• Under no circumstances should the housing of the welder be opened.

• Always protect your eyes and face with a welding mask.

• Wear appropriate protective clothing such as a welding apron and sleeved gloves

etc.

• Avoid exposing skin as UV rays are produced by the arc.

• ScreenotheworkplacetoprotectothersworkingnearbyfromUVrays.

• Welding materials with contaminated surfaces may generate toxic fumes. Ensure

the surface is clean before welding. Avoid operating on materials cleaned with

chlorinated solvents or near such solvents.

• Donotweldmetalequipmentthatholds/containsammablematerials,gasesor

liquid combustibles.

• Zinc-platedorgalvanizedmaterialshouldnotbeweldedasthefumescreatedare

highly toxic.

• Do not use the welder in damp or wet conditions.

• Do not use cables with worn insulation or loose connections.

• Disconnect from the power supply before replacing electrodes.

• Avoid direct contact with the welding circuit.

• Do not use the welder to defrost piping.

• Ensure the welder is placed on a level surface to prevent overturning.

• Provide adequate ventilation or a means for removal of the welding fumes

produced (forced circulation using a blower or fan).

Fumes

ToxicgasesaregivenoduringtheARCweldingprocess,whichmaycollectinthe

welding area if the ventilation is poor. Be alert at all times to the possibility of fume

build-up.Insmallorconnedareasuseafumeextractor.

Glare

The electric arc generated by the arc process gives direct heat and ultraviolet

radiation. It is essential that the eyes of the operator and bystanders are protected

from the glare during welding.

ALWAYS USE A FACESHIELD OR WELDING HELMET FITTED WITH THE

CORRECT GLASS FILTER.

Heat

It is desirable that welding gloves are worn whilst welding. They will protect the

handsfromultra-violetradiationanddirectheatofthearc.

Dress

In addition to face shield, welding gloves and overalls, other types of protective

clothing should be worn when welding. Additional protective clothing such as a

leather apron, sock protectors and a hat will all assist in reducing any injuries due to

heat, sparks and slag produced during welding.

OVERALLS should also be worn. They should be of type designed to be buttoned at

the wrists and the neck.

WELDER SAFETY WARNINGS

WARNING! When using mains-powered tools, basic safety precautions, including the

following, should always be followed to reduce risk of re, electric shock, personal injury

and material damage.

Readthewholemanualcarefullyandmakesureyouknowhowtoswitchthetooloinanemergency,before

operating the tool.

Save these instructions and other documents supplied with this tool for future reference.

The electric motor has been designed for 230V and 240V only. Always check that the power supply

corresponds to the voltage on the rating plate.

Note:Thesupplyof230Vand240VonOzitotoolsareinterchangeableforAustraliaandNewZealand.

If the supply cord is damaged, it must be replaced by an electrician or a power tool repairer in order to avoid

ahazard.

Using an Extension Lead

Always use an approved extension lead suitable for the power input of this tool. Before use, inspect the

extension lead for signs of damage, wear and ageing. Replace the extension lead if damaged or defective.

When using an extension lead on a reel, always unwind the lead completely. Use of an extension lead not

suitableforthepowerinputofthetoolorwhichisdamagedordefectivemayresultinariskofreandelectric

shock.

It is recommended that the extension lead is a maximum of 25m in length. Do Not use multiple extension

leads.

The power supply for this product should be protected by a residual current device (rated at 30mA or less). A

residual current device reduces the risk of electric shock.

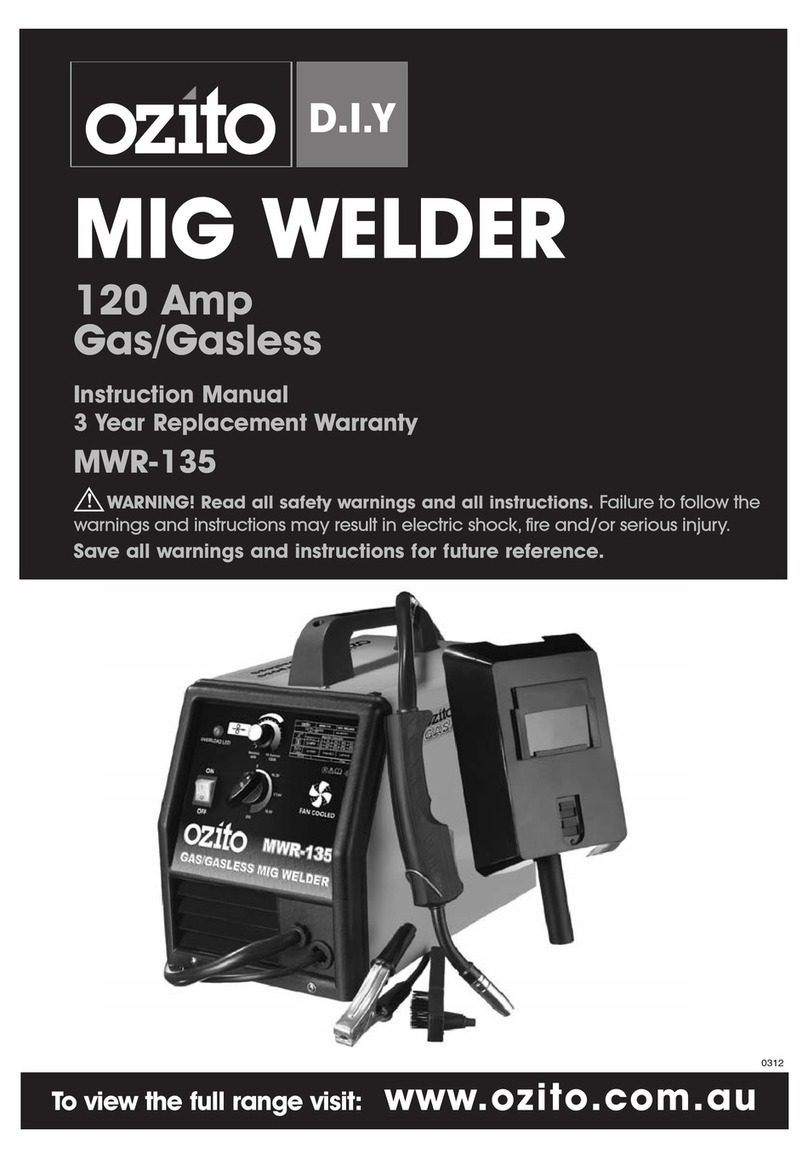

WARNING! Read all safety warnings and all instructions. Failure to follow the warnings and

instructionsmayresultinelectricshock,reand/orseriousinjury.

Save all warnings and instructions for future reference. The term “power tool” in the

warnings refers to your mains-operated (corded) power tool or battery-operated (cordless)

power tool.

1. Keep work areas clean. Cluttered work areas and benches can cause accidents.

2. Consider work area environment. Do not expose your equipment to high humidity or rain. Do not use

your equipment in damp or wet conditions. Keep the work area well lit. Do not use your tool where there

isariskofcausingreorexplosion,e.g.inthepresenceofammableliquidsandgases.

3. Keep children away. Do not allow children, visitors or animals to come near the work area or to touch

the equipment or accessories.

4. Dress appropriately. Wear the appropriate protective clothing. Wear a protective hair covering to keep

long hair out of the way.

5. Guard against electric shock. Prevent body contact with earthed or grounded surfaces. Electrical

safety can be further improved by using a high sensitivity (30 mA / 30 mS) residual current device (RCD).

6. Do not overreach. Keep proper footing and balance at all times.

7. Stay alert. Watch what you are doing. Use common sense. Do not operate the equipment when tired.

8. Secure work piece. If required, use clamps or a vice to hold the work piece.

9. Extension leads. Before use inspect the extension leads and replace if damaged. When using the

equipment outdoors, only use extension leads intended for outdoor use and marked accordingly.

10. Use appropriate equipment. Only use the equipment as outlined within this instruction manual. Do not

force the equipment to the job of heavier duty equipment. The equipment will do the job better and safer

at the rate for which it was intended. Do not force the equipment.

WARNING! The use of any accessory or attachment, or performance of any operation with this

equipment other than those recommended in this instruction manual may present a risk of personal

injury.

11. Check for damaged parts. Before use carefully check the equipment and power lead for damage.

Checkformisalignmentandseizureofmovingparts,breakageofparts,damagetoguardsandswitches

andanyotherconditionsthatmayaectitsoperation.Ensuretheequipmentwilloperateproperlyand

perform its intended function. Do not use the equipment if any parts are damaged or defective. Do

notusetheequipmentiftheswitchdoesnotturnitonando.Haveanydamagedordefectiveparts

repaired or replaced by an electrician or a power tool repairer. Never attempt any repairs yourself

12. Unplug the equipment. Unplug the equipment when it is not in use, before changing any parts,

accessories or attachments and before servicing.

13. Do not abuse the cord. Never carry the equipment by its cord or pull it to disconnect from the socket.

Keep the cord away from heat, oil and sharp edges.

14. Store equipment. When not in use, equipment should be stored in a dry, locked up or high place,out of

reach of children.

15. Maintain mains equipment with care. Keep the equipment clean and in good condition for better and

safer performance. Follow the instructions for maintenance and changing accessories. Keep handles

and switches dry, clean and free from oil and grease.

16. Have your tool repaired by an electrician or a power tool repairer. This power tool complies with

relevantsafetyrequirements.Toavoiddanger,electricalequipmentmustonlyberepairedbyqualied

technicians using original spare parts; otherwise this may result in considerable danger to the user.

17. Users.Thisequipmentisnotintendedforusebyyoungchildrenorinrmedpersonswithoutsupervision.

Young children should be supervised to ensure that they do not play with this equipment.

18. Replacement of the supply cord. If the supply cord is damaged, it must be replaced by an electrician

orapowertoolrepairerinordertoavoidahazard.

GENERAL POWER TOOL SAFETY WARNINGS

ELECTRICAL SAFETY