Fitel S123M User manual

S123M ver.2 NEW Features

The S123M Series Hand-Held Ribbon Fiber Fusion Splic-

ers have been enhanced and updated to version 2. The

battery is automatically charged internally when con-

nected to AC mains power even during operation. The

new illumination lamp lights up a wide area around the

V-grooves and helps operation in low light environment.

The redesigned and strengthened heater simplies the

protection sleeve loading process.

Features and Applications

With their low prole design and light weight bodies the S123M series offer not only ribbon ber

splicing but also single ber splicing with outstanding mobility and extreme ease-of-use. In addi-

tion, the rugged body is designed to endure harsh operating conditions by improving shock/impact

resistance with rubber pads embedded on 4 corners of the splicer body. It achieves water resistance

compliant IPX2 and dust resistance compliant IP5X.

The fast splice time and protection sleeve shrink time offers a highly efcient work environment.

Large battery capacity makes it possible to perform 70 cycles of splicing and heating for S123M4

and 160 cycles for S123M8 and S123M12 with two batteries, while it offers SOC solution as well.

By combining portability, ease-of-use, improved speed and durability, the S123M series become

and excellent option for use in the conventional telecommunications industry.

S123M Series

ver.2

NEW

NEW

RoHS IP52 5 Axis

Shock

Hand-Held Ribbon Fiber Fusion Splicer

Hand-Held Ribbon Fiber Fusion Splicer

PRODUCT LINE UP

Model Application

S123M4-A Single to 4 ribbon fiber (with Soft Case)

S123M4-B Single to 4 ribbon fiber (with Hard Case)

S123M8 Single to 8 ribbon fiber

S123M12 Single to 12 ribbon fiber

S123M4

S123M8

S123M12

Under Tough Environment

S123M series passed criteria as below *3

• Internalbatterycharging

• Illuminationlamplights up a wide area around V-grooves

• IP-52-Ruggedandcompacthandhelddesignfor demanding envi-

ronmental conditions

• Fastsplice(15sec)atlowlossandFastheating(36sec)forribbon

ber*1

• Simpleoperationwith Fixed V-groove

• Splicer is compatible with the Seikoh Giken Splice-on-connector

(9mmbareberSOC)

• 70cycles(Splicing&heating)forS123M4and160cyclesforS123M8

andS123M12withtwobatteries*2

• AvailableforAllMETRO/LAN/FTTxbers includingultrabend-insen-

sitivebers(e.g. EZ-Bend)

• Easymaintenance- Toolless electrode replacement/mirror free align-

ment system

• Up-and-downberclampsystemallows automatic ber re-positioning.

• Easysoftwareupgradevia the Internet

• PC interface software to allow user manage splicing programs and

results

• Auto-startshrink sleeve oven feature

• ImprovedGUIto further enhance ease-of-use

• RoHScompliant

*1 By using semi-auto mode for splicing and pre-heating mode for heating.

*2 By using semi-auto mode for splicing and regular mode for heating.

Key Features

◙ FITEL Splicer SOC partners

DustResistance

IP5X rating dust proof *5

WaterResistance

IPX2 rating drip proof *4

DropResistance

76 cm drops from 5 different angles

*3 Above tests were performed at Furukawa Electric Labs, and do not guarantee that the machine will be undamaged

under these conditions.

*4 IPX2 rating drip proof means that the machine can be exposed to 3 mm/min drip from 4 different angles with 15°

tilt for 2.5 min each and still functions.

*5 IP5X rating dust proof means that the machine can be exposed to dust particles with a diameter of 0.1 to 25 μm

for 8 hours and still functions.

NEW

NEW

NEW

NEW

NEW

NEW

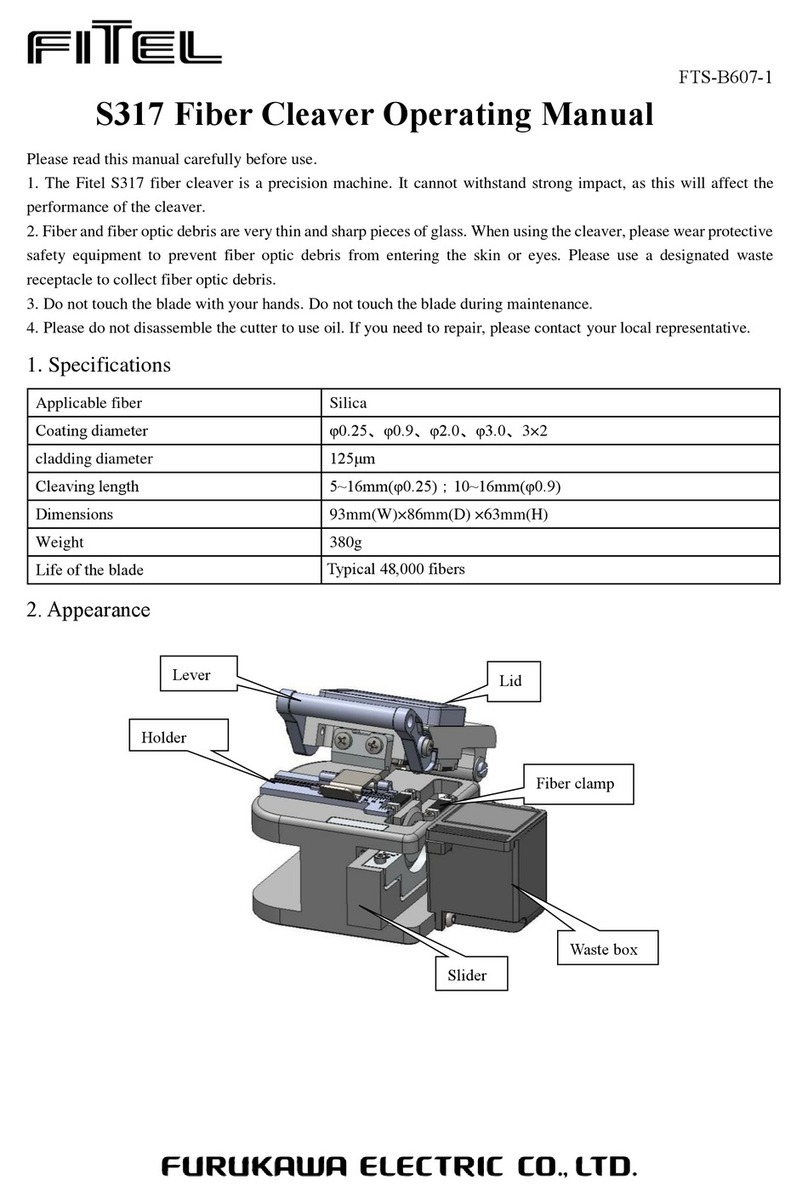

SPECIFICATIONS

Applicable Fibers SM (ITU-T G.652), MM (ITU-T G.651), DSF (ITU-T G.653),

NZD (ITU-T G.655), BIF/UBIF (Bend Insensitive Fiber ITU-T G.657)

Cladding Diameter 125μm

Coating Diameter Single fiber: 250 to 900μm, Ribbon fiber: 280 to 400μm (thickness)

Fibers Cleave Length 10 mm

Average Splice Loss SM: 0.05 dB, MM: 0.02 dB, DSF 0.08 dB, NZD 0.08 dB

Splice Time Single fiber: 15 seconds, Ribbon fiber: 15 seconds

Heat Time Ribbon fiber: 36 seconds*6 (S924: 40mm sleeve) (Pre-heat mode)

Splice Programs Max. 150

Heat Programs Max. 18

Automatic Heating Start Available

Applicable Sleeves 40/60 mm

Fiber Holding Fiber holder System

Tension Test 1.96 N

Return Loss of Splice 60 dB or more

Fiber Image Magnification 48X [S123M4], 28X [S123M8], 20X [S123M12]

Splice Memory Max.1500 [S123M4], Max.1000 [S123M8, S123M12]

Image Capture Capacity Last 100 images to be automatically captured + Up to 24 images to be stored permanently

Dimension

S123M4 127W×199D×81H mm (not including shock absorber)

159W×231D×104H mm (including shock absorber)

S123M8, S123M12 127W×199D×105H mm (not including shock absorber)

159W×231D×130H mm (including shock absorber)

Weight S123M4 1.4 kg (without battery), 1.6 kg (with battery)

S123M8, S123M12 1.6 kg (without battery), 2.0 kg (with two batteries)

Monitor 3.5” color LCD monitor

Data Output USB ver. 2.0 mini

Battery Capacity*7 Typical 70 splice/heat cycles with S943B battery (S123M4)

Typical 160 splice/heat cycles with two S943B batteries (S123M8, S123M12)

Wind Protection Max. wind velocity of 15 m/s.

Operating Temperature -10 to 50˚C (without excessive humidity)

Storage Temperature -40 to 60˚C (without excessive humidity)

Humidity 0 to 95% RH (non-condensing)

Power Source AC input 100 to 240 V (50/60 Hz), DC Input 11 to 17 V without any change of hardware

*6 The first heating after turning on the power can be longer than usual heating time.

*7 The number of the splicing and heating the machine can produce using a full charged battery at room temperature of 20˚C, semi-auto mode for splicing and regular mode

for heating. Depending on the condition of the battery and the operation environment, the number can vary.

*8 2nd battery can be purchased as an optional item.

STANDARD PACKAGE

Item P/N Quantity

S123M4-A

S123M4-B

S123M8 S123M12

S123M4 Main Body

S123-M4-A-0001

1 1 — —

S123M8 Main Body

S123-M8-A-0001

— — 1 —

S123M12 Main Body

S123-M12-A-0001

— — — 1

Soft Carrying Case

SCC-01

1 — — —

Hard Carrying Case HCC-01 — — 1 1

Hard Carrying Case HCC-02 — 1 — —

Battery Pack S943B 1 1 1*81*8

Spare Electrodes S969 1pair 1pair 1pair 1pair

AC Adapter for S123 and S958C

S976A 1 1 1 1

AC Cable Cord — 1111

Electrode Sharpener D5111 1 1 1 1

Cleaning Brush VGC-01 1 1 1 1

Tool Case TCC-01 1 1 1 1

Fiber Reformer (4)

S122-X-A-0007

1pair 1pair — —

Fiber Reformer (8/12)

S122-X-A-0008

— — 1pair 1pair

User Manual — 1111

Contact Us:

Furukawa Electric Co., Ltd.

Head Office:

2-3, Marunouchi 2-chome,

Chiyoda-ku, Tokyo,

100-8322, Japan

TEL: + 81 3 3286 3227

FAX: + 81 3 3286 3978

www.furukawa.co.jp

comsales@ho.furukawa.co.jp

Europe:

Furukawa Electric Europe, Ltd.

3rd Floor, Newcombe House

43-45 Notting Hill Gate,

London W11 3FE U.K.

TEL: + 44 20 7313 5320

FAX: + 44 20 7313 5310

www.furukawa.co.uk

splicers@furukawa.co.uk

North & South America:

OFS Fitel, LLC

2000 Northeast Expressway

Norcross, Georgia 30071, U.S.A

TOLL FREE: + 1 866 452 9516

TEL: + 1 678 783 1090

FAX: + 1 678 783 1093

www.ofsoptics.com

splicers@ofsoptics.com

China:

Furukawa Shanghai, Ltd.

Beijing Branch

1001A, Full Tower, No.09 Dong-

sanhuan ZhongRoad, Chaoyang

District, Beijing 100020, P.R. China

TEL: + 86 10 8591 0608

FAX: + 86 10 8591 0609

www.furukawa-sh.cn

South East Asia:

Furukawa Electric Singapore

Pte. Ltd.

10 Anson Road, #25-08

International Plaza, Singapore

079903

Tel: + 65 6328 9870

Fax: + 65 6224 2362

comms@furukawa.com.sg

* Furukawa Electric reserves the right to improve, enhance, or modify the features and specificactions of FITEL products without prior notification.

* Company and product names appearing in this catalogue are resisterd marks or trademarks of respective companies.

* This catalogue is printed using environmentally friendly paper and ink.

OPTIONAL COMPONENTS

Item P/N Quantity

Soft Carrying Case SCC-01 1

Battery Charger S958C 1

AC Adaptor for S958C S977A 1

Cooling Tray CTX-01 1

Angled Stand AGS-01 1

Working Belt WBT-01 1

USB Cable USB-01 1

Car Cigarette Cable CDC-01 1

Tripod Adaptor TPA-01 1

Fiber Holder

250 μm coating diameter fiber

500 μm coating diameter fiber *9

900 μm coating diameter fiber

2 Ribbon Fiber Holder

4 Ribbon Fiber Holder

6 Ribbon Fiber Holder

8 Ribbon Fiber Holder

10 Ribbon Fiber Holder

12 Ribbon Fiber Holder

12 Ribbon Fiber Holder Wide

Loose Tube Fiber (Left side)

Loose Tube Fiber (Right side)

S712S-250

S712S-500

S712S-900

S712A-002

S712A-004

S712A-006

S712A-008

S712A-010

S712A-012

S712A-012W

S712S-LT-L

S712S-LT-R

1pair

1pair

1pair

1pair

1pair

1pair

1pair

1pair

1pair

1pair

1

1

SOC Holders

<For Ferrule>

Seikoh Giken FC/SC connector (9 mm)

Seikoh Giken LC connector (9 mm)

<For Cordage>

Seikoh Giken Cordage (9 mm)

S712C-SGS9-L

S712C-SGL9-L

S712C-SGC9-R

1

1

1

Fiber Transporter

For S123M4 TRP-03 1

For S123M8, S123M12 TRP-04 1

Fiber Transporter Holders TRH-01 1

Smart Fuse

Software Interface for Machine SF-01 1

*9 Used for 400 to 500 μm coating diameter fiber.

JE-207 2D11 TR 200

AC2T-120068

Angled Stand in Action

-1 Working Belt in Action -2 Working Belt in Action

Fiber Transporter in Action

This logo mark indicates that the products and

services satisf y the standards of env ironmenta lly

friendly products of the Furukawa Electric Group.

eFriendly Logo Mark

Export Control Regulations

The products and/or technical information presented in this publication may be subject to the application of

the Foreign Exchange and Foreign Trade Act and other related laws and regulations in Japan.

In addition, the Export Administration Regulations (EAR) of the United States may be applicable.

In cases where exporting or reexporting the products and/or technical information presented in this

publication, customers are requested to follow the necessary procedures at their own responsibility and cost.

Please contact the Ministry of Economy, Trade and Industry of Japan or the Department of Commerce of the

United States for details about procedures.

Table of contents

Other Fitel Welding System manuals

Popular Welding System manuals by other brands

MOSA Weld

MOSA Weld MAGIC WELD 200 YDE Use and maintenance manual

Miller

Miller SRH-444 owner's manual

ESAB

ESAB Retrofit Aristo Mig 4004i WeldCloud instruction manual

Lincoln Electric

Lincoln Electric POWER WAVE 455TM IM583-A Operator's manual

INFRALAN

INFRALAN Splicer HS15 Series user manual

GYS

GYS Cutter Inverter 20 manual