Fischione 1010 ION MILL User manual

MODEL 1010 ION MILL

Standard Magnification Version

INSTRUCTION MANUAL

E.A. Fischione Instruments, Inc.

9003 Corporate Circle

Export, PA 15632 USA

Phone (724)325-5444

FAX (724)325-5443

www.fischione.com

PN 009-0988 Rev.3

Contents

Model 1010 Ion Mill – Standard Magnification Version

Contents

SAFETY 1

BACKGROUND 2

Ion Milling Theory 2

Model 1010 Features 2

Ion Sources 3

Basic Procedure for Sample Preparation and Ion Milling 3

SYSTEM OVERVIEW 4

Sample Chamber 5

Vacuum System 6

Gas Flow 7

Water Flow 7

Sample Cooling Capability (Optional) 7

Endpoint Detection Capability (Optional) 7

Visual Monitoring 8

Control System and Software 8

Specifications 8

INSTALLATION AND SETUP 9

Warnings, Cautions, and Notes 9

Assessing initial condition 9

Unpacking and Inspecting 9

Accessories 10

Connections 11

Process gas 11

Exhaust gas 12

Water 12

Microscope Installation 12

Process Control Computer 13

Laser Installation (optional) 14

Power Connections 14

For US application 14

For non-US application 14

To change operating voltage 15

OPERATION 16

Basic Startup Procedure 16

Dewar Bakeout 17

Laser Calibration 18

Loading TEM Specimens 19

Specimen Cooling (optional) 20

Ion Milling 21

Insert specimen 22

Microscope 22

Endpoint determination (optional) 22

Set milling parameters 22

Set data logging options 24

Save recipe 24

Start milling 25

View Data 27

Basic Shutdown Procedure 29

MAINTENANCE 30

Contents

Model 1010 Ion Mill – Standard Magnification Version

Preventive Maintenance Schedule 30

Cleaning the Air Filters 30

Changing the Fuses 31

Opening the Enclosure 32

Enclosure removal 32

Window Cleaning 33

Front access door window 33

Bottom light window 34

Cleaning o-rings 36

Lamp Replacement 36

Ion Source Maintenance 38

Disconnect gas line 39

Remove ion source cartridge 39

Remove cathode 41

Remove anode and extractor 41

Inspect components 42

Clean components 43

Service ion source body components 43

Ultrasonically clean and inspect components 45

Reassemble ion sources 45

Verify electrical connections 45

Replace ion source 46

Attach gas and electrical connections 46

Check leaks 46

Start up ion source 47

Ion Source Alignment 47

Adjust source alignment 47

Verify alignment 48

Dewar Maintenance 48

Remove Dewar 48

Change Zeolite® desiccant 51

Install Dewar 52

Evacuate Dewar wall space 52

Chamber and Specimen Stage Cleaning 52

Stage maintenance 52

Ion source flange 56

Pirani gauge tube 58

Bottom plate 59

Mass Flow Controllers 60

Verify electronics 60

Evaluate flow 61

Replace mass flow controller 61

Leak Detection 62

High pressure 62

Vacuum 63

Turbomolecular Vacuum Pump 64

Reinstall Enclosure 64

Back Panel 64

TROUBLESHOOTING 65

Diagnosis chart 65

Error messages 67

Laser 68

SPARE PARTS AND CONSUMABLES 69

REFERENCES 71

Contents

Model 1010 Ion Mill – Standard Magnification Version

Safety

1 Model 1010 Ion Mill

Standard Magnification Version

Safety

The following hazards are associated with the Model 1010 Ion Mill.

ELECTRICAL HAZARD. High voltages can cause severe injury or death. Do not

connect the power cord until after the initial inspection and after making gas connections.

Do not attempt to operate the instrument with the cover removed.

Before disconnecting the power cord from the instrument, wait one minute to ensure that

any charged electronic component will discharge.

HAZARDOUS MATERIALS. Toxic, reactive, or radioactive materials can cause

severe injury or death. If hazardous materials will be inserted into the Model 1010 for

processing, the ion mill must be connected directly to an exhaust system capable of

accommodating the hazardous material. If radioactive materials will be milled, the

instrument must be enclosed in protective shielding.

LASER HAZARD. Laser beams can cause severe eye damage. Do not point the laser

beam into your eye or into any other person’s eye. The ion mill contains a 670 nm red

(visible) Class II laser.

COMPRESSED GAS. High-pressure gas stream can injure exposed skin or eyes. Point

tubing away from personnel while connecting or disconnecting gas cylinders.

MECHANICAL HAZARD. Moving parts can injure fingers and hands. Do not attempt

to operate the instrument with the cover open.

Background

2 Model 1010 Ion Mill

Standard Magnification Version

Background

For many of today's advanced materials, ion milling is an excellent preparation technique

for specimens that require TEM analysis. Electron microscopy needs samples that are

clean, representative of the bulk state, and free of physical or chemical artifacts. To

prepare them for microscopy, samples are first mechanically sectioned and ground and

then polished or milled to remove additional material.

Electropolishing requires that a sample material possess a certain level of electrical

conductivity.

Ion milling is effective for all materials, including those that are relatively nonconductive

such as semiconductors and insulators as well as those that are conductive (metallic or

semimetallic). Ion mills bombard the substrate surface with an energetic ion beam.

E.A. Fischione’s Model 1010 Ion Mill is a state-of-the-art, compact, tabletop precision

ion milling/polishing system that consistently produces high-quality TEM specimens

with large electron transparent areas.

Ion Milling Theory

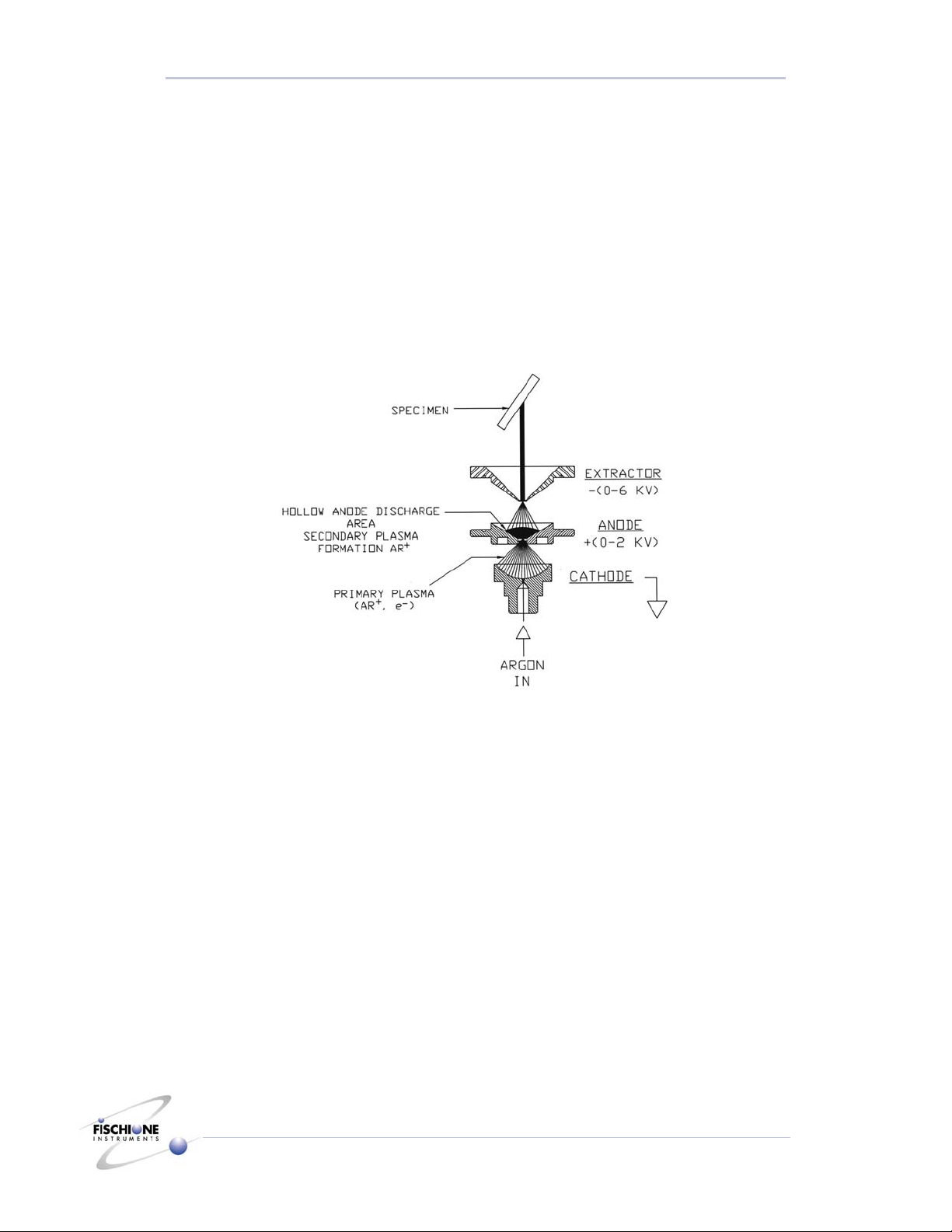

Ion milling uses an impinging incident HAD (Hollow Anode Discharge) ion to remove

(“sputter”) ions from the surface of a sample.

If an inert gas (for example, Ar or Ar+) is used for milling, sputtering is the result of

momentum transfer between the incident ion and the sample surface. If a reactive gas is

used, sputtering is enhanced by chemical reactivity.

Model 1010 Features

The Model 1010 is fully programmable, with features including two independently

adjustable Hollow Anode Discharge (HAD) ion sources which permit either rapid milling

or more gradual specimen polishing, automatic gas control, an oil-free vacuum system, a

milling angle range of 0 to 45°, specimen rotation or rocking, an optional liquid nitrogen

cooled specimen stage and optional automatic termination.

Sam

p

le Material

θ= 0 to 90o

Ar +

Sputtered

Sample

Material

Background

3 Model 1010 Ion Mill

Standard Magnification Version

The choice of single or dual ion source operation allows milling from either one or both

sides of the specimen. When using the Model 1010, total ion milling time is typically less

than two hours depending on the specimen material and its initial thickness.

Ion Sources

The Hollow Anode Discharge (HAD) ion sources operate over user-selectable ranges of

extractor voltage (0.5 kV to 6.0 kV) and current (3 mA to 8 mA), and are capable of

producing ion beam currents up to 400 microamps. To a first approximation, varying

voltage varies the average ion energy, while varying current varies the ion flux. The

milling rate for a given material generally increases as either parameter is increased. They

are fabricated from a combination of aluminum, brass, ceramics, polymers, and stainless

steel.

Hollow Anode Discharge (HAD) ion source.

Basic Procedure for Sample Preparation and Ion Milling

1. Mechanically section (cleave, saw) the sample.

2. Ultrasonically cut disks (3 mm diameter by <500 µm thick).

3. Rough grind (3 mm diameter by <75 µm thick).

4. Dimple grind (3 mm diameter by <10 µm center thickness).

5. Ion mill the top and bottom surfaces until they are electron transparent (3 mm

diameter by <100 nm thick).

6. Plasma clean.

System Overview

4 Model 1010 Ion Mill

Standard Magnification Version

System Overview

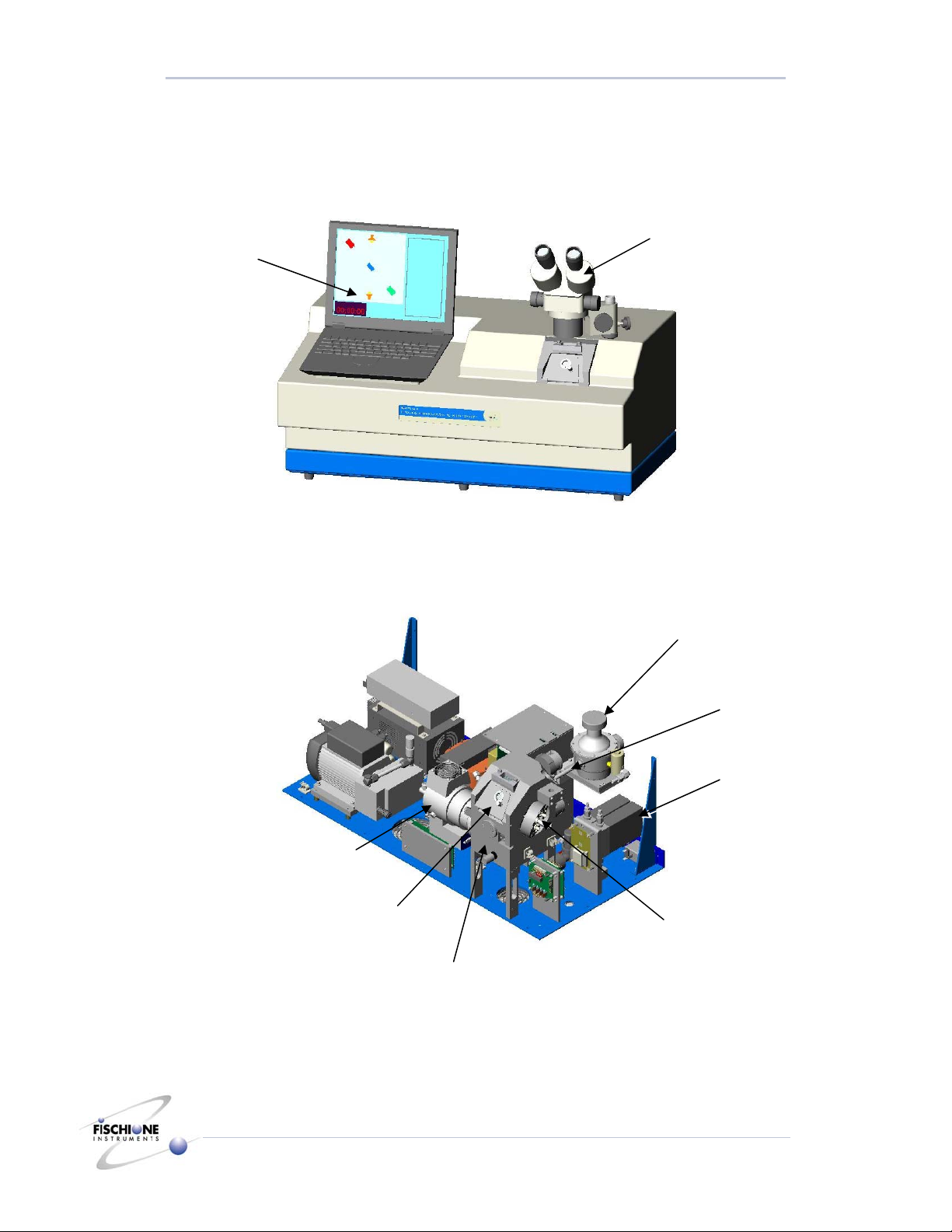

Turbomolecular pump (TMP)

Ion source

Mass flow

controller (MFC)

LN2

Dewar

Dewar rod

Microscope

Sample chamber

Process control

computer

Front access door

System Overview

5 Model 1010 Ion Mill

Standard Magnification Version

Sample Chamber

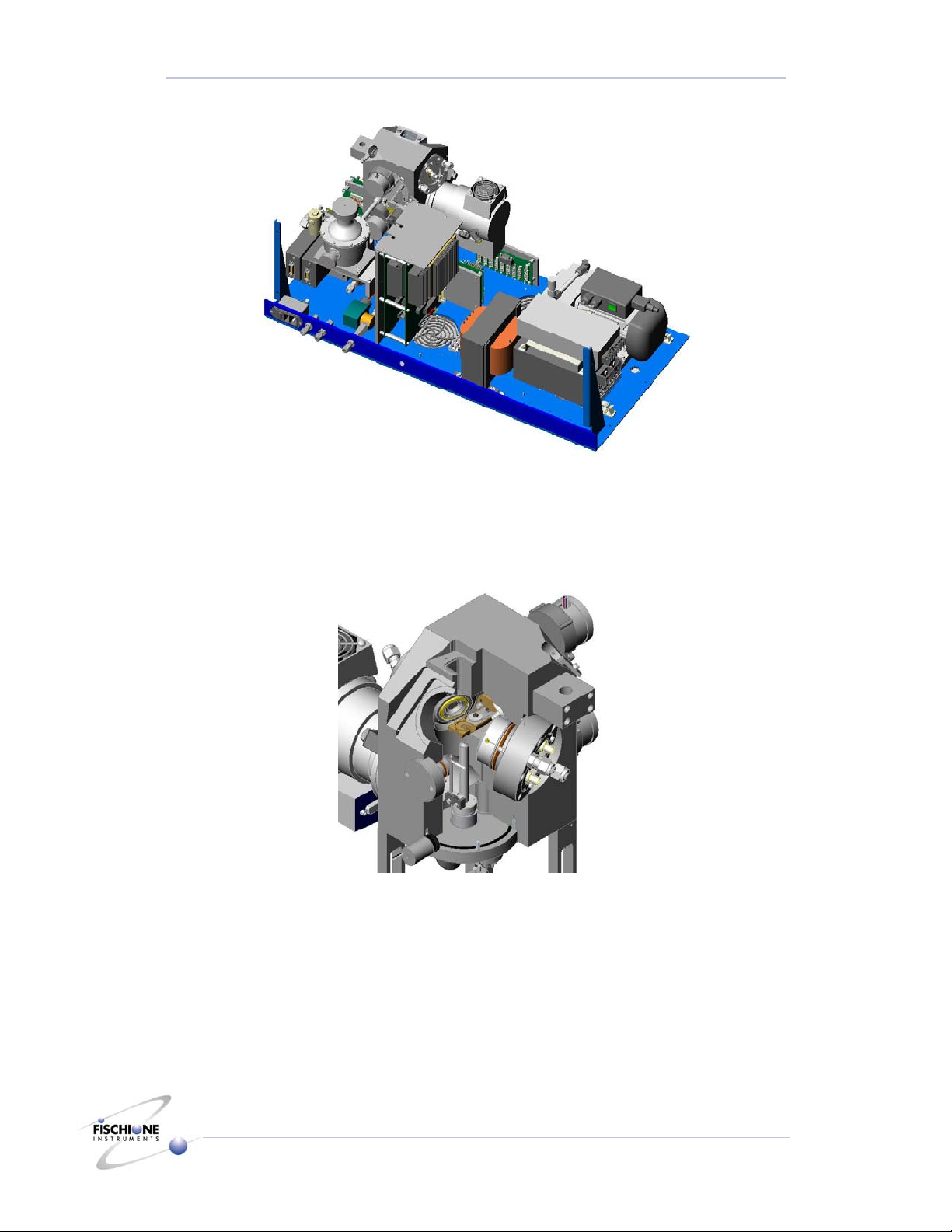

The sample chamber is fabricated from a single block of aluminum. The ion sources are

connected to the chamber via mounting and alignment flanges. Radial o-ring seals ensure

the vacuum integrity between the ion sources and the chamber.

Bottom: A vacuum flange mounted on the chamber bottom contains:

●The Pirani gauge for sensing vacuum.

●The bottom lamp assembly for observing the specimen using transmitted light.

●The detector for milling termination.

Rear: The rear of the chamber includes:

●The specimen stage rotator assembly.

●A series of electrical connections.

System Overview

6 Model 1010 Ion Mill

Standard Magnification Version

●The specimen rotation drive motor.

●The angle adjustment drive motor.

●The vacuum pumping port for the liquid nitrogen Dewar flask.

●The optical pick-up and encoder, which provides the milling angle indication.

Top: The top chamber surface includes:

●The top light assembly

Front: The front of the chamber includes:

•The electro-mechanical leak valve

•The chamber access door

Vacuum System

The Model 1010 is equipped with a 70 lps (minimum) turbomolecular vacuum pump. A

fan creates a constant air flow across the turbo pump cooling vanes to minimize the heat

associated with maintaining a vacuum under gas flow conditions. The Model 1010 also

includes an external rough pump. This is a diaphragm pump that provides backing

vacuum for the turbomolecular pump.

With no gas flow, ultimate chamber vacuum is 1 x 10-6 torr. Under normal milling

conditions, the system vacuum is between 1 x 10-4 and 2 x 10-5 torr. Total pump down

time is typically less than four minutes, although this time may vary based on ambient

temperature and relative humidity as well as the length of time that the chamber front

access door was open exposing the chamber to ambient conditions. Pump down times are

also increased following ion source cleaning or chamber maintenance.

The turbomolecular pump is directly mounted to the chamber by two bolts. An inlet

protection screen prevents debris from entering the pump and damaging the turbine

blades.

An electro-mechanical vent valve is installed directly onto the chamber and all venting is

controlled through the computer. Vacuum is sensed by a Pirani gauge and is continuously

indicated in the Ion Milling Program screen. In order to improve ion source performance,

argon flows through the ion sources during the venting process.

The specimen chamber vents through the normally closed solenoid valve located on the

front of the chamber. When the vacuum system is de-energized, both the diaphragm and

the turbomolecular pumps are turned off and voltage is applied to the vent valve. The

vent valve slowly bleeds ambient air into the chamber over approximately 20 seconds to

minimize stress on the rotary turbine blades in the turbo pump.

When liquid nitrogen is being used, venting will not occur until the specimen stage

temperature reaches +10°C, to prevent contamination of the specimen.

If the main instrument power switch is turned off while the vacuum system is energized,

the vacuum will be maintained, keeping the chamber sealed and free from ambient

contamination.

System Overview

7 Model 1010 Ion Mill

Standard Magnification Version

Gas Flow

The Model 1010 contains an internal, automatic gas control system. Process gas (usually

argon) is connected to the bulkhead fitting located on the rear of the instrument. The

purity of argon should be equal to or greater than 99.998% and supplied at a pressure of

10 psi (69 Mpa).

Two independently controlled mass flow controllers, located in a feedback control loop,

supply the appropriate amount of argon flow to the ion sources (between 0.4 sccm and

1.0 sccm). An internal pressure regulator is pre-set to provide the proper supply pressure

to the mass flow controllers.

The computer continuously monitors ion source performance and provides the

appropriate control signal to the flow controllers. The controllers are supplied with an

inlet voltage of +15 vdc and the control signal is 0-5 vdc proportional.

Water Flow

The high ion energies associated with the HAD (Hollow Anode Discharge) ion source

benefit from water cooling which both enhances performance and increases the time

interval between routine source maintenance. Cooling water circulates through the

alignment flange, which contains and is in thermal contact with the ion source cartridge.

Water enters the instrument though a bulkhead fitting on the rear panel. A solenoid valve

located within the instrument enclosure is normally closed. When the ion sources are

energized, the solenoid valve opens allowing water flow into the alignment flanges, thus

cooling the ion sources. A solenoid valve conserves water by only permitting flow when

required to cool an energized ion source.

The temperature of the inlet water is not critical but should be maintained between +5°C

and room temperature. Water flow of approximately 0.5 lpm is recommended. In the

unlikely event of the drain line becoming obstructed, the Model 1010 will not sense the

loss of flow. Therefore, periodically during operation, confirm that water is being drained

from the instrument.

Sample Cooling Capability (Optional)

A sample can be milled in the Model 1010 while actively being cooled to temperatures

approaching that of liquid nitrogen. The source of this cooling capability is an insulated

vessel (or “Dewar”) containing liquid nitrogen. A thermal path is provided by a

conduction rod passing through the Dewar to the rear of the sample stage. The maximum

temperature allowed during milling is selectable. It is selectable through the “Thermal

Safeguard” in the Ion Milling program.

To optimize the sample cooling capability, a vacuum must be maintained in the space

between the walls of the Dewar. Periodically the sample stage heater may need to be

activated to remove absorbed moisture and regenerate the Zeolite® desiccant. These

processes are controlled by the Dewar Bakeout program.

Endpoint Detection Capability (Optional)

The Model 1010 can be programmed to automatically de-energize the ion sources when

either a perforation in the sample is achieved or when the sample permits the

transmission of laser light. The detector circuitry is designed with a variable sensitivity

System Overview

8 Model 1010 Ion Mill

Standard Magnification Version

range. The scale is 1 to 10, with 1 being the most sensitive. These values are selectable in

the Ion Milling Program.

Note: Termination thresholds vary greatly based upon material and the desired

perforation size. Experimentation with varying parameters is necessary to obtain the

optimum termination point for different types of materials.

Visual Monitoring

The progress of an ion milling operation is monitored visually by using the standard

magnification stereo microscope. The magnification range with 10X eyepieces is 7 –

45X.

Control System and Software

All operations are controlled using four independent software programs.

Ion Milling Program Controls the milling operation. Allows the user to select milling parameters and

create the conditions necessary for manual or automatic operations.

Dewar Bakeout Program Controls the heating process for maintaining the Dewar insulation and Zeolite®

desiccant. Opens the vacuum connection, raises the temperature, and controls

the time at temperature

Laser Detector Calibration

Program

Calibrates the laser detector according to the transmissive properties of the

window protecting the laser sensor. Allows the user to choose the minimum

and maximum sensitivity values.

Data Logging Program Controls logging, retrieval, and display of milling parameters.

Specifications

Ion source type Hollow Anode Design

Ion source settings range Voltage: 0.5 – 6 kV, Current 3 – 8 mA

Specimen motion Full rotation (360o) or oscillation (0 to +/- 179o)

Milling rate Varies with material

Control platform PC compatible

Dimensions 33 in. wide by 19.5 in. deep by 26.5 in. high

Weight 115 lb (52 kg)

Power requirements 60 Watts

Water requirements Temperature of the inlet water is not critical but should be maintained between

+5°C and room temperature. Water flow should be approximately 0.5 lpm.

Gas requirements Argon equal to or greater than 99.998% and supplied at a pressure of 10 psi

(69 MPa)

Microscope capability 7-45X stereo zoom microscope

Turbomolecular vacuum

pump

70 lps (minimum). With no gas flow, ultimate chamber vacuum is 1 x 10-6 torr.

Under normal milling conditions, the system vacuum is between 1 x 10-4 and 2

x 10-5 torr

Installation and Setup

9 Model 1010 Ion Mill

Standard Magnification Version

Installation and Setup

Warnings, Cautions, and Notes

WARNING! LIFTING HAZARD. Do not try to lift the Model 1010 from the box

with only one person. The ion mill weighs about 115 pounds (52 kg).

WARNING! ELECTRICAL HAZARD. High voltages can cause severe injury or

death. Do not connect the power cord until after making gas and

water connections and after installing the microscope and computer.

Before disconnecting the power cord from the instrument, turn off

the instrument. Wait one minute to ensure that any charged

electronic component will discharge.

WARNING! COMPRESSED GAS HAZARD. High-pressure gas stream can

injure exposed skin or eyes. Point tubing away from personnel while

connecting or disconnecting gas cylinders.

CAUTION: Do not attempt to open the instrument enclosure while the

microscope or laser is installed. Remove the microscope, laser, and

post assembly before initiating service. Opening the Model 1010

while these components are installed could damage the microscope

and the enclosure.

CAUTION: Do not energize the ion sources unless Argon gas is supplied.

CAUTION: Do not energize the ion sources without a specimen in the specimen

holder. Failure to follow this caution will result in the ion beams

milling the outer components of the opposing ion source.

The Model 1010 is recommended for operation in an ambient temperature range of 12°C

to 40°C, and a relative humidity range of 10% to 70%.

The ion mill requires about 1 square meter of bench space.

Assessing initial condition

1. If the shipment has been received in good condition, proceed with unpacking.

2. If the shipment has been received with obvious damage, contact E.A. Fischione

Instruments before proceeding.

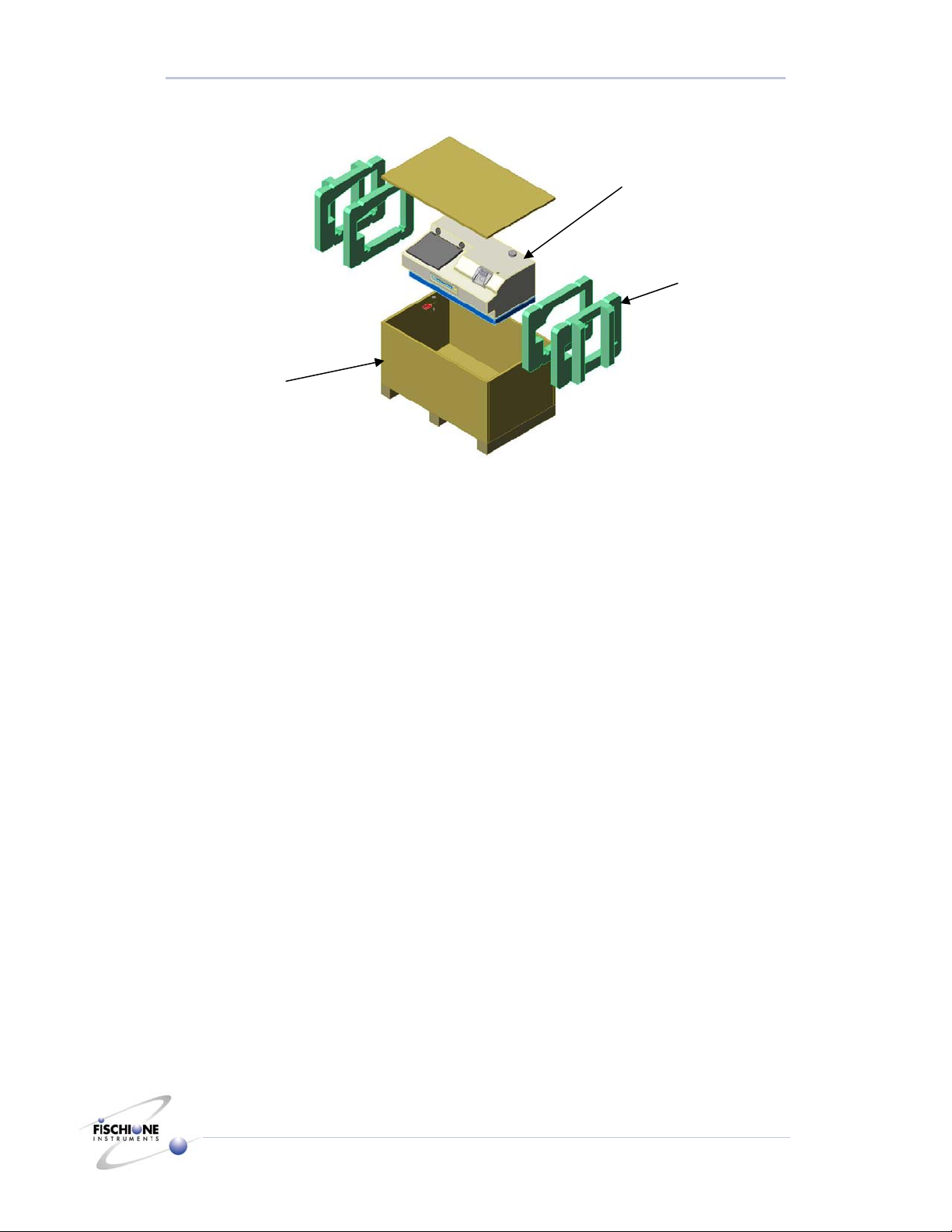

Unpacking and Inspecting

1. Remove the top of the crate.

2. Remove the accessory carton.

WARNING! LIFTING HAZARD. The ion mill weighs about 115 pounds. Use two

people to lift the ion mill.

3. Use two people to lift the Model 1010 from the base plate.

Installation and Setup

10 Model 1010 Ion Mill

Standard Magnification Version

4. Place the Model 1010 on a firm surface where it can be accessed from front and back.

5. Tilt the Model 1010 and remove the foam inserts.

6. Remove the Model 1010 from the plastic shipping bag.

Note: Save the shipping crate and packing materials in case the Model 1010 needs to

be returned to the factory for repair or maintenance.

7. Examine the outside of the Model 1010 for visible damage.

8. If there is evidence of damage, contact both the freight carrier and E.A. Fischione

Instruments before proceeding.

9. Place the Model 1010 on the surface where it will be operated.

Accessories

1. Open the box containing the accessories. This box includes:

•Microscope, microscope and spacer

•Specimen loading station and accessories

•Tool set

•Optional laser, Dewar cap, and / or exhaust kit if ordered

2. Inspect all components in this box for signs of damage.

3. If there is evidence of damage, contact both the freight carrier and E.A. Fischione

Instruments before proceeding.

Model 1010

Foam insert

Packing crate

Installation and Setup

11 Model 1010 Ion Mill

Standard Magnification Version

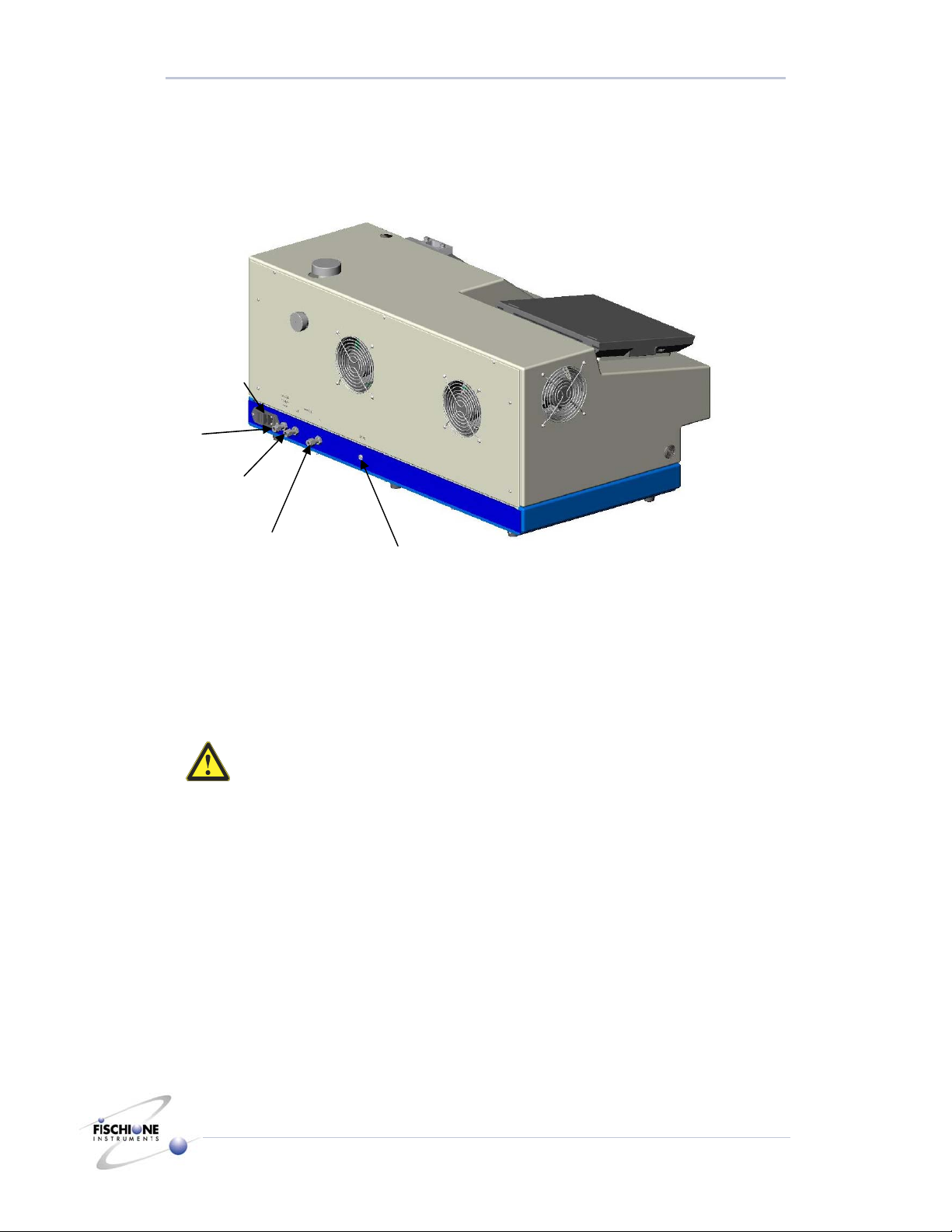

Connections

WARNING! ELECTRICAL HAZARD. High voltages can cause severe injury or

death. Do not connect the power cord until after making gas and

water connections and after installing the microscope and computer.

Process gas

Note: For plasma processing, E.A. Fischione Instruments recommends using argon with a

grade equal to or better than 99.998% purity.

WARNING! COMPRESSED GAS HAZARD. High-pressure gas stream can

injure exposed skin or eyes. Point tubing away from personnel while

connecting or disconnecting gas cylinders.

1. Position the process gas supply so that it is located within five feet of the ion mill.

2. Mount a suitable pressure regulator (Victor HPT 270 or equivalent) onto the process

gas supply.

3. Connect the ¼ in. tubing (supplied) between the pressure regulator on the process gas

supply and the gas inlet quick-connection on the rear of the Model 1010.

4. Tighten the connection 1¼ turns after finger tight.

5. Open both the cylinder and the process gas supply valves.

6. Adjust the cylinder pressure regulator to a pressure of 10 psi (69 MPa).

7. Close the process gas cylinder valve and observe the cylinder pressure regulator

gauge. The indicated pressure should remain constant for a minimum of five minutes.

This action ensures that the process gas connection is properly sealed.

8. Open the process gas cylinder valve.

Mains (power)

Gas

Water Out

Water In Laser

Installation and Setup

12 Model 1010 Ion Mill

Standard Magnification Version

Exhaust gas

If hazardous materials will be inserted into the Model 1010 for processing, the ion mill

must be connected directly to an exhaust system capable of accommodating the

hazardous material.

1. If the optional exhaust installation kit was purchased (P/N 009-0285) from E.A.

Fischione Instruments, it includes the fitting and length of tubing required for making

this connection.

Using gas tubing and fittings other than those specified is not recommended and will

void the warranty.

2. Remove the small plastic muffler from the pump exhaust.

3. Thread the connector into the pump exhaust.

4. Press the included Viton® tubing over the barb connector.

5. Connect the exhaust of the diaphragm pump to a suitable fume hood or equivalent

venting system.

Water

The Model 1010 Ion Mill requires a minimum water flow of 0.5 liters per minute (lpm).

Water temperature should be maintained at or below room temperature.

E.A. Fischione Instruments recommends using an in-line filtering system.

1. Connect ¼ in. tubing (not supplied) between the water inlet and outlet and the two

quick-connections on the rear of the Model 1010.

2. Tighten the connections 1¼ turns after finger tight.

Microscope Installation

1. Place the spacer over the end of the microscope post.

Installation and Setup

13 Model 1010 Ion Mill

Standard Magnification Version

2. Insert the microscope post through the cutout on top of the enclosure, into the

threaded hole

3. Rotate the microscope post clockwise until tight

4. Assemble the stereo microscope. Install the 10X eyepieces after removing their

individual lens caps, and then remove the lens cap on the microscope’s lens

5. Install the microscope onto its post, lowering its mount until it contacts the spacer

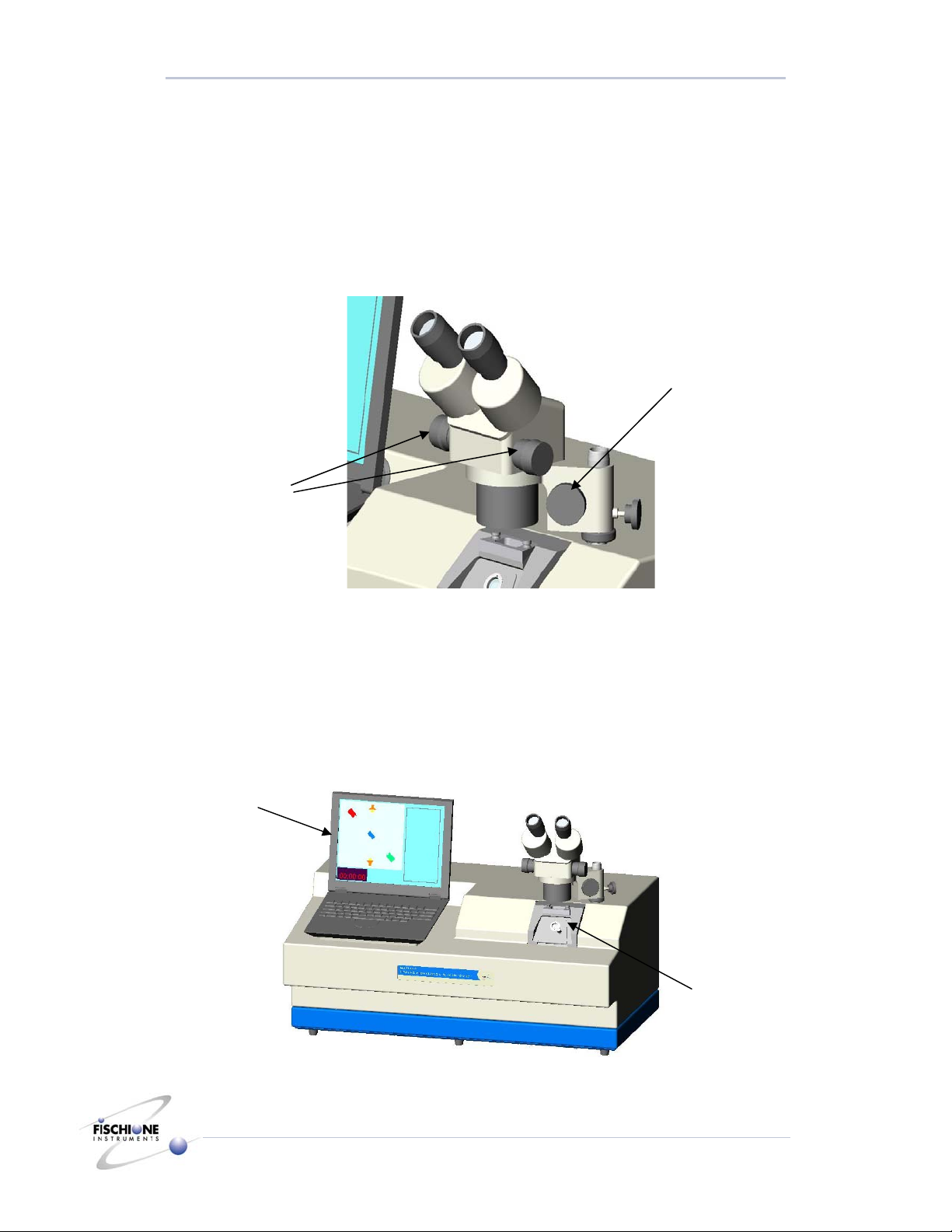

High magnification microscope installed

Process Control Computer

The process control computer is shipped already installed. The connections to the rear of

the computer should be checked before operation.

Coarse and fine

focus knobs

Hei

g

ht ad

j

ustment

Process control

computer

Sample chamber

Installation and Setup

14 Model 1010 Ion Mill

Standard Magnification Version

Laser Installation (optional)

Note: The laser will not be illuminated while conducting this procedure. The laser is

turned on during milling operations.

1. Lift and swing the microscope out of the way.

2. Connect the male connector of the laser cable to the receptacle on the rear of the

instrument.

3. Insert the laser into the receptacle above the top viewing window.

4. When not being used, insert the laser into the receptacle located on top of the

microscope post.

Power Connections

For US application

1. Verify that the operating voltage matches the requirements of the Model 1010.

The power entry module is equipped with two 6-amp fuses for 110 VAC operation

and two 3-amp fuses for 220VAC operation.

2. Connect the power cord between the power entry module and a suitable receptacle.

For non-US application

1. Attach a suitable connector to the bare wires of the power cord (supplied) using the

following color-coding:

Blue = Neutral (0V)

Brown = Phase (Line, AC)

Green and yellow striped = Ground (earth)

2. Verify that the operating voltage matches the requirements of the Model 1010.

110, 220, or 240 VAC can be used with the appropriate fuse.

3. Connect the power cord between the power entry module and a suitable receptacle.

Laser

Cable plug

Chamber insert

with viewin

g

window

Installation and Setup

15 Model 1010 Ion Mill

Standard Magnification Version

To change operating voltage

Model 1010 has been configured to operate with the operating voltage of the country of

the original purchase order. If the Model 1010 is to be used under other power conditions,

contact E.A. Fischione Instruments for more information. The instrument must be

reconfigured by a qualified service technician or returned to factory.

Operation

16 Model 1010 Ion Mill

Standard Magnification Version

Operation

CAUTION: Do not install any program onto the Model 1010 Ion Mill computer.

Installing other programs, including word processing and data

management programs, could interfere with the real-time control of

the ion mill and will void the warranty.

CAUTION: Never attempt to force or pry open the chamber insert. To insert a

specimen, the vacuum must be off and the stage temperature must

be at least 10°C.

Basic Startup Procedure

1. Verify that the ion mill is supplied with electricity, gas, and water.

2. Press the switch on the lower rear instrument panel (mains) to ON.

3. Press and hold the power button on the computer until the computer boots up.

A user identification dialog box will appear.

4. Click OK.

Note: “Click” means to use the touch pad on the computer to move the pointer

into position then press the left button of the touch pad.

The desktop screen will appear with icons for four Model 1010 programs:

•Dewar Bakeout

•Log Viewer

•Ion Mill

•Laser Calibration (if applicable)

Ion mill on/off

switch (on back)

Computer on/off

switch

Table of contents