fis The Solutionists FIBER FENCE SECURITY SYSTEM OMS-SPK Manual

Fiber Fence Splice Kit Instruction Guide

Fiber Instrument Sales Inc.

800-5000-FIS (347)

www.fiberinstrumentsales.com 1

SPLICING FIBER USING THE FIBER FENCE SPLICE KIT

CONTENTS OF THE SPLICE KIT

1. Cable Stripper: Used to remove the black cable jacket from the fiber cable; and a second plastic

coating on the glass fiber.

2. Simplex Cable: A connectorized length of simplex cable in a coil or spool used to repair broken

fiber.

3. Fiber Cleaver: Contains a blade to scratch the fiber and a mechanism to create a clean break in

the fiber.

4. Mechanical Splice: An alignment sleeve (Lab Splice) with a protective cover. The fiber ends are

inserted in this sleeve to create fiber alignment.

5. Alignment Sleeves (Lab Splices): A package of additional alignment sleeves for use with a

Mechanical Splice.

6. Quick Curing Adhesive: Used to permanently install the alignment sleeve in the protective

cover.

7. Visual Fault Locator (VFL) “Red Light”: Helps establish the alignment of the fiber in the

alignment sleeve and insure a good splice. The visual red light will also assist in finding the light

loss location in the fiber fence sensing cable.

8. Alcohol Wipes: Used to clean the fiber and connectors of oils and dirt whenever a fiber

connection is performed.

9. Splice Protection Kit: Protects the completed splice from harsh outside environments.

10. Instructions

11. Soft Case

1

2

3

4

5

5

6

7

8

9

10

0

11

0

Fiber Fence Splice Kit Instruction Guide

Fiber Instrument Sales Inc.

800-5000-FIS (347)

www.fiberinstrumentsales.com 2

INTRODUCTION

Permanently positioning 2 hair thin glass fibers so that a light signal will pass is called splicing.

Splicing is normally performed by skilled fiber optic technicians, but it is a skill that may be learned by a

steady hand, good eye sighted novice. All the tools and specific parts are provided in this kit to enable a

repair and/or extension of a Fiber Fence Security System. Carefully follow each procedure and a

successful protected splice will eliminate the need to call on an outside professional.

ATTENTION: Before performing your first splice at the break location, practice each critical step

several times on an indoor, well lighted table top.

SPLICING A BROKEN FIBER

Step 1 Install the batteries into the VFL and turn on the switch to establish that a red light it emitted.

Do not look directly at any light source or connector.

Step 2 Connect the VFL to the supplied connectorized end of the simplex cable. Observe the light

escaping from the other end.

Note: The VFL will help locate light loss up to 3km (1.8 miles). Once your system is installed, it can be

used to locate a zone break. As shown below, disconnect the connectors at the Zone Control Unit and

place the one connector into the VFL. Any light escaping the fiber will glow red showing the location of

a break or show the red light completing its journey to the connector on the other end of the fiber.

Fiber Fence Splice Kit Instruction Guide

Fiber Instrument Sales Inc.

800-5000-FIS (347)

www.fiberinstrumentsales.com 3

Step 3 Using the cable stripper, select the middle slot stripper (See graphic on stripper) and strip off 1

½” of cable jacket (black) off the end of the fiber that is not connectorized. Carefully remove ¼” lengths

at a time holding the stripper perpendicular to the fiber.

Practice stripping back the fiber jacket multiple times until the fiber does not break during the

procedure.

Notice that there is still a clear, plastic coating on the glass fiber.

Step 4 Using the 3rd and smallest slot on the stripper remove the coating in small segments exposing

1”of the shiny glass fiber. Notice the coating will stick to the stripper and should be brushed or blown

away. Use an alcohol wipe to carefully clean the fiber and the stripper.

Step 5 Now that the fiber is stripped and clean, it can be cleaved creating the perpendicular end of

the fiber.

Open the cover of the cleaver and move the slide all the way to the front. You will see that the blade

moves with the slide.

SHELL - BASE

SHELL - BASE

TOPALIGNM

ENT SLEEVE

MIDDLE SLOT

SMALLEST SLOT

Fiber Fence Splice Kit Instruction Guide

Fiber Instrument Sales Inc.

800-5000-FIS (347)

www.fiberinstrumentsales.com 4

Place the stripped fiber over the fiber groove on the left side of the cleaver. Align the end of the black

coating on the fiber with the 14mm mark on the scale allowing the stripped bare fiber to extend over

the opening in the cleaver and near the blade. The fiber must sit on both pads on either side of the

Blade and Slide.

Still holding the fiber, carefully close the cover of the cleaver and push the slide to the back. The slide is

now locked and will not release until the cover is raised. The fiber has been scored and may have

broken off cleanly on the scored line.

Carefully raise the cover and lift out the fiber. If the end of the fiber is still attached, gently push down

on the end of the bare fiber. If the fiber was properly scribed by the Blade, it will easily snap off.

Step 6 CAUTION: Disposing of broken fiber. This nearly invisible fiber will easily enter the skin

and cause inflammation. Adhering broken fiber to any sticky tape is a common safety measure. Discard

scraps away from children.

14mm

Fiber Fence Splice Kit Instruction Guide

Fiber Instrument Sales Inc.

800-5000-FIS (347)

www.fiberinstrumentsales.com 5

Step 7 A successfully cleaved fiber may be checked visually determining if the fiber end is shattered or

a clean cut. A magnifying glass will aid in this inspection. Or a second check method would be activating

the VFL and shining the cleaved end onto white paper. Strip and re-cleave the fiber until the desired

result is achieved.

Step 8 Now that the fiber is successfully cleaved, let us start to examine the alignment sleeve

(Mechanical Splice). The Mechanical Splice is in 3 parts: A gray top and base shell and an alignment

sleeve (Lab Splice). The sleeve will contain the ends of the fibers making the connection. The gray shells

will hold the sleeve and fibers in place after the connection is made.

Step 9 You are now going to insert the fiber end into the alignment sleeve. Clean the end of the fiber

with an alcohol wipe and let it dry a moment. Do not blow on it. Using both hands , with one hand

holding the fiber and one hand holding the sleeve, carefully insert the fiber into the center of the

alignment sleeve. Do not push hard or you will break the fiber. Insert the fiber about ½ way into the

splice sleeve. Turn on the VFL and confirm that it is emitting red light from the fiber end. The sleeve will

glow red.

Shattered fiber will be dim

or show scattered light.

Cleaved fiber will show a

concentrated light beam.

Fiber Fence Splice Kit Instruction Guide

Fiber Instrument Sales Inc.

800-5000-FIS (347)

www.fiberinstrumentsales.com 6

During this procedure, if the fiber breaks inside the alignment sleeve, remove the center core halves

from the cylinder. This allows total removal of the broken fiber before returning the halves to the

cylinder. If the broken fiber cannot be removed this way, use a new sleeve from the Lab Splice packet in

the kit. Color does not matter, but is used to identify the different fibers and sleeves. Steps 3

through 9 will need to be repeated for the broken fiber.

Step 10 The stripping and cleaving procedures will be repeated on a new cable. This newly prepared

fiber will mate in the other half of the alignment sleeve.

To continue this practice example, cut an 8-10” piece of cable off of the cable spool, carefully assuring

that the fiber does not break at the installed alignment sleeve. With the ability of the VFL you may now

prepare to strip and cleave the new cut on the spool as performed in the previous steps 3 -10.

Step 12 Upon preparing the new stripped and cleaved fiber cable, turn on the VFL and clean your

new fiber with an alcohol wipe. Insert the newly prepared fiber end into the opposite side of the

alignment sleeve.

When the two perpendicular cleaves meet each other most or all of the red light will disappear. You will

feel the two fibers touch at this time. Inspect the other end of the cable establishing the red light is

exiting.

You have completed your splice!

If the fiber breaks during this procedure repeat the previous steps 3-12.

Step 13 It is time to place the alignment sleeve into the protective covers. The shell base (larger half)

is where the alignment sleeve can be positioned. Take the top half of the housing, line up the tabs and

press the cover together snapping them into place. Put 1 or 2 drops of quick curing adhesive into the

holes in the bottom cover and let it dry. This will make a permanent splice.

Fiber Fence Splice Kit Instruction Guide

Fiber Instrument Sales Inc.

800-5000-FIS (347)

www.fiberinstrumentsales.com 7

Step 14 When outdoor protection of the splice is required it is necessary to install the Splice

Protection Kit.

IMPORTANT:The metal tube and rubber shrink tube must be threaded onto the cable before the

splice is finalized.

Final Installation: Slide the metal housing over the splice housing. It is a snug fit. Be careful to not bend

or break the fiber. Now slide the Shrink Tube over the metal tube evenly. Apply heat to the shrink tube

with a heat gun or at a distance from a flame to shrink the tube. Be careful to avoid damaging the splice

and cable with excessive heat. The mounting clamp allows you to permanently attach the protected

splice to the fence.

Step 15 Mounting the protected splice in a horizontal position avoiding water, direct sun or wind is

preferred.

Fiber Fence Splice Kit Instruction Guide

Fiber Instrument Sales Inc.

800-5000-FIS (347)

www.fiberinstrumentsales.com 8

TROUBLE SHOOTING AND SPLICING SOLUTIONS

Whenever possible, it is better to perform a splice with the assistance of the VFL. Once the splice

technique is mastered, a blind splice or one without using the VFL is common. Verification of a

successful splice may also be done by the acknowledgement of the through-put signal of the Zone

Control Unit.

Example 1

Used whenever there is slack in fiber cable that will allow a simple splice to repair a break.

Example 2

This shows fiber with no slack. A new piece of cable is introduced creating the need for two splices.

Fiber Fence Splice Kit Instruction Guide

Fiber Instrument Sales Inc.

800-5000-FIS (347)

www.fiberinstrumentsales.com 9

Example 3

Some applications call for duplex fiber (a lamp cord style cable) containing two fibers. A broken duplex

fiber will require two splices.

Example 4

Trouble shooting a system with a VFL may reveal the light loss location. Night time vs. day time light

provides a visual advantage.

Example 5

Often it is necessary to bury cable directly or in a conduit to gain access to the protected area. Splicing

fiber makes this possible. NOTE: The fiber used in the ground may be any 9/125 single mode fiber

spliced to the Fiber Fence Sensing Fiber.

Fiber Fence Splice Kit Instruction Guide

Fiber Instrument Sales Inc.

800-5000-FIS (347)

www.fiberinstrumentsales.com 10

Example 6

The Zone Control Unit contains 2 fiber connectors. If the connectors become damaged, a condition

which occurs when connections are made without cleaning the ends with alcohol wipes, a pigtail and

splice will replace the defective connector. A factory purchased pigtail is a fiber optic cable with an

installed connector.

Example 7

In trouble shooting a non-functioning system, continuity of a fiber optic system can be confirmed by

observing the red light at the far end. Disconnect the connectors from the Zone Control Unit and inject

red light using the VFL observing the far end.

Example 8

When cable is buried under a gate it does not detect a gate opening. The Opti-Mag Sensor may be

tapped into the fiber using two splice points causing an alarm when the gate is opened.

Fiber Fence Splice Kit Instruction Guide

Fiber Instrument Sales Inc.

800-5000-FIS (347)

www.fiberinstrumentsales.com 11

TWO SPLICE POINTS

Popular Protection Device manuals by other brands

SECO-LARM

SECO-LARM Enforcer VS-1V12BQ installation manual

ABB

ABB RELION 650 SERIES Communication protocol manual

Syntech

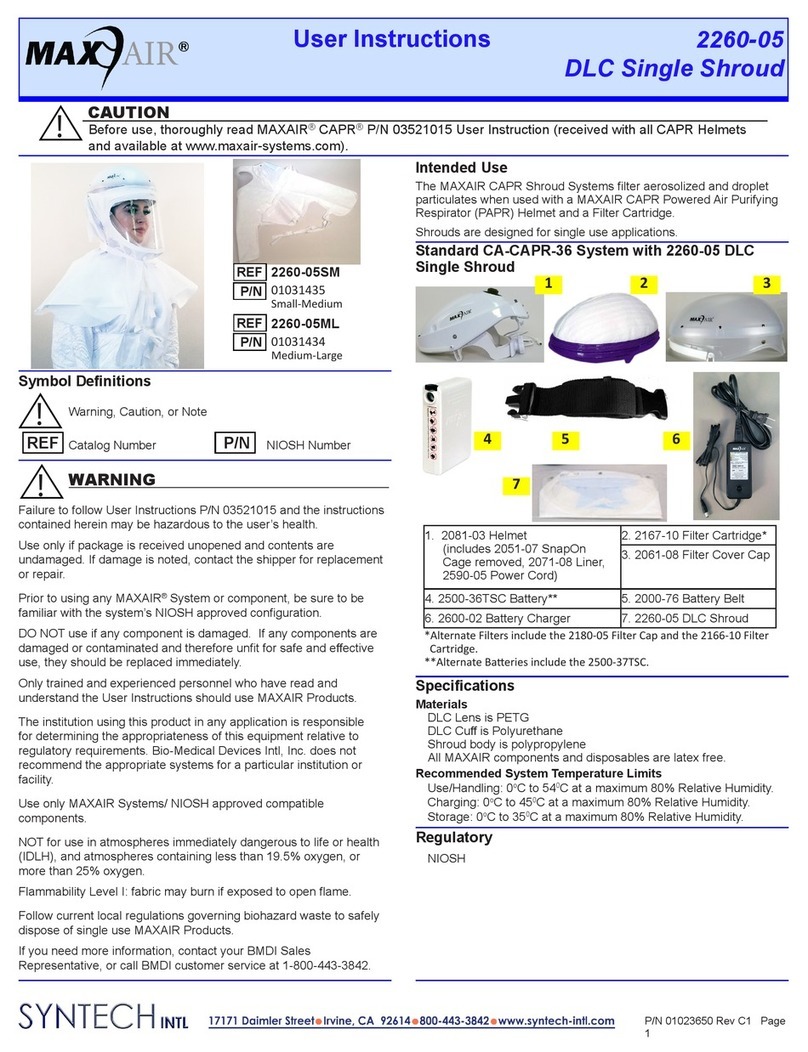

Syntech MAX-AIR 2260-05SM User instructions

Citadele

Citadele DIGIPASS 320 operating instructions

Phyn

Phyn Plus Installer's guide

scheider electric

scheider electric MiCOM P746 Technical manual