flamco Flexfiller 125D Manual

www.flamcogroup.com

© 2014 Flamco group. All rights reserved.

We reserve the right to change designs and technical specifications of our products.

Rev 8.1 Aug-15 Page 1/ 44

Flexfiller Digital Pressurisation Equipment

Flexfiller Models (125D, 225D, 150D, 250D, 280D)

Midi Models (125D, 225D, 150D, 250D)

Mini Models (130D, 230D)

Operation & Maintenance

Manual

Rev 8.3

www.flamcogroup.com

© 2014 Flamco group. All rights reserved.

We reserve the right to change designs and technical specifications of our products.

Rev 8.1 Aug-15 Page 2/ 44

Customer Details

Please fill in information future reference:

Company: Contact:

Address: Tel No:

Fax No:

Post Code: E-mail:

Equipment Details

Details of model and serial number may be found on the label

Model: Serial No:

Purchase date: Purchase From:

Note:

It is highly recommended to have this equipment commissioned by a Flamco approved engineer. Any damage or

loss incurred through incorrect commissioning by an unapproved engineer will not be covered by the warranty.

If you wish for Flamco to arrange this please contact us. (See contact details)

Please see the warranty section for details.

Remember to fill in details for future use for re-commission unit.

Remember: When installing a expansion vessel with the pressurisation unit make sure the cold pressure is the

same in order for the system to work effectively.

Flexfiller Mini 130D & 230D - Under no circumstances must be used to fill a system of any size.

www.flamcogroup.com

© 2014 Flamco group. All rights reserved.

We reserve the right to change designs and technical specifications of our products.

Rev 8.1 Aug-15 Page 3/ 44

Commissioning Record

FILL IN RECORD TO VALIDATE WARRANTY OF PRESSURISATION UNIT

Site Reference:

PU Reference:

Date Commissioned:

/

/

Engineer Name:

Company:

COLD FILL:

Bar

FILL SYSTEM:

YES / NO

Delete as appropriate

HIGH SET:

Bar

PUMPS NUMBER:

1 / 2

Delete as appropriate

LOW SET:

Bar

PUMP TYPE:

0 / 1

Delete as appropriate

DIFFERENTIAL:

Bar

PUMP SENSE:

YES / NO

Delete as appropriate

FLOOD LIMIT:

Minutes

SENSOR TYPE:

0 / 1 / 2

Delete as appropriate

PUMP 1 COUNT:

SPC CONTROLLER:

NO

PUMP 1 HOURS:

GLYCOL UNIT:

NO

PUMP 2 COUNT:

ID NUMBER:

PUMP 2 HOURS:

RELAY

INVERSION:

YES / NO

Delete as appropriate

ALARM COUNT:

OVERUN:

POWER

INTERRUPTED:

PRESSURE ALARM AUTO RESET:

YES / NO

Delete as appropriate

PULSE:

YES / NO

Delete as appropriate

EXCESSIVE START:

YES / NO

Delete as appropriate

YES / NO

Delete as appropriate

SERVICE:

YES / NO

Delete as appropriate

YES / NO

Delete as appropriate

Notes:

Commissioning certificate can be obtained please contact Flamco representative

Engineer Signature:

Date:

/

/

Customer Signature:

Date:

/

/

www.flamcogroup.com

© 2014 Flamco group. All rights reserved.

We reserve the right to change designs and technical specifications of our products.

Rev 8.1 Aug-15 Page 4/ 44

Contents

Customer & Equipment details 2

Commission Record 3

About this Manual

Where to find more Information 5

Equipment Overview

Principal of Operation 6

Installation

Pipe Connections 7

Typical Installation Diagram 7

Flow Restrictors (Midi & Mini models only) 8

Flexfiller Clearance and Connection Requirements 9

Midi Clearance and Connection Requirements 10

Mini Clearance and Connection Requirements 11

Electrical Power Supply 12

Fault Contacts 13

Commissioning

Pre-Commissioning Checklist 14

Controller Overview 15

Controller Programming 16

Program List 17 –19

Hydraulic Commissioning 20 - 24

Operation

Fault Codes 25

Shutdown Procedure 26

Start-Up Procedure 26

Maintenance

Maintenance information 27 - 28

Wiring Diagram 29

Wiring Location 30

Spares

Electrical Items (All Models) 31

Flexfiller Models (125D, 225D, 150D, 250D, 280DS) 32

Midi Models (125D, 225D, 150D, 250D) 33

Mini Models (130D, 230D) 34

Troubleshooting 35 - 37

Service Log 38 - 39

Warranty Information 40

www.flamcogroup.com

© 2014 Flamco group. All rights reserved.

We reserve the right to change designs and technical specifications of our products.

Rev 8.1 Aug-15 Page 5/ 44

About this Manual

This Operation and Maintenance Manual contains all the necessary information to install, commission, operate

and maintain Flexfiller pressurisation equipment.

It is recommended to read all parts of this manual before undertaking any work on the equipment.

Conventions used in this Manual

This manual makes use of symbols to identify key pieces of information. Please take note of the following

symbols and their meaning:

DANGER –Important safety related information intended to prevent injury and/or damage to the

equipment, system or property.

CAUTION - Important information intended to prevent damage to the equipment, system or

property.

IMPORTANT - Important information intended to ensure that the equipment functions correctly.

USEFUL –Useful information which may be helpful, but is not necessarily required for the unit to

function correctly.

Typography

This manual makes use of different typography to identify different types of information.

Italics Key words and phrases

(Round Brackets) Used to identify a button on the digital controller

[Square Brackets] A parameter on the digital controller

<Inequality Symbols> A message/fault code displayed on the digital controller

Where to find more Information

For further information please visit the Flamco Limited Website at the following URL:

www.flamco.co.uk

Alternatively, please contact the Flamco Limited head office using the details below:

Phone: 01744 744 744

Fax: 01744 744 700

www.flamcogroup.com

© 2014 Flamco group. All rights reserved.

We reserve the right to change designs and technical specifications of our products.

Rev 8.1 Aug-15 Page 6/ 44

Equipment Overview

The function of this pressurisation unit is to provide a means of automated water top-up to sealed heating and

cooling systems. The equipment is designed to provide periodic water top-up to compensate for minor losses in

system pressure (e.g. slow leaks, air venting, etc.).

This equipment is not designed to cope with sudden losses of system pressure (e.g. manual

draining) or major water losses (e.g. large leaks). The equipment is also not intended to be used

for water boosting applications.

Principal of Operation

The following schematic shows the internal arrangement of a pressurisation unit:

The pressurisation unit is fitted with a break tank (1) which is filled from the mains water supply (2) via a float

operated valve (3). The break tank is fitted with an overflow (4) in case the break tank overfills, and a weir

overflow (5) in case the primary overflow fails.

The pressurisation unit is connected into the heating system (6) via an isolation valve (7).

The pressure sensor (8) monitors the system pressure.

If the pressure sensor detects a drop in pressure, the pump (9a) will pump water from the break tank into the

system. Once the required pressure has been reached, the pump will stop.

On twin pump models, a second pump (9b) is provided. The two pumps will run in a duty/standby configuration

(i.e. the active pump will alternate with each pump start).

The pump(s) are fitted with non-return valves (10a, 10b) to prevent backflow.

A drain valve (11) is provided for draining down the unit and for commissioning purposes.

www.flamcogroup.com

© 2014 Flamco group. All rights reserved.

We reserve the right to change designs and technical specifications of our products.

Rev 8.1 Aug-15 Page 7/ 44

Installation

This pressurisation unit is not designed to be installed in an outdoor environment. The unit must

be installed in a frost free environment, away from precipitation and water sprays/jets. If there is

a risk of flooding, the unit must be installed on a raised plinth.

Please refer to the appropriate datasheet for the maximum working pressure and temperature of

the pressurisation unit. The conditions at the point of connection to the system must not exceed

these values.

Pipe Connections

To avoid damaging the float valve, the mains water supply pipe must be flushed before

connection to the pressurisation unit.

All pipe connections must be made with appropriate jointing compound/PTFE tape.

If PTFE tape is used, care must be taken to ensure that the tape does not obstruct the orifice of

the fitting.

Non-return valves, pressure reducing valves and RPZ valves must not be installed between the

pressurisation unit and the heating/cooling system. These devices will prevent the pressure

sensor from reading the system pressure.

The pressurisation unit and expansion vessel should be connected to the system at the same

point, to provide a neutral pressure reading. This point of connection should be in the system

return, on the suction side of the circulation pump.

Typical Installation Diagram

www.flamcogroup.com

© 2014 Flamco group. All rights reserved.

We reserve the right to change designs and technical specifications of our products.

Rev 8.1 Aug-15 Page 8/ 44

Flow Restrictors (Mini & Midi Models Only)

Pressurisation equipment fitted with a plastic, side-entry torbeck valve must be fitted with a filter

and –depending on the mains water pressure –a flow restrictor. Failure to do this may result in

damage to the equipment.

Two different flow restrictors are supplied with the equipment, both of which include an integral filter. The

selection of the appropriate flow restrictor is based on the maximum mains water pressure at the point of

installation. Please refer to the following table for selection.

Mains Water Pressure

Requirement

Below 1 Bar

No Restrictor. Install Filter Only

1 –4 Bar

Low Pressure Restrictor (coloured)

Above 4 Bar

High Pressure Restrictor (white)

If no restrictor is required, the filter must be removed from one of the restrictors and installed on its own. The

following diagram shows how to remove the filter:

To install the flow restrictor/filter, hold it by the tab and push it into the opening of the float valve connection,

as shown in the diagram below:

www.flamcogroup.com

© 2014 Flamco group. All rights reserved.

We reserve the right to change designs and technical specifications of our products.

Rev 8.1 Aug-15 Page 9/ 44

Flexfiller Clearance and Connection Requirements

Connection

Size

Notes

Mains

Water Feed

½” BSP M

An isolation valve must be

installed on the mains water feed

for servicing.

Break Tank

Overflow

22mm

Guidance on drainage

requirements should be obtained

from the local water authority.

System

Connection

½” BSP M

/ 15mm

The pressurisation unit and

expansion vessel should be

connected to the system at the

same point.

The point of connection should

be in the system return, on the

suction side of the circulation

pump.

Non-return valves, pressure

reducing valves and RPZ valves

must not be used.

www.flamcogroup.com

© 2014 Flamco group. All rights reserved.

We reserve the right to change designs and technical specifications of our products.

Rev 8.1 Aug-15 Page 10 / 44

Midi Clearance and Connection Requirements

Connection

Size

Notes

Mains

Water Feed

½” BSP M

An isolation valve must be

installed on the mains water

feed for servicing.

Break Tank

Overflow

22mm

Guidance on drainage

requirements should be

obtained from the local water

authority.

System

Connection

½” BSP M

/ 15mm

The pressurisation unit and

expansion vessel should be

connected to the system at the

same point.

The point of connection should

be in the system return, on the

suction side of the circulation

pump.

Non-return valves, pressure

reducing valves and RPZ valves

must not be used.

www.flamcogroup.com

© 2014 Flamco group. All rights reserved.

We reserve the right to change designs and technical specifications of our products.

Rev 8.1 Aug-15 Page 11 / 44

Mini Clearance and Connection Requirements

Connection

Size

Notes

Mains

Water Feed

½” BSP M

An isolation valve must be

installed on the mains water

feed for servicing.

Break Tank

Overflow

22mm

Guidance on drainage

requirements should be

obtained from the local water

authority.

System

Connection

¼” BSP F

The pressurisation unit and

expansion vessel should be

connected to the system at the

same point.

The point of connection should

be in the system return, on the

suction side of the circulation

pump.

Non-return valves, pressure

reducing valves and RPZ valves

must not be used.

www.flamcogroup.com

© 2014 Flamco group. All rights reserved.

We reserve the right to change designs and technical specifications of our products.

Rev 8.1 Aug-15 Page 12 / 44

Electrical Power Supply

This equipment must be electrically isolated before removing the covers. Cables connected to the

volt free contacts may be supplied from another source and may remain live after the unit is

isolated. These must be isolated elsewhere.

All electrical connections must be carried out by a suitably qualified and competent person.

The mains power supply to the pressurisation unit must be connected into the fused terminal block as shown

below:

On some larger models, the fused terminal block is replaced by a fused spur. If this is the case, the power supply

must be connected into the fused spur, as shown below:

It is recommended to supply power to the pressurisation unit via a lockable isolator. This should

be installed within 2m of the equipment.

This equipment can be damaged by the high voltages produced by electrical installation testing

equipment. When performing electrical installation tests, the equipment must be isolated from

the supply.

www.flamcogroup.com

© 2014 Flamco group. All rights reserved.

We reserve the right to change designs and technical specifications of our products.

Rev 8.1 Aug-15 Page 13 / 44

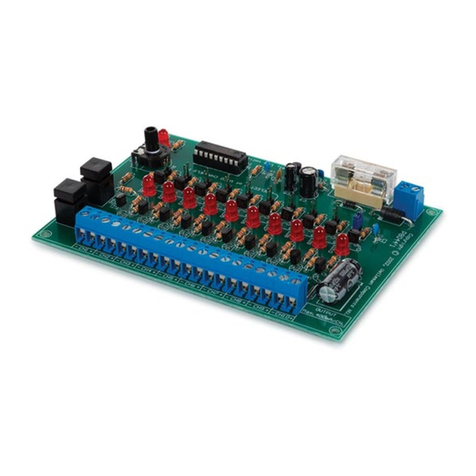

Micro Controller

Fault contacts

There are 6 volt free fault contacts which can be used for connection to a BMS system, or as a boiler interlock.

These are terminals 1-12, located on the digital controller:

With the exception of the Common Alarm, it is possible to convert all other fault contacts to

normally closed. For further information please refer to the commissioning section of this manual.

www.flamcogroup.com

© 2014 Flamco group. All rights reserved.

We reserve the right to change designs and technical specifications of our products.

Rev 8.1 Aug-15 Page 14 / 44

Commissioning

It is highly recommended to have this equipment commissioned by a Flamco approved engineer.

Any damage or loss incurred through incorrect commissioning by an unapproved engineer will not

be covered by the warranty.

Pre-Commissioning Checklist

The following conditions must be met before starting the commissioning process. Failure to meet

these conditions may result in injury or damage to the equipment, system and property.

Equipment is sited in a frost free area, away from precipitation and water sprays/jets

All necessary pipe/electrical connections have been made to a satisfactory standard

The temperature and pressure at the point of connection are within the operating limits of the

pressurisation unit.

The heating/cooling system is fitted with a safety valve and expansion vessel

The following conditions must be met for the pressurisation unit and heating/cooling system to

function correctly. If these conditions have not been met, it is not advisable to proceed with the

commissioning process.

The system connection has been made into the system return header/pump suction

There are no non-return valves, pressure reducing valves or RPZ valves installed between the

pressurisation unit and the heating/cooling system

The expansion vessel is pre-charged to the correct pressure (equal to fill pressure)

It is advisable to fill the heating/cooling system prior to commissioning. If this is not possible, the

pressurisation unit can be used to fill the system after commissioning. Depending on the size of

the system, this may take a considerable amount of time.

The heating/cooling system is filled and pressurised to the required cold fill pressure, with the water at

ambient temperature (approximately).

www.flamcogroup.com

© 2014 Flamco group. All rights reserved.

We reserve the right to change designs and technical specifications of our products.

Rev 8.1 Aug-15 Page 15 / 44

Controller Overview

The following image shows the front of the pressurisation unit digital controller. 4 buttons are provided for

programming, and an LED display which shows scrolling messages.

When the controller is first powered up, it will display the controller version number. This manual

relates to controller version >8.0. If the controller is of a different version, there may be

differences in the menu items available.

When in normal operation, the controller will display the current system pressure. If a fault occurs, the

controller will display a fault code and produce an audible alarm.

In normal operation, the functions of the buttons are as follows:

Button

Function

Press

Hold

SET

-

Show Current System Pressure

MUTE

Mute Audible Alarm

Reset Unit

+

-

Enter Programming Menu

-

-

Enter Programming Menu

www.flamcogroup.com

© 2014 Flamco group. All rights reserved.

We reserve the right to change designs and technical specifications of our products.

Rev 8.1 Aug-15 Page 16 / 44

Controller Programming

Do not alter any settings without first understanding the implications of doing so. Incorrect

settings may cause damage to the equipment, system or property.

To enter the programming menu, hold the (+) button until “enter code” appears on the screen, followed by

“0000” with a flashing cursor after the first digit.

To gain access to the programming menu, one of the following codes must be entered:

Customer Code

Standard set of options

2601

Engineer Code (≥V6.3)

Extended set of options

4706

To enter the code, change the first digit with the (+) and (-) buttons, then press (SET) to move onto the next

digit. Repeat for all digits, then once the correct code is shown on the display, press (SET) to enter the

programming menu.

Once a correct code has been entered, the first option [COLD FILL] will appear on the screen.

Once in the menu, the value of the current menu item can be changed using the (+) and (-) buttons. Once the

current value has been set, pressing the (SET) button will move on to the next option.

It is not possible to navigate backwards through the menu. To return to a previous setting in the

menu, press the (SET) button repeatedly to scroll through to the end of the menu, and then re-

enter the appropriate code.

If the controller looses power while in the programming menu, all changes made will be erased.

To confirm all changes, the end of the menu must be reached, and the “SAVING...” message must

be displayed.

www.flamcogroup.com

© 2014 Flamco group. All rights reserved.

We reserve the right to change designs and technical specifications of our products.

Rev 8.1 Aug-15 Page 17 / 44

Program List

The table below gives details of all menu items, in the order that they will appear:

#

Menu Item

Function

Default

Value

1

COLD FILL

The required fill pressure, i.e. pump ‘cut-out’ pressure.

The recommended setting is 0.3 BAR above the static pressure of the system

(0.1 Bar per meter of static height).

For example, a 14m high installation will have a static pressure of 1.4 Bar,

making the recommended cold fill pressure 1.7 Bar.

It is not possible to enter a value higher than the current [HIGH SET] or lower

than the current [LOW SET] values.

1.0 Bar

2

HIGH SET

The high pressure alarm setting.

If the pressure in the system reaches this value, the <HIGH PRESSURE> alarm

and common alarm will be activated.

The recommended setting is 10% below the safety valve rating.

For example, if the safety valve rating is 3 Bar, the recommended setting is 2.7

Bar.

It is not possible to enter a value lower than the current [COLD FILL] value.

2.7 Bar

3

LOW SET

The low pressure alarm setting.

If the pressure in the system falls below this value, the <LOW PRESSURE>

alarm and common alarm will be activated, and the pressurisation pumps will

not run.

The recommended setting is 0.5 Bar below the [COLD FILL] pressure.

It is not possible to enter a value higher than the current [COLD FILL] value.

0.5 Bar

4

DIFFERENTIAL

The differential between the ‘cut-in’ and ‘cut-out’ pressures of the

pressurisation pumps.

The cut-in pressure will be equal to the [COLD FILL] pressure, minus the

differential pressure.

For example, if the [COLD FILL] pressure is set to 1.5 bar, and the differential

set to 0.2 Bar, the pump ‘cut-in’ pressure will be 1.3 Bar (1.5 – 0.2 = 1.3)

0.2 Bar

5

FLOOD LIMIT

The maximum continuous run time for each of the pressurisation pumps.

If a pump runs continuously for longer than this period, the pump will stop

and a <FLOOD LIMIT> alarm will be activated.

This is to prevent the unit from pumping large amounts of water in the event

of a large leak/burst pipe.

For very large systems, this may need to be increased.

The value can be changed in increments of 10 minutes, to a maximum of 990.

10 MINS

6

PUMP 1 COUNT

The cumulative number of pump starts for pump 1.

This is a cumulative counter, the value of which cannot be modified. If using

the engineer’s code, the counter can be reset to zero by holding the (MUTE)

button.

-

7

PUMP 1 HOURS

The cumulative run time in hours for pump 1.

This is a cumulative timer, the value of which cannot be modified. If using the

engineer’s code, the counter can be reset to zero by holding the (MUTE)

button.

-

www.flamcogroup.com

© 2014 Flamco group. All rights reserved.

We reserve the right to change designs and technical specifications of our products.

Rev 8.1 Aug-15 Page 18 / 44

#

Menu Item

Function

Default

Value

8

PUMP 2 COUNT

The cumulative number of pump starts for pump 2.

This is a cumulative counter, the value of which cannot be modified. If using the

engineer’s code, the counter can be reset to zero by holding the (MUTE)

button.

-

9

PUMP 2 HOURS

The cumulative run time in hours for pump 2.

This is a cumulative timer, the value of which cannot be modified. If using the

engineer’s code, the counter can be reset to zero by holding the (MUTE)

button.

-

10

ALARM COUNT

The cumulative number of all alarm incidents.

This is a cumulative counter, the value of which cannot be modified. If using the

engineer’s code, the counter can be reset to zero by holding the (MUTE)

button.

-

11

POWER

INTERRUPTED

The cumulative number of power interruptions (i.e. controller turned off/

power cut).

This is a cumulative counter, the value of which cannot be modified. If using the

engineer’s code, the counter can be reset to zero by holding the (MUTE)

button.

-

12

PULSE

When enabled, if a pump has been inactive for 60 days, it will start and run for

2 seconds.

This is to prevent the pumps from seizing.

YES

13

EXCESSIVE

START

When enabled, if there are more than 3 individual pump runs within an 8 hour

period, the unit will register an <EXCESSIVE DEMAND> alarm.

Enabling this option may cause false alarms on some systems.

NO

14

SERVICE

When enabled, a service reminder will be displayed after 12 months from when

the option was enabled.

To reset the service reminder, set the value to ‘NO’ and exit the menu. Then,

re-enter the menu and set the value to ‘YES’ again.

NO

15

FILL SYSTEM

When enabled, the <LOW PRESSURE> and <FLOOD LIMIT> alarms will be

disabled, and pump 1 will run continuously for up to 24 hours until the cold fill

pressure has been reached.

Once the cold fill pressure has been reached, this option will automatically be

deactivated, and the low pressure alarm and flood limit will be reactivated.

This function is used to fill a system that is empty or at low pressure.

Care must be taken using this option as the flood limit alarm is disabled,

increasing the risk of flooding.

This option cannot be enabled on Mini pressurisation units.

NO

If using the customer code, the menu will end at this point. After pressing (SET) once more, the

controller will display “SAVING...” and return to normal operating mode. If using the engineer’s

code, additional menu items will be displayed.

The following settings are all pre-programmed in the factory and should not need to be

modified on site. If these settings appear to have been reset, the most likely cause is a power

spike. If this problem persists, a power filter may be required.

www.flamcogroup.com

© 2014 Flamco group. All rights reserved.

We reserve the right to change designs and technical specifications of our products.

Rev 8.1 Aug-15 Page 19 / 44

The following settings are for experienced engineers only. Incorrect configuration of these

settings can cause the equipment not to function correctly, and may cause damage to the

equipment, system or property.

#

Menu Item

Function

Default

Value

16

PUMPS NUMBER

The number of pumps installed in the pressurisation unit.

This can be set to either 1 or 2.

2

17

PUMP TYPE

The type of pump installed in the pressurisation unit.

There are two options, which are as follows:

0 –Centrifugal Pump (Flexfiller /Digifiller/ Midi)

1 –Piston Pump (mini units only)

1

18

PUMP SENSE

Disabling this option will stop the controller from monitoring the pumps and

generating <PUMP FAIL> faults.

It is not recommended to disable this option. Please consult Flamco Technical

before doing so.

YES

19

SENSOR TYPE

The type of pressure sensor installed in the unit.

There are two options which are as follows:

1 –1-6V Output, 0-10 Bar Range

2 –1-6V Output, 0-16 Bar Range

1

20

SPC

CONTROLLER

Not required on standard Pressurisation unit

NO

21

ADDITIVE

Not required on standard Pressurisation unit

NO

22

ID NUMBER

A user configurable identification number.

This option does not serve any functional purpose.

01

23

RELAY

INVERSION

When enabled, all normally open fault contacts (i.e. all except the common

alarm) are converted to normally closed.

NO

24

OVERRUN

Allows the pump to continue running for a set period of time after the required

pressure has been reached.

This will prevent the pumps from ‘hunting’.

The value can be set from 0 –10 seconds.

5

25

PRESSURE

ALARM AUTO

RESET

When enabled, the <HIGH PRESSURE> and <LOW PRESSURE> alarms will be

cleared automatically if and when the pressure returns to normal.

If disabled, the alarms must be manually reset.

YES

26

CASCADE

Allows the pumps to operate in duty/assist mode.

After either pump starts, the other pump will start after a set period of time.

This option can be set to OFF, or 5 –30 seconds.

OFF

27

BOOST

When enabled, the controller will allowing the pumps to run even if the system

pressure is zero.

YES

28

SOLENOID

CONTROLLER

When enabled, the “high water” input is used to trigger a top up solenoid valve

connected to the “sensor healthy” volt free contact.

This option should only be enabled on units which utilize a solenoid valve as the

means of top-up.

NO

Note:

21 = GLYCOL UNIT / 28 = FLOMAT ON (>7.3 VERSION CONTROLLER)

www.flamcogroup.com

© 2014 Flamco group. All rights reserved.

We reserve the right to change designs and technical specifications of our products.

Rev 8.1 Aug-15 Page 20 / 44

Hydraulic Commissioning

1 –Float Valve Setting

Ensure that the break tank float valve is set to its lowest position:

Flexfiller Units Mini & Midi Units

If a drain valve is fitted to the break tank, ensure that it is closed. Then, turn on the mains water supply and

allow the break tank to fill.

When the float valve operates for the first time, it may not close immediately, causing the break

tank to overfill. Once the internals of the valve have been fully wetted this should not occur again.

2 –Bleeding Pumps

This step is only necessary for Flexfiller and Midi units. For Mini units, move on to the next step.

Make sure that the internal isolation valve within the pressurisation unit is closed by following the

steps below. Failure to do this may cause injury or damage to the equipment, system or property.

Un-screw cap turn cap push cap on socket Twist cap

This manual suits for next models

10

Table of contents