

42.5

12.3

Note 1: Projector (through-beam)

Receiver (through-beam)

Note 2: Projector (polarized retroreective,

background suppression)

Note 3: Receiver (polarized retroreective)

Dimensions

Mounting Brackets

With Mounting Bracket

All dimensions in mm.

Material: Stainless Steel

R9.5

ø25

6.2

2-R25

25

3.2

3.2

25

19

14°

4

46

18

13

2.5

7°

6

ø55

ø39

19

29

7

20°

40°

5.5

5.5

1.2

19.5

29.0

0.6

15.0

(5.3)

31.5

ø39.0

ø55.0

9.3

7.2

(3.2)

17.1

25.4

8.0

12.3

10.8

13.0

(18.0)

(55.0)

(Note 1)

(Note 3)

(Note 2)

SA9Z-K03

Note 1: Projector (through-beam)

Receiver (through-beam)

Note 2: Projector (polarized retroreective,

background suppression)

Note 3: Receiver (polarized retroreective)

With Mounting Bracket

1.2

14.6

34.8

55.0

10.6

ø3.4

Material: Stainless Steel

15.3 25.48.4

14°

4.5

12.0 5.0

4.5

6.0

17.6

21.5

12.7

1.2

1.0 19.5

21.5

12.7

31.5

25.4

12.3

15.3

28.0

34.8

8.0

55.0

10.6

1.2

8.0

14.6 (3.2)

17.1

(Note 1)

(Note 3)

7.2

(Note 2)

Note 1: Projector (through-beam)

Receiver (through-beam)

Note 2: Projector (polarized retroreective,

background suppression)

Note 3: Receiver (polarized retroreective)

SA9Z-K02

9

SA1E-L Miniature Laser Photoelectric Switches (Built-in Amplifier)

14

8

3.4

30

25

57

t=1.2

32

77

24

25.4

3.2

Material: Stainless Steel

All dimensions in mm.

SA9Z-K04

Reector

61

8

(Reflecting surface: 47 × 47)

2-ø4.5

30

40

30.4

51.2

51.2

IAC-R8IAC-R5

(Reflecting surface: 47.2 × 47.2)

2-ø4.3

51

72

60

3

9

(Reecting surface 47 × 47.6)

6.1

3.5

4.4

61.6

51

5

51.6

40

20

2-R 2.2 2-R 2.2

IAC-R9

28.4

24.8

10.8

13.4

19.51.6

With Mounting Bracket

10

SA1E-L Miniature Laser Photoelectric Switches (Built-in Amplifier)

Dimensions

Reector Mounting Brackets

Connector Cable (connector on one end)

Cable length:

2 or 5m

33.7

ø4.7

ø10

➃

Black ➁White

➂Blue ➀Brown

28.1

18.9

27.2

5°

ø4.7

ø10

➃

Black ➁White

➂Blue ➀Brown

Cable length:

2 or 5m

Straight (SA9Z-CM8K-4S)

•

Dielectric strength when installed on the SA1E-L: 1000V AC (between live part and mounting bracket, except between live part and tightening ring)

Right-angle (SA9Z-CM8K-4L)

•The SA9Z-A02 air blower mounting block

is supplied with two mounting screws

(M3 × 20 mm sems screws), one screw

for plugging the air supply port (M5 × 6

mm), and one gasket (1 mm thick) for

plugging the air supply port.

•An air tube tting can be installed to

either the top or side. Tighten the tting

to a torque of 0.5 N·m maximum.

•The air tube tting and mounting bracket

are not supplied and must be ordered

separately (recommended mounting

bracket: SA9Z-K01).

All dimensions in mm.

5.8

14.0

8.0

37.0

25.4

25.0

6.9

M5P0.8

M5P0.8

(Material: Anodized aluminum surface)

2-ø3.2

(3.2)3.5 19.5 2.0

(3.8)

31.5

Recommended

mounting

bracket (SA9Z-K01)

Air Blower

Mounting Block

10.9

14.0

8.0

3.4

Air supply port

Plugging screws

for air supply port

(M5), Gasket

(used on one

side only)

6.5

42.5

With Mounting Bracket

IAC-L2 (for IAC-R5)

IAC-L3 (for IAC-R9) IAC-L5 (for IAC-R8)

Material: SPCC (zinc plating)

42

5.5 19

6

28

37

74

113

2

2-ø3.4

4-ø4.4

30

58

70

60

44

20

1.6

25

1610

8

6

Material: SPCC (zinc plating)

8-M3 × 0.5 holes

25

4.5

11

10

35

(3)

40

4.5

10

Material: SPCC (zinc plating)

26

12 35

(28)

(3)

20

(2)

61

16

15

18

7

40

50

11

8-M3 ×0.7 holes

Air Blower Mounting Block

SA9Z-A02

11

SA1E-L Miniature Laser Photoelectric Switches (Built-in Amplifier)

Characteristics (Typical)

1. Through-beam SA1E-LT

Excess Gain (without slit) Excess Gain (with round slit) Lateral Displacement (without slit)

Excess Gain

1

10

100

50403020100

Excess Gain

1

10

100

20 25151050

ø2.0 mm

Slit on receiver

ø1.0 mm

Slit on receiver

ø0.5 mm

Slit on receiver

Lateral Displacement Y (mm)

-30

-20

-10

0

0 5 10 15 20 25 30 35 40 45 50

10

20

30

X

Y

Sensing Distance (m) Sensing Distance (m) Sensing Distance (m)

Angle (without slit) Light Beam Diameter

Receiver Angle θ(°)

-20

-15

-10

-5

0

0510 15 20 25 30 35 40 45 50

5

10

15

20

θ

X

Light Beam Diameter (mm)

0

10

20

30

40

50

60

70

80

90

100

0510 15 20 25 30 35 40 45 50

B

A

A

B

Sensing Distance X (m) Sensing Distance (mm)

2. Polarized Retroreective SA1E-LP

Excess Gain Lateral Displacement Angle

Excess Gain

1

10

100

20151050

IAC-R5/R8

IAC-R9

Lateral Displacement Y (mm)

-15

-10

-5

0

5

10

15

012345678910

X

YIAC-R5/R8

IAC-R9

Reector Angle θ(°)

-50

-40

-30

-20

-10

0

10

20

30

40

50

01 23 45 67 8910

IAC-R9

IAC-R5/R8

X

θ

Sensing Distance (m) Sensing Distance X (m) Sensing Distance X (m)

Light Beam Diameter

Light Beam Diameter (mm)

0

10

20

30

40

50

60

70

80

90

100

0510 15 20 25 30 35 40 45 50

B

A

A

B

Sensing Distance (mm)

Operation

Level

Operation

Level

Operation

Level

(Light beam diameter)

Reference value (visual inspection)

(Light beam diameter)

Reference value (visual inspection)

12

SA1E-L Miniature Laser Photoelectric Switches (Built-in Amplifier)

Characteristics (Typical)

3. Background Suppression (BGS) SA1E-LB

Lateral Displacement (Preset 150 mm) Lateral Displacement (Preset 300 mm) Light Beam Diameter

Lateral Displacement Y (mm)

-3

-2

-1

0

1

2

3

200150100500

White

Paper

Black

Paper

Object: 100 ×100 mm matte paper

(black/white)

X

Y

Lateral Displacement Y (mm)

-3

-2

-1

0

1

2

3

4003002001000

Object: 100 ×100 mm matte paper

White

Paper

X

Y

Light Beam Diameter (mm)

0.0

050100 150200 250300 350400 450500

0.5

1.0

1.5

2.0

2.5

3.0

A

A

B

B

Sensing Distance X (mm) Sensing Distance X (mm) Sensing Distance (mm)

Light beam diameter:

Dened as 1/e2(13.5%) of the center intensity

Color Matte Paper and Other Materials

(Preset 150 mm)

Color Matte Paper and Other Materials

(Preset 300 mm)

Control Knob vs. Sensing Distance

Sensing Distance (mm)

50

0

100

150

200

White

Green

Red

Blue

Gray

Black

Cardboard

Aluminum

Stainless Steel

Black Rubber

Brass

Sensing Distance (mm)

0

50

100

150

200

250

300

350

White

Green

Red

Blue

Gray

Black

Cardboard

Aluminum

Stainless Steel

Black Rubber

Brass

Sensing Distance (mm)

0

100

200

300

400

500

600

700

01 2345 67

Object: 100 ×100 mm

matte paper (white)

Comparison of sensing distance when set to detect

white matte paper (100 × 100 mm) at 150 mm

Comparison of sensing distance when set to detect

white matte paper (100 × 100 mm) at 300 mm

Control Knob (turns)

13

SA1E-L Miniature Laser Photoelectric Switches (Built-in Amplifier)

Indicator and Output Operation

(Through-beam/Polarized Retroreflective)

Stable LED (green)

Operation LED (yellow)

Sensitivity Control

Operation Mode Switch

•The operation LED turns on (yellow) when the control output is

on.

•The stable LED turns on (green) either at stable incident or stable

interruption. Make sure to use the photoelectric switch after the

stable operation is ensured.

•In the light ON operation, the output turns on when the receiving

light intensity level is 1.0 or over as shown below.

•In the dark-ON operation, the output turns on when the receiving

light intensity level is 1.0 or less as shown below.

Receiving Light

Intensity Level

Light

Receiving

Status

Stable

LED

(green)

Operation LED (yellow)/

Control Output

Light ON Dark ON

Operation

Level

1.3 and

over

Stable

Incident ON

ON OFF

1.0

Unstable

Incident OFF

Unstable

Interruption OFF ON

0.7 and

below

Stable

Interruption ON

Optical Axis Alignment (Light ON)

Through-beam

Fasten the receiver temporarily. Place the projector to face the

receiver. Move the projector up, down, right and left to nd the

range where the operation LED turns on. Fasten the projector in

the middle of the range. Next, move the receiver up, down, right

and left in the same manner and fasten in the middle of the range

where the operation LED turns on. Make sure that stable LED turns

on at stable incident and stable interruption.

Polarized Retroreective

Install the reector perpendicularly to the optical axis. Move the

SA1E-L photoelectric switch up, down, right and left to nd the

range where the operation LED turns on. Fasten the switch in the

middle of the range. Make sure that stable LED turns on at stable

incident and stable interruption. When installing the reector

near the photoelectric switch, adjust the angle and positions of

photoelectric switch and reector so that sensing objects can be

detected reliably.

Background Suppression (BGS)

Place the SA1E-L photoelectric switch where the switch can

detect the object. Move the switch up, down, right and left to nd

the range where the operation LED tuns on. Fasten the switch in

the middle of the range. Make sure that stable LED turns on at

stable incident and stable interruption.

Sensitivity Adjustment

(Through-beam/Polarized Retroreflective)

•Referring to the table below, adjust the sensitivity of the SA1E-

L photoelectric switch when necessary, in such cases as the

through-beam is used to detect small or translucent objects. The

table explains the status of operation LED when the operation

mode is set to light ON.

Step

Photoelectric

Switch Status

Sensitivity

Control Adjusting Procedure

1

Receiving light

•Through-beam,

polarized

retroreective:

No object

detected

A

Min. Max.

Turn the control counter-

clockwise to the mini-

mum. Then turn clockwise

until the operation LED

turns on (turns off with

dark ON type) (point A).

2

Light is interrupted

•Through-beam,

polarized

retroreective:

Object detected B

Min.

A

Max.

At interruption status,

turn the control clockwise

from point A, until the

operation LED turns on

(turns off with dark ON

type) (point B).

If the operation LED

does not turn on (turn off

with dark ON type) even

though the control has

reached the maximum,

set the maximum position

as point B.

3—

B

C

Max.Min.

A

Set the middle point

between point A and B as

point C.

•After adjusting the sensitivity, make sure that stable LED turns on

at stable incident and stable interruption. For detecting objects

too small to turn on the stable LED, use an optional slit.

•Sensitivity is set to the maximum at the factory before shipment.

When adjusting the sensitivity, use the screwdriver supplied with

the SA1E-L photoelectric switch to turn the control as shown

below, to a torque of 0.05 N·m maximum.

Adjustment of Sensing Range for

Background Suppression (BGS)

•When adjusting the sensing range, follow the instruction below.

Step

Distance Control Adjusting Procedure

1

A

Install the photoelectric switch and the object

rmly. Turn the control counterclockwise until

the operation LED turns off (turns on with dark

ON type). From this point, turn the control

clockwise until the operation LED turns on

(turns off with dark ON type) (point A).

2

B

A

Remove the object, and conrm that the

operation LED turns off (turns on with dark

ON type). Turn the control clockwise until the

operation LED turns on (detecting the back-

ground) (turns off with dark ON type) (point B).

(Note 1)

3

B

C

A

Set the middle point between point A and B as

point C. (Note 2)

Note 1: When the background is far off and not detected, turn the

control 360°, and set the point as point C.

Note 2: Because the control is multi-turn, it may take more than

one turn to move from point A to point B.

•Turning the control clockwise lengthens the sensing distance.

Operation LED (yellow)

Sensing Range Contro

l

(Note 3)

Stable LED (green)

eratn e St

Instructions

14

SA1E-L Miniature Laser Photoelectric Switches (Built-in Amplifier)

Power Supply and Wiring

•Do not use the SA1E-L photoelectric switch in the transient

status immediately after turning on the power (approx. 100 ms).

When the load and switch use different power supplies, make

sure to power up the switch rst.

•Use a power supply with little noise and inrush current, and use

the photoelectric switch within the rated voltage range. Make

sure that the ripple is within the allowable limit. Do not apply AC

voltage, otherwise the switch may blow out or burn.

•When using a switching power supply, make sure to ground the

FG (frame ground) terminal, otherwise high-frequency noise may

affect the photoelectric switch.

•Turn power off before inserting/removing the connector on

photoelectric switch. Make sure that excessive mechanical force

is not applied to the connector. Connect the connector cable to a

tightening torque of 0.5 N·m maximum.

•To ensure the degree of protection, use the applicable connec-

tor cable for the connector type. Connector cables are ordered

separately (see page 5).

•Avoid parallel wiring with high-voltage or power lines in the same

conduit, otherwise noise may cause malfunction and damage.

When wiring is long, use a separate conduit for wiring.

•Use a cable of 0.3 mm2minimum core wires, then the cable can

be extended up to 100 m.

Installation

Installing the Photoelectric Switch

•Do not install the SA1E-L photoelectric switches in an area where

the switches are subject to the following conditions, otherwise

malfunction and damage may be caused.

∗Inductive devices or heat source

∗Extreme vibration or shock

∗Large amount of dust

∗Toxic gases

∗Water, oil, chemicals

∗Outdoors

•Make sure to prevent sunlight, uorescent light, and especially

the uorescent light of inverters from entering the receiver of

the photoelectric switch directly. Keep the through-beam type

receiver away from intense extraneous light.

•Interference prevention allows two SA1E-L switches to be

mounted in close proximity. However, the through-beam model is

not equipped with interference prevention. Maintain appropriate

distance between the switches referring to the lateral displace-

ment characteristics.

•Because the SA1E-L photoelectric switches are IP67 waterproof,

the SA1E-L can be exposed to water. However, wipe water drops

and smears from the lens and slit using a soft cloth to make sure

of the best detecting performance.

•Acrylic resin is used for optical elements. Do not use ammonia or

caustic soda for cleaning, otherwise optical elements will be dis-

solved. To remove dust and moisture build-up, use soft dry cloth.

•Tighten the mounting screws (M3) to a torque of 0.4 to 0.5 N·m.

Do not tighten the mounting screws excessively or hit the switch

with a hammer, otherwise the protection degree cannot be

maintained.

Installing the Reflector

•Use M4 mounting screws for the IAC-R5 and IAC-R8 reectors.

Tighten the mounting screws to a tightening torque of 0.4 to 0.5

N·m maximum. Do not tighten the mounting screws excessively,

otherwise the screw holes of the reector will be damaged.

•While optional reector mounting bracket IAC-L2 is not sup-

plied with mounting screws or nuts, the IAC-L3 and IAC-L5 are

supplied with mounting screws for mounting the reector on the

bracket.

15

SA1E-L Miniature Laser Photoelectric Switches (Built-in Amplifier)

Installing the air blower mounting block SA9Z-A02

•When installing the SA9Z-A02 on the SA1E-L photoelectric

switch, use the attached M3 mounting screws and tighten to a

torque of 0.4 to 0.5 N·m maximum.

•Mounting bracket is not supplied with SA9Z-A02 and must be

ordered separately. SA9Z-K01 mounting bracket can be used

with SA9Z-A02. When installing the SA9Z-K01 mounting bracket

on SA9Z-A02 air blower mounting block, use the M3 × 20 mount-

ing screws supplied with SA9Z-A02. Do not use the mounting

screws (M3 × 12) supplied with SA9Z-K01.

•The SA9Z-A02 cannot be used with the through-beam slits

(SA9Z-S12, SA9Z-S13, and SA9Z-S14).

•The air tube tting (M5) can be installed to either the top or side.

The air tube is not supplied.

•Close the unused port using the supplied air supply port plugging

screw (M5 × 6) and gasket to a tightening torque of 1 to 2 N·m

maximum. The recommended air pressure is 0.1 to 0.3 MPa.

Installing the background suppression (BGS) type

•This sensor can detect objects correctly when the sensor head is

installed perpendicular to the moving object. Install the sensor

head as shown below to minimize sensing errors.

•If the SA1E-L is used in a place subject to large variations in the

ambient temperature, the characteristics may change depending

on the target object. Be sure to check the operation under the

actual operating conditions.

•Polarized retroreective: when the sensing objects have mirror

surface, the reected light from the mirror surface might cause

false detection. Make sure that the reected light does not enter

the receiver.

Correct

Object Object Object

Correct Incorrect

Using a laser product

•The SA1E-L photoelectric switches radiate a visible laser beam.

Do not look directly at laser beam. Also, do not look at the laser

beam reected by a mirror surface.

•IEC 60825-1 (Safety of laser products) sets safety standards of

laser products. The SA1E-L photoelectric switches are classied

as Class 1 product.

•The SA1E-L photoelectric switches comply with 21 CFR 1040.10

and 21 CFR 1040.11 according to Laser Notice No. 50, dated

June 24, 2007, issued by the CDRH (Center for Devices and Ra-

diological Health) under the FDA (Food and Drug Administration).

•Labels

According to IEC 60825-1 and FDA regulations, the SA1E-L

has the warning and certication/identication labels as shown

below. When installing the SA1E-L on a system/equipment used

in the United States, ensure that the labels are attached to the

SA1E-L.

Certification/identification LabelWarning Label

SA1E-L Miniature Laser Photoelectric Switches (Built-in Amplifier)

Seven sensing methods available.

Easy

Installation

IP67

Specications and other descriptions in this brochure are subject to change without notice.

Cat. No. EP1441-2 FEBRUARY 2016 PDF

IDEC ELEKTROTECHNIK GmbH

IDEC (SHANGHAI) CORPORATION

IDEC (BEIJING) CORPORATION

Tel: +86-10-6581-6131

IDEC (SHENZHEN) CORPORATION

Tel: +86-755-8356-2977

IDEC IZUMI (H.K.) CO., LTD.

IDEC TAIWAN CORPORATION

IDEC IZUMI ASIA PTE. LTD.

IDEC ASIA (THAILAND) CO.,LTD.

www

.idec.com

IDEC CORPORATION (USA)

Tel: +1-408-747-0550 / (800) 262-IDEC (4332)

E-mail: [email protected]

IDEC CANADA LIMITED

Tel: +1-905-890-8561, Toll Free: (888) 262-IDEC (4332)

E-mail: [email protected]

IDEC AUSTRALIA PTY. LTD.

Tel: +61-3-8523-5900, Toll Free: 1800-68-4332

E-mail: [email protected]

6-64, Nishi-Miyahara 2-Chome, Yodogawa-ku, Osaka 532-0004, Japan

Tel: +81-6-6398-2571, Fax: +81-6-6392-9731, E-mail: [email protected]

p

SA1E Miniature LED Photoelectric Switches (Built-in Amplifier)

•For detecting

transparent objects

Photo: Polarized

retroreective

Cable Model

All dimensions in mm.

10.8

31.5

19.5

Photo:

Through-beam

Connector Model

10.8

31.5

10.8

19.5

1 2 3 4 5

1

T Through-beam (Infrared LED)

TA Through-beam (Red LED)

P Polarized Retroreective (Red LED)

D Diffuse-reective (Infrared LED)

N Small-beam Reective (Red LED)

B Background Suppression (BGS) (Red LED)

G Convergent Reective (Infrared LED)

XCoaxial Polarized Retroreective

(Transparent Object Sensing) (Red LED)

2N NPN output

P PNP output

31 Light ON

2 Dark ON

4Blank w/ Sensitivity Adjustment

5

Blank 1 m cable

-2M 2 m cable

-5M 5 m cable

C Connector

Part No. Development

SA1E - T -NA -M

Model

Through-beam

SA1E-T

Through-beam

SA1E-TA

Polarized Retroreective

SA1E-P

Diffuse-reective

SA1E-D

Detectable Object Opaque Opaque Opaque Opaque/transparent

Sensing Range 20 m 10 m 2.5 m 700 mm

Current Draw Projector: 15 mA

Receiver: 20 mA

Projector: 15 mA

Receiver: 20 mA 30 mA 30 mA

Response Time 1 ms max. 1 ms max. 1 ms max. 1 ms max.

Model

Small-beam Reective

SA1E-N

Background Suppression

(BGS)

SA1E-B

Convergent Reective

SA1E-G

Coaxial Polarized

Retroreective

SA1E-X

Detectable Object Opaque/transparent Opaque Opaque/transparent Opaque/transparent/

mirror-like objects

Sensing Range 50 to 150 mm 20 to 200 mm 5 to 35 mm 2 m

Current Draw 30 mA 30 mA 30 mA 20 mA

Response Time 1 ms max. 1 ms max. 1 ms max. 0.5 ms max.

•For details, see Cat No. EP1491-0.

•Package quantity: 1

Reflectors

This manual suits for next models

24

Table of contents

Other IDEC Switch manuals

IDEC

IDEC SA1E Series User manual

IDEC

IDEC HS5D-11 User manual

IDEC

IDEC SX5E Series User manual

IDEC

IDEC SA1E Series User manual

IDEC

IDEC SX5E Series User manual

IDEC

IDEC HS5E-K User manual

IDEC

IDEC HS3A Series User guide

IDEC

IDEC HS5E Series User manual

IDEC

IDEC MICRO/I HG9Z-1D4PN05 User manual

IDEC

IDEC HE1B Series User manual

IDEC

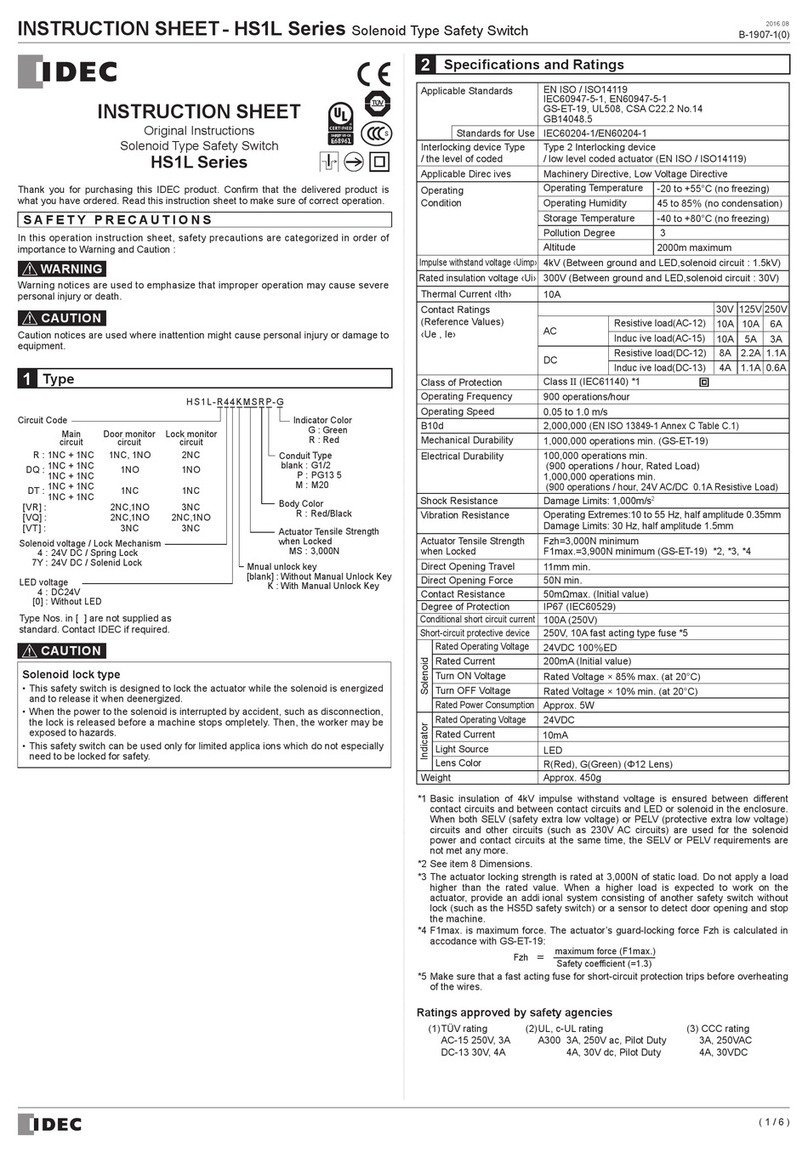

IDEC HS1L Series User manual

IDEC

IDEC HS1L Series User manual

IDEC

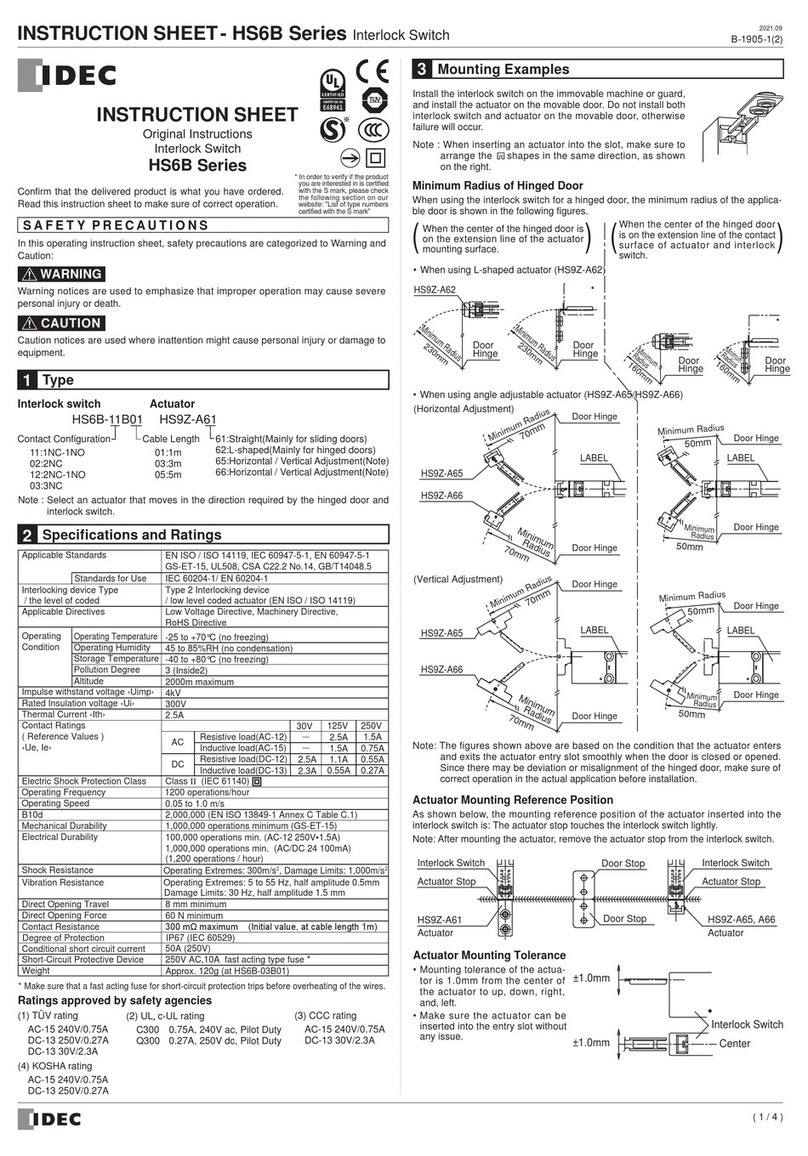

IDEC HS6B Series User manual

IDEC

IDEC HS1E Series User manual

IDEC

IDEC HS5L Series User manual

IDEC

IDEC HS1C Series User manual

IDEC

IDEC HS6E Series User manual

IDEC

IDEC HS1T Series User manual

IDEC

IDEC SA1E Series User manual

IDEC

IDEC HS1C Series User manual