Firebelly Razen CS1 User manual

Table of contents

Other Firebelly Stove manuals

Popular Stove manuals by other brands

US Stove Company

US Stove Company Ashley AP5710 Owner's operation and instruction manual

Quadra-Fire

Quadra-Fire SAPPHIRE Sapphire Cast Iron Specifications

Masport

Masport Masport G51-NG Owners & installation manual

England's Stove Works

England's Stove Works 25-PDVC Installation & operation manual

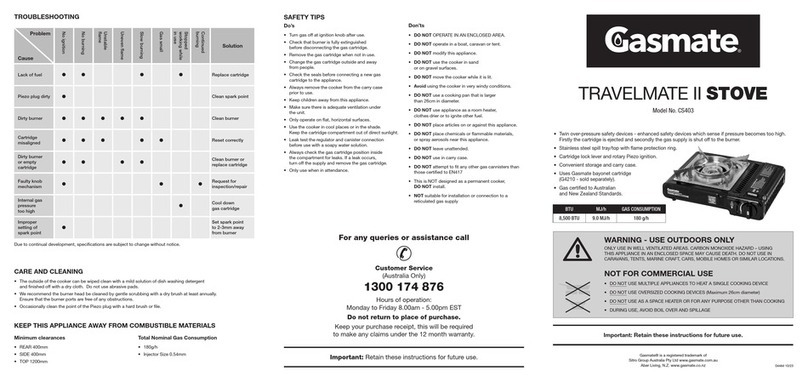

Gasmate

Gasmate TRAVELMATE II manual

Desa

Desa SL30NT/SL30PT OWNER'S OPERATION AND INSTALLATION MANUAL

WANDERS

WANDERS DANTA 500 Installation, servicing and user instructions

Napoleon

Napoleon Arlington GDS20N Installation and operating instructions

Kayoba

Kayoba 025531 operating instructions

Teuvan

Teuvan parra 14 Installation and instructions for use

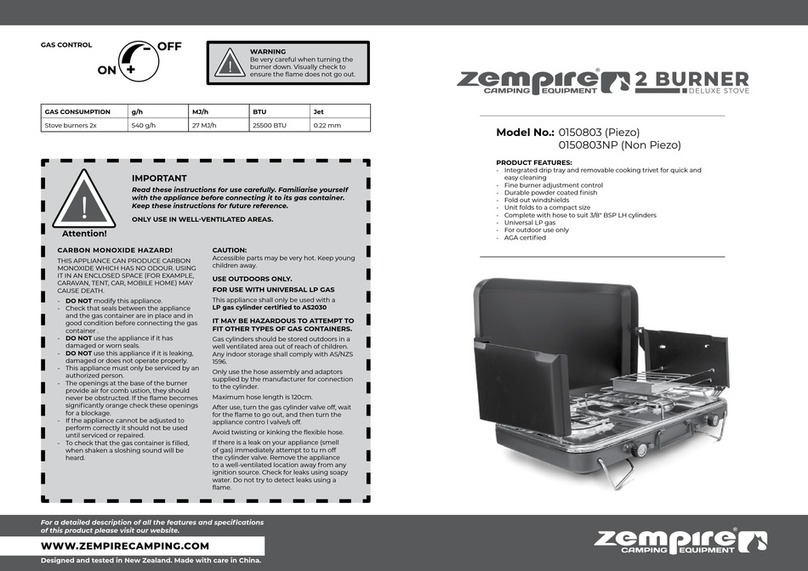

Zempire

Zempire 0150803 manual

Ravelli

Ravelli Chronos Use and maintenance manual

ECOFOREST

ECOFOREST MIAMI Installation and maintenance manual

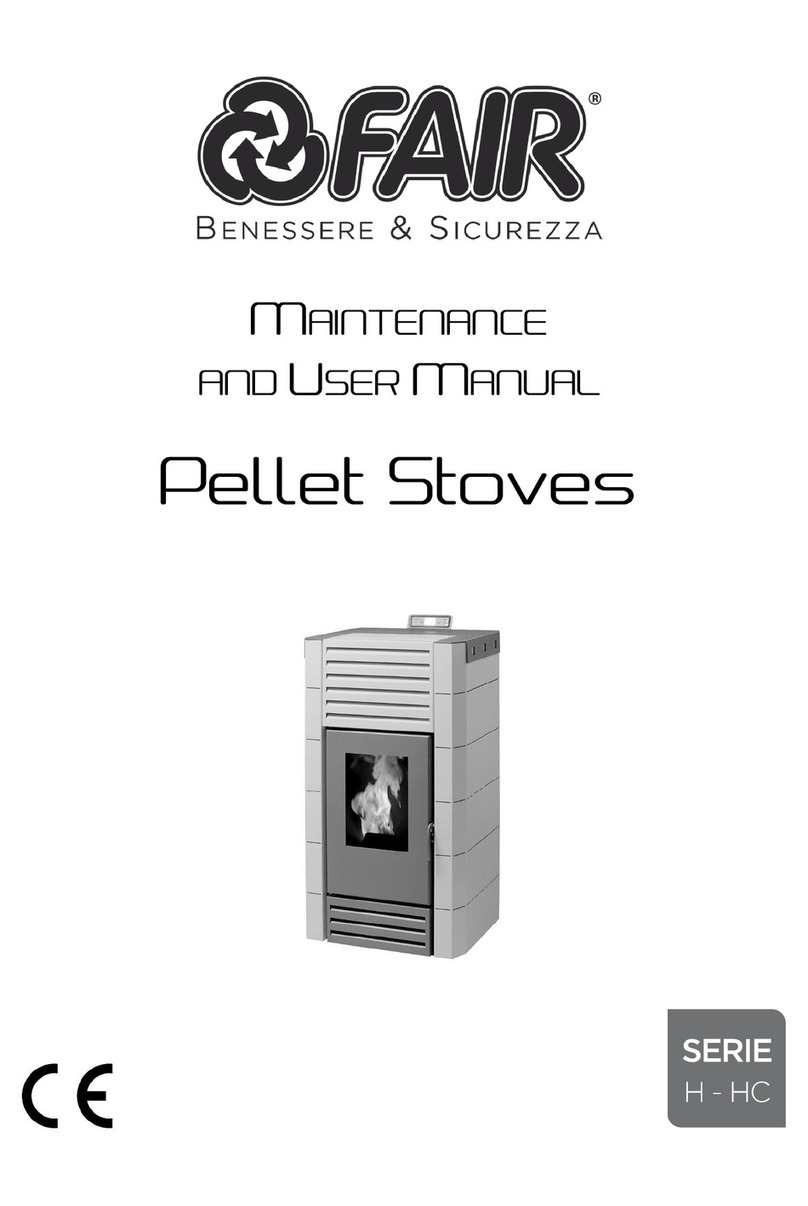

FAIR

FAIR H18 Maintenance and user manual

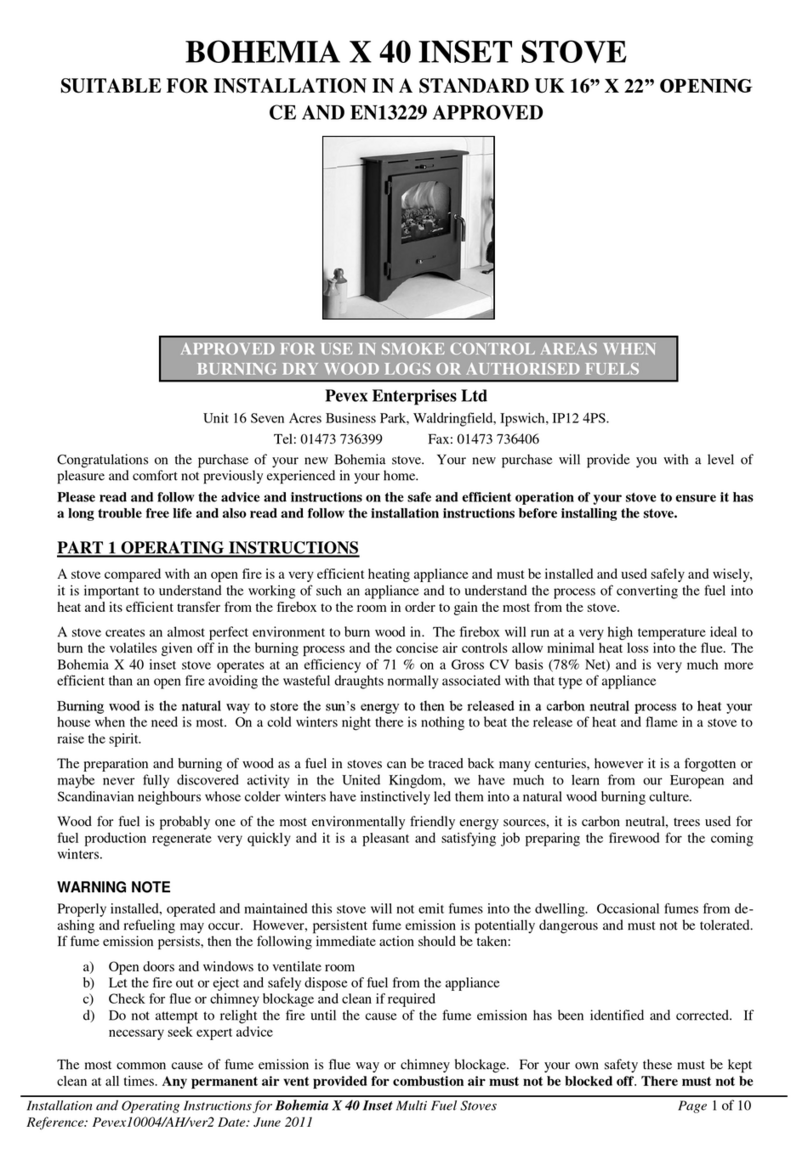

Pevex

Pevex BOHEMIA X 40 operating instructions

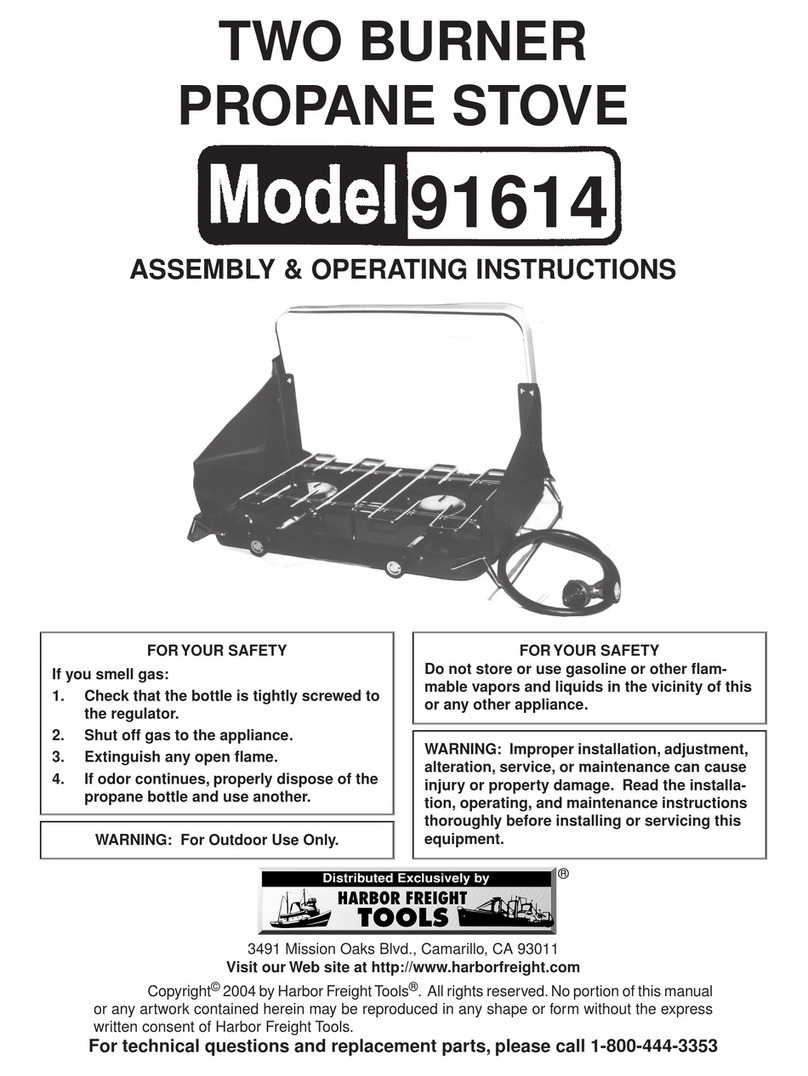

Harbor Freight Tools

Harbor Freight Tools 91614 Assembly & operating instructions

Olymberyl

Olymberyl HF-217 BabyGabrie user guide

Travis Industries

Travis Industries Avalon owner's manual