Florida Pneumatic Universal Tool UT4425E-CWS Manual

FLORIDA-PNEUMATIC.COM

Please contact 1-800-356-3392 for further assistance.

Universal Tool

™

UT4425E-CWS

Extended Cone Wheel Grinder

GRINDERS & CUT-OFF TOOLS

General Safety Information & Replacement Parts

WARNING: Risk of injury to persons. Read and

understand operation instructions. Always become familiar

with all the instructions and warnings before operating any

pneumatic tool.

TABLE OF CONTENTS

General Safety Information ...........................2

Air Compressor and Air Tool Safety...................2-3

Tool Specifications ..................................3

Installation ........................................4

Maintenance / Lubrication ............................4

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Troubleshooting ....................................6

Warranty ..........................................6

Service Parts.......................................7

WARNING:This product contains chemicals known to

the State of California to cause cancer and birth defects or

other reproductive harm. Wash hands after handling.

WARNING:This product contains lead, a chemical known to

the State of California to cause cancer and birth defects or

other reproductive harm. Wash hands after handling.

Universal Tool a Division of Florida-Pneumatic Manufacturing Corporation

851 Jupiter Park Lane, Jupiter FL 33458

7.2.2.3 GENERAL SAFETY RULES

• Multiplehazards.Readandunderstandthesafetyinstructionsbefore

installing,operating,repairing,maintaining,changingaccessorieson,

orworkingnearthepowertool.Failuretodosocanresultinserious

bodilyinjury.

• Onlyqualiedandtrainedoperatorsshouldinstall,adjustorusethe

powertool.

• Donotmodifythispowertool.Modicationsmayreducetheeffec-

tivenessofsafetymeasuresandincreasetheriskstotheoperator.

• Donotdiscardthesafetyinstructions–givethemtotheoperator.

• Donotuseatoolifthetoolhasbeendamaged.

• Warningsshallbegivenagainsttheriskofexplosionorreduetothe

materialbeingprocessed;

• Warningsshallbegivenagainsttheriskofcutting.

7.2.2.4 PROJECTILE HAZARDS

• Failureoftheworkpiece,ofaccessories,orevenofthetoolitselfmay

generatehighvelocityprojectiles.

• Alwayswearimpact-resistanteyeprotectionduringoperationofthe

tool.Thegradeofprotectionrequiredshouldbeassessedforeach

use.

7.2.2.5 ENTANGLEMENT HAZARDS

• Entanglementhazard-choking,scalpingand/orlacerationscanoccur

ifneckware,hairorglovesarenotkeptawayfromtoolandacces-

sories.

7.2.2.6 OPERATING HAZARDS

• Useofthetoolmayexposetheoperator’shandstohazardsincluding

crushing,impacts,cutsandabrasionsandheat.Wearsuitablegloves

toprotecthands.

• Operatorsandmaintenancepersonnelmustbephysicallyableto

handlethebulk,weightandpowerofthetool.

• Holdthetoolcorrectly:bereadytocounteractnormalorsudden

movements–havebothhandsavailable.

• Maintainabalancedbodypositionandsecurefooting.

• Keephandsawayfromrotatingorreciprocationaccessories,spindles

orothermovingparts.

• Releasethestartandstopdeviceinthecaseofaninterruptionofthe

energysupply

• Useonlylubricantsrecommendedbythemanufacturer.

7.2.2.7 REPETITIVE MOTIONS HAZARDS

• Whenusingapowertool,youmayexperiencediscomfortinyour

hands,arms,shoulders,neck,orotherpartsofyourbody.

• Whileusingapowertool,positionyourbodyinacomfortable

posture.Maintainsecurefootingandavoidawkwardoroff-balanced

postures.Changingyourpostureduringextendedtasksmayhelp

avoiddiscomfortandfatigue.

• Ifyouexperiencesymptomssuchaspersistentorrecurringdiscom-

fort,pain,throbbing,aching,tingling,numbness,burningsensation,

orstiffness,donotignorethesewarningsigns.Promptlytellyour

employerandconsultaqualiedhealthprofessional.

7.2.2.8 ACCESSORY HAZARDS

• Onlyusesizesandtypesofaccessoriesandconsumablesthatare

recommendedbythepowertoolmanufacturer.

7.2.2.9 WORKPLACE HAZARDS

• Slips,tripsandfallsaremajorcausesofworkplaceinjury.Beaware

ofslipperysurfacescausedbyuseofthetoolandalsooftriphazards

causedbytheairlineorhydraulichose.

• Proceedwithcareinunfamiliarsurroundings.Hiddenhazardsmay

exist,suchaselectricityorotherutilitylines.

• Thispowertoolisnotintendedforuseinpotentiallyexplosiveatmo-

spheresandisnotinsulatedfromcomingintocontactwithelectric

power.

• Makesuretherearenoelectricalcables,gaspipesetc.thatcould

causeahazardifdamagedbyuseofthetool.

7.2.2.10 DUST AND FUME HAZARDS

• Dustfromsomeworkprocessescancausecancer,birthdefectsor

otherrespiratorydiseases.Riskassessmentofthesehazardsand

implementationofappropriatecontrolsisessential.

• Ifthepneumatictoolisusedinadustlledenvironmentexhaust

aircancauseadusthazard

• Dustsandfumesgeneratedwhenusingpowertoolscancause

illhealth(forexample:cancer,birthdefects,asthmaand/order-

matitis);riskassessmentofthesehazardsandimplementationof

appropriatecontrolsofisessential.

• Riskassessmentshouldincludedustcreatedbytheuseofthetool

andthepotentialfordisturbingexistingdust.

• Operateandmaintainthepowertoolasrecommendedinthese

instructions,tominimizedustorfumeemissions

• Directtheexhaustsoastominimizeddisturbanceofdustinadust

lledenvironment

• Wheredustsorfumesarecreated,thepriorityshallbetocontrol

thematthepointofemission.

• Allintegralfeaturesoraccessoriesforthecollection,extractionor

suppressionofairbornedustorfumesshouldbecorrectlyused

andmaintainedinaccordancewiththemanufacturer’sinstructions.

• Select,maintainandreplacetheconsumable/insertedtoolas

recommendedintheseinstructions,topreventanunnecessary

increaseindustorfumes

• Userespiratoryprotectionasinstructedbyyouremployeroras

requiredbyoccupationalhealthandsafetyregulations;

7.2.2.11 NOISE HAZARDS

• Unprotectedexposuretohighnoiselevelscancausepermanent,

disabling,hearinglossandotherproblemssuchastinnitus(ring-

ing,buzzing,whistlingorhummingintheears);

• Riskassessmentofthesehazardsandimplementationofappropri-

atecontrolsofisessential.

• Appropriatecontrolstoreducetheriskmayincludeactionssuchas

dampingmaterialstopreventworkpiecesfrom‘ringing’

• Usehearingprotectionasinstructedbyyouremployeroras

requiredbyoccupationalhealthandsafetyregulations;

• Operateandmaintainthepowertoolasrecommendedinthese

instructions,topreventanunnecessaryincreaseinnoiselevels;

• Select,maintainandreplacetheconsumable/insertedtoolas

recommendedintheseinstructions,topreventanunnecessary

increaseinnoise.

7.2.2.12 VIBRATION HAZARDS

• Exposuretovibrationcancausedisablingdamagetothenerves

andbloodsupplyofthehandsandarms;

• Wearwarmclothingwhenworkingincoldconditionsandkeep

yourhandswarmanddry;

• Ifyouexperiencenumbness,tingling,painorwhiteningoftheskin

inyourngersorhands,stopusingthepowertool,andtellyour

employer.Youshouldalsoseekmedicaladvicefromaqualied

occupationalhealthprofessional.

• Operateandmaintainthepowertoolasrecommendedinthese

instructions,topreventanunnecessaryincreaseinvibration;

• Select,maintainandreplacetheconsumable/insertedtoolas

recommendedintheseinstructions,topreventanunnecessary

increaseinvibrationlevels;

• Supporttheweightofthetoolinastand,tensionerorbalancer,

becausetheoperatorcanthenusealightergriptosupportthetool.

• Holdthetoolwithalightbutsafegriptakingaccountofthe

requiredhandreactionforces,becausetheriskfromvibrationis

generallygreaterwhenthegripforceishigher.

7.2.3ADDITIONAL SAFETY INSTRUCTIONS FOR PNEUMATIC

POWER TOOLS - AIR SUPPLY & CONNECTION HAZARDS

• Airunderpressurecancausesevereinjury.

• Alwaysshutoffairsupply,drainhoseofairpressureanddiscon-

necttoolfromairsupplywhennotinuse,beforechangingacces-

soriesorwhenmakingrepairs.

• Neverdirectairatyourselforanyoneelse.

• Whippinghosescancausesevereinjury.Alwayscheckfordam-

agedorloosehosesandttings.

• Wheneveruniversaltwistcouplings(clawcouplings)areused,lock

pinsmustbeinstalled.

• Donotexceedthemaximumairpressurestatedonthetool.

• Usewhipchecksafetycablestosafeguardagainstpossiblehoseto

toolandhosetohoseconnectionfailure.

• Nevercarryanairtoolbythehose.

Safety Information

FLORIDA-PNEUMATIC.COM

Please contact 1-800-356-3392 for further assistance.

Safety Information (continued)

AIR COMPRESSOR AND AIR TOOL SAFETY

1. Risk of Bursting. Do not adjust the regulator to result in output

pressure greater than the marked maximum pressure of this air

tool.

2. Ensure the hose is free of obstructions or snags. Entangled or

snarled hoses can cause loss of balance or footing and may

become damaged.

3. Never leave a tool unattended with the air hose attached.

4. Do not operate this tool if it does not contain a legible warning

label.

5. Do not continue to use a tool or hose that leaks air or does not

function properly.

6. Never direct a jet of compressed air toward people or animals.

7. Protect your lungs. Wear a face or dust mask if the operation is

dusty.

WARNING: Some dust created by power sanding, sawing,

grinding, drilling and other construction activities contains

chemicals known to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are:

Lead from lead based paint, crystalline silica from bricks

and cement and other masonry products, arsenic and

chromium from chemically-treated lumber.

Your risk from those exposures varies, depending on how

often you do this type of work. To reduce your exposure to

these chemicals: work in a well-ventilated area, and work

with approved safety equipment, such as dust masks that

Important Warnings - Grinders & Cut-Off Tools

1. The stopping time, if longer than 5 seconds, shall be stated, and it shall be recommended to put the grinder in a stable position.

2. When cutting-off, the workpiece shall be so supported that the slot is kept at constant or increasing width during the whole operation.

3. If the abrasive product gets jammed in a cut slot, shut off the grinder and ease the wheel free. Check that the wheel is still correctly

secured and not damaged before continuing the operation.

4. Grinding wheels and cut-off wheels shall not be used for side grinding. (Exception: grinding wheels designed for side grinding.) Grinders

should not be used over the maximum rated speed of an abrasive product.

5. The operator shall pay attention that no bystanders are in the vicinity.

6. The personal protective equipment such as gloves, apron and helmet shall be used.

7.

8.

9. Only use grinding wheels and cut-of wheels and wire brushes that meet ANSI standards, ISO standards or both-this will be shown on the

wheel manufacturers label.

10. Only use grinding wheels and cut-off wheels and wire brushes that have the correct center mounting hole or correct threaded insert

center to match the spindle thread on the grinder.

11. Never adjust the grinder, adjust the guard or change the wheel unless the air supply and air hose is disconnected from the grinder.

12. Only personnel trained in the correct methods to adjust guards and change grinding wheels or cut-off wheels or wire brushes should

conduct these operations.

13. Always ensure that you are aware of the direction of the sparks being created by the grinding operation and ensure that the sparks are

not directed to the operator or other persons in the area.

14.

15.

16. Never attempt to modify or adapt a grinder or cut-off tool to accept a grinding wheel or cut-off wheel or wire brush that the grinder was

not designed for use with.

17. Eye protection, hearing protection, safety gloves and safety aprons must always we worn when operating a grinder

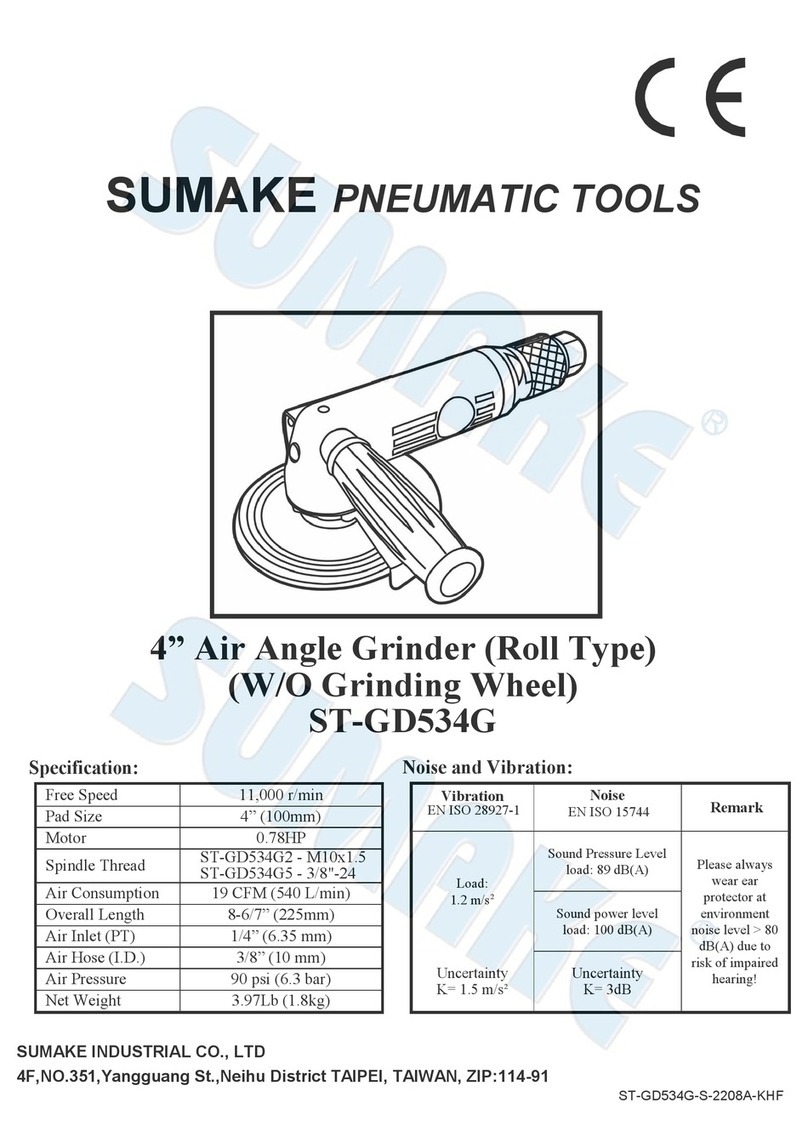

Motor Max. Wheel Speed Spindle/Collet Weight Length Rec. Air Inlet Rec. Hose Air Cons

Model (HP) Dia. (in.) (RPM) Size (in.) (lb.) (in.) Pressure (NPT) (I.D. in.) (cfm)

UT4425E-CWS 1.0 2” 20,000 1/4” 5.0 23.75 90 psi-6.2 bar 1/4" 3/8" 5.0

Vibration Level (m/sec2): 0.49 Noise Level (dBA): 78.4

Universal Tool a Division of Florida-Pneumatic Manufacturing Corporation

851 Jupiter Park Lane, Jupiter FL 33458

Installation

1 Cleaning the air hose

□A 3/8" air hose is required, with a maximum length of 25 ft.

□Clean the air hose of accumulated dust and moisture

before connecting it to the air supply.

NOTE: If a longer air hose is required, connect a 1/2"

air hose to the 3/8" air hose to ensure the grinder has the

necessary air supply.

Ensure the air line is shut-off and drained of air before removing this tool for service or changing sockets. This will prevent the tool from

operating if the throttle is accidentally engaged.

LUBRICATION

□An in-line lter-regulator-lubricator is recommended as it increases tool life and keeps the tool in

sustained operation.

□Regularly check and ll the in-line lubricator with air tool oil. Avoid using excessive amounts of oil.

□Adjust the in-line lubricator by placing a sheet of paper next to the tool’s exhaust ports and holding

the throttle open approximately 30 seconds. The lubricator is properly set when a light stain of oil collects on the paper.

□If it is necessary to store the tool for an extended period of time (overnight, weekend, etc.), generously lubricate the tool through the air

inlet. Run the tool for approximately 30 seconds to ensure the oil is evenly distributed throughout the tool. Store the tool in a clean and

dry environment.

□Recommended lubricants: Air tool oil or any other high grade turbine oil containing moisture absorbent, rust inhibitors, metal wetting

agents, and an EP (extreme pressure) additive.

Maintenance

Recommended Air Line Set-Up

Part Description

AAir Tool

B Quick Plug

C Quick Coupler

D Air Hose

E In-line Regulator

F In-line Lubricator

G In-line Filter

H Air Compressor

FLORIDA-PNEUMATIC.COM

Please contact 1-800-356-3392 for further assistance.

Operation

1 Operating the grinder

□This Grinder is designed to operate on 90 PSIG. Lower

pressure (below 90 PSIG) will reduce performance of

the tool. Higher air pressure (over 90 PSIG) raises the

performance of the tool beyond its rated capacity and

could cause serious damage to the tool and the user.

2 Installing the grinding stone

WARNING: Disconnect the tool from the air supply before

servicing or changing accessories.

WARNING: Always use ANSI approved grinding stones

with the rated tool RPM.

3 Removing the grinding stone

WARNING: Disconnect the tool from the air supply before

servicing or changing accessories.

4 Grinding and deburring

WARNING: You must wear the ANSI approved eye

protection during the operation; failure to follow this this may

result in serious injury or damage to the operator.

WARNING: Hearing protection is strongly recommended. A

protective respirator is recommended.

□Loosen the collet nut with the wrench.

□Insert the grinding stone in the collet.

□Tighten the collet nut with the wrench.

□Loosen the collet nut with the wrench.

□Remove the grinding stone from the collet.

□Tighten the collet nut with the wrench.

Universal Tool a Division of Florida-Pneumatic Manufacturing Corporation

851 Jupiter Park Lane, Jupiter FL 33458

Troubleshooting

Problem Possible Cause Solution

The tool runs slowly or will not

operate.

There is grit or gum in the tool. □Flush the tool with air tool oil or gum solvent.

The tool is out of oil. □Lubricate the tool according to the lubrication

instructions in this manual.

The air pressure is low. □Adjust the regulator on the tool to the

maximum setting.

□Adjust the compressor regulator to the tool’s

maximum setting of 90 psi.

The air hose leaks. □Tighten and seal the hose ttings with pipe

thread tape if leaks are found.

The air pressure drops. □Ensure the hose is the proper size. Long

hoses or tools using large volumes of air may

require a hose with an I.D. of ½" or larger

depending on the total length of the hose.

□Do not use a multiple number of hoses

connected together with a quick connect

tting. This causes additional pressure drops

and reduces the tool power. Directly connect

the hoses together.

There is a worn rotor blade in the motor. □Replace the rotor blade.

There is a worn ball bearing in the motor. □Remove and inspect the bearing for rust, dirt,

and grit. Replace or clean and grease the

bearing with bearing grease.

There is moisture blowing out

of the tool’s exhaust.

There is water in the tank. □Drain the tank. (See the air compressor

manual for instructions.) Lubricate the tool

and run it until water is not evident. Lubricate

the tool again and run for 1-2 seconds.

Warranty

Limited Warranty: Universal Tool warrants its tools to be free from defects in material and workmanship for one year from the date of

purchase. This warranty does not apply to tools which have been abused, misused, modied or repaired by someone other than Universal

Tool or its authorized service centers. If a UT tool proves defective in material or workmanship within one year after purchase, return

it to any authorized service center or Universal Tool freight prepaid. Please enclose your name, address and adequate proof of date of

purchase and a short description of the defect. Universal Tool will,at its option, repair or replace defective tools free of charge. Repairs or

replacements are warranted as described above for the remainder of the original warranty period. Universal Tool's sole liability and your

exclusive remedy under this warranty is limited to repair or replacement of the defective tool.

There are no other warranties expressed or implied and Universal Tool shall not be liable for incidental, consequential or special damages,

or any other damages,costs or expenses excepting only the cost or expense of repair or replacement as described above.

FLORIDA-PNEUMATIC.COM

Please contact 1-800-356-3392 for further assistance.

Service Parts / Exploded View Drawing

Universal Tool a Division of Florida-Pneumatic Manufacturing Corporation

851 Jupiter Park Lane, Jupiter FL 33458

Universal Tool

™

Questions, problems, missing parts?

Call Customer Service

8 a.m.-5 p.m., EST, Monday-Friday

1-800-356-3392

FLORIDA-PNEUMATIC.COM

Retain this manual for future use.

Table of contents

Other Florida Pneumatic Grinder manuals

Florida Pneumatic

Florida Pneumatic Universal Tool UT8715-20 User manual

Florida Pneumatic

Florida Pneumatic FP-759R-2 User manual

Florida Pneumatic

Florida Pneumatic UT8749ADG-1 User manual

Florida Pneumatic

Florida Pneumatic Universal Tool UT8724 Manual

Florida Pneumatic

Florida Pneumatic Universal Tool RAPTOR UT8727-20 Manual

Florida Pneumatic

Florida Pneumatic Universal Tool RAPTOR UT8727-12 Manual

Florida Pneumatic

Florida Pneumatic Universal Tool DIE GRINDER Series Manual

Florida Pneumatic

Florida Pneumatic Universal Tool UT8728S Manual

Florida Pneumatic

Florida Pneumatic Universal Tool UT2720 Manual

Florida Pneumatic

Florida Pneumatic Universal Tool UT8728 Manual