Flo TTV 1100 User manual

Operating manual

(Translation of the original version)

TTV 1100

Table of contents

TTV 1100 I

Table of contents

1Introduction....................................................................................................................................... 4

1.1 Usage conformant with intended purpose .......................................................................... 4

2Safety information............................................................................................................................ 5

3Device Description ........................................................................................................................... 7

3.1 Initial Startup ................................................................ Fehler! Textmarke nicht definiert.

4Operation........................................................................................................................................... 9

4.1 Driving ................................................................................................................................. 9

4.1.1 Safety information................................................................................................ 9

4.1.2 Starting the Sweeping & Suction Machine .......................................................... 9

4.1.3 Cold start: ............................................................................................................ 9

4.1.4 Driving forward: ................................................................................................. 10

4.1.5 Driving backwards: ............................................................................................ 10

4.2 Sweeping .......................................................................................................................... 10

4.2.1 Operatting the Sweeping Rollers....................................................................... 10

4.2.2 Operating the Filter Cleaning Device ................................................................ 11

4.2.3 Operating the Side Brushes .............................................................................. 11

4.2.4 Operating the Suction........................................................................................ 12

4.3 Adjustment of Driver`s Seat .............................................................................................. 12

4.4 Turning Off the Sweeping & Suction Machine .................................................................. 12

4.5 Operating the Filter Cleaning Device................................................................................ 13

4.6 Emptying the Dust Container............................................................................................ 13

4.6.1 Removing the Dust Container ........................................................................... 13

4.6.2 Reinserting the Dust Container ......................................................................... 14

5Service and Maintenance .............................................................................................................. 15

5.1 Safety Information............................................................................................................. 15

5.2 Cleaning ............................................................................................................................ 15

5.3 Brake................................................................................................................................. 16

5.3.1 Adjusting the Brake ........................................................................................... 16

5.4 Brake Check ..................................................................................................................... 17

5.4.1 Correct Operating of Brake................................................................................ 17

5.5 Wheels .............................................................................................................................. 17

5.6 Steering............................................................................................................................. 17

Table of contents

II TTV 1100

5.7 Removing the main trim panel (hood)............................................................................... 18

5.7.1 Lifting off the hood ............................................................................................. 18

5.7.2 Replacing the hood............................................................................................ 18

5.8 Replenishing operating fluids............................................................................................ 18

5.8.1 Checking the hydraulic oil filling level................................................................ 19

5.8.2 Replenishing fuel ............................................................................................... 20

5.9 Safety information regarding hydraulics ........................................................................... 20

5.10 Replacement of Filter........................................................................................................ 21

5.10.1 Removal............................................................................................................. 21

5.10.2 Reinsertion ........................................................................................................ 22

5.11 Sweeping Rollers Replacement........................................................................................ 22

5.11.1 Dismounting the Sweeping Rollers ................................................................... 22

5.11.2 Installing the Sweeping Rollers ......................................................................... 23

5.12 Setting the Sweeping Rollers............................................................................................ 24

5.12.1 Sweeping Contour Adjustment.......................................................................... 24

5.12.2 Adjusting the Sweeping Contour ....................................................................... 24

5.12.3 Further Possible Adjustment: ............................................................................ 25

5.13 Replacing the Side Brush ................................................................................................. 26

5.13.1 Dismounting the Side Brush.............................................................................. 26

5.13.2 Mounting the Side Brush ................................................................................... 26

5.14 Adjustment of the Side Brush ........................................................................................... 26

5.15 Maintenance Chart............................................................................................................ 28

5.15.1 Daily maintenance ............................................................................................. 28

5.15.2 After each 50 operating hours also ................................................................... 28

5.15.3 After each 100 operating hours also ................................................................. 28

5.15.4 After each 200 operating hours also ................................................................. 29

5.16 Disturbances, Disturbance Display, Remedy ................................................................... 29

5.17 Technical Data .................................................................................................................. 30

5.18 Product Certification.......................................................................................................... 32

5.19 Disposal ............................................................................................................................ 32

5.20 Accessories and spare parts ............................................................................................ 32

5.21 Service .............................................................................................................................. 32

5.22 Transport........................................................................................................................... 33

6EC Declaration of conformity (Translation of the original version) .......................................... 34

Introduction

4 TTV 1100

1 Introduction

This operating manual contains instructions for using the hand-operated

sweeper.

Our products are subject to continuous improvement. Therefore, design

changes that were made after this manual went to print could not be

incorporated. If you have any questions, please contact our Service

department.

The operating manual must be read and applied by all persons who

operate the sweeper.

Apart from the operating manual and the regulations for accident pre-

vention applicable in the country of use and the location of use, the

common, recognised rules for safe and technically correct working must

also be followed.

1.1 Usage conformant with intended purpose

The appliance is intended exclusively for sweeping on solid surfaces (for

example.: parking areas, walkways, shop floors). The area to be swept

should not be wet.

The sweeper may only be used by reliable and instructed personnel.

revent children, juveniles and other unauthorised persons from using the

machine (e.g. by pulling out the key after use).

Any other use, or any use over and above that, will be considered to be

non-conformant with intended purpose. The manufacturer rejects any

and all liability for damage resulting from such use. The risk is that of the

user alone.

Usage conformant with intended purpose also includes compliance with

the operating manual and the inspection and maintenance specifica-

tions. Drive the sweeper only along expressly marked routes and

spaces.

Safety information

TTV 1100 5

2 Safety information

1. The machine should only be used in a flawless state, as

well as in keeping with its intended purpose, in a safety-

conscious and risk-conscious manner and in compliance

with these operating instructions.

2. In addition to the operating manual, please heed general le-

gal and other binding regulations for accident prevention

and environmental protection.

3. Sweeping and picking up of flammable, toxic or explosive

substances, along with flammable gases or diluted acids

and solvents, burning or smouldering objects is prohibited!

4. The appliance is not suitable for picking up fluids, cables,

cords, wires or the like.

5. The machine should only be used with the dust box fitted to

prevent injuries caused by parts being slung out.

6. Transporting loads with the sweeper is not allowed.

7. Faults should be eliminated immediately, particularly those

that could impair safety.

8. Do not make any changes, modifications or additions to the

sweeper without the approval of the manufacturer.

9. Replacement parts must meet manufacturer specifications.

This is always ensured by using original replacement parts.

10. Ensure that operating media, auxiliary media and replace-

ment parts are disposed of in a safe and environmentally-

friendly manner, particularly batteries!

11. Suitable non-slip footwear should be worn to avoid acci-

dents.

12. If you have any questions, please contact our Service de-

partment.

13. Persons (including children) who are not able to use this

machine safely due to their physical, sensory or mental ca-

pabilities or their inexperience or lack of knowledge may not

use this machine without the supervision or instruction by a

responsible person! Children should be supervised to en-

sure that they do not play withthe appliance.

14. Caution: loose clothing can be caught and drawn in on rotat-

ing parts.

15. Observe the maximum climbing capability and maximum

permissible slant specified in the technical data when driv-

ing transversely to an incline. The unit can topple over if the

Safety information

6 TTV 1100

steering is turned too sharply, particularly on inclines. Adjust

your driving style and speed to suit conditions.

16. The machine is not approved for use on roads or streets.

17. Warning: risk of crushing. Maintain a safety clearance of 2

metres to other people during emptying through high dump-

ing.

18. Maintenance and repair work on the hydraulics and high

dumping mechanism should only be entrusted to a special-

ist firm.

19. Personal safety equipment, particularly hearing protection,

must be worn when operating the machines.

20. The machine should only be used outdoors or in ade-

quately-ventilated rooms.

21. Removal of the motor filter while the motor is running can

lead to a sudden increase in motor speed. This applies in

particular if the filter is dirty or blocked in another manner.

22. Work using the unit should be interrupted at regular inter-

vals.

23. Observe general guidelines relating to explosive, inflamma-

ble and highly flammable fuels. Particular care should be

exercised when filling the machine with fuel to ensure that

the motor is deactivated and cold, and that filling is only re-

alised outdoors or in a well-ventilated location.

24. Warning: parts of the machine become hot during use.

There is a risk of burn injuries.

Device Description

TTV 1100 7

3 Device Description

The Sweeping & Suction Machine is driven hydraulically by an internal

combustion engine.

Model TT/V 900 operates by using a pivotable side brush to convey the

sweepings to the two sweeping rollers arranged parallel to the direction

of motion. These project the sweepings overhead into the dust container

positioned behind it.

Optionally two side brushes may be installed. Model TT/E 1100 is

equipped with two pivotable side brushes. If necessary, the dust stirred

up by the sweeping rollers is caught by the dust suction unit in a lamel-

lar filter inside the machine. The lamellar filter is cleaned by an electri-

cally controlled filter cleaning device.

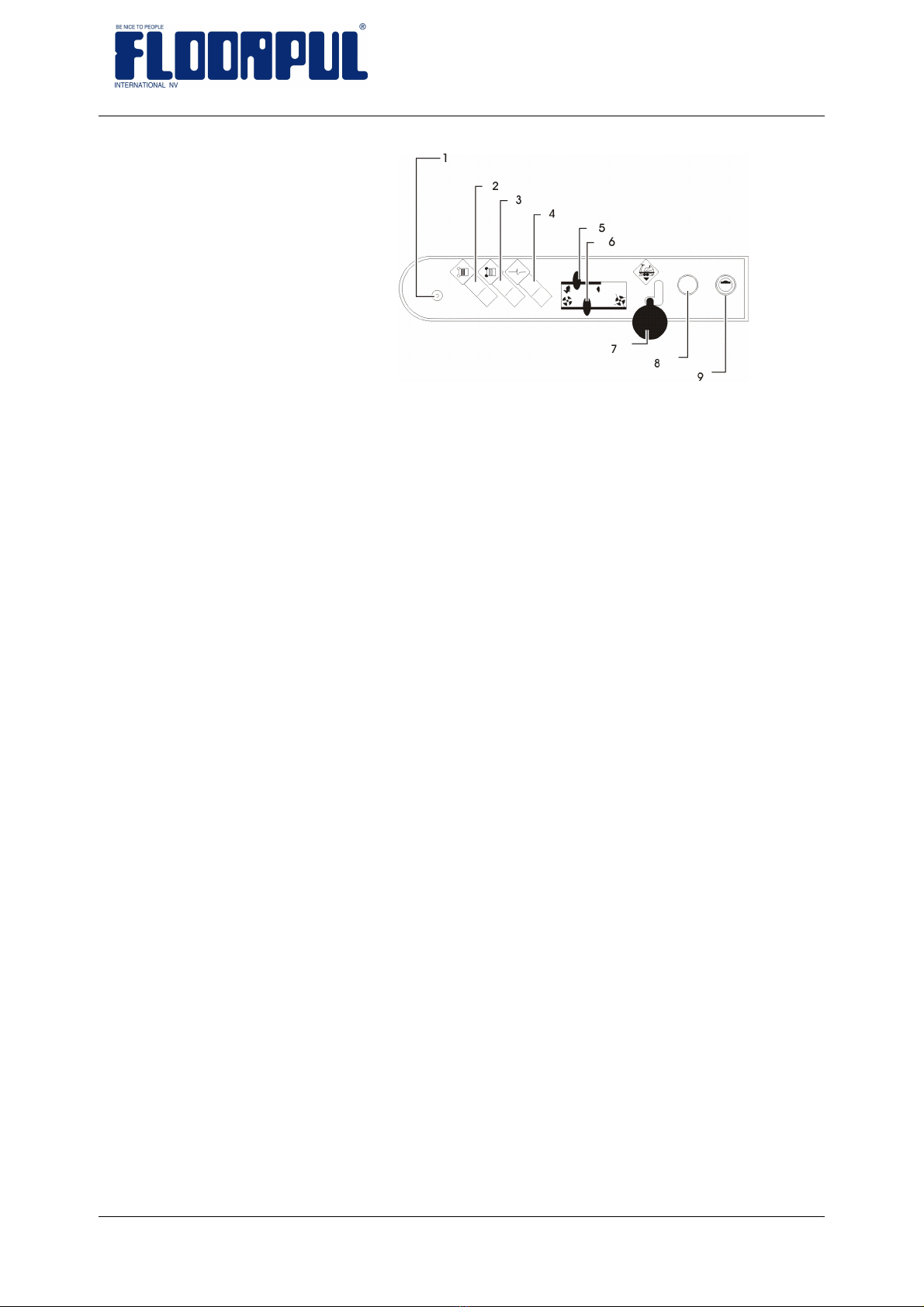

1 Battery check light 2 Switch for the sweeping

rollers

3 Switch for the side brushes

4 Switch for filter cleaning

5 Speed control for the motor

6 Suction control

7 Lowering lever for the

sweeping rollers

8 Cold starting device

9 Key-operated switch

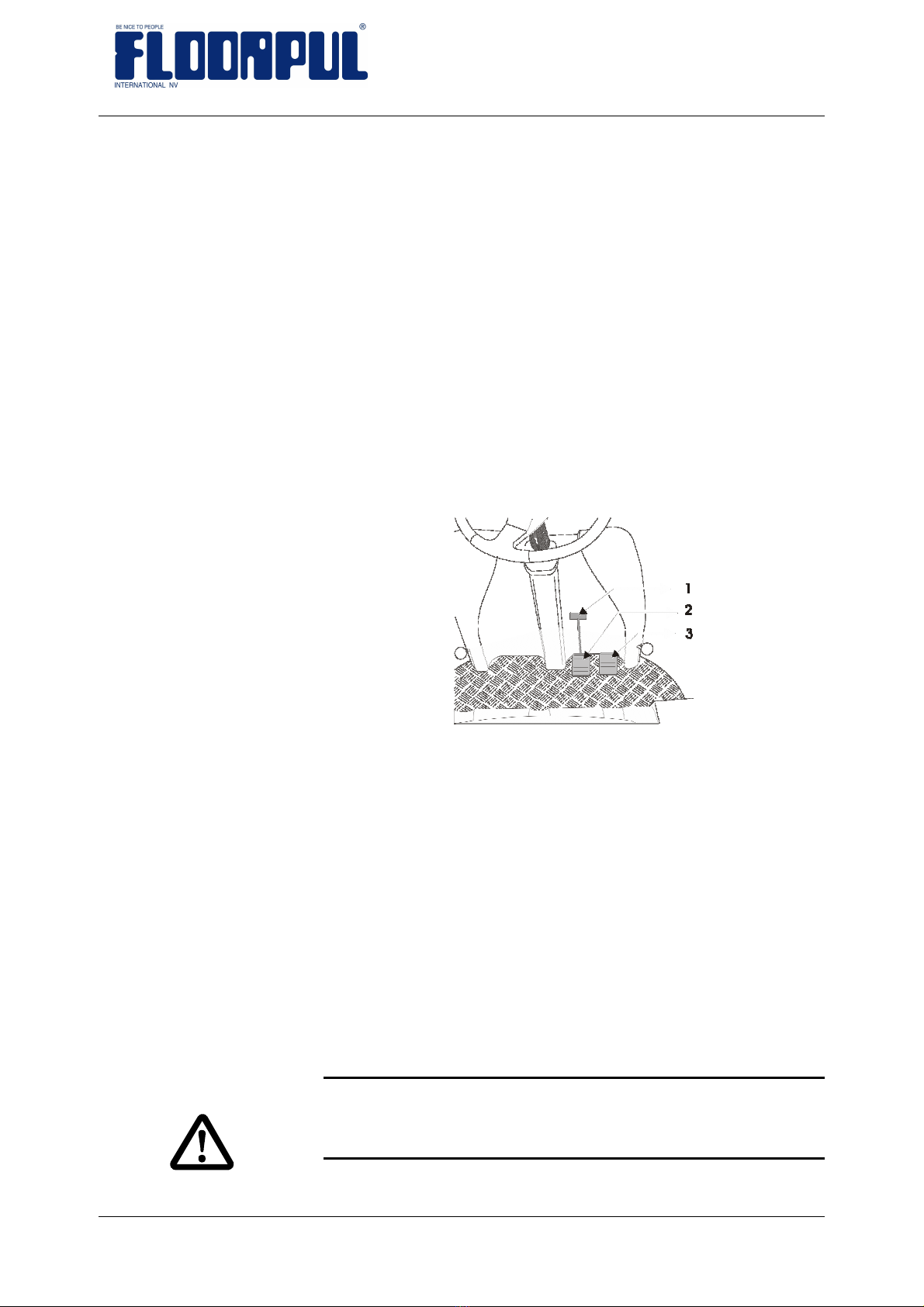

1

steering wheel with steer-

ing pillar

2

driver`s seat

3

main trim panel

4

steering pillar trim

5

dust container

6

front trim panel

7

driving wheel

8

left side trim panel

9

rear wheel with drum break

10

lowering lever for side

brushes

11

pivotable side brushes

Device Description

8 TTV 1100

3.1 Initial Startup

The Sweeping & Suction Machine is supplied with batteries

Standard:

Open the transport packaging.

Take off the complete hood. Lift up hood at back and lift the front

spigots of the hood out of the retaining.

Fit in the batteries.

Replace the hood panel.

Mount the side brushes.

The Sweeping & Suction Machine is ready for use.

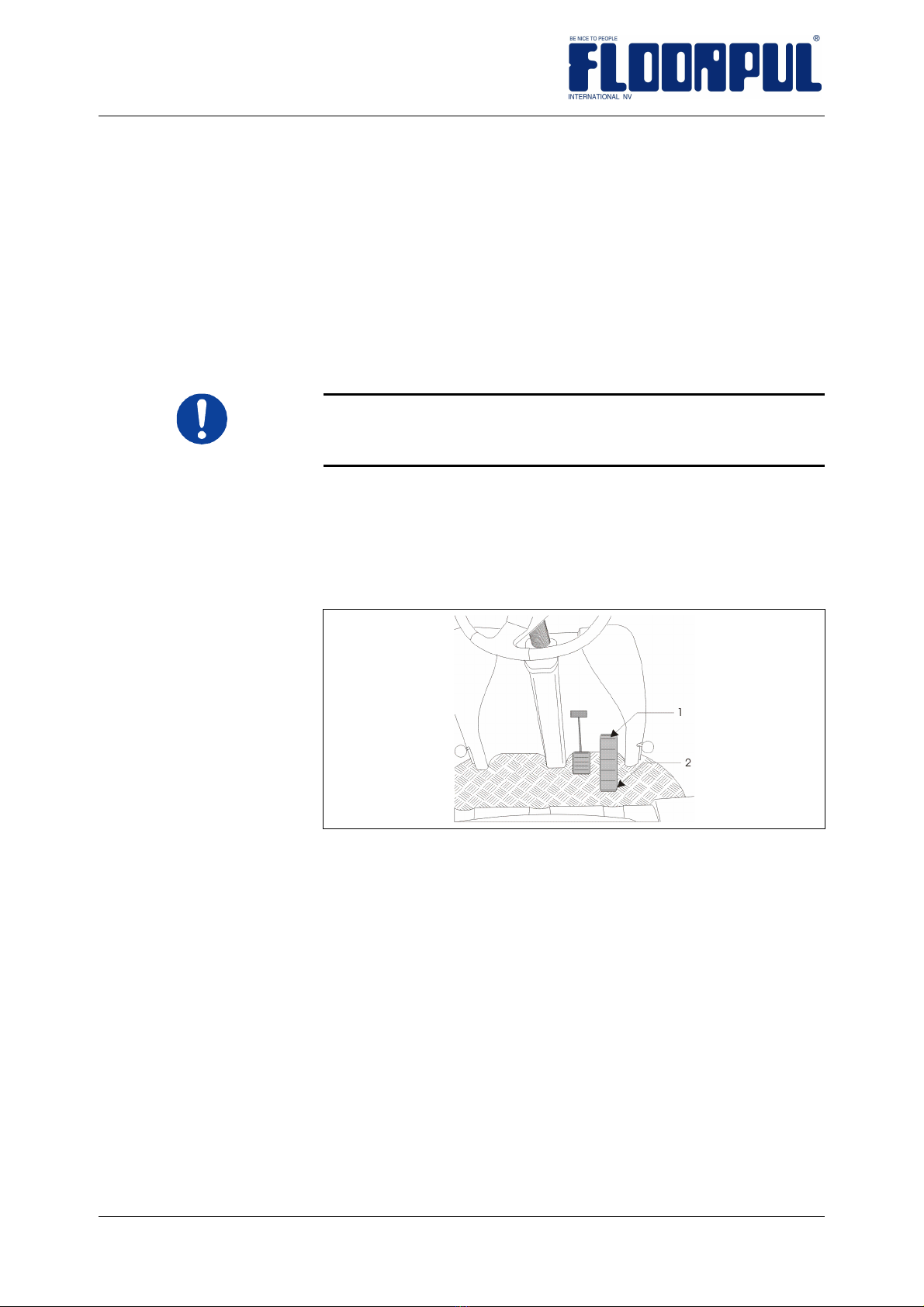

Drive the Sweeping & Suction Machine over a ramp out of the trans-

port packaging.

Use a unit ramp. The ramp must be designed in such a way as to allow

the rear wheel as well as the drive wheels to travel across it.

If this is not observed, damages to the Sweeping & Suction Machine

mechanics will occur.

1

Unit Ramp

Operation

TTV 1100 9

4 Operation

4.1 Driving

4.1.1 Safety information

The motor must be started from the driver's seat only.

The motor must not be started by short-circuiting the electric connectors

at the starter: Otherwise the machine may begin to move immediately!

4.1.2 Starting the Sweeping & Suction Machine

Sit down in the driver's seat.

Do not press the accelerator-pedal during starting procedure.

Press down the brake pedal

1 Parking brake 2 Brake pedal

3 Accelerator pedal for- and

backwards (wig-wag)

4.1.3 Cold start:

Cold starting is necessary, if the Suction & Sweeping Machine has not

been used for some time and/or at cold outdoor temperatures.

To do a cold start, proceed like this:

Pull the knob of the cold starting device all the way up.

Set the motor speed lever to idle speed.

Start up the Suction & Sweeping Machine.

Let the motor run.

Do not allow the motor to run in a closed space.

Danger of poisoning by exhaust fumes!!

When the motor is running smoothly:

DANGER!

Operation

10 TTV 1100

Push the knob of the cold starting device downward.

Adjust the speed to operating speed. (motor speed control to the

very front position).

4.1.4 Driving forward:

Start up the Suction & Sweeping Machine

Step on the brake.

Push the driving direction switch forward.

The drive-system only can be operated when speed control for the mo-

tor is pushed to working-rpm (flywheelclutch).

Carefully step on the accelerator (forward).

4.1.5 Driving backwards:

Carefully step on the accelerator (backwards)

1

Forwards 2

Backwards

4.2 Sweeping

4.2.1 Operatting the Sweeping Rollers

Start the Sweeping & Suction Machine.

Switch the toggle switch for the sweeping rollers to ON Position.

Unlatch the lowering lever of the sweeping roller.

Stopping Sweeping Rollers Operation.

Pull lowering lever of the sweeping rollers towards yourself.

Switch toggle switch for the sweeping rollers to OFF position.

Let the lever snap in arresting position.

Operation

TTV 1100 11

1 Battery check light 2 Switch for the sweeping roll-

ers

3 Switch for the side brushes 4 Switch for filter cleaning

5 Speed control for the motor 6 Suction control

7 Lowering lever for the sweep-

ing rollers

8 Cold starting device

9 Key-operated switch

4.2.2 Operating the Filter Cleaning Device

The filter cleaning device prevents the lamellar filter from being blocked

by debris.

The suction can be stopped by shutting down the motor or by clos-

ing the suction cover.

Depress the toggle switch for the filter cleaning device for about 5 to

10 seconds.

The filter cleaning device begins operation.

4.2.3 Operating the Side Brushes

The side brushes are fixed to swingers. Whenever the side brushes hit

an obstacle they swing back under the vehicle to avoid damages.

Start the Sweeping & Suction Machine.

Unlatch the lowering lever of the side brushes.

Switch toggle switch for the side brushes to ON position.

Push the lever down.

Stopping Side Brush Operating.

Pull up the lowering lever for the side brushes.

Switch toggle switch for the side brushes to OFF position.

Let the lever snap in arresting position.

Operation

12 TTV 1100

4.2.4 Operating the Suction

The suction prevents dust formation duringsweeping operations.

Start the Sweeping & Suction Machine.

Push the suction control forward to open the cover of the suction.

To avoid damage to the filter, use the lever to close the cover be-

fore picking up wet sweepings!

Depress the toggle switch for the filter cleaning device for about 5 to

10 seconds.

The filter cleaning device begins operation.

4.3 Adjustment of Driver`s Seat

Loosen the seat arresting device and shift the driver's seat on the

seat support to a position that feels comfortable to you.

4.4 Turning Off the Sweeping & Suction Machine

Depress the brake pedal.

Lock the brake by pulling the locking lever towards the driver's seat.

When the brake now is relieved the brake pedal must remain in de-

pressed position.

All of the pilot lamps on the switch are off.

Switch off all actuators.

Lift up the side brushes and arrest the lowering lever for the side

brushes.

Lift up the sweeping rollers and arrest the lowering lever for the

sweeping rollers.

Turn the key counterclockwise and remove it from the key switch.

Turn the battery master switch counterclockwise and remove it from

the socket.

CAUTION!

Operation

TTV 1100 13

4.5 Operating the Filter Cleaning Device

The filter cleaning device prevents the lamellar filter from being blocked

by debris.

Close the exhaust flaps.

Wait until ventilation wheel stands still.

Apply filter cleaning device at regular intervals.

Depress the toggle switch for the filter cleaning device for about 5 to

10 seconds.

The filter cleaning device begins operation.

4.6 Emptying the Dust Container

The dust container is the place where the sweepings are collected.

It is positioned at the back of the Sweeping & Suction Machine.

The dust container must be emptied regularly and especially after each

use.

4.6.1 Removing the Dust Container

Turn the dust container locking upward.

Pull out the dust container from the Sweeping – & Suction Machine by

the gripping handle until the front dust container guide rails are free.

1

locking device 2

recessed grip

3

locking device 4

guide rail

5

dust container guides 6

roller

At the back of the dust container two guiding rollers are installed to

make the removal easier.

Lower the dust container to the ground

Operation

14 TTV 1100

A number of rollers and a recessed grip are positioned at the bottom of

the dust container.

Remove the dust container completely from the Sweeping & Suction

Machine.

In order to empty the dust collecting box use the free hand to take

hold of the recessed grip.

The sweepings are discharged through the opening at the bottom of

the dust bin.

Empty sweepings into appropriate containers only.

4.6.2 Reinserting the Dust Container

Place the dust container before the dust container retaining.

Bring the dust container's front guides up to the same level as the

guide rails.

Slide the dust container into the Sweeping & Suction Machine.

Turn the locking device downward.

Service and Maintenance

TTV 1100 15

5 Service and Maintenance

5.1 Safety Information

Only complete the type of maintenance work described in the following

chapter. All other maintenance and upkeep work may only be carried

out by the manufacturer or by companies and persons authorised by the

manufacturer, who are familiar with the relevant safety specifications,

because portable devices in industrial use are subject to the safety test

according to VDE 0701.

Closely follow the steps listed in the maintenance instructions. The im-

proper completion of maintenance tasks may result in malfunctions

when using the sweeper and may possibly render the warranty granted

null and void.

Disconnect the spark plug when working on the engine Observe the

machine's safety stickers!

Maintenance work/ troubleshooting at the electric motor must not be

done while the electric motor is running.

Use only flawless and appropriate tools to complete maintenance work.

Note the requirements for spare parts (see Spare parts).

If covers and/or safety devices were removed during maintenance

work/repairs, they will have to be reattached prior to starting the

sweeper.

For carrying out any work on the sweeper, it must be switched off and

secured from rolling away by accident.

The open hood always has to be secured by the hood arresting device.

5.2 Cleaning

The suction sweeper may only be cleaned in the off state, when it is dry.

The suction sweeper is a machine with electrical components.

Moisture damages the eletronics of the device. Moisture can result

in leakage currents and short-circuits.!

Do not use any high-pressure cleaners

WARNING

Service and Maintenance

16 TTV 1100

5.3 Brake

The brake is a component affecting operational safety. All work

pertaining to the maintenance and replacement of brake parts must

be executed by professionally trained personnel!

The brake (drum brake) acts on the rear wheel and is controlled via

Bowden pull wire by the brake pedal.

The brake adjustment is situated on the right side of the rear wheel fac-

ing in driving direction.

5.3.1 Adjusting the Brake

Hold the adjustment nut of the Bowden pull wire in place with a

wrench.

Loosen the back nut of the Bowden pull wire.

Push the brake lever upward until the brake lever is obstructed.

Hold the brake lever in this position.

Tighten the back nut of the Bowden pull wire.

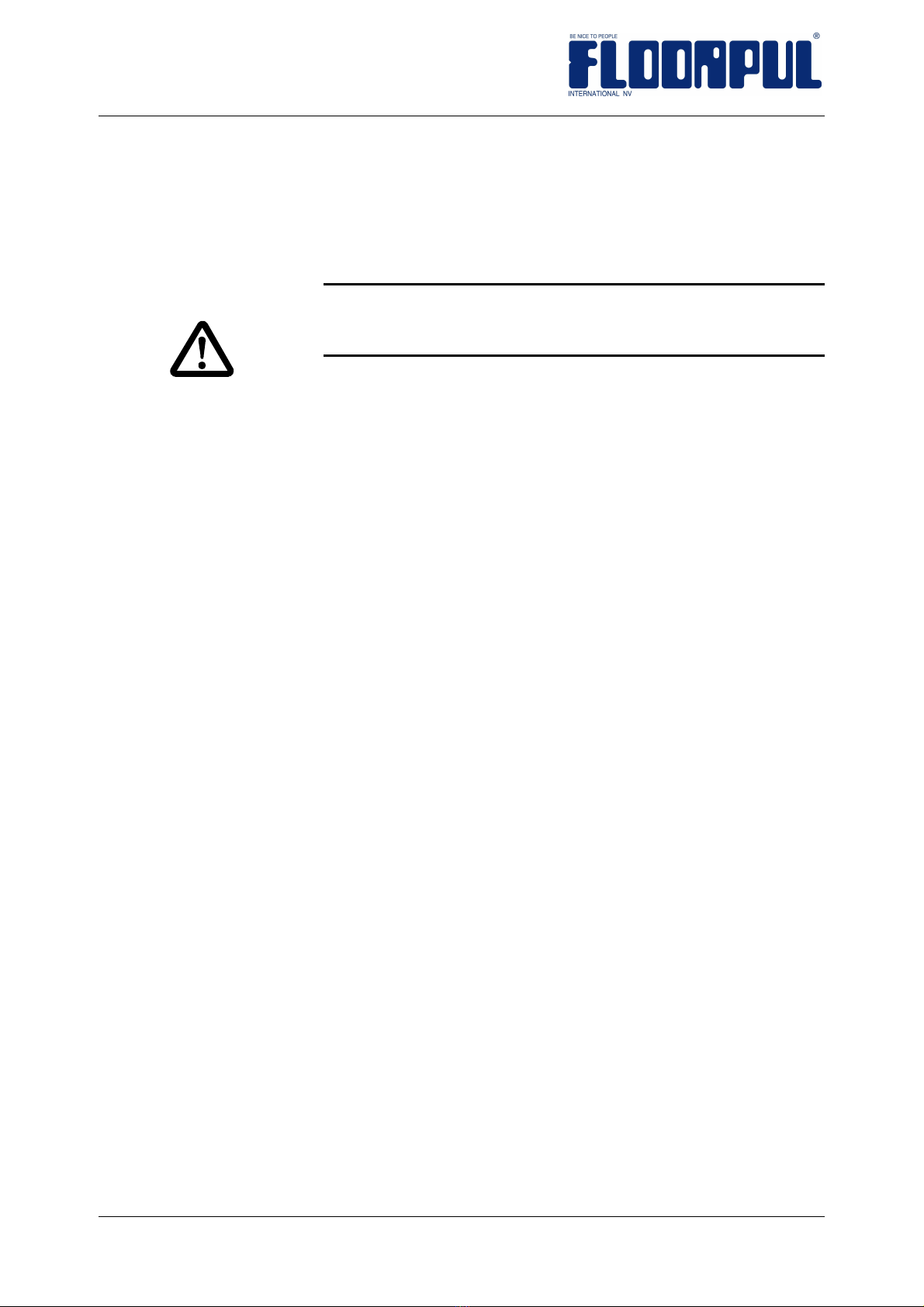

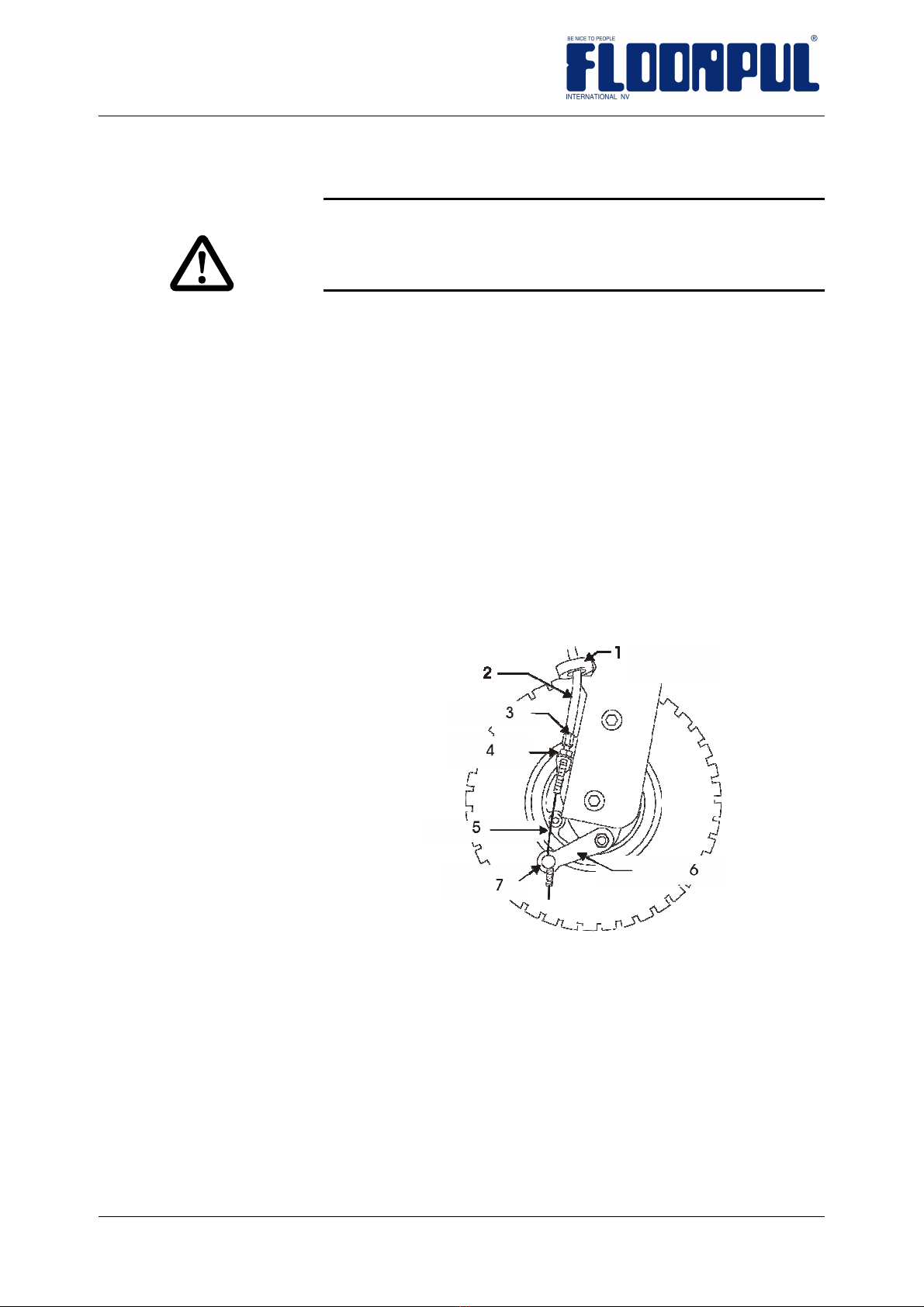

1

Bowden pull wire guiding 2

Bowden pull wire

3

adjustment nut 4

back nut

5

brake pulley 6

brake lever

7

brake pulley arresting

Now conduct a brake check.

DANGER!

Service and Maintenance

TTV 1100 17

5.4 Brake Check

Free Movement of Rear Wheal

You must be able to move the Sweeping & Suction Machine by pushing

when the brake is released.

The rear wheel must not be blocked. Brakes that are set too tightly

damage the brake drum.

5.4.1 Correct Operating of Brake

Carefully drive a few meters at moderate speed.

Depress the brake pedal. The Sweeping & Suction Machine must stop.

If the brake check should not render a satisfying result the setting pro-

cedure must be repeated.

Further Setting Possibility:

The Bowden pull wire does not allow tightening in the way described

above any longer.

Loosen the brake pulley arresting.

Lift the brake lever up until it is obstructed.

Hold the brake lever in this position.

Pull the brake pulley down and push the brake pulley arresting up-

ward.

Fasten the brake pulley arresting.

Carry out the above described brake check.

5.5 Wheels

The Sweeping & Suction Machine is equipped with three wheels.

The standard rear wheel tire is made of solid rubber.

The two drive wheels are standard equipped with pneumatic tires.

Optionally the drive wheels are delivered sith solid rubber tires.

Defective tires must be repaired or replaced by expert shops only.

Deliver the complete wheel (rim and tire) to the tire shop.

5.6 Steering

The steering transferral to the rear wheel is man aged by a chain and

two chain sprockets.

Grease the chain sprockets at regular intervals. Cf. Maintenance Chart.

Service and Maintenance

18 TTV 1100

5.7 Removing the main trim panel (hood)

The hood of the Suction & Sweeping Machine can be removed for main-

tenance and repair work purposes.

5.7.1 Lifting off the hood

Pull the key out of the key-operated switch.

Open the hood.

Lock the hood against unintentional shutting.

Insert the hood arresting into the hole.

Disconnect the plug connection for the contact switch of the driver's

seat.

Close the hood.

Reach underneath the driver's seat and to the rear edge of the

hood.

Lift up the hood.

Remove the hood

5.7.2 Replacing the hood

Reach underneath the driver's seat and to the rear edge of the

hood.

Lift up the hood.

Put the hood in place on the Suction & Sweeping Machine.

At the front edge of the hood there are two locating pins.

Insert these pins into the receptacles in the floor panels.

Open the hood.

Lock the hood against unintentional shutting.

Insert the hood arresting into the hole.

If the plug connectors are not connected, the Suction & Sweeping Ma-

chine cannot be started.

Close the hood

5.8 Replenishing operating fluids

Safety information for handling operating fluid

Do not keep easily combustible materials such as fuel, matches, or simi-

lar, in the vicinity of a running motor.

Only replenish fuel in an open or well ventilated place.

Service and Maintenance

TTV 1100 19

Fuel is highly combustible and explosive!

Only replenish fuel at motor stand-still!

There must not be any fuel in the filler cap! Do not overfill the tank!

Make sure the tank cap is closed.

Do not smoke, and keep away open fire while filling the tank and in the

fuel storage area.

Remove spilled fuel immediately in the vicinity of the motor!

Wait before starting the motor until the petrol fumes have evaporated!

Observe the specified oil and fuel qualities (see page 29 Technical Data

Filling Substances) and store all of these substances in certified con-

tainers only.

Be careful when draining hot oil.

Danger of burning.

Dispose of used oil according to legal requirements.

5.8.1 Checking the hydraulic oil filling level

Open the hood.

On the left hand side of the machine, seen in travel direction, the hy-

draulic pump is positioned. Next to this pump, there is a hydraulic tank

containing 1 litre of hydraulic oil. If the level of the hydraulic oil can be

seen in the middle of the two markings “min” and “max”, the oil-level is

correct.

If the oil-level is below “min”, hydraulic-oil will have to be filled up.

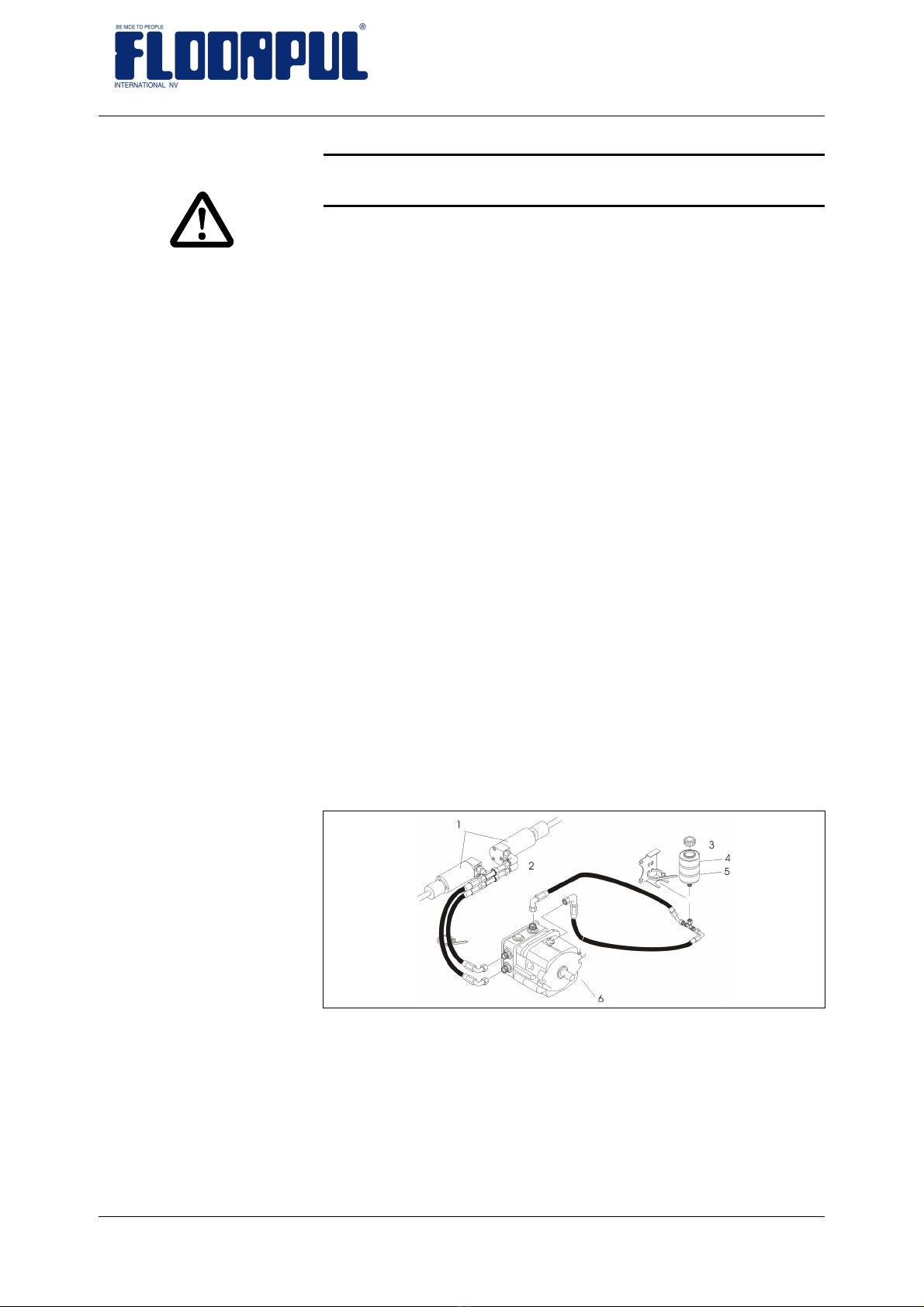

1

Rear-axle motors 2

Rear-axle motors

3

Hydraulic-tank 4

Max

5

Min 6

Hydraulic Pump

Unscrew the cap of the hydraulic tank.

Place a clean funnel into the tank carefully add hydraulic oil (HLDP

46 oder HLP 46) until the level reaches middle-position between

“min” and “max”

CAUTION!

Table of contents