flakt woods RoomMaster ABR-2 Guide

RoomMaster ABR-2

Commissioning

Fläkt Woods 8061 GB 2009.05 2 Specifications are subject to alteration without further notice.

RoomMaster ABR-2 COMMISSIONING

GENERAL

Locking of operating mode keys ..............................................................................................................3

Control panel ...............................................................................................................................................3

Function of operating mode keys, operating menu...............................................................................3

Activation of setting keys ..........................................................................................................................4

Locking of setting keys...............................................................................................................................4

Setting menu structure...............................................................................................................................4

Function of setting keys .............................................................................................................................4

START-UP

Factory settings on delivery ......................................................................................................................5

Calibration of unit.......................................................................................................................................3

Interrupted calibration ...............................................................................................................................5

Unit self-test.................................................................................................................................................5

Alarm ............................................................................................................................................................5

Selecting operating mode STOP................................................................................................................5

Example: Changing standard flow...........................................................................................................5

Program version..........................................................................................................................................6

Checking prior to commissioning ............................................................................................................6

Commissioning applicable to program version R2d .............................................................................6

PROCEDURE - SETTING

Setting of temperature regulation of desired value for temperature ..................................................7

Setting of exhaust air flow, standard and reduced flow

and supply air/exhaust air flow ratio......................................................................................................8

Reading actual values (Window 20).........................................................................................................8

Setting operating times and operating mode in weekly rhythm (Window 30) .................................9

Setting operating times and operating mode in weekly rhythm (Window 40) ...............................10

Setting clock (Window 50) ....................................................................................................................... 11

Activation of summer night-time cooling (Window 60) .....................................................................12

Calibration of unit (Window 71b)...........................................................................................................13

Self-test of unit (Window 71a).................................................................................................................13

Reset default values (Window 71c) ........................................................................................................14

Activation (blocking) of operating mode keys .....................................................................................15

Activation of electric coil and cooling coil ............................................................................................15

Program version (Window 77) ................................................................................................................16

PRESENCE SENSOR Setting operating times and operating mode in annual rhythm .................16

Alarm and fault-finding...........................................................................................................................17

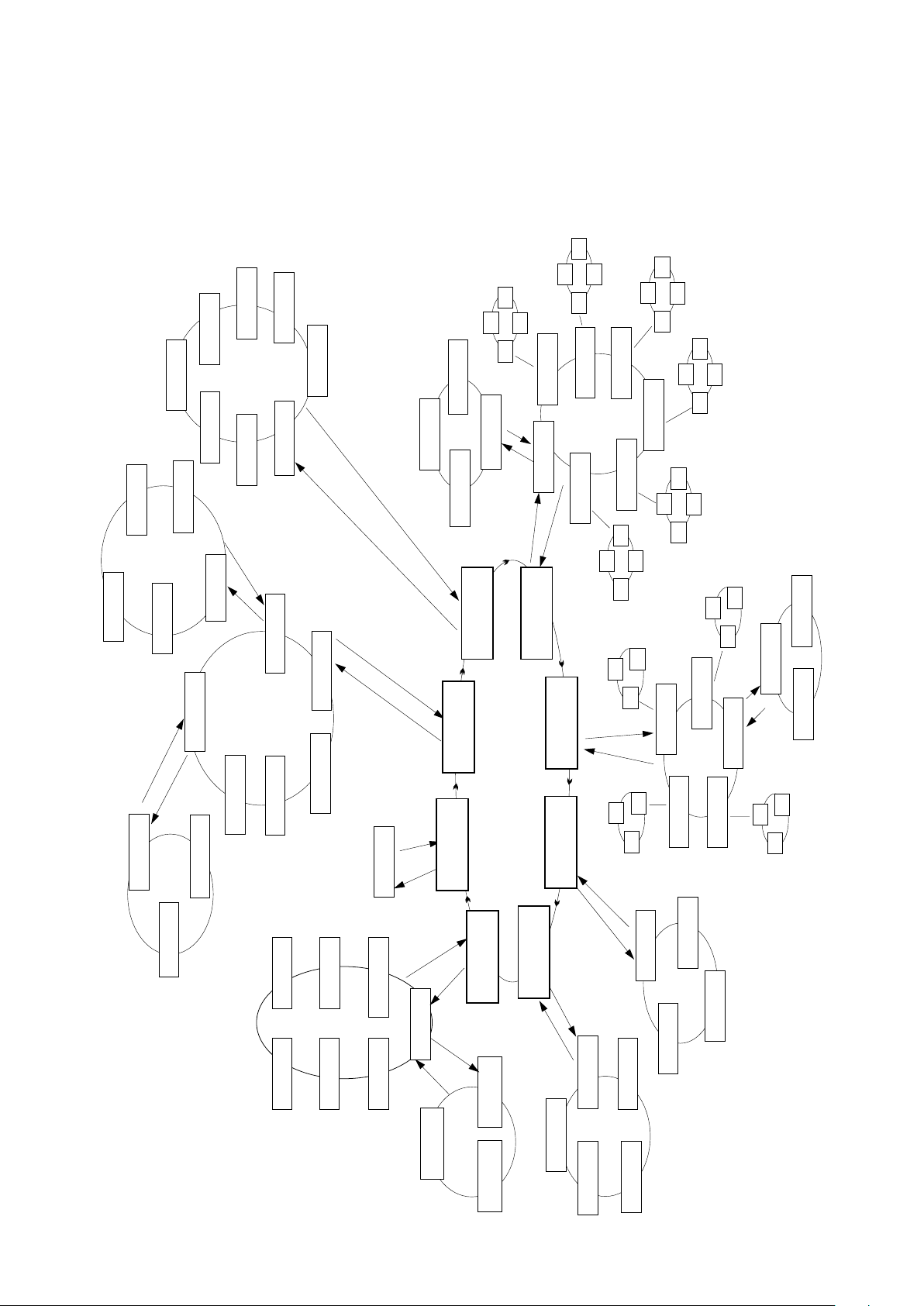

Menu Structure..........................................................................................................................................18

List of parameters .....................................................................................................................................19

Content

Fläkt Woods 8061 GB 2009.05 3 Specifications are subject to alteration without further notice.

RoomMaster ABR-2 COMMISSIONING

Fig. 20

STOP

OVERTIME

(h:m)3:00

AIRING

(min) 15

AUTOMATIC

Calibration

AUTO

AUTOMATIC

Weekly rhythm Std flow

AUTOMATIC

Annual rhythm Std flow

" Red.flow " Red.flow " Red.flow

Stop " Stop " Stop

AUTOMATIC

Presence Std flow

AUTOMATIC

Demand control

AUTOMATIC

Self-test Heat exchanger

AUTOMATIC

Calibration

" Electric coil

Filter

AUTOMATIC

Central clock Std flow

AUTOMATIC

Night-time cooling

Locking of operating mode keys

The operating mode keys “Overtime operation“, “Ven-

tilation“ and “Stop“ can be blocked individually, if re-

quired; see also page 13, “Activation (blocking) of operat-

ing mode keys“.

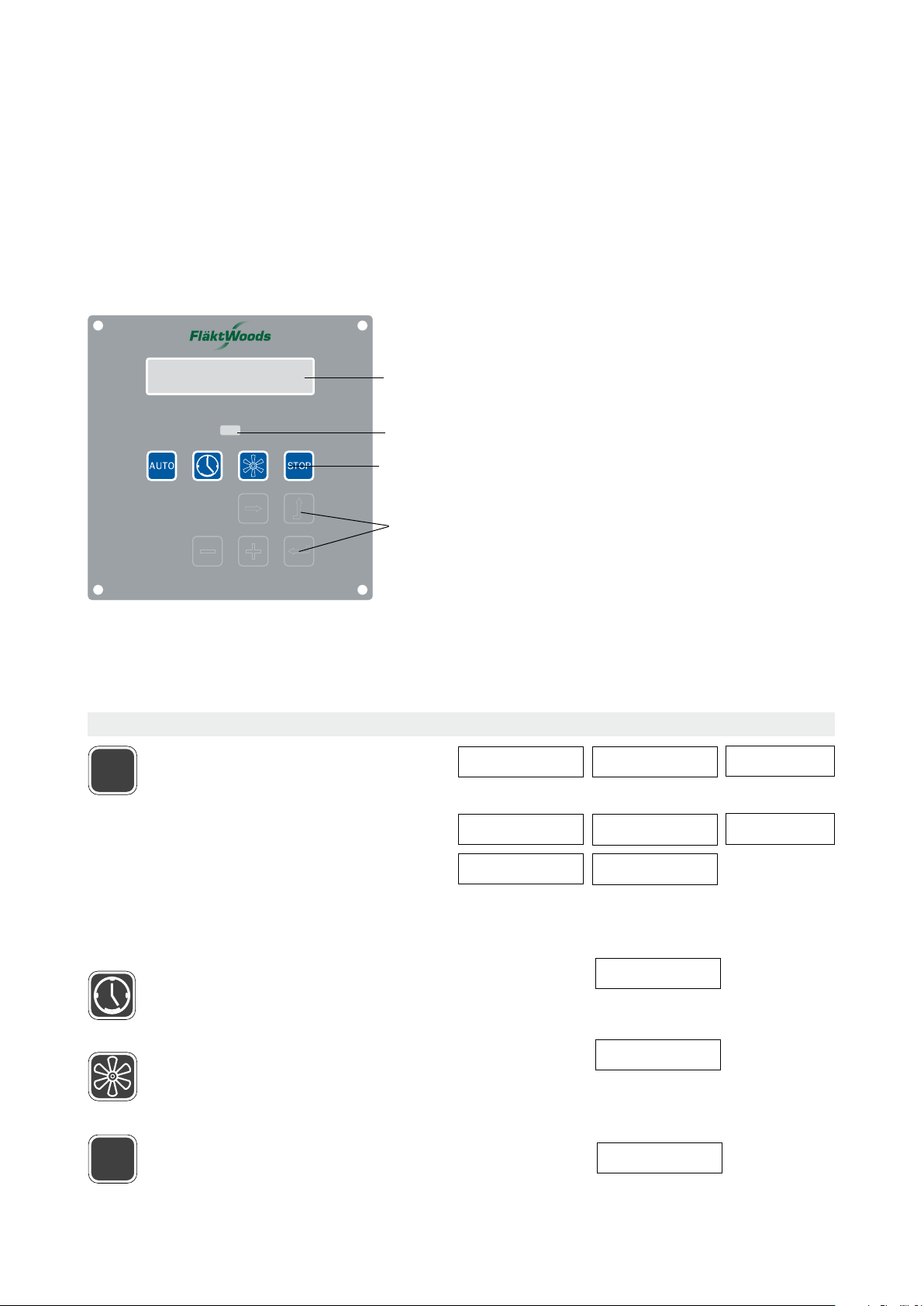

Control panel

The control panel is equipped with a 2 x 20 character

window of the LED backlight type, where the operating

status, air flow, temperatures and other setting values

and parameters are displayed in clear text; see Fig. 20.

Four operating mode keys are used to select the de-

sired operating status. The current operating status is

shown in the operating menu in the window.

Each operating status can be interrupted at any time

for a new operating status by pressing the appropriate

operating mode key.

Five setting keys are provided to set and read the air

flows and temperatures, etc., to increase and reduce the

values, and to move around in the menu structure. The

values are displayed in the setting menu on the window.

The red LED on the panel will flash in the event of

a fault function. The fault function is displayed in the

alarm menu in the window.

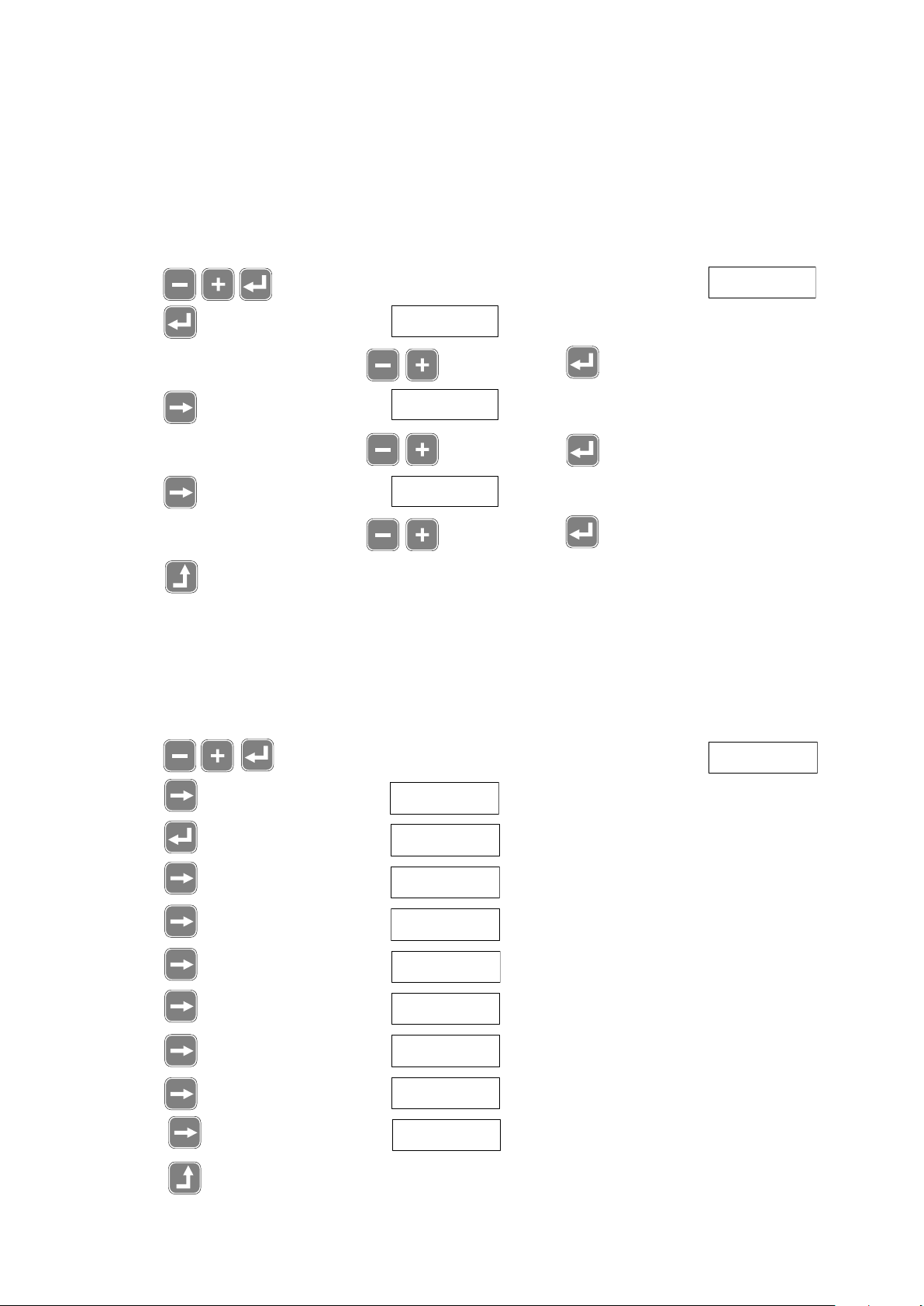

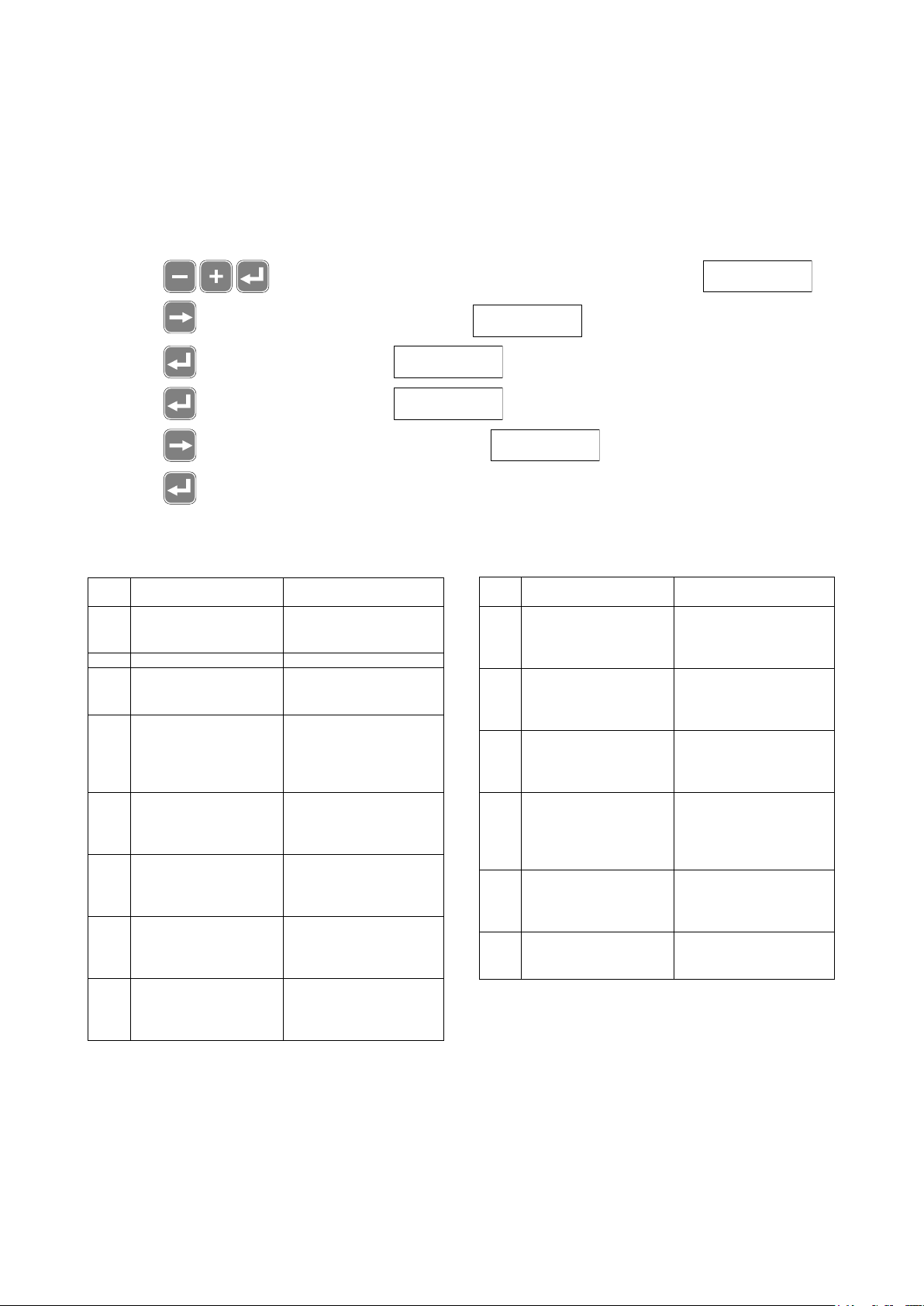

Function of operating mode keys, operating menu

Symbol Function Operating menu

Locking and function of operating mode keys

Window

Alarm

Operating

mode

keys (4)

Setting

keys (5)

Automatic mode, in which the unit is control-

led by the following alternatives:

* Internal annual clock (weekly rhythm,

annual rhythm)

* Presence sensor, CO2 sensor

* Night-time cooling

* Self-test or Calibration

Menu shows the current operating mode for

the unit.

Possible operating modes are: Standard flow;

Reduced flow; Variable flow; Shut-down unit;

Night-time cooling and Self-test.

Overtime operation; the unit operates for 3

hours outside ordinary operating time. Op-

erating status is standard flow. Menu shows

remaining time.

Ventilation; the unit is forced to max. flow

(max. controlled voltage) for 15 minutes. The

desired value for the supply air temperature is

always 15ºC. Menu shows remaining time.

Stop; the unit stops.

Fläkt Woods 8061 GB 2009.05 4 Specifications are subject to alteration without further notice.

RoomMaster ABR-2 COMMISSIONING

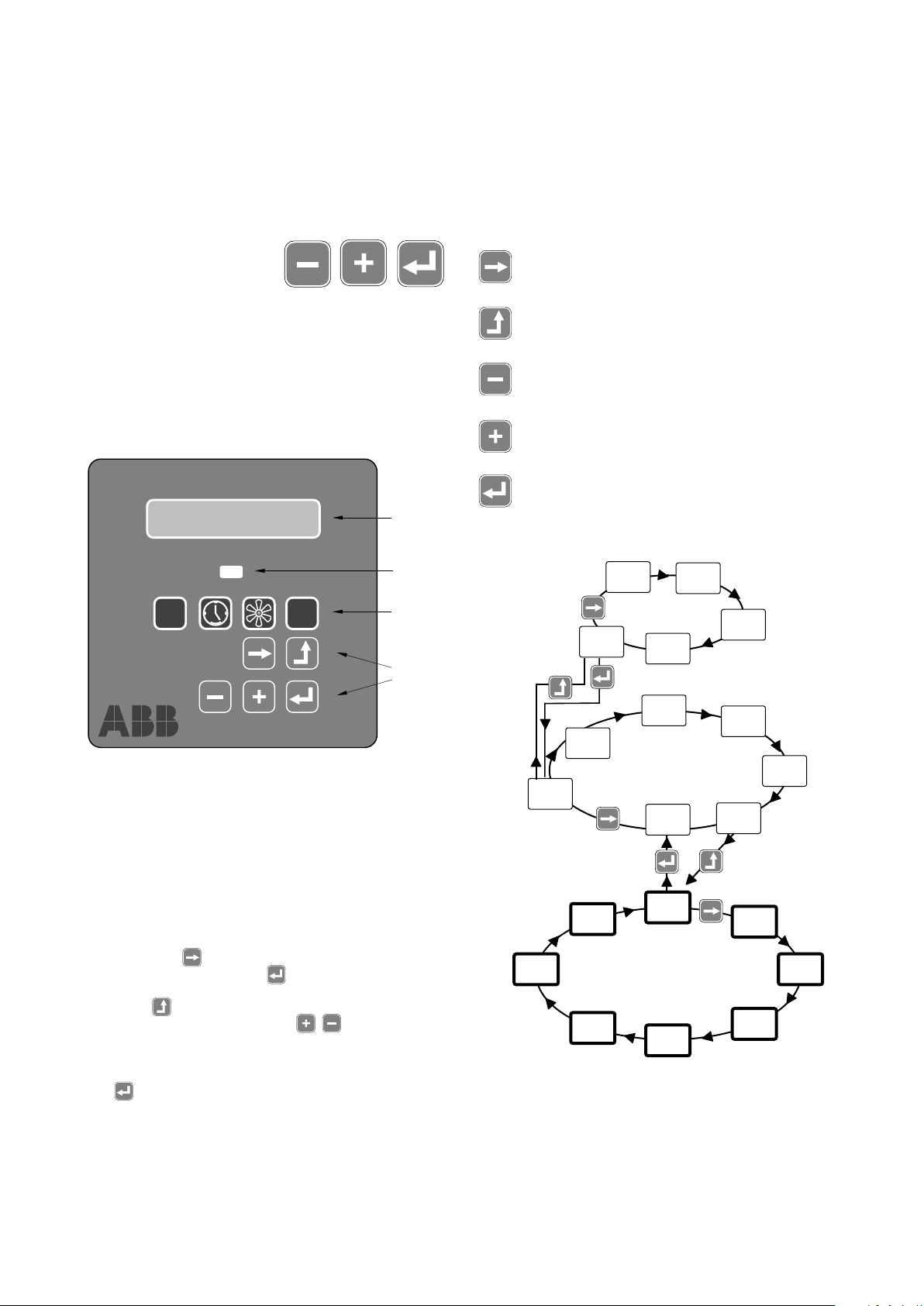

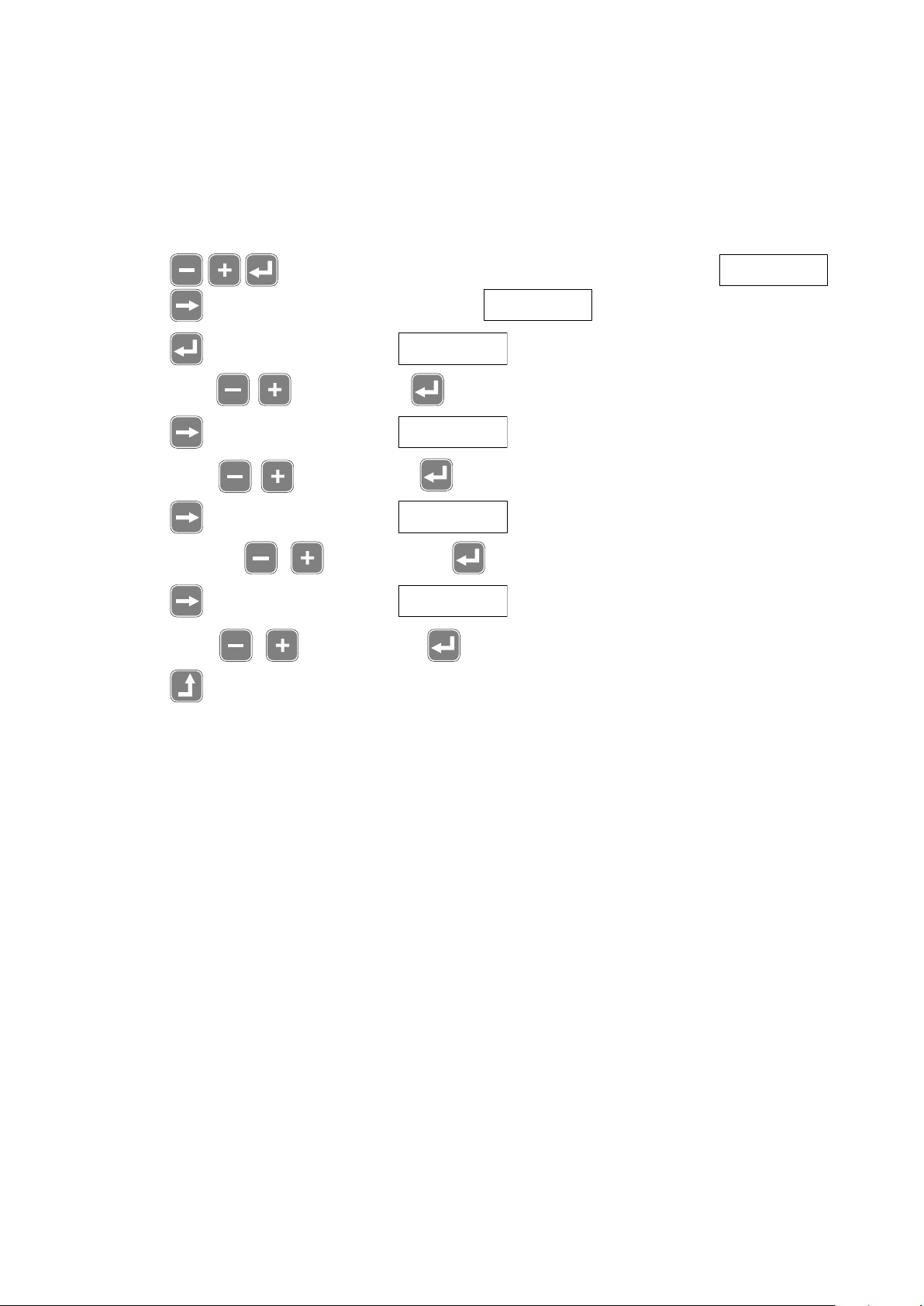

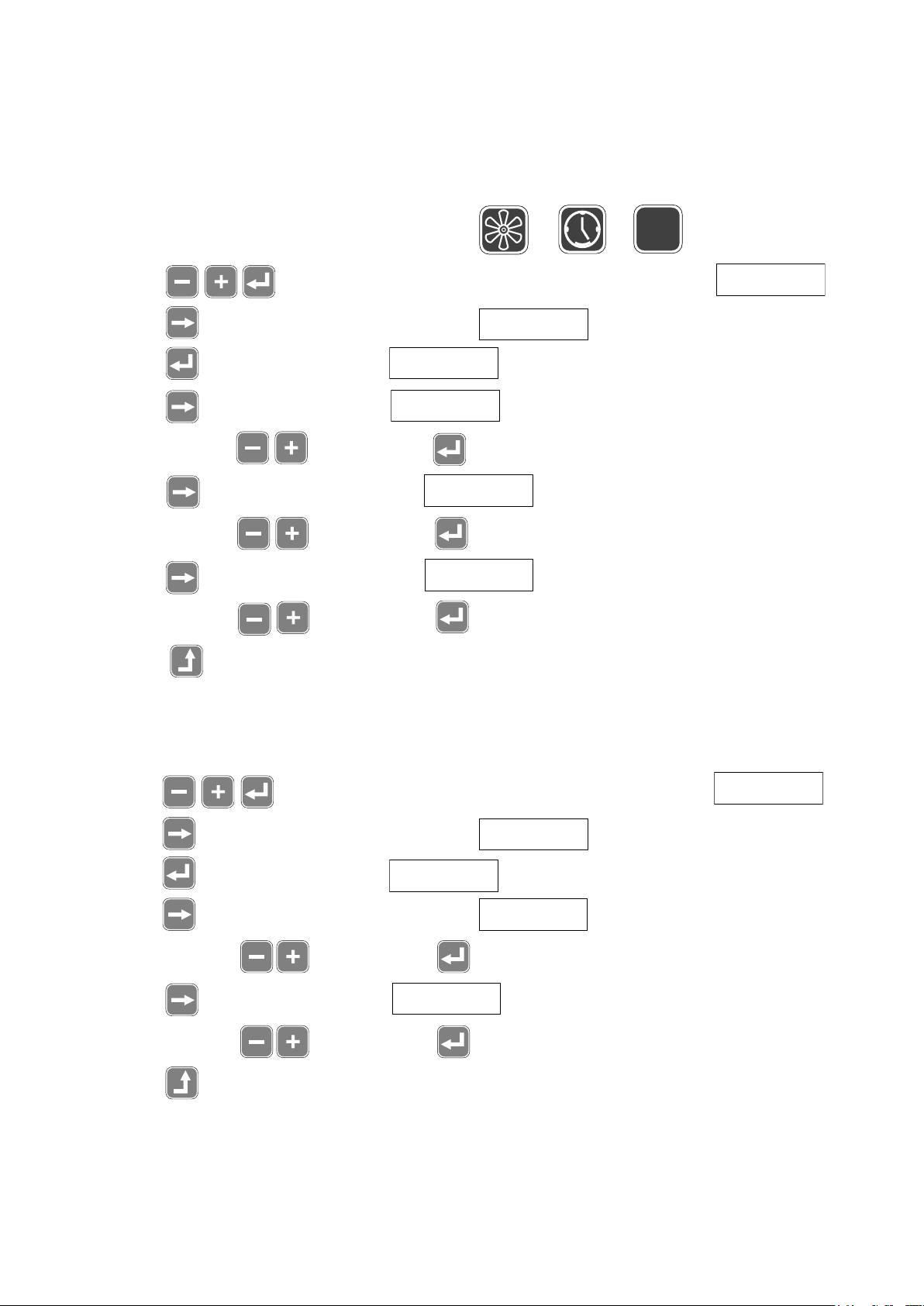

Setting menu structure

The menu structure has 3 levels: a main menu plus sub-

menus 1 and 2. The main menu is numbered in tens - 10,

20, etc., and the windows in sub-menu 1 beneath window

10 in the main menu are numbered singly - 11, 12, etc. Cer-

tain sub-menus also include a sub-menu 2. The windows

in sub-menu 2 under window 12 in sub-menu 1 are identi-

fied with a letter in addition to the number - 12a, 12b, etc.

Moving around in the same menu level is done with

the “Next“ key . Moving down one step to a sub-menu

is done with the “Enter“ key . Moving up one step, e.g.

from a sub-menu to the main menu, is done with the “Es-

cape“ key .

The “Plus“ and “Minus“ keys are used to

change a numerical or text parameter. The parameter val-

ue then begins to flash at the same time as it is changed.

Acknowledgement of the value is done with the “Enter“

key . The parameter value then stops flashing.

Fig. 21

10

50

20

40

80

60

3070

11

14

12

17

13

15

12d

Huvudmeny

Undermeny 1

Undermeny 2

12e

12b

12a

12c

16

Function of setting keys

Sub-menu 2

Sub-menu 1

Main menu

Fig. 22. Main menu and sub-menu.

Next. Used to move to the next window at the

same menu level.

Escape. Used to escape from a current measure

and to move up one level in the menu.

Minus. Used to reduce and change the value of

numerical and text parameters.

Plus. Used to increase and change the value of

numerical and text parameters.

Enter. Used to enter the content of the current

window, or to initiate the measure described in

the window.

AUTO

AUTOMATIC

Weekly rhythm Std.flow

STOP

Window

Alarm

Operating

mode

keys (4)

Setting

keys(5)

Activation of setting keys

Press down the setting keys

simultaneously for 5 seconds.

Activation is confirmed by a new text and a number ap-

pearing in the display. The window contains the number

10 and the text “Set desired value“. It is now possible to

change the desired value and operating times, etc.

Locking of setting keys

The setting keys can be blocked via a terminal on the

control card. The lock is activated by jumping terminals

23 and 24.

Activation, locking and function of setting keys

Fläkt Woods 8061 GB 2009.05 5 Specifications are subject to alteration without further notice.

RoomMaster ABR-2 COMMISSIONING

Example: Changing standard flow

The standard flow must be changed from 200 l/s to 220

l/s. Activation of the setting keys brings you automati-

cally into the main menu with window number 10.

Press key to show window 11

Press key until 220 l/s is displayed

Press key to confirm

Factory settings on delivery

Self-test and Calibration are always carried out prior to

delivery from the factory. Setting and checking the func-

tion are adapted to suit the ordered variant and the speci-

fied accessories.

The following functions/accessories influence the setting:

❒Electric coil installed

❒Cooling installed

❒Presence sensor as an accessory

Calibration of unit

The unit must always be calibrated for a new installation.

The calibration time is approx. 5 minutes.

During calibration the control unit checks the prevail-

ing operating condition and adapts the operating point of

thefans to the selected setting data.

Interrupted calibration

In the event of a power supply failure or other operating

breakdown which interrupts calibration before it is com-

plete the calibration procedure must be repeated.

Unit self-test

Self-test is intended to be used for checking important

components in the unit during service and after correct-

ing any faults.

The self-test time is approx. 20 minutes.

Alarm

In the event of an alarm, the response should be as in-

dicated in the alarm message (see also PROCEDURE -

Alarm and fault-finding).

Activate self-test by pressing “AUTO“ twice.

The unit switches automatically to automatic mode once

self-test is complete. The self-test time depends on the

type of fault.

Selecting operating mode STOP

It is recommended that the unit is operated continuously

for normal air treatment. In order to be able to select the

STOP operating mode, dampers are required in the out-

door air and the extract air duct. The absence of a damper

will allow impurities to enter the unit by “the back way“,

and the room and the unit will be cooled down during

cold times of the year. Cooling of the room leads to in-

creased heating costs and increases the risk of operating

breakdowns with the unit.

10 Ställ in

börvärde

50

20

40

80

60

30

70

15

12

11 Normalflöde:

200 l/s

13

14 16

Huvudmeny

Undermeny 1

Fig. 23. Example: Changing standard flow.

Sub-menu 1

Main menu

11 Standard

flow: 200 l/s

10 Set desi-

red value

Commissioning - start-up

Fläkt Woods 8061 GB 2009.05 6 Specifications are subject to alteration without further notice.

RoomMaster ABR-2 COMMISSIONING

Program version

These instructions are applicable to program version 1.0.

Information about the type of program version in a unit

can be found in window 77 and/or on the control card.

Checking prior to commissioning

In order to obtain a functionally reliable system, a simple

check is necessary in conjunction with commissioning a

new unit and modifying a previously selected setting. See

also Commissioning below.

Choice of language in text window

The program contains three different languages to be

chosen between with keys on the control panel.

See further page 16, window 81.

Commissioning applicable to program version 1.0

What to do?

See page

Window

number

See PROCEDURE - SETTING if other settings and operating data are required.

What must always be done/checked ?

1. Check that the installation is correctly executed

2. Open the unit and check that nothing has been left lying inside the unit

3. Push the plug into an earthed wall socket

4. Activate the setting keys 3

5. Choice of language in text window 14 81

6. Perform setting of: Standard flow and Reduced flow 7 11 and 12

7. Perform setting of: Operating time per weekday, weekly rhythm 8 30

(without presence sensor)

8. If a presence sensor is fitted, set annual rhythm period 1 14 41

9. Check year, date, weekday and time 10 51,52,53,54

10. Select summer night-time cooling 11 60

11. Check/select electric heater and cooling coil 14 75 and 76

12. Start calibration. N.B. THIS MUST ALWAYS BE DONE 12 71b

13. Select AUTO operating mode (after completed calibration)

Are there any other settings that may be changed, if required ?

14. Choice of temperature control (change to supply air regulation) 6 14

15. Setting of room temperature for room control (default value 20ºC) 6 15a

16. Setting of lowest supply air temperature for room control (default value 19ºC) 6 15b

17. Setting of supply air temperature for supply air control (default value 19ºC) 6 15c

18. Locking (blocking) of “Overtime“,“Ventilation“ and “Stop“operating mode keys 14 72,73,74

19. Locking of setting keys (parameter lock) 3

Commissioning - start-up

Fläkt Woods 8061 GB 2009.05 7 Specifications are subject to alteration without further notice.

RoomMaster ABR-2 COMMISSIONING

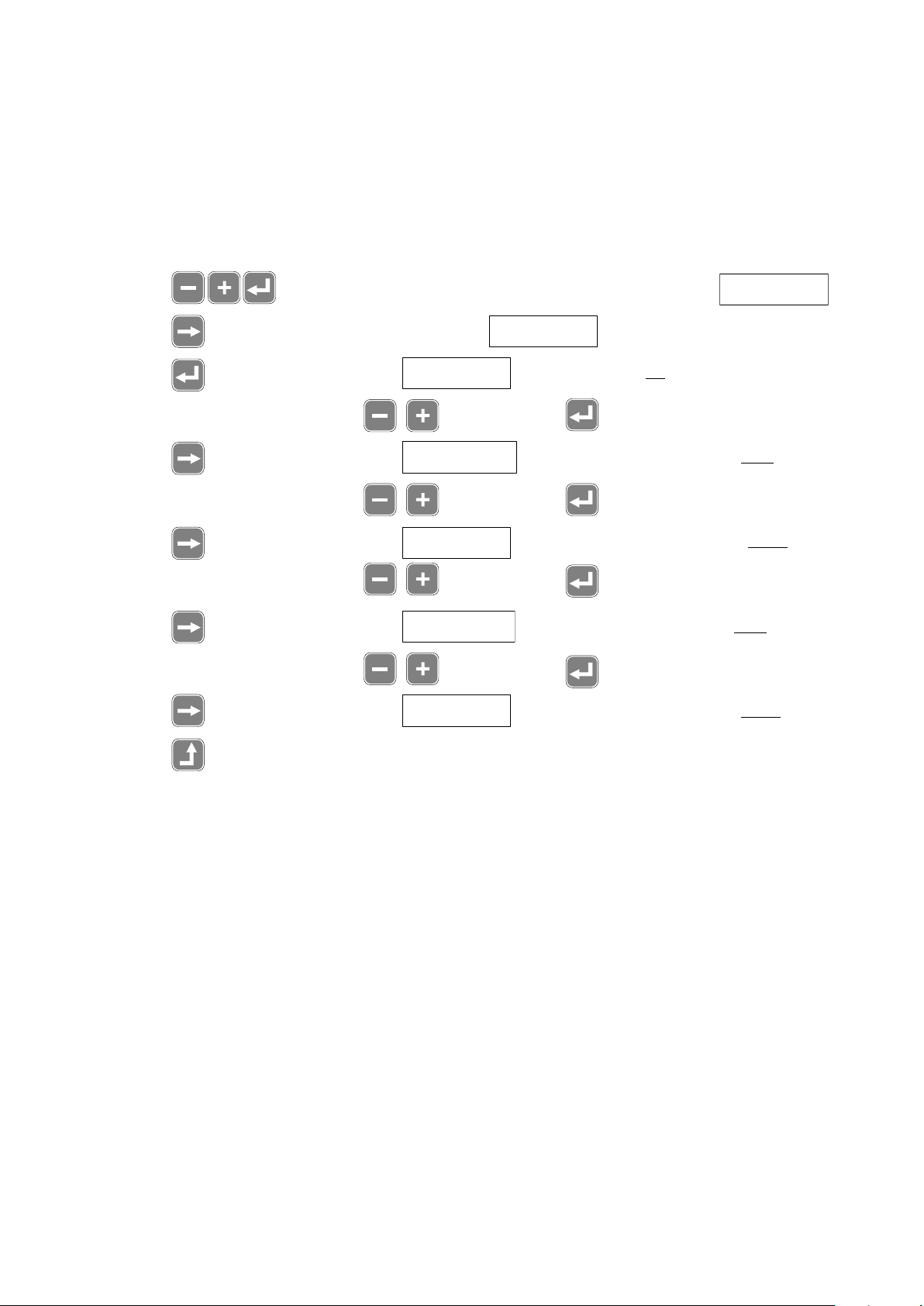

Setting temperature regulation and desired temperature value

The setting ranges are shown after the current window. The default value is underlined.

1. Press the keys at the same time for approx. 5 seconds. Window 10 is displayed

2. Press the key. Window 11 is displayed

3. Press the key 3 times until window 14 is displayed Room regulation - Supply air regulation

4. Select Room regulation or Supply air regulation with , and confirm with (cursor stops flashing)

5. Press the key. Window 15 is displayed

6. Press the key. Window 15a is displayed 10.0 <–> 30.0ºC 20.0ºC

7. Change to the desired value with , and confirm with (cursor stops flashing)

8. Press the key. Window 15b is displayed 15.0 <–> 25.0ºC 19.0ºC

9. Change to the desired value with , and confirm with (cursor stops flashing)

10. Press the key. Window 15c is displayed 10.0 <–> 30.0ºC 19.0ºC

11. Change to the desired value with and confirm with (cursor stops flashing)

12. Press the key 3 times to return to the operating window.

13. The unit will now operate with the new set values.

10

Set desired value

11 Standard flow

exhaust air: 200 l/s

14 Temperature

regulation: Room reg.

15b Min supp.air.tem.

(Room reg.) 19,0oC

15a Room temp.

(room.reg. 19oC

15

Set temperature

15c Suppl. air temp.

(suppl air reg)19,0oC

Procedure - setting

Fläkt Woods 8061 GB 2009.05 8 Specifications are subject to alteration without further notice.

RoomMaster ABR-2 COMMISSIONING

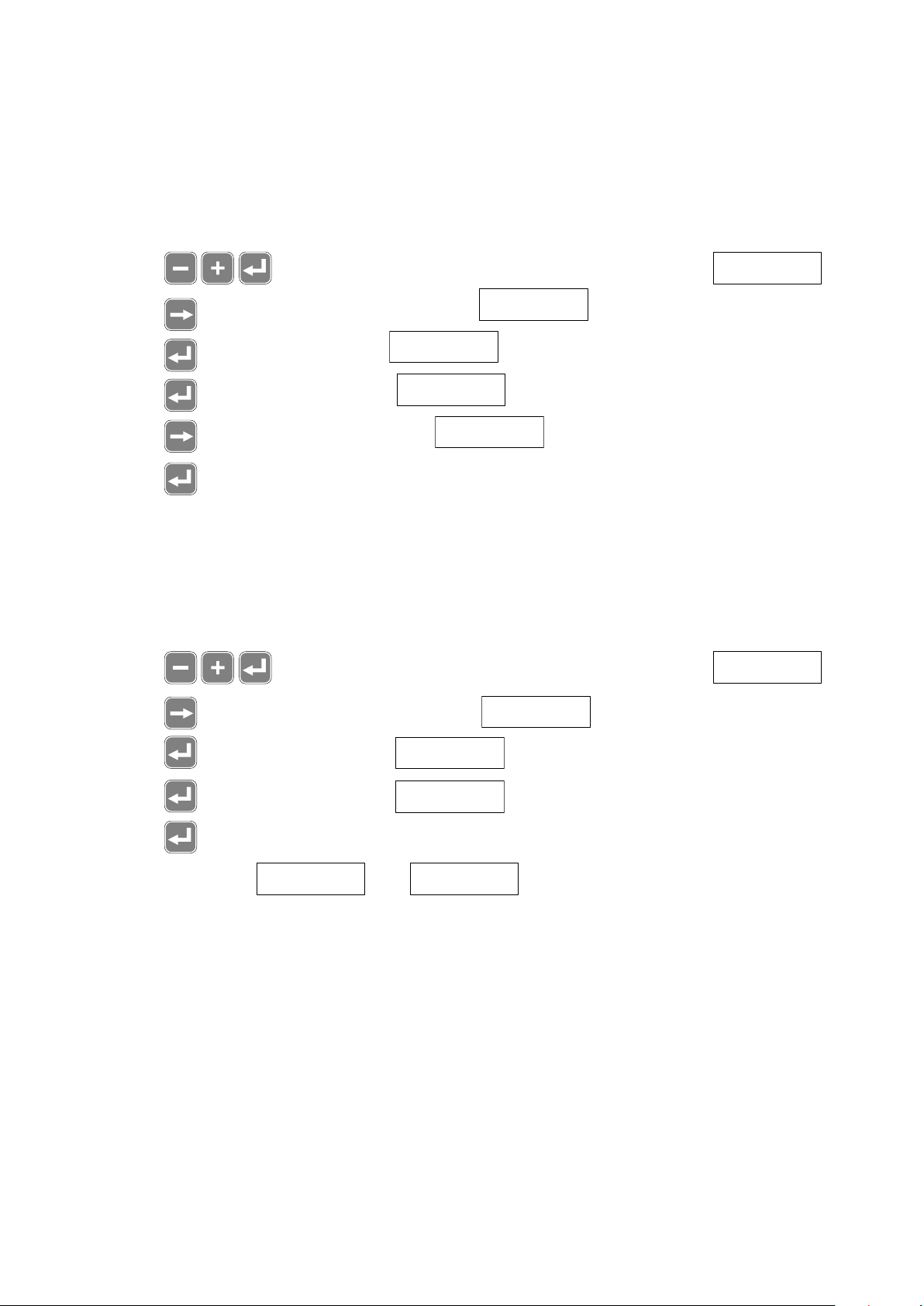

Setting of exhaust air flow, standard and reduced flow and supply air/exhaust air flow ratio

The setting ranges are shown after the current window. The default value is underlined.

1. Press the keys at the same time for approx. 5 seconds. Window 10 is displayed

2. Press the key. Window 11 is displayed 150 <-> 300 l/s 200 l/s

3. Change to the desired standard flow with , and confirm with (cursor stops flashing)

4. Press the key. Window 12 is displayed 75 <-> 150 l/s 100 l/s

5. Change to the desired standard flow with , and confirm with (cursor stops flashing)

6. Press the key. Window 13 is displayed 0.7 <-> 1.3 1.0

7. Change to the desired standard flow with , and confirm with (cursor stops flashing)

8. Press the key 2 times to return to the operating window.

9. The unit will now operate with the new set values.

Reading actual values (Window 20)

1. Press the keys at the same time for approx. 5 seconds. Window 10 is displayed

2. Press the key. Window 20 is displayed

3. Press the key. Window 21 is displayed current exhaust air temperature can be read

4. Press the key. Window 22 is displayed current supply air temperature can be read

5. Press the key. Window 23 is displayed current outdoor air temperature can be read

6. Press the key. Window 24 is displayed current exhaust air flow can be read

7. Press the key. Window 25 is displayed current supply air flow can be read

8. Press the key. Window 26 is displayed current speed of heat exchanger rotor can be read

9. Press the key. Window 27 is displayed current power output from the electric coil can be read

10. Press the key. Window 28 is displayed current output signal can be read

Press the key 2 times to return to the operating window.

10

Set desired value

11 Standard flow

exhaust air: 200 l/s

12 Red.flow exhaust

air: 100 l/s

13 Supply air/exhaust

air ratio: 1,0

10

Set desired value

20

Read actual values

21 Exhaust air temp.

= 21,5 oC

22 Supply air temp.

= 19,5 oC

23 Outdoor air

temp. = 59,0 oC

24 Exhaust air flow

= 245 l/s

25 Supply air flow

= 245 l/s

26 Heat exchanger

rotor speed= 9,2 rpm

27 Output of

electric coil = 50 %

28 Control voltage

for cooling coil=10,0V

Procedure - setting

Fläkt Woods 8061 GB 2009.05 9 Specifications are subject to alteration without further notice.

RoomMaster ABR-2 COMMISSIONING

Setting operating times and operating mode in weekly rhythm (Window 30)

The setting ranges are shown after the current window. The default value is underlined.

1. Press the keys at the same time for approx. 5 seconds. Window 10 is displayed

2. Press the key (2 times) until window 30 is displayed

3. Press the key. Window 31 is displayed

4. Press the key. Window 31a is displayed Setting of hour and minute 8.00

5. Change to the desired change-over time 1 with , and confirm with (cursor stops flashing)

6. Press the key. Window 31b is displayed Standard flow - Reduced flow - Stop

7. Change to the desired activity 1 with , and confirm with (cursor stops flashing)

8. Press the key. Window 31c is displayed Setting of hour and minute 17.00

9. Change to the desired change-over time 2 with , and confirm with (cursor stops flashing)

10. Press the key. Window 31d is displayed Standard flow - Reduced flow - Stop

11. Change to desired activity 2 with , and confirm with (cursor stops flashing)

12. Press the key. Window 31 is displayed

13. Press the key. Window 32 is displayed

14. Repeat the above procedure to set the desired operating times and operating modes for the other days of the week.

15. Press the key 3 times to return to the operating window.

The default values for Tuesday to Friday are the same as for Monday.

The default values for Saturday and Sunday are:

Change-over time 1 = 8.00 Activity 1 = Reduced flow

Change-over time 2 = 17.00 Activity 2 = Reduced flow

N.B. For normal air handling, it is recommended that the unit is operated continuously. In order to be able to select the

“Stop“ activity, i.e. if the unit is stopped during the night, dampers are required in the outdoor air and the extract air duct.

10

Set desired value

30

Set weekly rhythm

31 Set time/activity

for Monday

31a Change-over

screen1 Mon: 8:00

31b Activity1 Monday

Standard flow

31c Change-over

time 2 Monday:17:00

31d Activity 2 Monday

Reduced flow

31 Set time/activity

for Monday

32 Set time/activity

for Tuesday

Procedure - setting

Fläkt Woods 8061 GB 2009.05 10 Specifications are subject to alteration without further notice.

RoomMaster ABR-2 COMMISSIONING

Setting operating times and operating mode in weekly rhythm (Window 40)

The setting ranges are shown after the current window. The default value is underlined.

1. Press the keys at the same time for approx. 5 seconds. Window 10 is displayed

2. Press the key (3 times) until window 40 is displayed

3. Press the key. Window 41 is displayed

4. Press the key. Window 41a is displayed No effect - Standard flow - Reduced flow - Stop

5. Change to the desired activity with , and confirm with (cursor stops flashing)

6. Press the key. Window 41b is displayed Setting of month and day

7. Change to the desired starting time for period 1 with , and confirm with (cursor stops flashing)

8. Press the key. Window 41c is displayed Setting of month and day

9. Change to the desired stop time for period 1 with , and confirm with (cursor stops flashing)

10. Press the key. Window 41 is displayed

11. Press the key. Window 42 is displayed

12. Repeat the above procedure to set the desired operating times and operating modes for periods 2, 3, 4 and 5.

13. Press the key 3 times to return to the operating window.

Periods 2, 3, 4 and 5 have the same default value as period 1.

N.B. For normal air handling, it is recommended that the unit is operated continuously. In order to be able to select the “Stop“

activity, i.e. if the unit is stopped during the night, dampers are required in the outdoor air and the extract air duct.

Presence sensor (accessory)

The following settings should be made for period 1 when connecting a presence sensor.

See also PRESENCE SENSOR on page 16.

10

Set desired value

40

Set annual rhythm

41 Set time/activity

for period 1

41a Activity period 1:

Reduced flow

41b Starting time

period 1: 01-01

41c Finishing time

period 1: 01-01

41 Set time/activity

for period 1

42 Set time/activity

for period 2

41a Activity period 1:

Reduced flow

41b Starting time

period 1: 01-01

41c Finishing time

period 1: 01-01

Procedure - setting

Fläkt Woods 8061 GB 2009.05 11 Specifications are subject to alteration without further notice.

RoomMaster ABR-2 COMMISSIONING

Setting clock (Window 50)

1. Press the keys at the same time for approx. 5 seconds. Window 10 is displayed

2. Press the key (4 times) until window 50 is displayed

3. Press the key. Window 51 is displayed Year

4. Set the year with , and confirm with (cursor stops flashing)

5. Press the key. Window 52 is displayed Month - Day

6. Set the date with , and confirm with (cursor stops flashing)

7. Press the key. Window 53 is displayed Weekday

8. Set the weekday with , and confirm with (cursor stops flashing)

9. Press the key. Window 54 is displayed Hours - Minutes

10. Set the time with , and confirm with (cursor stops flashing)

11. Press the key 2 times to return to the operating window.

10

Set desired value

50

Set clock

51 Set year

1996

52 Set date

2-10 (m-d)

53 Set weekday:

Friday

54 Set time:

16:19 (h:m)

Procedure - setting

Fläkt Woods 8061 GB 2009.05 12 Specifications are subject to alteration without further notice.

RoomMaster ABR-2 COMMISSIONING

Activation of summer night-time cooling (Window 60)

The setting ranges are shown after the current window. The default value is underlined

1. Press the keys at the same time for approx. 5 seconds. Window 10 is displayed

2. Press the key (5 times) until window 60 is displayed

3. Press the key. Window 61 is displayed No - Yes

4. Activate summer night-time cooling with , and confirm with (cursor stops flashing)

5. Press the key. Window 62 is displayed 0.0 <-> 10.0ºC 5.0ºC

6. Change to the desired temperature with , and confirm with (cursor stops flashing)

7. Press the key. Window 63 is displayed 16.0 <-> 32.0ºC 22.0ºC

8. Change to the desired temperature with , and confirm with cursor stops flashing)

9. Press the key. Window 64 is displayed 2.0 <-> 5.0ºC 2.0ºC

10. Change to the desired temperature with , and confirm with (cursor stops flashing)

11. Press the key. Window 65 is displayed 5.0 <-> 20.0ºC 12.0ºC

12. Press the key 2 times to return to the operating window.

Windows 62, 63, 64 and 65 have no effect if summer night-time cooling is not activated in window 61

10

Set desired value

60 Set summer

night-time cooling

61 Summer night-

time cooling: Yes

62 Exhaust air temp.

outd.air temp>=:5,0oC

63 Exhaust air temp

greater than: 22,0oC

64 Temp reduction

in the room: 2,0oC

65 Outdoor temp.

not below: 12,0oC

Procedure - setting

Fläkt Woods 8061 GB 2009.05 13 Specifications are subject to alteration without further notice.

RoomMaster ABR-2 COMMISSIONING

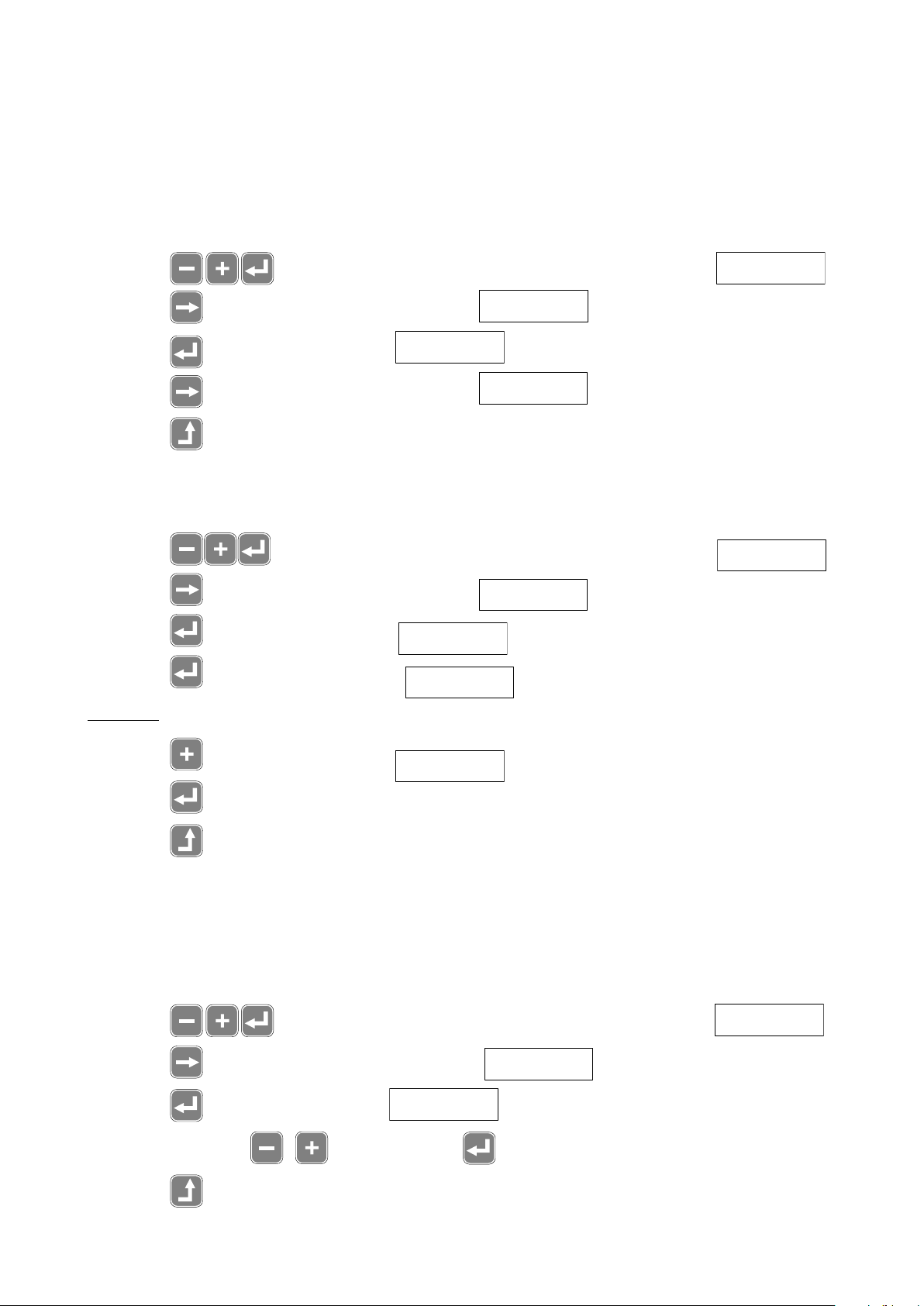

Calibration of unit (Window 71b)

1. Press the keys at the same time for approx. 5 seconds. Window 10 is displayed

2. Press the key (6 times) until window 70 is displayed

3. Press the key. Window 71 is displayed

4. Press the key. Window 71a is displayed

5. Press the key, once. Window 71b is displayed

6. Press the key Calibration is activated

Calibration is complete when the ‘calibration‘ text disappears from the operating window.

The time required for calibration is approx. 5 minutes.

Self-test of unit (Window 71a)

1. Press the keys at the same time for approx. 5 seconds. Window 10 is displayed

2. Press the key (6 times) until window 70 is displayed

3. Press the key. Window 71 is displayed

4. Press the key. Window 71a is displayed

5. Press the key. Self-test is activated

6. The operating windows and will be displayed during the self-test.

The self-test is complete when the ‘self-test‘ and ‘filter test‘ text disappears.

The time required for the self-test is approx. 20 minutes.

10

Set desired value

70 Test /Default value

/ Configuration

71a Self-test

71 Test /Calibration

/ Default value

71b Calibration

10

Set desired value

70 Test /Default value

/ Configuration

71 Test /Calibration

/ Default value

71a Self-test

Automatic

Filter test

Automatic

Self-test

Procedure - setting

Fläkt Woods 8061 GB 2009.05 14 Specifications are subject to alteration without further notice.

RoomMaster ABR-2 COMMISSIONING

Reset default values (Window 71c)

1. Press the keys at the same time for approx. 5 seconds. Window 10 is displayed

2. Press the key (6 times) until window 70 is displayed

3. Press the key. Window 71 is displayed

4. Press the key. Window 71a is displayed

5. Press the key, (2 times). Until window 71c is displayed

6. Press the key the values are reset to default values according to the list below.

Window Description Default value

No.

11 Standard flow: Exhaust air 200 l/s

12 Reduced flow: Exhaust air 100 l/s

13 Ratio: Supply air/Exhaust air 1

14 Temperature regulation Room regulation

15a Room temperature (Room reg.) 20 oC (Room reg.)

15b Min supply air tem. (Room reg.) 19 oC "

15c Supply air tem. (Supply air reg.) 19 oC (Suuply air reg.)

16a Temp.reg. P-band 1,0 oC

16b Temp.regl. I-time 5,0 min

16c Compensation factor k1 4,2 (Room regl.)

16d Compensation factor k2 3,2 "

16e Compensation factor k3 0,3 "

31a Change-over time 1 Monday 8,00 (Weekly rhythm)

31b Activity1 Monday Standard flow "

31c Change-over time 2 Monday 17.00 "

31d Activity2 Monday Reduced flow "

32a Change-over time 1 Tuesday 8,00 "

32b Activity 1 Tuesday Standard flow "

32c Change-over time 2 Tuesday 17.00 "

32d Activity2 Tuesday Reduced flow "

33a Change-over time 1 Wedn.day 8,00 "

33b Activity 1 Wednesday Standard flow "

33c Change-over time 2 Wedn.day 17.00 "

33d Activity 2 Wednesday Reduced flow "

34a Change-over time 1 Thursday 8.00 "

34b Activity 1 Thursday Standard flow "

34c Change-over time 2 Thursday 17.00 "

34d Activity 2 Thursday Reduced flow "

Window Description Default value

No.

35a Change-over time 1 Friday 8.00 (Weekly rhythm)

35b Activity 1 Friday Standard flow "

35c Change-over time 2 Friday 17.00 "

35d Activity 2 Friday Reduced flow "

36a Change-over time 1 Saturday 8,00 (Weekly rhythm)

36b Activity 1 Saturday Reduced flow "

36c Change-over time 2 Saturday 17.00 "

36d Activity 2 Saturday Reduced flow "

37a Change-over time 1 Sunday 8,00 "

37b Activity 1 Sunday Reduced flow "

37c Change-over time 2 Sunday 17.00 "

37d Activity 2 Sunday Standard flow "

41a Activity period 1 No effect (Annual rhythm)

42a Activity period 2 No effect "

43a Activity period 3 No effect "

44a Activity period 4 No effect "

45a Activity period 5 No effect "

61 Summer night-time cooling No

62 Exhaust air temp.-outd. temp. 5,0 oC (Summer cooling)

63 Exhaust aur temp.greater than 22,0 oC "

64 Temp. reduction in room 2,0 oC "

65 Outdoor temp. not below 12,0 oC "

75 Electric coil installed Yes

77 Program version R2d ABR2 SV

N.B. This setting is used only if it is wished to revert to the default data of the control and regulation system necessary in

order to be able to run the unit. The default values are stored in an erasable programmable read only memory (EPROM) and

CANNOT be changed via the control panel.

Settings (system-dependent data) that are made via the control panel on delivery from the factory and in conjunction with

installation are stored in a RAM with battery back-up and a real time clock (annual clock).

10

Set desired value

70 Test /Default value

/ Configuration

71 Test /Calibration

/ Default value

71a Self-test

71c Calibration

Procedure - setting

Fläkt Woods 8061 GB 2009.05 15 Specifications are subject to alteration without further notice.

RoomMaster ABR-2 COMMISSIONING

Activation (blocking) of operating mode keys

1. Press the keys at the same time for approx. 5 seconds. Window 10 is displayed

2. Press the key (6 times) until window 70 is displayed

3. Press the key. Window 71 is displayed

4. Press the key. Window 72 is displayed No - Yes

5. Select Yes or No with , and confirm with (cursor stops flashing)

6. Press the key, once. Window 73 is displayed No - Yes

7. Select Yes or No with , and confirm with (cursor stops flashing)

8. Press the key, once. Window 74 is displayed No - Yes

9. Select Yes or No with , and confirm with (cursor stops flashing)

10. Press the key twice to return to the operating window.

Activation of electric coil and cooling coil

1. Press the keys at the same time for approx. 5 seconds. Window 10 is displayed

2. Press the key (6 times) until window 70 is displayed

3. Press the key. Window 71 is displayed No - Yes

4. Press the key (4 times) until window 75 is displayed No - Yes

5. Select Yes or No with , and confirm with (cursor stops flashing)

6. Press the key. Window 76 is displayed No - Recycling - Cooling coil/recycling

7. Select Yes or No with , and confirm with (cursor stops flashing)

8. Press the key twice to return to the operating window.

STOP

10

Set desired value

70 Test /Default value

/ Configuration

71 Test /Calibration

/ Default value

72 Overtime button

activated Yes

73 Ventilation button

activated Yes

74 Stop button

activated Yes

10

Set desired value

70 Test /Default value

/ Configuration

71 Test /Calibration

/ Default value

75 Electrical coil

installed Yes

76 Cooling

No

Procedure - setting

Fläkt Woods 8061 GB 2009.05 16 Specifications are subject to alteration without further notice.

RoomMaster ABR-2 COMMISSIONING

Program version (Window 77)

1. Press the keys at the same time for approx. 5 seconds. Window 10 is displayed

2. Press th key (6 times) until window 70 is displayed

3. Press the key. Window 71 is displayed

4. Press the key (6 times) until window 77 is displayed

5. Press the key twice to return to the operating window.

PRESENCE SENSOR Setting operating times and operating mode in annual rhythm

The setting ranges are shown after the current window. The default value is underlined

1. Press the keys at the same time for approx. 5 seconds. Window 10 is displayed

2. Press the key (3 times) until window 40 is displayed

3. Press the key. Window 41 is displayed

4. Press the key. Window 41a is displayed

No effect - Standard flow - Reduced flow - Stop

5. Press the key until window 41a shows

6. Press the key to confirm

Press the key twice to return to the operating window.

Function: The unit operates at reduced flow when the presence sensor does NOT sense any movement in the room.

N.B.

For normal air handling, it is recommended that the unit is operated continuously. In order to be able to select the “Stop“

activity, i.e. if the unit is stopped during the night, dampers are required in the outdoor air and the extract air duct.

10

Set desired value

70 Test /Default value

/ Configuration

71 Test /Calibration

/ Default value

77 Program version

1.0

10

Set desired value

40

Set annual rhythm

41 Set time/activity

for period 1

41a Activity period 1:

Reduced flow

41a Activity period 1:

Reduced flow

Choice of language (Window 81)

1. Press the keys at the same time for approx. 5 seconds. Window 10 is displayed

2. Press the key (7 times) until window 80 is displayed

3. Press the key. Window 81 is displayed English, German, French

4. Choose language with and confirm with (cursor stops flashing)

5. Press the key twice to return to the operating window.

10

Set desired value

80

Choose language

81 Language:

English

Procedure - setting

Fläkt Woods 8061 GB 2009.05 17 Specifications are subject to alteration without further notice.

RoomMaster ABR-2 COMMISSIONING

Alarm and fault-finding

The alarm message is displayed in the window in clear text at the same time as a red LED flashes on the control panel.

Alarm message Operation Cause Remedy

Unit stops Power supply to motor interrupted. Contact a service engineer. Check

the motor connections, any integral overheating protection and the

motor.

Unit stops Power supply to motor interrupted. Contact a service engineer. Check

themotor connections, any integral overheating protection and the

rotor.

Unit stops Sensor signal to control card Contact a service engineer to check

interrupted or unacceptable. the sensors.

Unit in operation Sensor signal to control card Contact a service engineer to check

Room regulation interrupted or unacceptable. the sensors.

switched automatically

to supply air regulation

Unit stops Supply air temperature has fallen Check the exhaust air temperature

below the set desired value by 10 (see window 21).

degrees for more than 15 minutes. Check the setting of the lowest

This may occur if there is a fault in: supply air temperature

heat exchanger, electric coil. 15c). (see windows 15b or

It may also be due to low room Check the heat exchanger and electric

temperature and setting of operating coil (see Alarm, heat exchanger and

data, such as: stopping the unit electric coil).

without a damper, lowest supply air Check that an electric coil is installed

temp. too high, electric heater not (see window 75).

connected. Check setting of operating mode (see

If a presence sensor is fitted, the windows 30 and 40).

unit will stop if the "no effect" Check whether a damper is fitted in

activity is selected for period 1 the outdoor air duct, and setting of

(see window 41a) activity.

Unit in operation No output or low efficiency from Check that the heat exchanger drive

heat exchanger. belt is sound and fully tensioned.

Unit in operation Power supply interrupted. Check the electric coil connections

Overheating protection tripped. and overheating protection.

Reset the overheating protection

on the electric coil.

Unit in operation Block filters. Replace the filter and re-calibrate.

An alarm with clean filters indicates

that calibration was NOT carried out

during installation.

Acknowledgement of alarm text is done by pressing once; the alarm text disappears, and the LED continues to flash.

Press once more to activate selftest.

AUTO

AUTO

ALARM

Fan, supply air

ALARM

Fan, exhaust air

ALARM

Temp.sensor supp air

ALARM

Temp.sensor exh. air

ALARM

Low supply air temp.

ALARM

HE- rotor not work.

ALARM

Elec.Coil not working

ALARM

Replace air filter

Procedure - setting

Fläkt Woods 8061 GB 2009.05 18 Specifications are subject to alteration without further notice.

RoomMaster ABR-2 COMMISSIONING

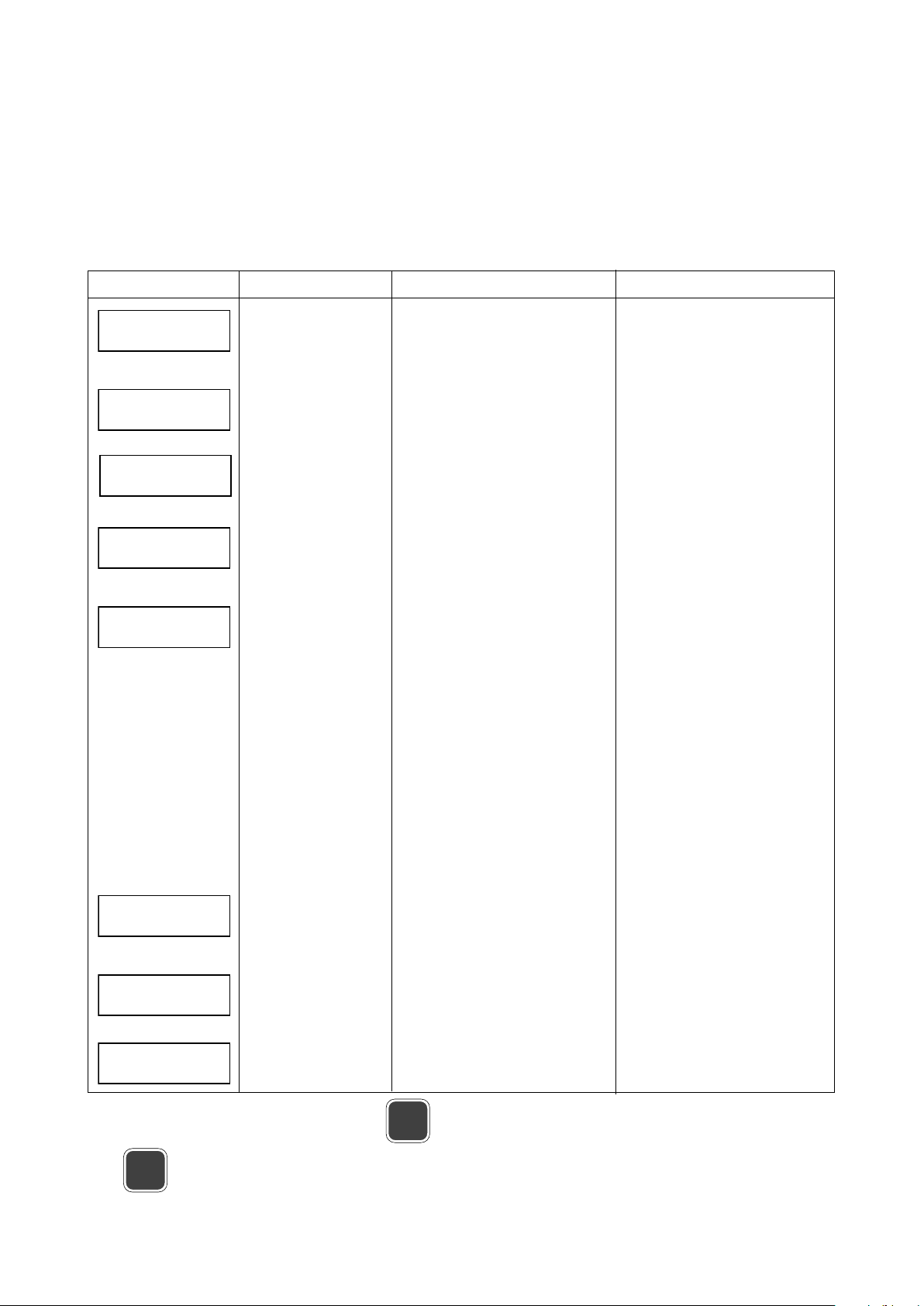

AUTO

11 Standard flow

exhaust airt: 200 l/s

12 Reduced flow

exhaust air 100 l/s

14 Temperature regulation

Room regulation

13 Supply air/exhaust air

ratio: 1,0

15

Set temperature

15c Supply air

temperature 19,0 C

21 Exhaust air

temperature = 21,5 C

16 Set regulation

parameters supply air

22 Supply air

temperature = 19,5 C

16aTemp.reg.

P-band: 1,0 C

23 Outdoor air

temperature = –59,0 C

24 Exhaust air flow

= 200 l/s

25 Supply air flow

= 200 l/s

16b Temp.reg.

I-time: 5,0 min

16c Compensation

factor k1: 4,2

26 Heat exchanger

rotor speed= 9,2 rpm

16d Compensation

factor k2: 3,2

27 Output of electric

coil = 50 %

28 Control voltage for

cooling coil= 10.0 V

32 Set time/activity

Tuesday

33 Set time/activity

Wednesday

34 Set time/activity

Thursday

35 Set time/activity

Friday

36 Set time/activity

Saturday

37 Set time/activity

Sunday

41 Set time/activity

period 1

51 Set year:

1996

75 Electric coil

installed Yes

76 Cooling

No

81 Language:

English

64 Temp. reduction

in the room: 2.0 C

42 Set time/activity

period 2

52 Set date:

4-19 (m-d)

72 Overtime button

activated: Yes

73 Ventilation button

activated Yes

74 Stop button

activated Yes

77 Program version

= R2c ABR2 SV

62 Exhaust air.temp.-

outdoor air temp.: >=5 C

61 Summer night-time

cooling No

65 Outdoor temperature

not below: 12.0 C

43 Set time/activity

period 3

53 Set weekday:

Monday

54 Set time:

14:34 (h:m)

71a Self-test

71 Test/Calibration

Default value

71c Reset to

default values

71b Calibration

63 Exhaust air temp

greater than: 22.0 C

44 Set time/activity

period 4

45 Set time/activity

period 5

31 Set time/activity

Monday

31a Change-over

time 1 Monday

43b Starting time

period 3

43c Stopping time

period 3

31c Change-over

time 2 Monday

43a Activity period 3:

31b Activity 1 Monday

Standard flow

31d Activity 2 Monday

Reduced flow

16e Compensation

factor k3: 0,3

15a Room temperaturer

20,0 C

15b Min. Supply air

temperature 19,0 C

Next

Next

Next

Next

Next

Next Next

Next

Next

Next Next

Next

Next

Next

Next

Next

Next

Next

Next

Next

Next

Next

Enter

Enter

Enter

Enter

Escape

Escape

Escape

Escape

Escape

Escape

Escape

Escape

Escape

Escape

Escape

Escape

Escape

Enter

Next

Next

Next

Next

Next

Next

Next

Next

Next

Next

Next

Next

Next

Enter

Enter

Enter

Enter

Enter

Enter

Enter

Enter Enter

Next

Next

Next

Next

Next

Next

Next

Next Next

Next

Next Next

Next

Next

Next

Next

Next

Next

Next

Next

Next

Next

Next

Next

Next

Next

Next

Next

Next

Next

Next

Next

32a

41a

42a

44c

45b

33a

34a

35a

36d

37c

32d

33d

34d

35d

36c

37b

32c

41c

42c

44b

45a

33c

34c

35c

36b

37a

32b

41b

42b

44a

45c

33b

34b

35b

36a

37d

No effect

.

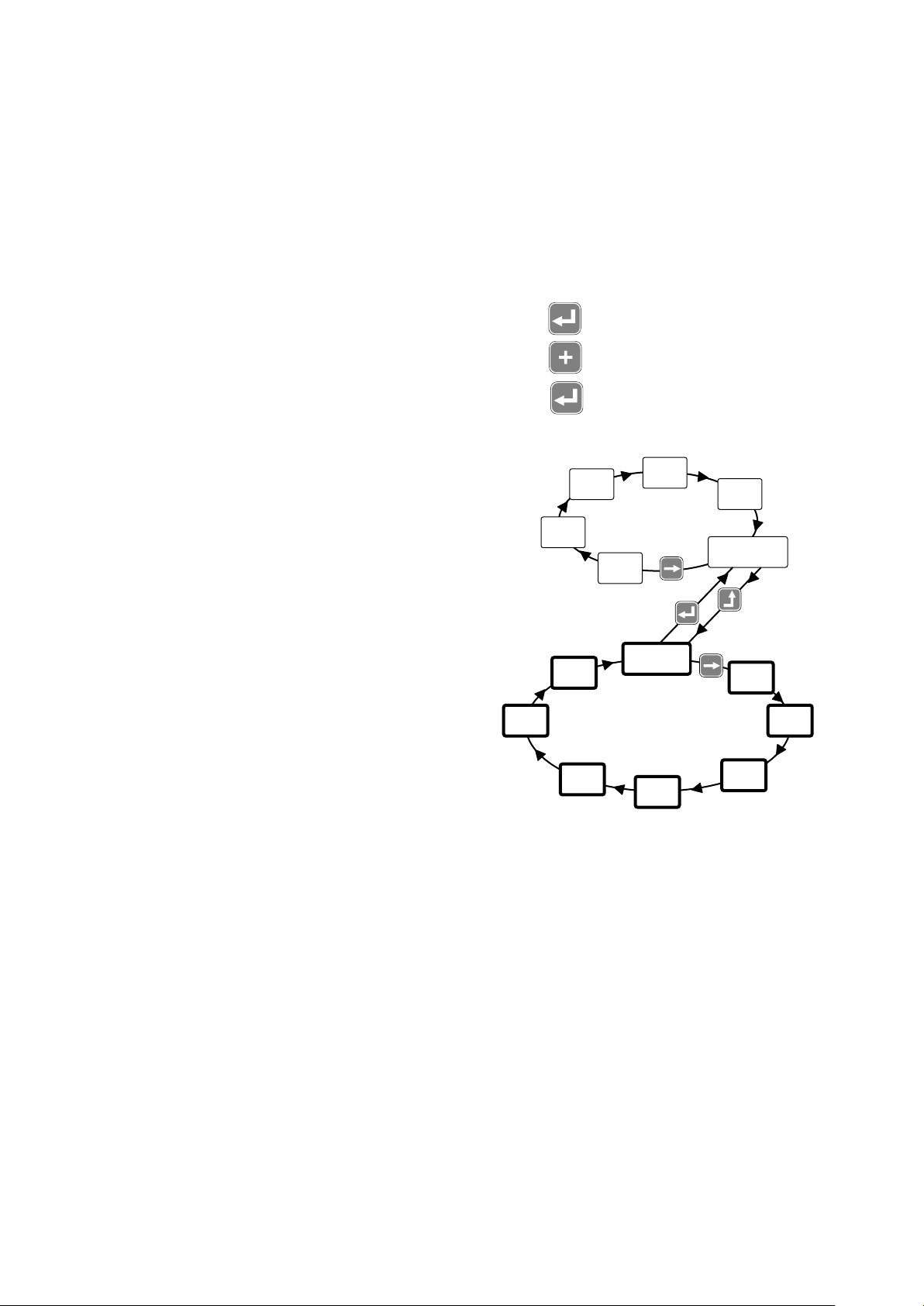

60 Setting of summer

night cooling

70 Test/Default

Configuration

80 Select language 10 Set desired

value

50 Setting clock 40 Set annual

rhythm

30 Set weekly

rhythm

20 Read actual

values

Program version 1.0

Menu Structure

Procedure - setting

Fläkt Woods 8061 GB 2009.05 19 Specifications are subject to alteration without further notice.

RoomMaster ABR-2 COMMISSIONING

Wind. Description Default Own

No. value setting

36 Set time/activity Saturday

36a Change-over time 1 Saturday 8:00

36b Activity 1 Saturday Standard flow

36c Change-over time 2 Saturday 17:00

36d Activity 2 Saturday Reduced flow

37 Set time/activity Sunday

37a Change-over time 1 Sunday 8:00

37b Activity 1 Sunday Reduced flow

37c Change-over time 2 Sunday 17:00

37d Activity 2 Sunday Reduced flow

Annual rhythm

40 Main menu Set annual rhythm

41 Set time/activity period 1

41a Activity period 1 No effect

41b Starting time period 1 01-01

41c Stopping time period 1 01-01

42 Set time/activity period 2

42a Activity period 2 No effect

42b Starting time period 2 01-01

42c Stopping time period 2 01-01

43 Set time/activity period 3

43a Activity period 3 No effect

43b Starting time period 3 01-01

43c Stopping time period 3 01-01

44 Set time/activity period 4

44a Activity period 4 No effect

44b Starting time period 4 01-01

44c Stopping time period 4 01-01

45 Set time/activity period 5

45a Activity period 5 No effect

45b Starting time period 5 01-01

45c Stopping time period 5 01-01

Clock

50 Main menu Set clock

51 Set year Current year

52 Set date Current date

53 Set weekday Current day

54 Set time Current time

Summer night-time cooling

60 Main menu Set summer night-time cooling

61 Summer night-time cooling No

62 Exhaust air temp. - outd.temp. 5,0oC

63 Exhaust air temp. greater than 22,0oC

64 Temp.reduction in room 2,0oC

65 Outdoor temp. not below 12,0oC

Test / Calibration / Default values

70 Main menu Test/Default

71 Self-test

72 Calibration

73 Set default values

75 Electric coil installed No

76 Cooling coil installed No

77 Program version 1.0

Language

80 Main menu Select language

81 Language English

Procedure - setting

Wind. Description Default Own

No. value setting

Air flow

10 Main menu Set desired value

11 Standard flow: exhaust air 200 l/s

12 Reduced flow: exhaust air 100 l/s

13 Ratio: Supply/Exhaust 1.0

Temperature regulation

14 Temperature regulation Room regul.

15 Set room temperature

15a Room temperature (room regul.) 20oC

15b Loweat supply air temp. (room reg.) 19°C

15c Supply air temp (supply air regul.) 19°C

16 Set supply air regulation parameters

146a Temp.reg. P-band 1,0oC

16b Temp.reg. I-time 5,0 Min.

16c Compensation factor k1 4,2

16d Compensation factor k2 3,2

16e Compensation factor k3 0,3

Actual values

20 Main menu Read actual values Value read off

21 Temperature, exhaust air (oC) "

22 Temperautre, supply air (oC) "

23 Air flow, exhaust air (l/a) "

24 Air flow, supply air (l/a) "

25 Heat exch. rotor speed(U/min) "

26 Electric coil output (%) "

27 Control for cooling coil (V) "

Weekly rhythm

30 Main menu Set weekly rhythm

31 Set time/activity Monday

31a Change-over time 1 Monday 8:00

31b Activity 1 Monday Standard flow

31c Change-over time 2 Monday 17:00

31d Activity 2 Monday Reduced flow

32 Set time/activity Tuesday

32a Change-over time 1 Tuesday 8:00

32b Activity 1 Tuesday Standard flow

32c Change-over time 2 Tuesday 17:00

32d Activity 2 Tuesday Reduced flow

33 Set time/activity Wednesday

33a Change-over time 1 Wednesday 8:00

33b Activity 1 Wednesday Standard flow

33c Change-over time 2 Wednesday 17:00

33d Activity 2 Wednesday Reduced flow

34 Set time/activity Thursday

34a Change-over time 1 Thursday 8:00

34b Activity 1 Thursday Standard flow

34c Change-over time Thursday 17:00

34d Activity 2 Thursday Reduced flow

35 Set time/activity Friday

35a Change-over time 1 Friday 8:00

35b Activity 1 Friday Standard flow

35c Change-over time 2 Friday 17:00

35d Activity 2 Friday Reduced flow

List of parameters

Fläkt Woods AB 551 84 Jönköping

t036 - 19 30 00 f036 - 19 36 20

wwww.flaktwoods.com

FWG_AHU_ABR2 Technical instruction_2009.05_GB_8061 Condesign Info Productions AB ABF5533

Other manuals for RoomMaster ABR-2

1

Table of contents

Other flakt woods Air Conditioner manuals