INSTALLATION:

-

Check that the appliance is suitable for the type of gas supplied.

-

CONNECTION MUST BE PROVIDED.

- A clearance of at least 1000mm must be available in front of the appliance to

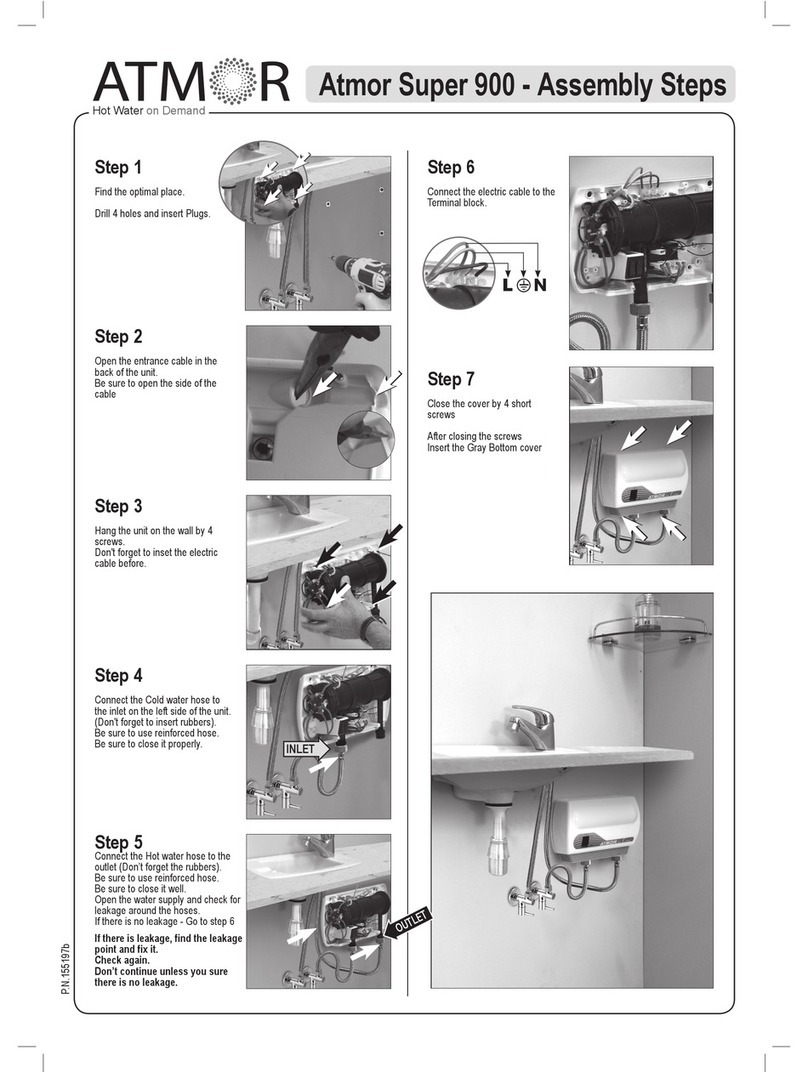

WATER CONNECTION

Connection to the water system must be carried out by using pipes with the

same Ø as that shown in the table. Connect to the water inlet pipe, marked on

the appliance with a blue ring, the water safety unit (not supplied), which must

comply with standard EN89 paragraph 5.5, and must consist of:

- a shutoff valve,

- a check valve,

- a check valve monitoring device,

- a safety valve,

- a draining device.

If the mains pressure exceeds 6 bar, a pressure relief valve must be installed as

far away from the appliance as possible. A shutoff valve must also be installed

on the mains inlet pipe to enable any maintenance operations on the appliance

to be carried out.

The pipes must then be flushed with water to remove any debris, which could

damage the system.

Connect the appliance pipes to the water system pipes (the water inlets and

outlets on the appliance are identified by blue and red rings respectively).

During the appliance normal operation, especially during the heating stage, the

safety valve will drip a little to release pressure from the system, if required. It

is therefore recommended to connect this valve to an open drain and to install

downstream of the safety valve an expansion vessel for food use with a capacity

no lower than 4% of the total capacity of the appliance.

DRAIN

During installation, fit a drain valve. To drain the water heater, proceed a follows.

- Close the shutoff valve located upstream of the appliance.

- Open the water taps downstream of the water heater.

- Open the drain valve.

- Full drainage of the appliance is carried out by siphoning.

- Connect a hose to the drain valve.

RECIRCULATION

For water recirculation, connect the circuit to allow recirculation to the fitting (fig.1)

FILLING UP

The appliance must work with the tank full and at the operating pressure; before

operating the appliance, the tank must therefore be filled up by following the

instructions below:

- after connecting the appliance to the water system, open the cold water supply

valve and a hot water tap (for the bath, bidet, sink etc).

Wait until a continuous flow of water comes out of the tap.

When this happens, the water heater is full and the water tap can be closed,

whilst the water supply valve must be left open.

ELECTRICAL CONNECTION

Connect the appliance to a 200V, single phase, earthed mains power supply.

In the proximity of the appliance, fit a two-pole main switch to stop appliance

operation if necessary. Connect the appliance power cable, making sure CEI

electrical standards are complied with.

IMPORTANT: When connecting the power cable to the mains power supply,

observe the correct polarity (live-neutral). In case of inverted polarities or

live-live power supply, the appliance cannot work.

THE MANUFACTURER CANNOT BE HELD RESPONSIBLE FOR ANY DAMAGES

CAUSED BY THE ELECTRICAL SYSTEM BEING UNEARTHED.

ROOM VENTILATION

FLUE GAS VENTING

Installer Section

Installation Instructions

ease burner installation, adjustment and inspection operations. A clearance

of 1300mm must also be provided above the appliance to clean the flue gas

venting pipes, and of 500mm at the back and at the side of the appliance to

allow access to the internal cleaning holes.

These appliances have been designed to be floor mounted. A DRAINING

The appliance must be installed in compliance with all local relevant

applicable standards esta-blished by standards, which must be referred

to for issues which are not contemplated in this manual. This model of

water heater has been designed to be fixed mounted to the floor. If the

floor is made of wood or of a synthetic material, the water heater must

be positioned on a fire retardant base. If the appliance is to be installed in

an enclosed room without windows, adequate, fresh ventilation must be

provided. An inadequate ventilation can cause fire, explosion or

suffocation. Refer to national or local legislation.

The openings must be made in such a way as to avoid obstructions both from

inside and outside of the wall. Grilles, wired mesh etc. may be used to protect the

openings, without reducing the free net section mentioned above. These openings

must be positioned as close as possible to the ground and they must not interfere

with the flue gas vents

.

Warning: this appliance can only be used inside permanently ventilated

rooms,more specifically, the room must be ventilated with the quantity of air

required by all appliances installed in the room.The air must enter through

permanent openings made on the outside walls of the room to be ventilated.

These openings must have a net free section of at least 6cm² for each kW

installed on the appliance, with a minimum of 100cm²

This appliance is a B23 type appliance and is therefore fitted with a flue gas vent,

which must be directly connected to a chimney or a flue of established efficiency,

with a pipe section at least 50cm long. Only if these devices are not available the

appliance may be directly connected outdoors to vent the combustion products,

as long as the requirements established are complied with. It is also advisable

to read the text of this standard also for the purpose of viewing possible

solutions for making a venting pipe, which are shown in details. The flue gas

venting pipe must have the diameter shown in the table and must be resistant

to acid corrosion caused by condensation. For the oil-fired version, this

pipe must be made of stainless steel. For all versions, the

maximum length of the venting pipe must not exceed 8 metres.

Electrical anode protection

Certain areas of the country have particularly soft water and

therefore poor conductivity of the water with less than 200

micro-siemens per centimetre, such as Cornwall, Scotland and

Devon for example. In these areas of soft water, the magnesium

sacrificial anodes may not suffice in providing adequate protection

against corrosion of the water heater. In these geographical areas,

or other areas with particularly soft water, we insist that you use our

electrical anode protection system, as it is more effective at

providing protection in these circumstances. It is also to be noted

that a constant and uninterrupted power supply is required to these

anodes to ensure the full protection of the water heater.

Our oil-fired storage water heaters are all fitted with removable

magnesium sacrificial anodes as standard which ensuring excellent

protection against corrosion of the water heater. Clearance is

required above the water heater for maintenance and replacement

of the magnesium sacrificial anodes. Should you have insufficient

clearance above the water heater that will prevent anode

replacement using the standard magnesium anodes, then electrical

anode protection may be fitted, instead of the magnesium anodes

Sacrificial anode protection