FireBird Bio-Tec User manual

Other FireBird Boiler manuals

FireBird

FireBird Enviromax User manual

FireBird

FireBird P90 User manual

FireBird

FireBird Heatpac 12-18kW User manual

FireBird

FireBird silverpac 15-20kW User manual

FireBird

FireBird Enviromax Popular C26 User manual

FireBird

FireBird Enviromax Popular C12 User manual

FireBird

FireBird OIL FIRED BOILERS Operating and maintenance manual

FireBird

FireBird Silver Series User manual

FireBird

FireBird Combi Range Guide

FireBird

FireBird Heatpac 12-18kW User manual

FireBird

FireBird Enviromax Popular C20 User manual

FireBird

FireBird Enviromax Popular C20 User manual

FireBird

FireBird System Range User guide

FireBird

FireBird Systempac 20-26kW User manual

FireBird

FireBird Systempac 12-20kW User manual

FireBird

FireBird BLUE FLAME ENVIROMAX User manual

FireBird

FireBird Enviromax Popular C20 User manual

FireBird

FireBird System 90 User manual

FireBird

FireBird Bio-Tec User manual

FireBird

FireBird Envirogreen Combipac HE User manual

Popular Boiler manuals by other brands

NTI

NTI C85-340 Installation and operation instructions

Vaillant

Vaillant ecoTEC plus VUI Installation and maintenance instructions

Viessmann

Viessmann VITOLADENS 300-T Service instructions

Immergas

Immergas VICTRIX PRO 35 2ErP user manual

Ariston

Ariston EuroCombi Type C A23 MFFI Servicing instructions

Bryant

Bryant 245 installation instructions

Sime

Sime Brava Slim Series user manual

Raypak

Raypak Raytherm H-181 specification

Slant/Fin

Slant/Fin VICTORY II VHS Series Installation and operating instructions

NOORI KOREA

NOORI KOREA longspeak X Instructions for use

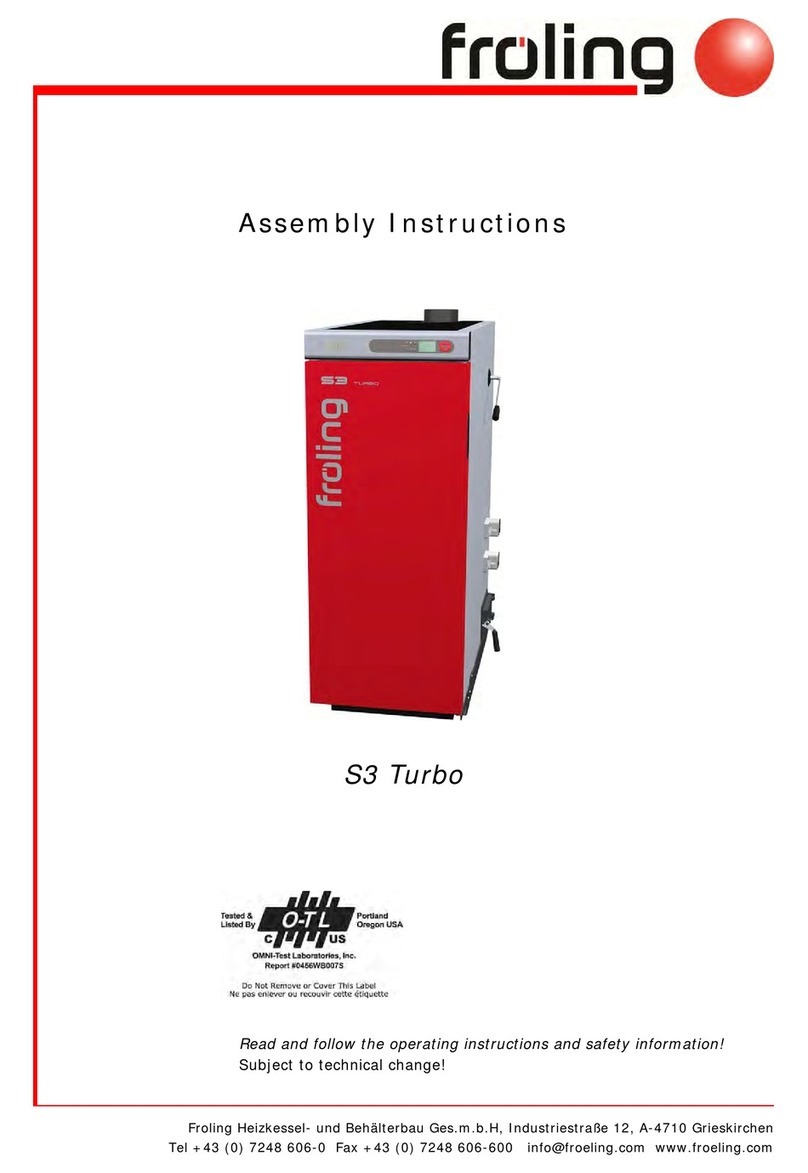

Fröling

Fröling S3 Turbo Assembly instructions

U.S. Boiler Company

U.S. Boiler Company SERIES 3 Installation, operating and service instructions

Viessmann

Viessmann VITODENS 333 Service instructions

HTW

HTW ESSENTIAL DIGITAL HTWTV30ESSDIG Owners and installation manual

Viessmann

Viessmann VITOLIGNO 300-C operating instructions

IDEAL

IDEAL Logic HEAT 12 user guide

UNMAK

UNMAK UKY/DUO Series user manual

Baxi

Baxi LUNA3COMFORT Installers and users instructions