FITOP M Series User manual

M-series OPERATIONS MANUAL

WIRE ROPE HOIST INSTRUCTION MANUAL

CONTENT

Ⅰ.FOREWARD

1-1 Dear Customers

1-2 Customers’ responsibility

1-3 Disclaimer

1

1

1

Ⅱ.NOTES BEFORE INSTALLATION

2-1 General Examination

2-2 Insulation

2-3 Rail

2-4 Notes of installation on power feeding system

2-5 Distribution of the control panel (electricals)

2-6 Voltage

2

2

2

2

2

3

Ⅲ.INSTALLATION OF HOIST

3-1 Mono-rail

3-2 Double-rail

3-3 Lifting hoist (Cargo elevator)

3

3

3

Ⅳ.TESTING

4-1 Confirmation before running

4-2 Confirmation before un-loading running

4-3 Confirmation before full-loading running

4-4 Confirmation after testing your hoist

4-5 Confirmation of safety device

4

4

4

4

4

Ⅴ.IMPROPER OPERATIONS

5-1 Correct Operation

5-2 Prohibitions

6

6

Ⅵ.MAINTENANCE

6-1 Notes for maintenance

6-2 Limitations of Use

6-3 Items examined daily

6-4 Items examined monthly

6-5 Items examined quarterly

6-6 Items examined yearly

6-7 Structure & Mechanism

6-8 Electrical device

10

10

13

13

13

14

15

17

Ⅶ.TROUBLESHOOTING AND MAINTENANCE

7-1 Notes of Maintenance

7-2 Mechanism

18

18

I.FOREWARD

1-1. Dear Customers:

Now you are the owner of “FiTOP” M-series Electric Wire Rope Hoist, and we are confident

that it will meet your expectation. The product is a best tool of automation for lifting and

carrying purposes. It is produced under careful design, manufacturing, and strict quality

assurance. Before leaving the factory, every set is tested to meet CNS regulation for

domestic and overseas markets. It is surely safe!

However, in order to perform it effectively, this operations manual is compiled by FiTOP to

let you fully understand the operations and maintenance. Please read it carefully before

operation, and the manual will serve you with clear instructions since your growth in

business and prosperities are our greatest achievements!

1-2. Customers’ responsibility

For safety and durability, please follow the contents which include daily and periodic

guidance for maintenance. You are required to follow the advices as the following:

1-2-1. Please follow the manual to operate the equipment

1-2-2. Please follow the contents as your daily and periodic maintenance. If you need to

solve technical or maintenance issues, kindly let your regional distributor be

acknowledged

1-2-3. Please use the original spares provided by FiTOP

1-2-4. If the hoist has problem, please inform your regional distributors to deal with it at

the same time

1-2-5. If you have sold out the equipment to other end-users, please let your regional

distributor be advised about it

1-2-6. Kindly obey the official regulations with the requirements specified by your central

and state governments

1-2-7. For safety, please educate your employees before they start using the equipment

and hire a qualified person as your staff who has obtained a certified permission in

operating above 3-ton-capacity hoist

1-3. Disclaimer

If the following behaviours caused either direct or indirect damage, FiTOP will NOT take any

responsibility:

1-3-1. Wrong operations and incorrect use of the hoist

1-3-2. Change and adjust from the original design on the hoist

1-3-3. If NOT using the spares or grease provided by FiTOP

1-3-4. Kindly stop using the equipment if NOT following the instructions on the daily and

regular guidance for maintenance

2

II.NOTES BEFORE INSTALLATION

2-1. General Inspection

2-1-1. Inspect IF the specifications are in compliance with the requirements

2-1-2. Inspect IF the hoist is damaged during the process of carrying

2-1-3. Inspect IF all parts on the following are enclosed:

(1) Button switch

(2) Fuse

(3) Structural drawing

(4) Circuit diagram

(5) Wire rope

(6) Other specific demands

2-2. Insulation

Inspect the resistance of insulation system: Using 500V high-impedance metre to measure

if the resistance of each individual part is above 1ΜΩ

2-3. Rail

2-3-1. A device in condition of rest should be set on the rail

2-3-2. The gap between each rail connection should NOT exceed 0.8 cm

2-3-3. The installation of rail should be complied with government regulations and be sure

to keep the level at transversal and horizontal directions to avoid instability during

operations

2-4. Notes of installation on power feeding system

Type of safety rail:

(1) The fixing clamp should be in the same line and level

(2) The welding of towing-arm should be formed as squared-iron stick

(3) Fix-squared- bar should be in parallel with the surface of safety rail, and the

distance is 70+10 mm

2-5. Distribution of the control panel (electricals):

For standard specifications, please refer to circuit diagram: Fig. 1, 2, 3, 4, and 5; for others,

kindly refer to the circuit diagram inside the box of control panel.

2-6 Voltage:

If the voltage is less than 5%, the motor will not reach the operating voltage; thus, before

using the hoist, kindly check if the voltage is normal or not.

III.INSTALLATION OF HOIST

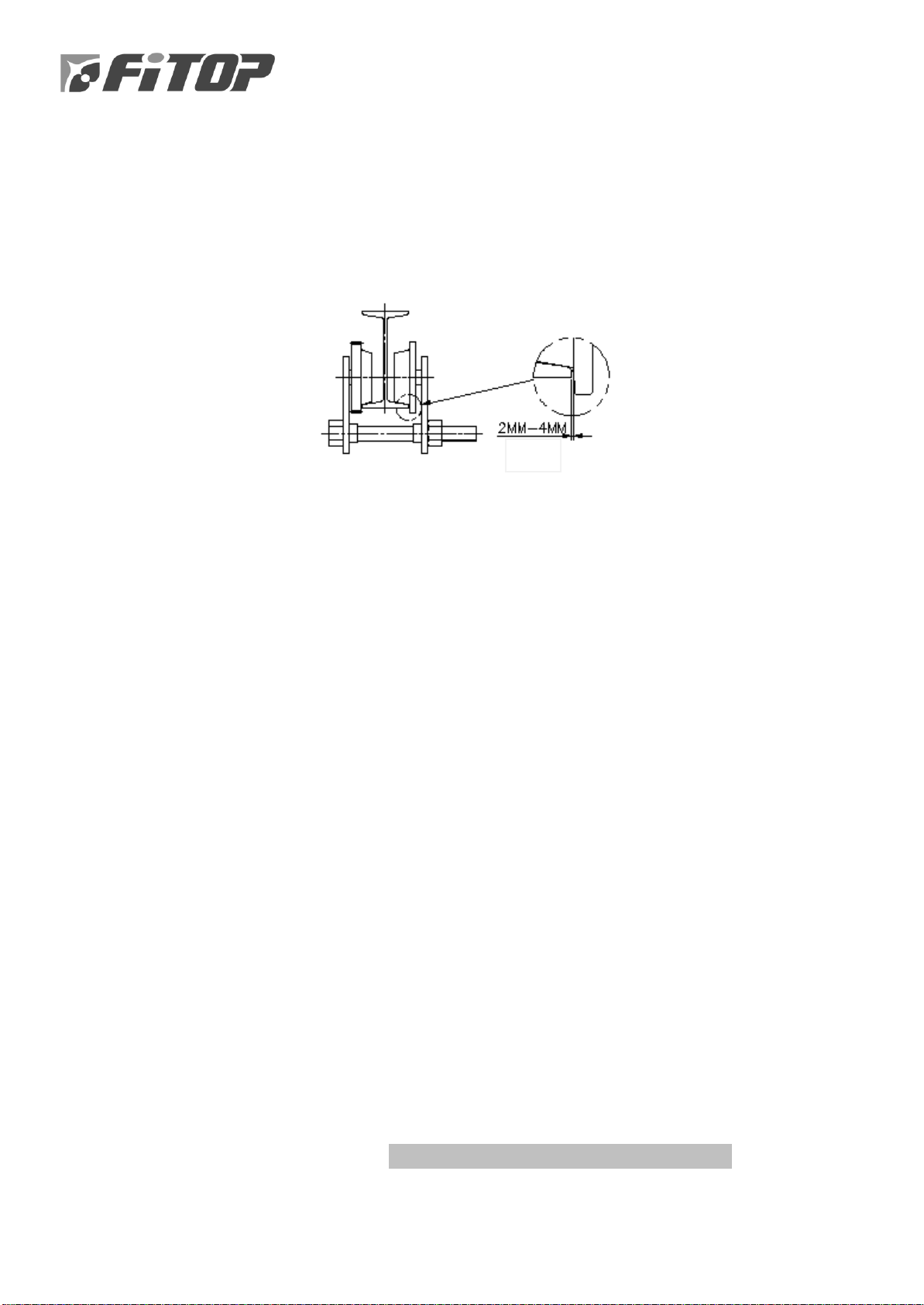

3-1. Mono-rail

3-1-1. The width of I / H-beam girder should be >= (the base width of trolley

wheel + 2 to 4 mm gap) shown as the following:

3-1-2. When one end of girder is opened, the hoist and trolley could be combined and

installed from the opening end

3-1-3. When both ends of girder are closed, or the end of girder cannot be opened to

cause hoist to fail entering-in, please release the trolley plates and install it.

3-2. Double-rail

After hoist and trolley are combined, please set it on the traversing rail directly.

REMARK: There is an eccentricity self-regulation device for the axle of double-rail hoist,

so the movement of the trolley wheel can be balanced on the rail. When main hoist has

no loading, the four trolley wheels may not touch to the rail simultaneously; however,

this circumstance will not be happened after loading.

3-3. Lifting hoist (Cargo elevator)

Lifting cabin should be elevated to the top-end. Kindly move the hoist in order to keep

the centre of gravity of hook is the same as the vertical line of lifting box; then, please fix

the hoist horizontally and correctly.

IV.TESTING

4-1. Confirmation before running

4-1-1. The auxiliary supporting line of the control pendent should be tied firmly and

correctly, to avoid the cable being deformed under force

4-1-2. The position of control pendent should be at 1 metre distance from the floor

4-1-3 A stable voltage is normally (R, S, T,) 3-phase averaged range: 5%~+5%; if the voltage

is insufficient, will cause the motor burn up

Gap

4

4-2. Confirmation before un-load running

4-2-1. Testing the control pendent:

Please press the button “UP” first when testing; do NOT press the button “DOWN”

first. After pressing “UP”, the hook will be lifted up, indicating that it has no

problem; if the hook moves downward, the power connection of hoist is NOT

correct (error phase sequence). As a result, please change two wires of R, S, T,

alternatively, and repeat the above steps until this problem has been solved. If the

hoist was used with a wrong wire-connection (error phase sequence), the limit

switch will be INVALID and it may cause the wire-rope BROKEN or severe damage

of the hoist accidents; therefore, be careful and pay attention to this condition

4-2-2. Press the button switch to keep the hook lifting up:

When hook reaches the position of UP LIMIT, the limit-switch will start to stop the

hook automatically; please press “DOWN” to make sure if the hook is moved

downward

4-2-3. To let the hoist load 100 kg-200 kg loading and move full-distance up and down,

please check the following when moving:

(1) Is the rail proper?

(2) Is any interference for cable?

(3) Is the space enough between the hook and building?

(4) Could the hoist touch the building?

4-3. Confirmation before full-load running

4-3-1. First, please test its lifting up and down movements, and check if the sliding is

appropriate or not after braking?

4-3-2. Is it stable or not? When the hoist is moving?

4-3-3. When hoist is moving, test the voltage of trolley. The voltage should NOT exceed 7%

of the voltage of motor that shows on the nameplate of motor

4-4. Confirmation after testing your hoist

4-4-1. After testing the hoist, please check the rope press block on the drum, if it is

loosened or not?

4-4-2. Check the traversing and runway rail, if they are loosened or not?

4-4-3. Check the temperature of motors, if they are normal or not?

4-5. Confirmation of safety device

4-5-1. Upper- and lower-limit-switch:

Use the spiral limit-switch to ensure that the wire rope would stop when it reaches

upper- and lower-limit during operation

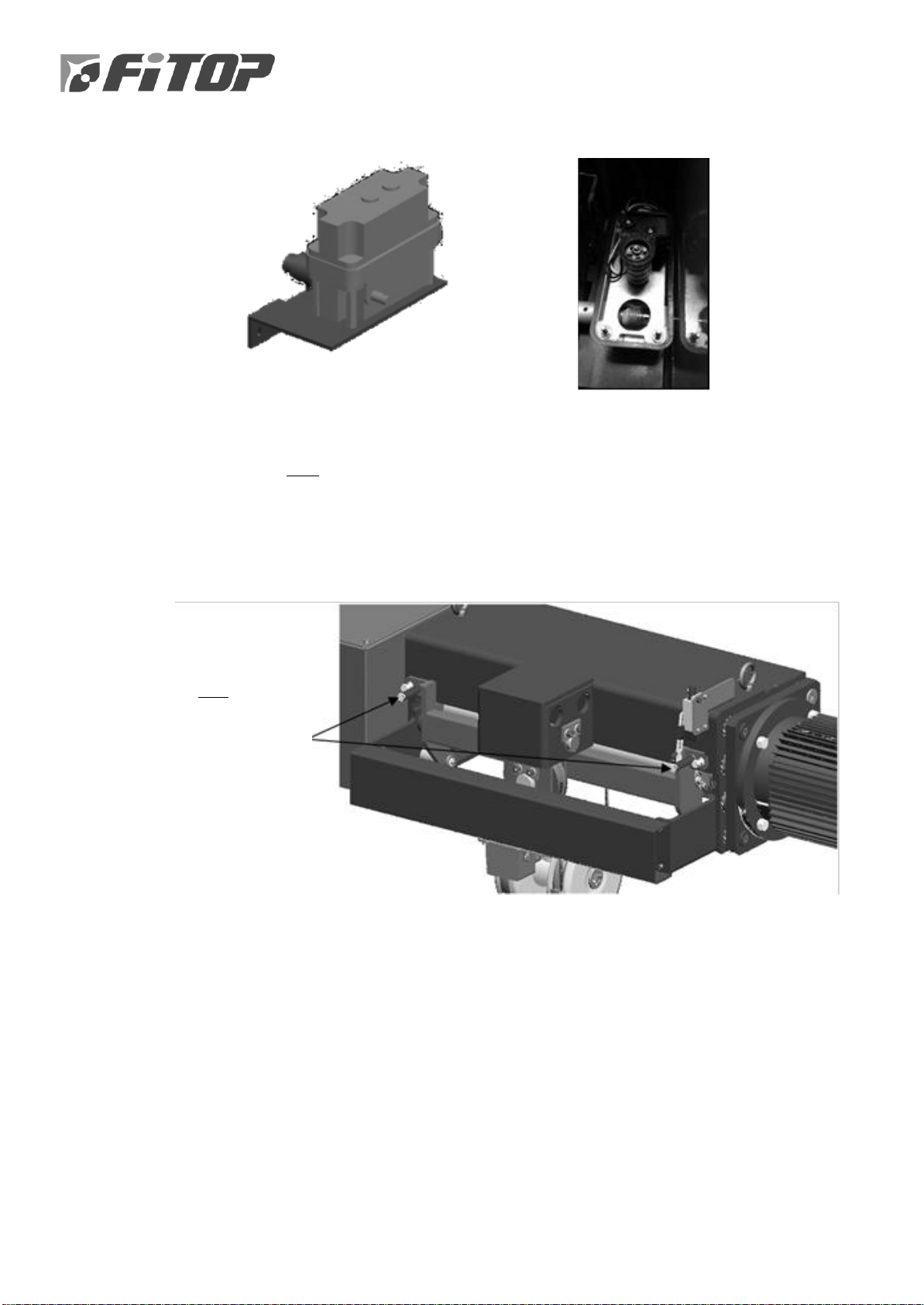

4-5-2. Drum-typed strut rope guide:

Please use the two screws to adjust the rope guide as to touch the wire rope on the

drum; adjust the rope guide limit-switch to ensure that the rope is winded into the

groove, if the rope is out of the groove; press the button (down) so that the rope

could return to its normal way for operation

4-5-3. Overload protection device could prevent over-loading:

In the case of excessive over-loading, the protection device will disconnect the

power of motor to prevent material lifting and declining

Use the two screws

to adjust the rope

guide to touch the

wire rope on the

drum

6

V.IMPROPER OPERATIONS

5-1. Correct Operation

5-1-1. During operation, please be sure that the wire rope is fastened at correct position

for safety; otherwise, with loosened hook, the cargo it hoisted will be fallen and

caused damage

5-1-2. Slightly loosen the tight wire rope; besides, the loose wire rope shall be tightened

steadily

5-1-3. Please make sure the wire rope has been re-organised before operating

5-1-4. Sharp angles could cause wire rope damaged; please use a smooth material to

protect the wire rope at that particular place

5-1-5. Do not impact the cargo before operating as to avoid load falls down

5-1-6. When you lift a single cargo with two hoists, please keep it well-balanced in the

centre of gravity

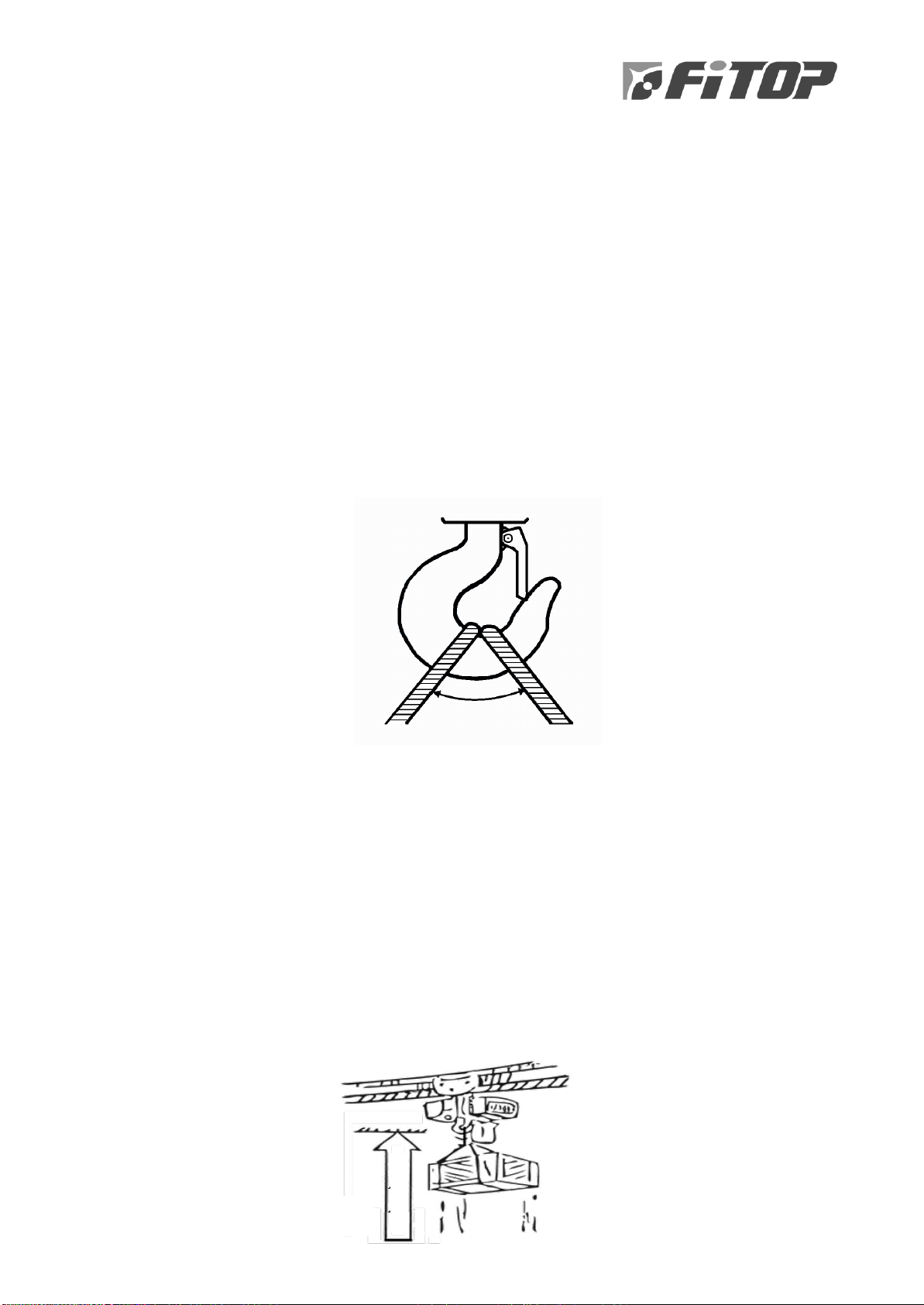

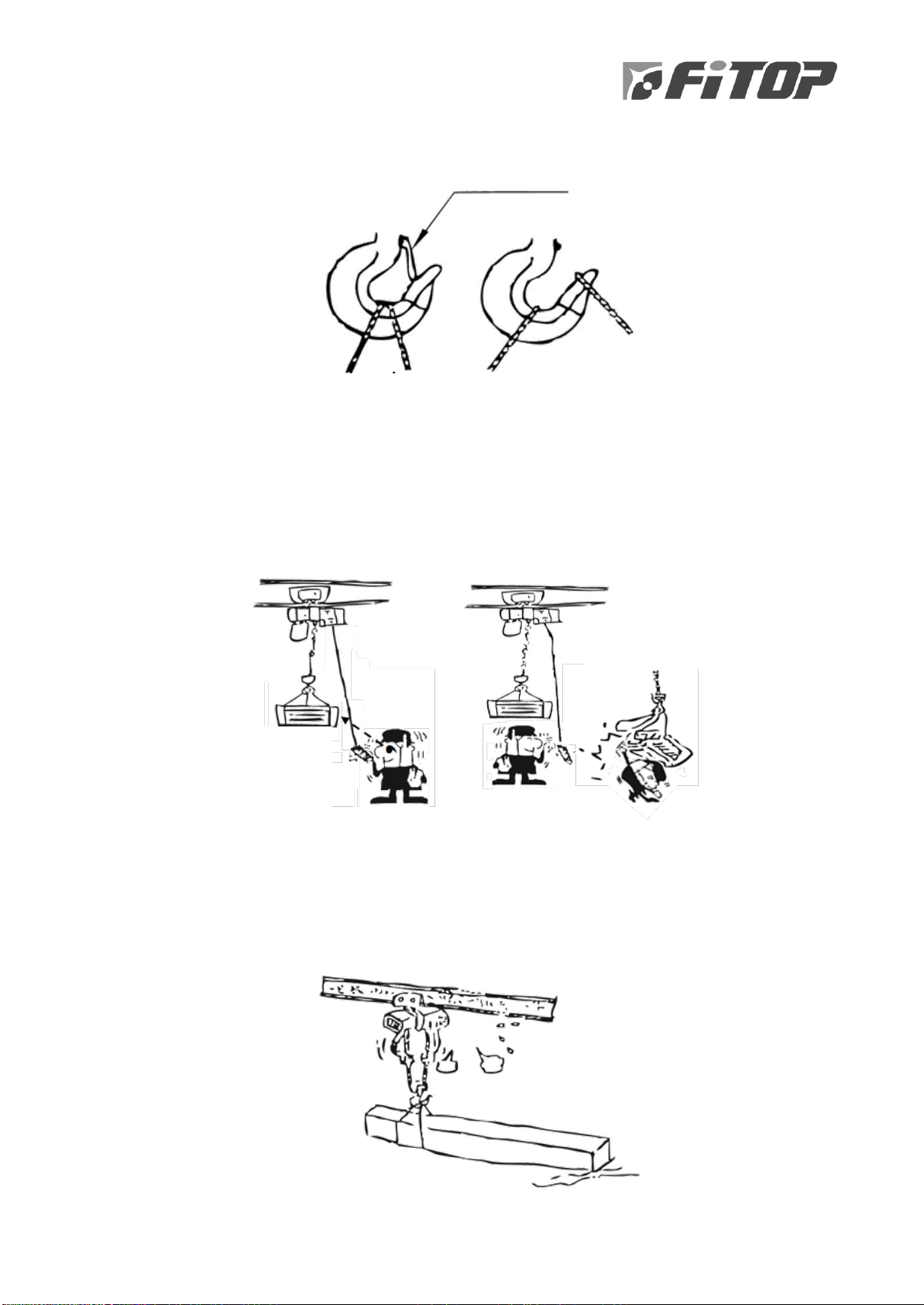

5-1-7. Keep the opening of hook’s wire rope within 60°as shown below:

5-2. Prohibitions

5-2-1. Do NOT lift weights which exceeds its allowable capacity

5-2-2. Do NOT weld a hoisted material and use the hoist to connect ground

5-2-3. Do NOT put the sheave on the ground, because the slings of the drum loosen. If the

drum reverses, will lead the wire rope reversed and fall down. The wire rope will

break down as it escapes from its correct groove

5-2-4. Do NOT load or unload when you could NOT see if there is anything on the ground

or anything between the hook and ground

5-2-5. Do NOT let the hook carries with material and keep it unloaded. It causes danger!

Kindly lift your cargo to its destiny and unload it

5-2-6. When you are lifting a material, the hook must be 2 metres above ground; the hoist

itself shall always be on the top of the material to lift

Max. 60∘

Hook is 2 metres above

ground

2

M

The hoist itself shall be above the

material to lift up

5-2-7. Do NOT let the chain be slant while lifting goods, no matter it is traversing or

travelling. When slant, the angle of traversing should NOT exceeded 15°, and

travelling should NOT exceeded 3°. Moreover, do NOT push the loading onto one

side to avoid slanting

5-2-8. Do NOT move quickly or stop suddenly; must always operate it smoothly. When

lifting, please (1) tight up the wire rope slowly, (2) stop, (3) lift it 20cm above the

ground, (4) stop, ensure its safety, and (5) then lift it

5-2-9. Pay attentions anytime, avoid swinging while lifting your materials vertically

Traversing, do NOT

exceed 15°

Travelling, do

NOT exceed 3°

Tight up the

wire rope

Above the ground

20cm

Roll it up slowly

and stop

Operating

Stop

Avoid swinging

8

5-2-10. Do NOT dis-assemble the Safety Tab of hook for safety

5-2-11. If the lifting have to stop while operating, please let it stop at a zone which is OUT

of a walk-way NOR a working area

5-2-12. Lift the material up to a fixed height, then move it horizontally, the operator must

focus on the load itself; do not let the material pass over any person’s head, and

must operate it steadily to avoid swinging

5-2-13. While operating, must be aware of its conditions, such as extra noise, shaking,

heating, and fumes. If it was happened, must stop using it and check its problem

or inform maintenance engineer

5-2-14. Kindly ensure that the materials are correctly loaded. Please keep your eyes on

the safety since it matters to the happiness of a family

OK

NG!

The operator must

focus on the load

Do NOT let the material

pass over people’s head

Safety tab

5-2-15. Do NOT clean, check, lubricate while lifting materials

5-2-16. You may use the hoist for dis-assembling purposes

5-2-17. Do NOT use the hoist to pull out its lifting rope

5-2-18. If the weight of a material needs to be shared by two hoists, please balance it by,

e.g., 2 sets of 1-ton-capacity hoist, the total load must be less than 1.5 tons

5-2-19. Please press the ON/OFF buttons firmly. Let it stop first, and press button for

going backwards (reverse). If the reverse button is used suddenly, the

consumption will increase, and the motor will become heated. Avoid inching.

Please use hand to press the buttons. Do NOT beat or press two buttons at the

same time

5-2-20. Spiral limit switch up and upper limit switches are the protections for the hoist. If

the load touches the position of up limit, ensure to stop operating; please do NOT

use this function frequently to avoid parts damage and lost this protection. Do

NOT disassemble this spiral limit switch to avoid severe danger

10

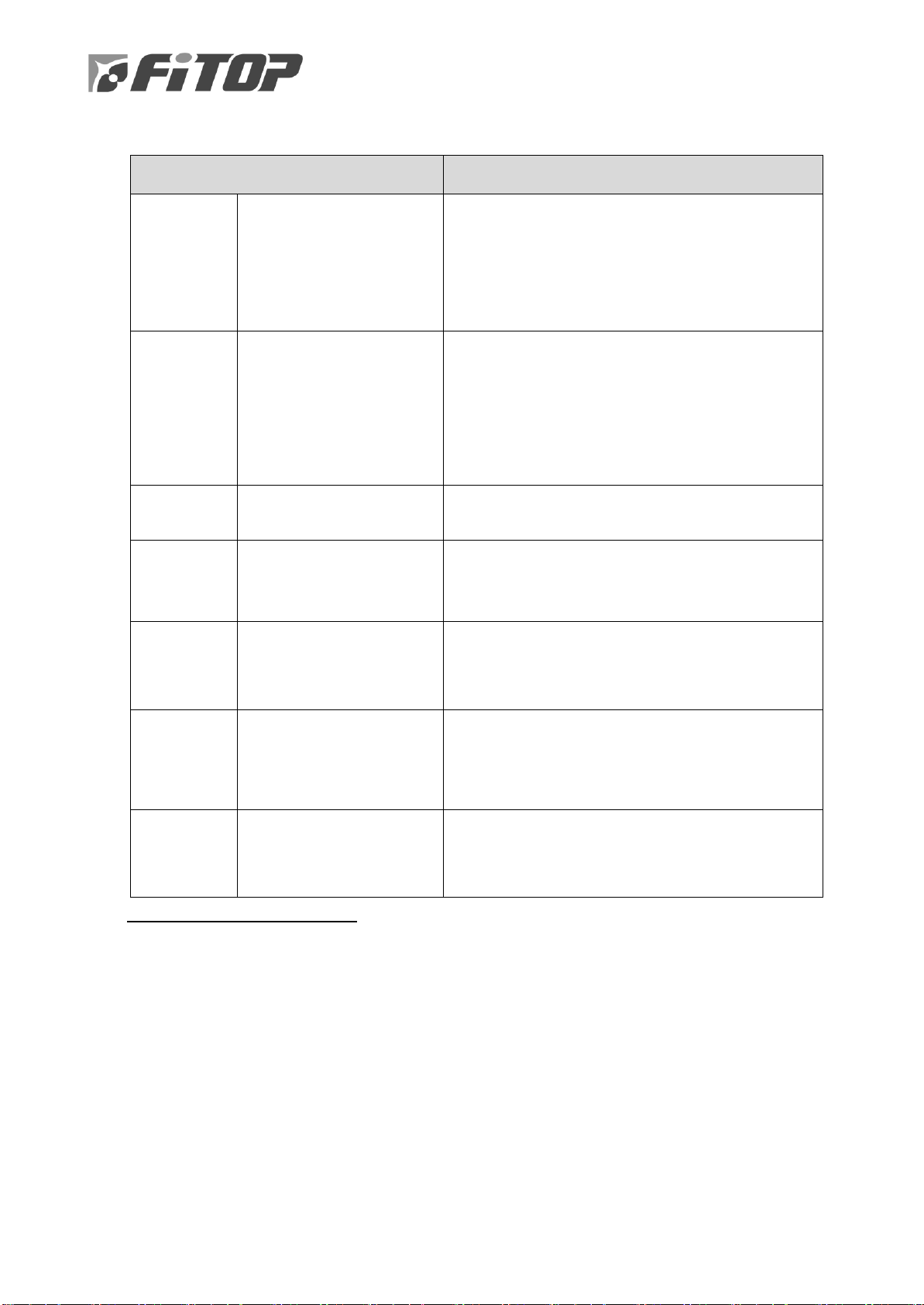

VI.MAINTENANCE

6-1. Notes for maintenance

6-1-1. Periodically clean the RAIL of trolley

6-1-2. Periodically check the FUNCTIONS of limit switch

6-1-3. Periodically lubricate the following items as instructed:

Place to

lubricate

Method of

Lubrication

Interval

(Temp.: -10℃~ 60℃)

Lubrication recommended

CPC

(www.cpc.com.tw)

JIS-standard

Gear box

Oil bathing

If necessary

Gear oil #90

Grease No.2

K-2219 (1983)

Gear oil

Wire rope

Smearing

Check it monthly

If necessary

Wire rope oil

W450

K-2220 (1980)

Grease

Bearing

Oil filling

Every year

If necessary

Grease for

Ball bearing

K-2220 (1980)

Grease

Opened

gear

Smearing or

spraying

Check it quarterly

If necessary

Grease No.2

k-2220 (1980)

Grease

Up sheave

& shaft

Oil filling

Check it quarterly

If necessary

Bearing oil No.3

K-2220 (1980)

Grease

Sheave &

shaft

Oil filling

Check it quarterly

If necessary

Bearing oil No.3

K-2220 (1980)

Grease

6-2. Limitations of Use

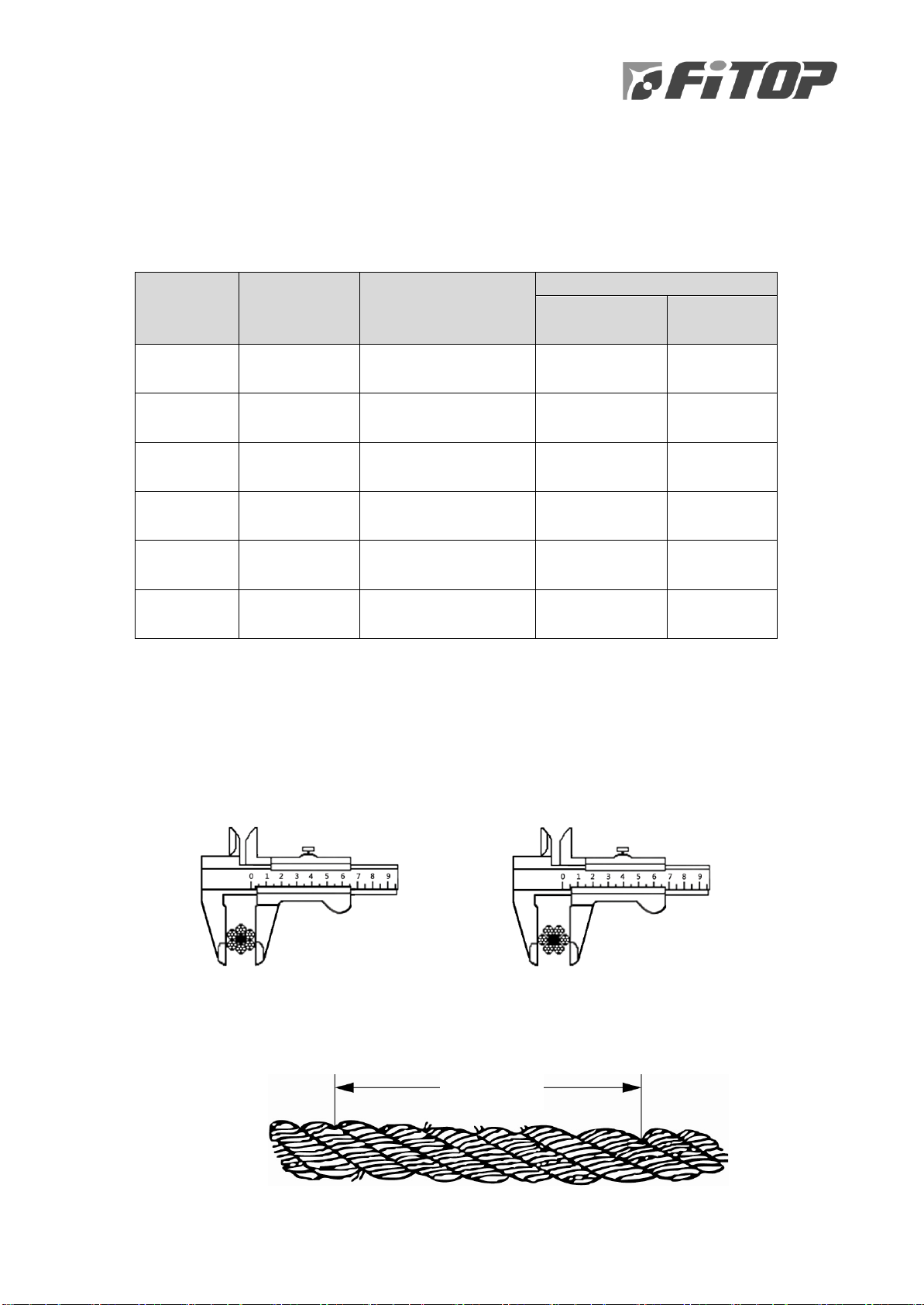

6-2-1. Wire rope

The wearing of wire rope’s O. D. should NOT exceed 7%; otherwise, a replacement

is necessary

(a) Wrong measuring (b) Correct measuring

The NUMBER of broken threads should NOT exceed 10% of the total thread

number in one (1) unit.

One Unit

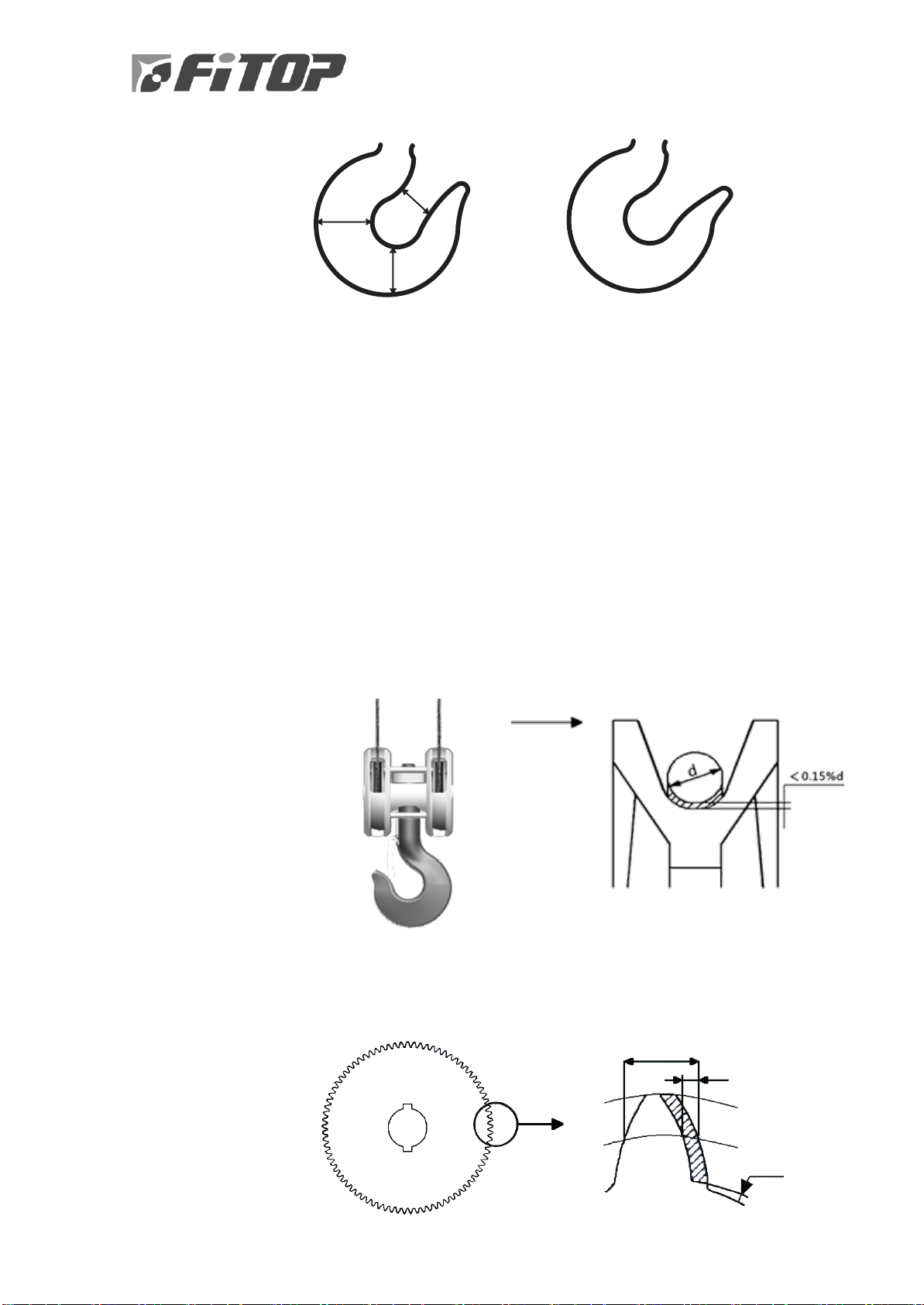

6-2-2. Hook

Chart 1: Chart 2:

NORMAL Hook opening BAD opening

(Do NOT use it)

6-2-2-1. Do NOT use it if the hook is cracked or deformed

6-2-2-2. The Wear and tear’s limitation of H-value is under 5% of standard

thickness

6-2-2-3. If the opening width (B at Chart 1) of hook has been deformed, please

replace it immediately for safety

6-2-3. Sheave

The wear and tear limitation of CAST IRON SHEAVE is under 30% of wire rope’s O.

D.; however, the wear and tear limitation of INNER WALL of sheave would depend

on its condition

6-2-4. Gear

The wear and tear limitation of GEAR depends on the thickness above the pitch

circle.

Thickness

Pitch circle

diameter

H1

H2

B

Wearing

Gap

Blank

diameter

Dedendum

diameter

12

6-2-4-1. The wear and tear limitation of DRIVING GEAR for trolley is at 40%

6-2-4-2. The part of WINDING UP should NOT exceed 30% of original size

6-2-4-3. The first section of GEAR should NOT exceed 10% of original size

6-2-4-4. SHAFT COUPLER should NOT exceed 20% of original size

6-2-5. The wear and tear condition of ELECTRICAL CONNECTION should NOT below

65% of original thickness

6-2-6. The wear and tear of LINING should NOT exceed 50% of original thickness

(Original thickness: 3.5mm)

6-2-7. Wheel

6-2-7-1. The wear and tear limitation of FLANGE thickness is 50% of original

size

6-2-7-2. The wear and tear limitation of WHEEL GROOVE is 5% of original dia.

6-2-7-3. The TOLERANCE of roundness on groove dia. should NOT exceed 1mm

6-2-7-4. The tolerance of Left/Right dia.:

Driving (active) wheel should NOT exceed 0.2%

Driven (passive) wheel should NOT exceed 0.5%

6-3. Items to examine daily

Checking items

Standard of Judgment

Wire rope

▪Prolonged

▪Worn out

▪Deformed

▪Corroded

▪Broken

▪Abnormal prolong condition

▪The thread wiring is exceeded the limitation

▪Deformation is continuing

▪Corrosion is obvious

▪Broken, exceeds its greatest extent

Hook

▪Widened opening

▪Deformed

▪Other damaged defects

▪Performance

▪Safety tab

▪The opening is becoming wider

▪It is curved & deformed

▪Cracked, scared, or other defects

▪Performs smoothly when moving upwards and

downwards

▪If the safe tab is loosened?

Up-limit-

switch

Assembly of up- and

upper-limit

When the loading touches the up- limit-switch,

the power of hoist would be disconnected

Motor

The function of hoist,

trolley and end-carriage

Is the function normal or not? Any noise?

Brake

The function of hoist,

trolley and end-carriage

Check the function of brake, no sliding-down,

and no noise?

Push

Button

Outlook and Operation

▪If the outer shell is damaged or deformed

▪All hoist motion is normal

▪The moving directions of hoist are as the same

as the signs shown on push button

Hanging

tool

Wear and tear

Deformed

Check if it is under abnormal wear and tear

deformed, cracked conditions?

Daily checking point form as Annex 1. (Pg. 26)

6-4. Items to examine monthly

Checking parts 6-7 (pg. 14-15) and 6-8 (pg. 16), the record form Annex 2

(pg. 27-30), checking by the items

6-5. Items to examine quarterly

6-5-1. Check the INSULATION of cable wire and cable

6-5-2. Check all NUTS & BOLTS of connecting part

6-5-3. Check the CABLE of push button pendant

6-5-4. Check all BOLTS on the trolley wheel and motor

14

Examination table as Annex 2. (Pg. 27-30)

6-6. Items to examine yearly

6-6-1. Check and fill in LUBRICANT OIL for every part of the hoist after it has been

operated for one year

6-6-2. Check GEAR BOX of hoist:

Check the wear condition of gear, the function of ball bearing, and the tightness

of locking bolt

6-6-3. Check BRAKE

Check the wear of lining, brake plate, lining’s motion, and test its function

6-6-4. Examine if ELECTRO-MAGNETIC BRAKE is in good condition

6-6-5. Examine MOTOR

Examine if you could hear NOISE when motor runs, please see if the BALL

BEARING is in good condition

6-6-6. Inspect LIMIT SWITCH

Check the wear of contact point, tightness of bolt, and test the switch’s

performance

6-6-7. SHEAVE and WIRE ROPE shall be examined monthly

6-6-8. Check Trolley wheels & end carriage wheels:

Inspect the wearing condition of wheel surface, ball bearing, and gear

6-6-9. If each part has been identified as NORMAL, then lift the goods 10-20cm higher

and decline the goods 10-20cm lower repeatedly. If nothing wrong, general lifting

activity may be started again

Examination form as Annex 2. (Pg. 27-30)

6-7. Structure & Mechanicals

Checking items

Checking items

Beam, saddle, and traveling machinery sections

Beam and saddle

Button switch

1. Check the fixed screw is loosened or not

2. Check the trolley rail is damaged or not

3. Remain rampant in a stopped status

4. Add oil to the gear and shaft

5. Are (i) traveling gear wheel flange and

(ii) flange surfaces wear and tear?

16. Whether it looks weird or cracked

17. Each chain of operation button is complete?

18. Wiring and bolts for earth wire are loosened?

19. Each contact point is good?

20. Control wires are fractured?

Rail

Electro-magnetic brake

6. The scuff on the RAIL is more than 10%

comparing to its original thickness?

7. Are track-bolts loosened?

8. Cracks can be seen on the welded section of

the orbital welding?

9. Wagon or large block buffer is damaged?

21. Whether the actions of brake are correct?

22. Any strange noise, vibration, oblique, or

irregular movements?

23. Whether the gap of brake is normal?

24. Brake disc worn more than 50% of the original

thickness?

25. Braking force is good?

26. Any parts of brake is lost, loosened, deformed,

or wear?

Traveling mechanical device

Wire rope

10. The device is deformed, dropped off, or

bolts loosened?

11. Traveling motor reducer’s bolts are

loosened?

12. From the oil-adding condition of the driven

shaft bearings, the bearing has no weird

noise

13. Wear loosened driven shaft?

14. Cracks on the wheel surface?

15. Rim thickness has exceeded 50% than its

original thickness

27. With or without significant deformation or

corrosion?

28. The balance wheel which in contact with the

side part is normal?

29. The cable is coated with oil?

30. Has it burnt more than 10% of the prime line,

and it has slightly broken? 7% of the wire rope

in nominal diameter is diminished?

31. The condition of the end of the handle and reel

is appropriate

Drum

Oil

32. Cracks on the drum or grooves are obvious?

33. The wire rope is well-tightened on the

drum?

34. The body of drum is deformed?

35. The fixed block on the drum is loosened?

47. The refuelling state of the external gear and

gearbox

48. The gear is obviously cracked or scuffed?

49. Any weird noise during operation?

Wiring inside the machine

50. Has the control box been well-fixed?

51. The appearance of cable is obvious?

52. The screw of each contact is in good condition?

53. Insulation condition is good?

16

Checking items

Checking items

Hook

Security check

36. By visual, any distortion or crackings can be

seen?

37. Opening gauge of the original size has 5%

difference, comparing to its original condition?

38. The contact part of the hook is scuffed more

than 5%, comparing to its original condition?

39. The screw of shaft and nut scuffed?

40. Is the tab or any slip-prevention device not

performing when it should have?

41. Is the condition of hanging fine?

42. Is the condition of the rotation fine?

54. Safety ladders are secure?

55. Hand-rails are secure?

56. Check the function of overload-prevention

device is normal

57. The function of falling-prevention device

(outdoor-typed) is normal

58. Safety sidewalk is clean and has no

corrosions

59. The function of over-winch (upper- and

lower-limit) is normal

60. Traveling and traversing limit switch are

normal

61. The buffer of traveling and traversing

direction is normal

62. The alarm for the straight direction and

warning device are normal

Sheave

Others

43. Sheave (including the balance wheel) wheel

flange and other parts of the ditch, with or

without obvious cracks and wear?

44. Whether the shaft and bearing are obviously

damaged?

45. Key plate, locking pins, stopper bolt, cotter pins

dropped off, loosened, or damaged?

63. Is the licence overdue?

Gear box

46. Cracking or leaking?

6-8. The electricals (including control panel)

Component

Checking items

Component

Checking items

Electric

motor

1. The motor wire is

damaged? Is insulation

fine?

2. Terminal wires are

loosened?

3. Any weird noise when

hoist is running?

4. Three-phase current

balance in full loading?

Power-

feeding

system

Safe rail

21. The scuff of safe rail

22. End-tension device for safe rail

23. Anti-conduction device

24. Insulant is abnormal and its

condition of insulation

Control

panel

5. Fixed screw of panel

6. Fixed contactor &

transformer

Current Collector

25. The scuff of collector

26. Oil feeding to the mechanism

27. The insulating state of the

system

28. Fix terminal, bolt, and screw

Electro-

magnetic

contactor

7. The absorbent surface,

enamelled wire, and weird

noise of steel core

8. Contact surface of the

slice

9. The scuff of contact point

10. The moving status of

contactor

Power-supply cable

29. Scuffs of the cables that are

exposed

30. Extension of cable

31. Terminal, bolt are well-

screwed

32. The leading mechanism of

cable

Interior

wiring

11. Fix the terminal of

Contactor

12. Internal wiring and

insulation

13. Mounting bolts

14. Conduction device

Other

devices

Signal light

33. Fixing part of terminal

Push

button

(pendant)

15. The slice of contact

surface

16. Keep the contact depth of

contact point

17. Keep the direction of

movement

18. Cable inlet

19. The condition of box and

cover

20. The protection of the wire

rope

Lightening device

34. Fix the terminal

35. Mounting part & break-proof

bulb

Limit switch

36. Contact point of contactor

37. The spring of contactor point

38. Limit lever deformed?

39. Performance & its position of

action

40. Bolt mounting

18

VII. TROUBLE-SHOOTING AND MAINTENANCE

7-1. Notes of Maintenance

7-1-1. Before the maintenance work of runway beam and hoist, you MUST (1) advise with

public notice within the factory, and (2) disconnect the power supply and remove

lead wire. The work could only be started in un-loading statues.

7-1-2. Do NOT maintain or repair machine when the power supply is on.

7-1-3. After the maintenance is completed, close all doors or covers of the hoist. Do NOT

leave any tools or spares on the hoist or the rail.

7-1-4. When implementing Chapter 7-2 (Mechanicals), please CONTACT the supplier or

the regional distributor in advance.

7-2. Mechanicals

Trouble

Possible causes

Trouble-shooting

1. Wire rope is NOT on the

groove of drum when rolling

(1) The hoist swinged, wire rope

jumped over, caused overlapping

(2) Wire rope scuffed or deformed

(1) Roll wire rope DOWN and re-roll

wire rope UP

(2) Contact the supplier or the

regional distributor

2. Loud noise

The speed reducer is over-scuffed

Contact the supplier or the regional

distributor

3. The loosen motion of disk

brake is becoming slower

(1) Too large the gap between the

lining and brake plate

(2) The inner hole of sliding portion

is rusted or burnt (by visual

inspection)

Contact the supplier or the regional

distributor

4. Disc brake takes long time

to perform functions

(1) The inner hole of sliding portion

is rusted or burnt (by visual

inspection)

(2) Can see there are dirt on the

sliding surface of brake plate

(3) The manually-loosened bolt is

performing

(4) The brake spring is loosened

Contact the supplier or the regional

distributor

5. Main hoisting sliding down

(1) Too large the brake gap

(2) Brake Lining is scuffed

(3) The brake spring is loosened

Contact the supplier or the regional

distributor

6. Trolley sliding

(1) The brake adjustment screw is

not tightened

(2) The lining is scuffed

(3) The brake spring is loosened

Contact the supplier or the regional

distributor

7. End carriage sliding and

running unevenly

(1) The brake-adjustment-screw is

not tightened

(2) The lining is scuffed

(3) The brake spring loosened

Contact the supplier or the regional

distributor

Table of contents

Popular Chain Hoist manuals by other brands

RED ROOSTER

RED ROOSTER TCS-500-LF user manual

Tractel

Tractel DD Series manual

POWERTEX

POWERTEX PCB-S1 Instructions for use

J. D. NEUHAUS

J. D. NEUHAUS PROFI 25TI Original operation and assembly instructions

Ingersoll-Rand

Ingersoll-Rand KX Series Product Maintenance Information

XTline

XTline XT108600 Operation manual