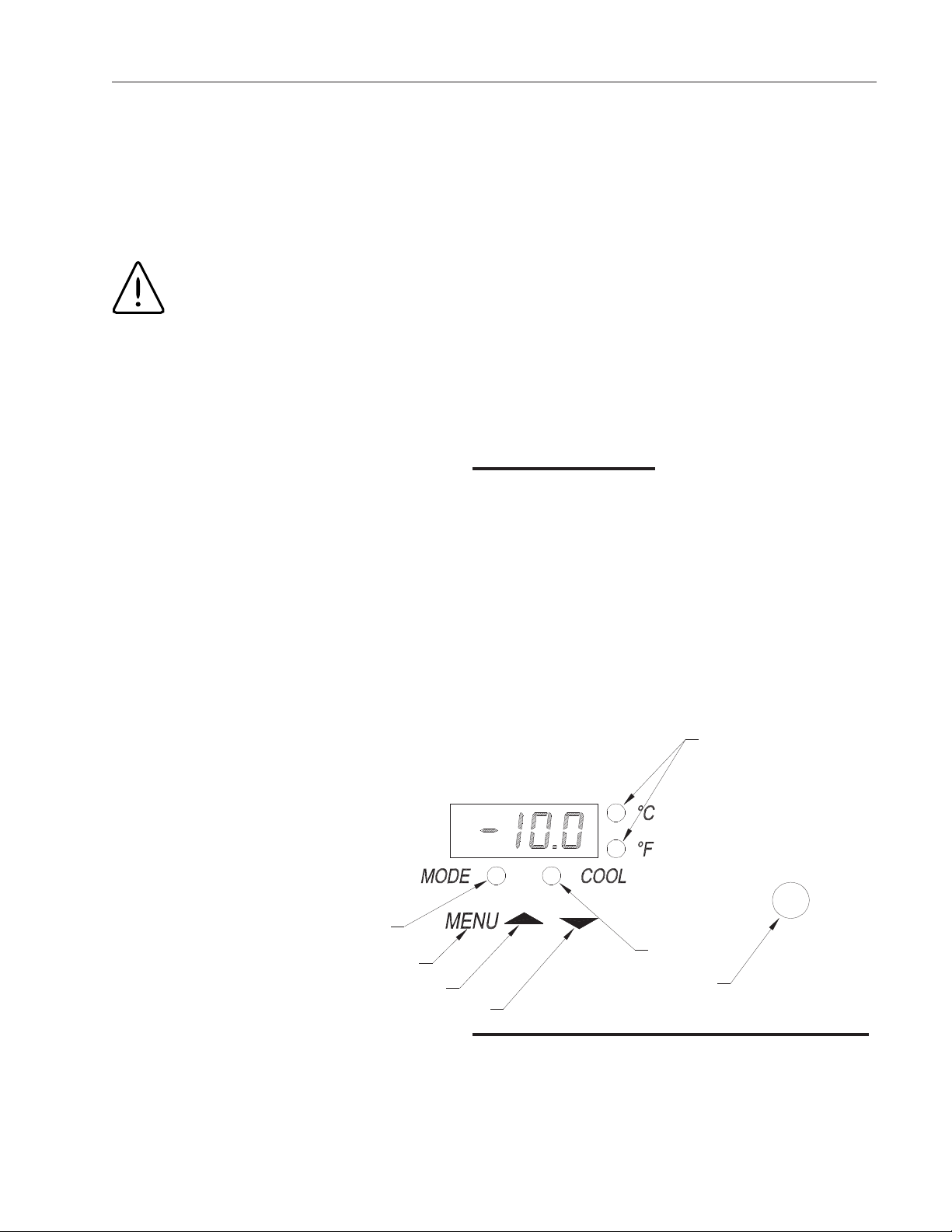

Shelves

Shipped inside each cabinet are 3 epoxy coated shelves

per door opening. Epoxy coated filler shelves are provid-

ed for units with more than one door. Shelf supports,

located in the plastic bag, are pushed into the side

pilasters, one in each corner, at the desired shelf height.

Replacement shelves are available individually. See

Replacement Parts for shelf part numbers. See Figure 2

for shelf installation.

Electrical Connection

Determine the total amount of current presently being

used by other apparatus connected to the circuit that will

be used by this freezer. It is critical that this added cur-

rent demand and other equipment on this circuit not

exceed the rating of the fuse or circuit breaker in use.

The frequency and nominal voltage requirements for the

unit are specified on the data plate, which is located on

the interiorʼs upper left side. Plug the unit only into a

power source that meets these requirements. Low line

voltage is often the cause of service complaints. With the

unit running, check that the line voltage is within ±10% of

that specified on the data plate.

The customer should have the wall receptacle and circuit

checked by a qualified electrician to verify the receptacle

is properly grounded and is connected to the proper

power supply. The following list gives the NE A

plug/receptacle configuration for the corresponding freez-

ers.

6

UNPACKING AND INS ALLA ION

Caution

If the unit was tilted in excess of 30

degrees, level it and do not apply

electrical power for a minimum of 12

hours.

Warning

Be sure that the power supply is the

same voltage that is specified on the

freezerʼs data plate.

Warning

For personal safety this unit must be

properly grounded. DO NOT under

any circumstance cut or remove the

ground prong from the power cord.

DO NOT use a plug adapter that elimi-

nates the ground prong.

Lab Freezers (115V)

Catalog Noʼs NE A Plug NE A Receptacle

13-986-142 5-20P 5-20R

13-986-144 5-20P 5-20R

Lab Freezers (230V)

Catalog Noʼs NE A Plug NE A Receptacle

13-986-143 L14-20 L14-20

13-986-147 L14-20 L14-20

Caution

Do not use an extension cord. Use of

an ungrounded cord or an overloaded

circuit VOIDS the compressor warran-

ty.

Figure 2

Caution

Catalog numbers ending in HK are

international 3-Wire systems and

should not be confused with 230V

domestic units which are 4-Wire sys-

tems. Consult a qualified electrician

before powering this unit.