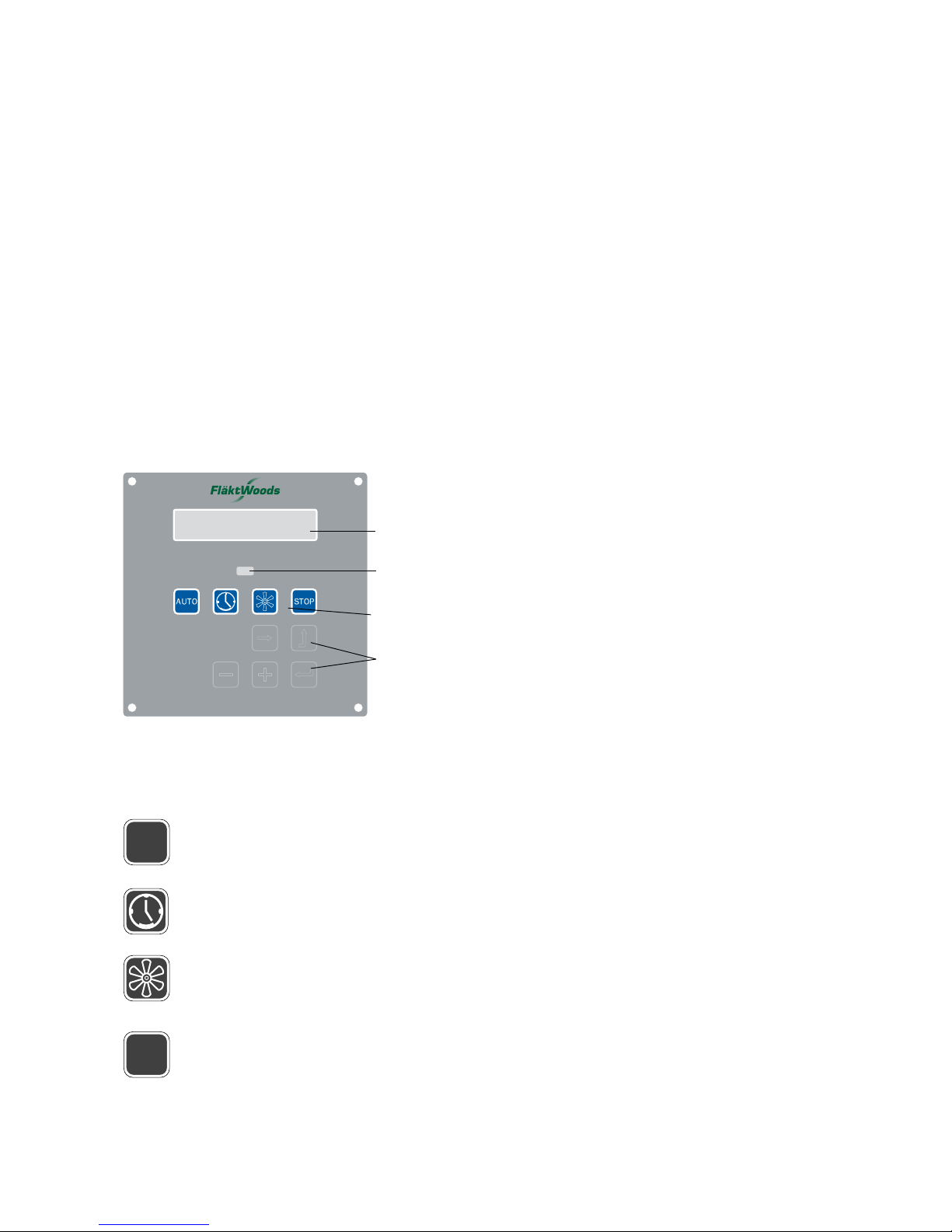

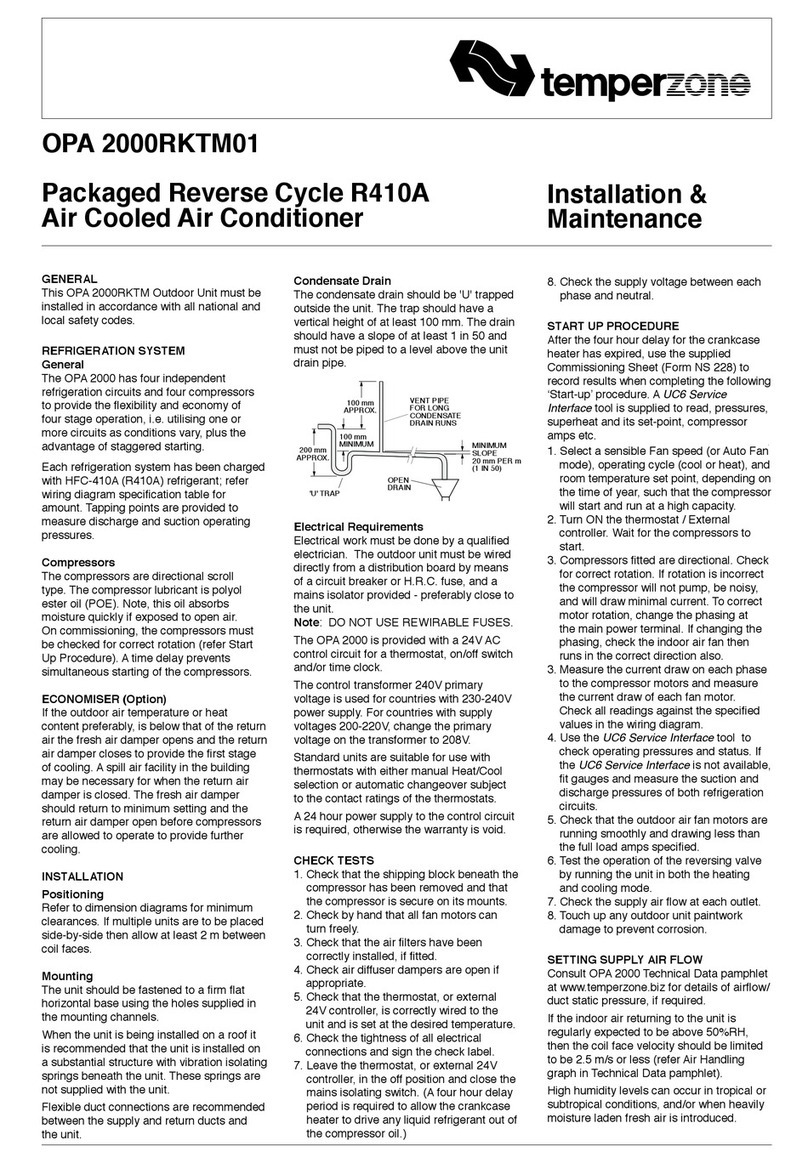

Fig. 7.

Fig. 8.

Overheating protection for electrical coil

The coil is equipped with two temperature limiters: one

with automatic resetting, set to 40º C, and an overheating

protector with manual resetting, which trips at 120º C.

Resetting is performed with two buttons on the over-

heating protector positioned on the rear of the dividing

wall on which the coil is located (where the exhaust air

filter is located).

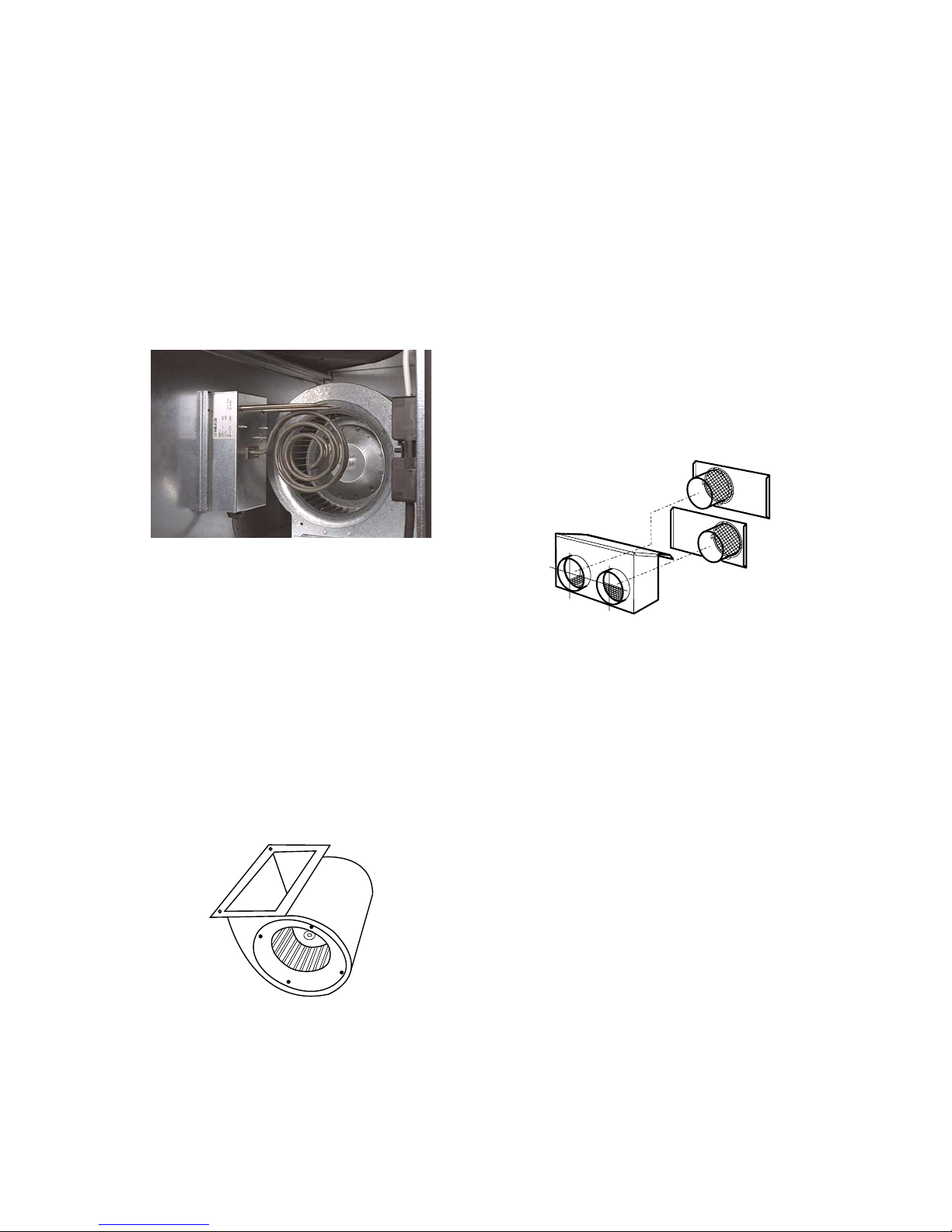

Cleaning of fans

The fans for the ABR room unit are directly driven. Both

fans should be checked and cleaned as required. Wipe the

fan with a cloth. Clean the fan impeller using a vacuum

cleaner fitted with a soft brush nozzle. Take care to clean

all the fan blades, to prevent imbalance arising in the fan.

Dismantling and re-assembly of fan unit

1. Separate the connector for the fan. Note the lock.

2. Remove the electrical heater, if present (applies to

supply air fan).

3. Remove the front two bolts, and lift out the fan unit.

Check the vibration damping when refitting.

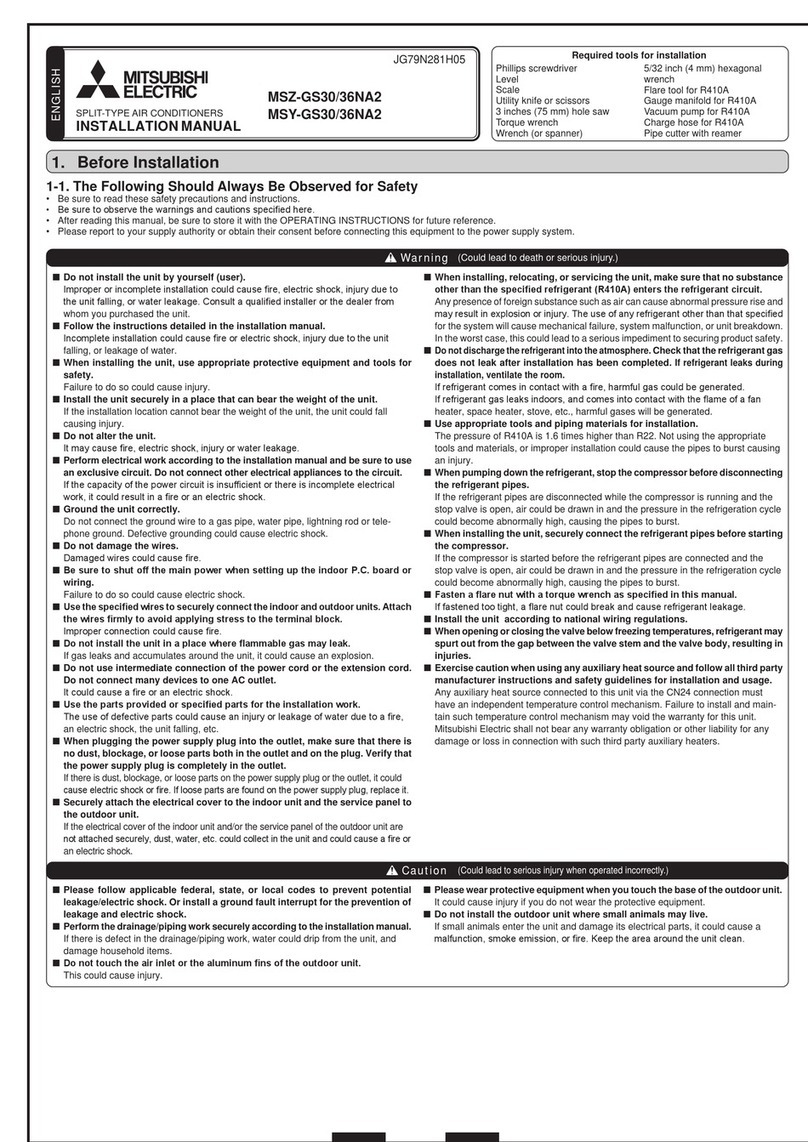

Electrical coil

The electrical coil should be checked and cleaned as re-

quired, since an accumulation of dust can cause odours

and, in the worst case, fire.

If the need arises, the dividing wall complete with the

electrical coil can be pulled out. Allow the coil to cool be-

fore pulling it out and cleaninging it. First disconnect the

connector. Note the lock.

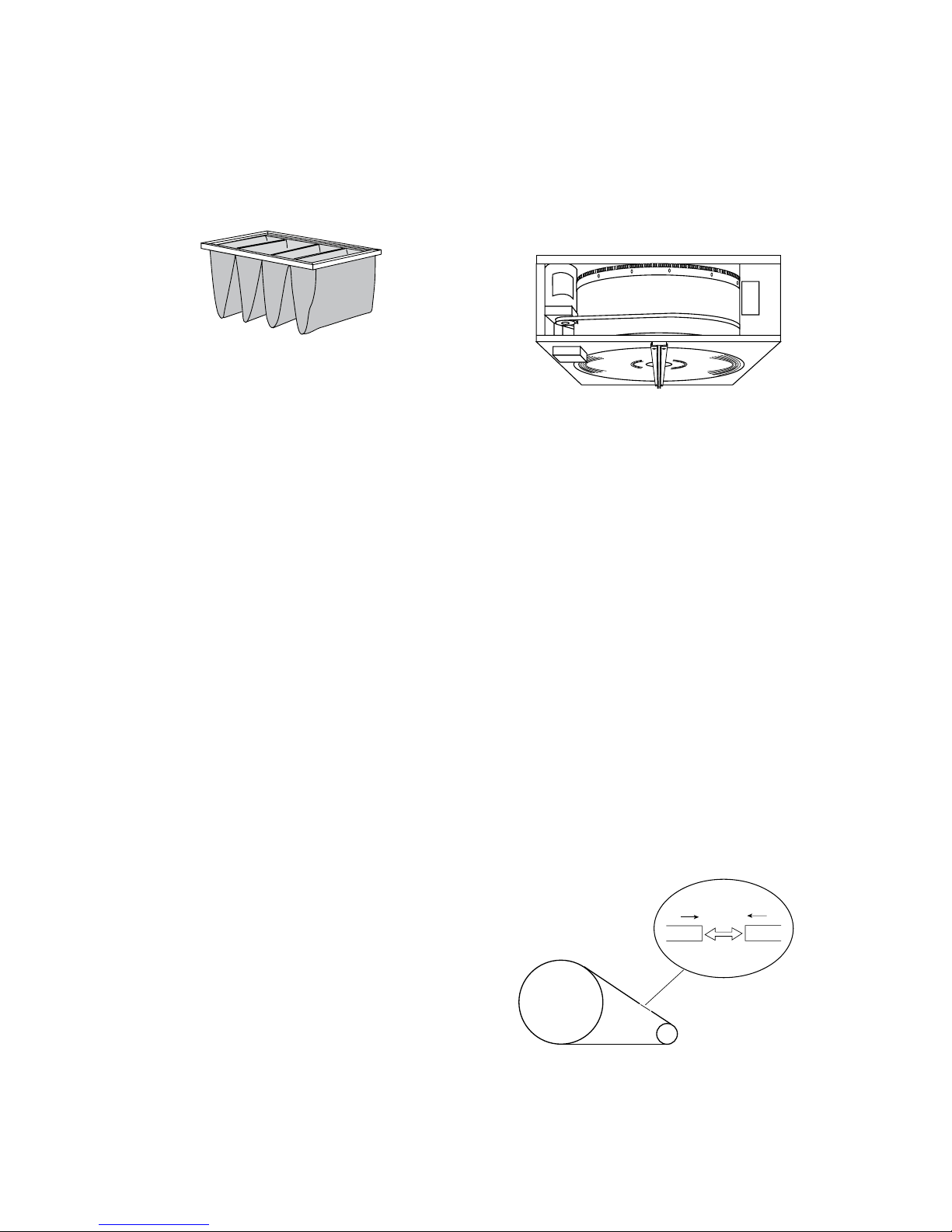

Fig.9.

Replacement of bearings and fan impeller

wheel

The bearings in the fan motor are lubricated at the factory

and maintenance-free.

The entire fan unit must be replaced in the event of

damage. This ensures that high quality, with a balanced

unit, is achieved for the fans.

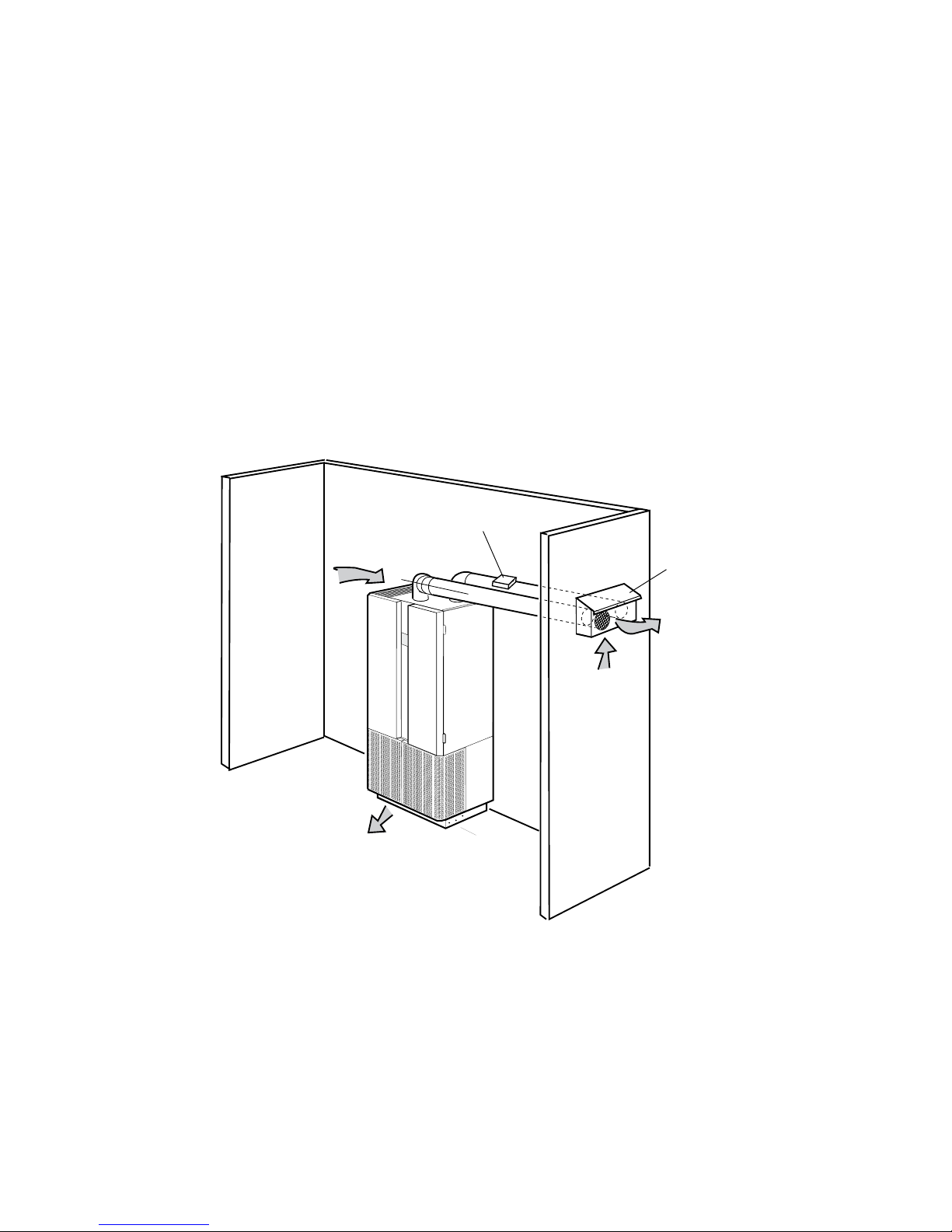

Ducts and combi-hood

The front panel is detachable to allow the connected

ducts to be checked; these should be cleaned, if necessary.

If any other type of supply air and extract air terminal

device is used, the maintenance should be adapted to the

design in question.

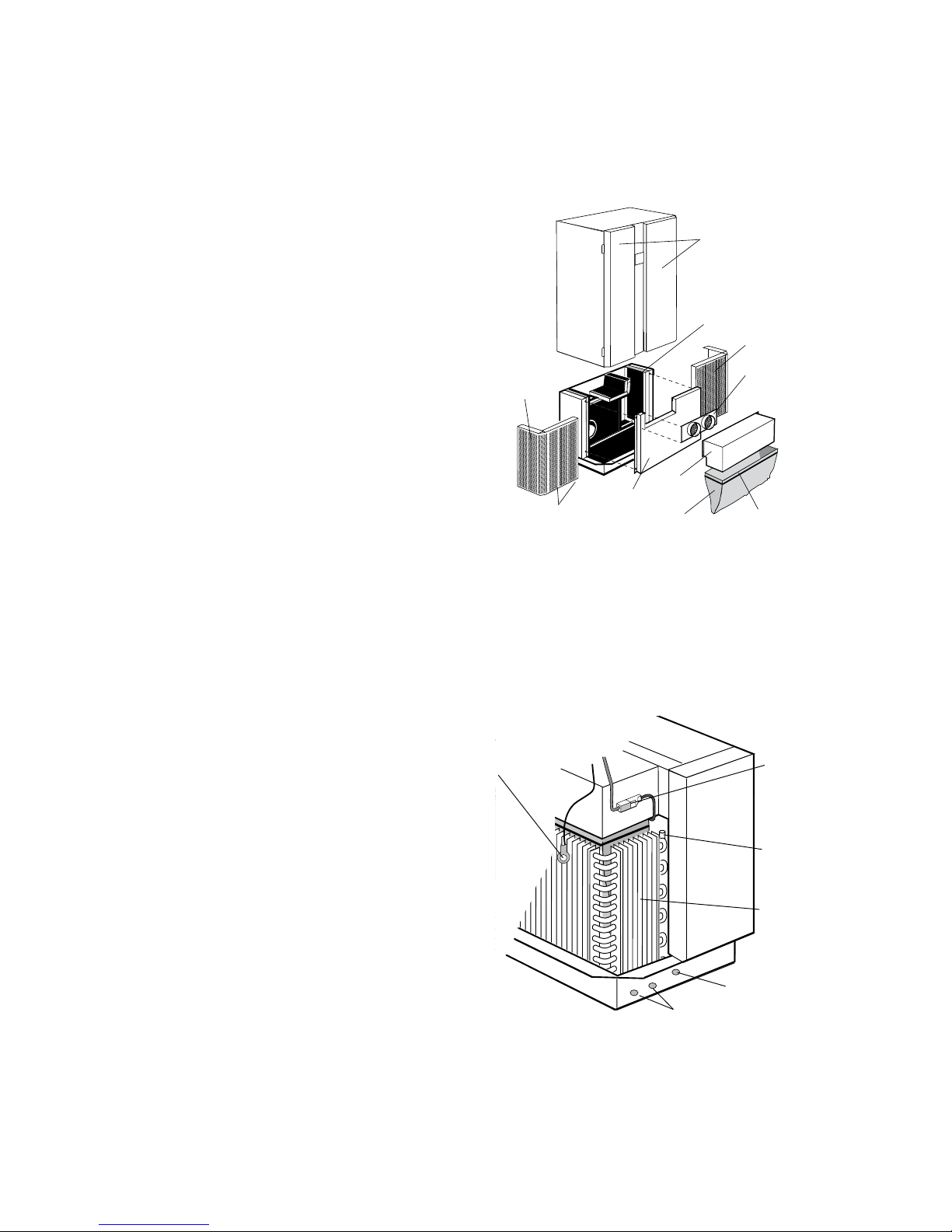

Maintenance

Supply air terminal device

The front grille consists of two halves, each of which are

detachable in order to permit the supply air device and

the sound attenuator to be checked and, if necessary,

cleaned.

Vaccum both sides of the supply air device once a

year.

Cleaning of sound attenuator

1. Open the inspection covers, and remove the two bolts

located on the top edge of the front grille.

2. Undo the four bolts (using a 13 mm spanner) located

on the bottom edge of the front grille by approx. two

turns, and pull out and lift off the front grille.

3. If the unit has a cooling coil, fold it forwards; the coil

has flexible hoses for the water connection.

4. Undo the bolts along the edge of the central plate, and

lift out the central plate with the dividing bag.

5. Lift out the terminal device insert.

N.B. On re-assembly, the terminal device insert must be

secured laterally in a groove on the fan outlet on the rear

edge of the terminal device.